Method for detecting soldering points of electronic product complete machines and performing tin soldering on electronic product complete machines

A technology for detecting electronic products and solder joints, used in welding equipment, welding equipment, auxiliary devices, etc., can solve the problems affecting the processing efficiency and processing quality of electronic products, repeated soldering, and missing solder, etc., to achieve automatic detection and The effect of repair welding operation, increasing accuracy and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

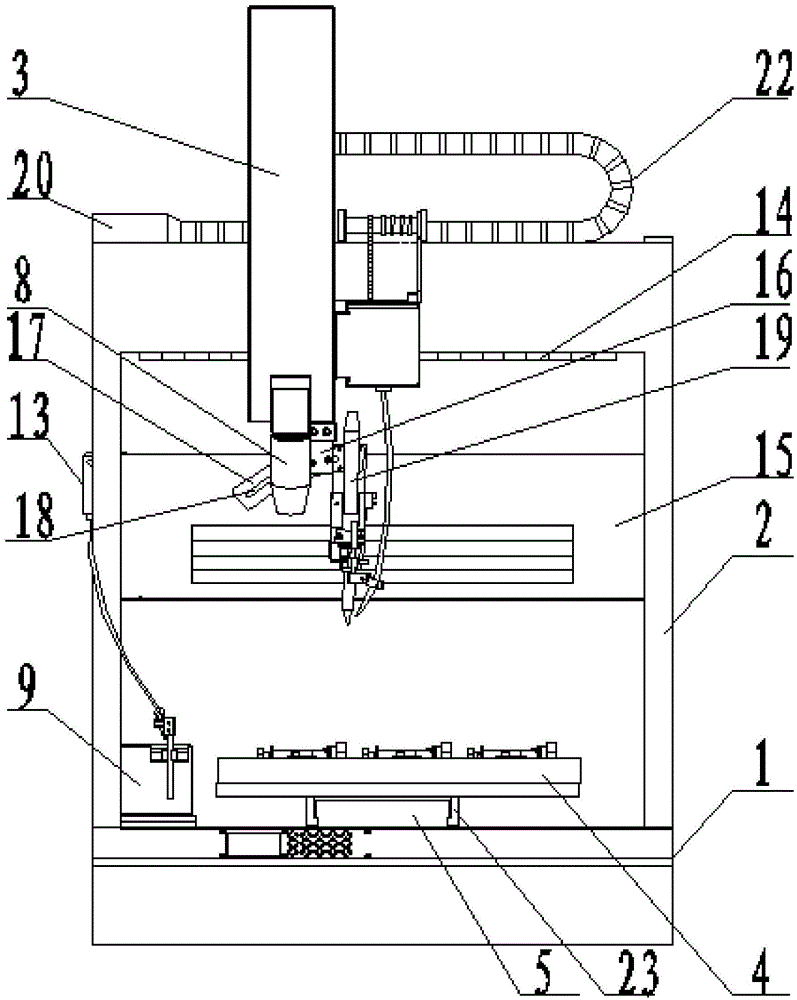

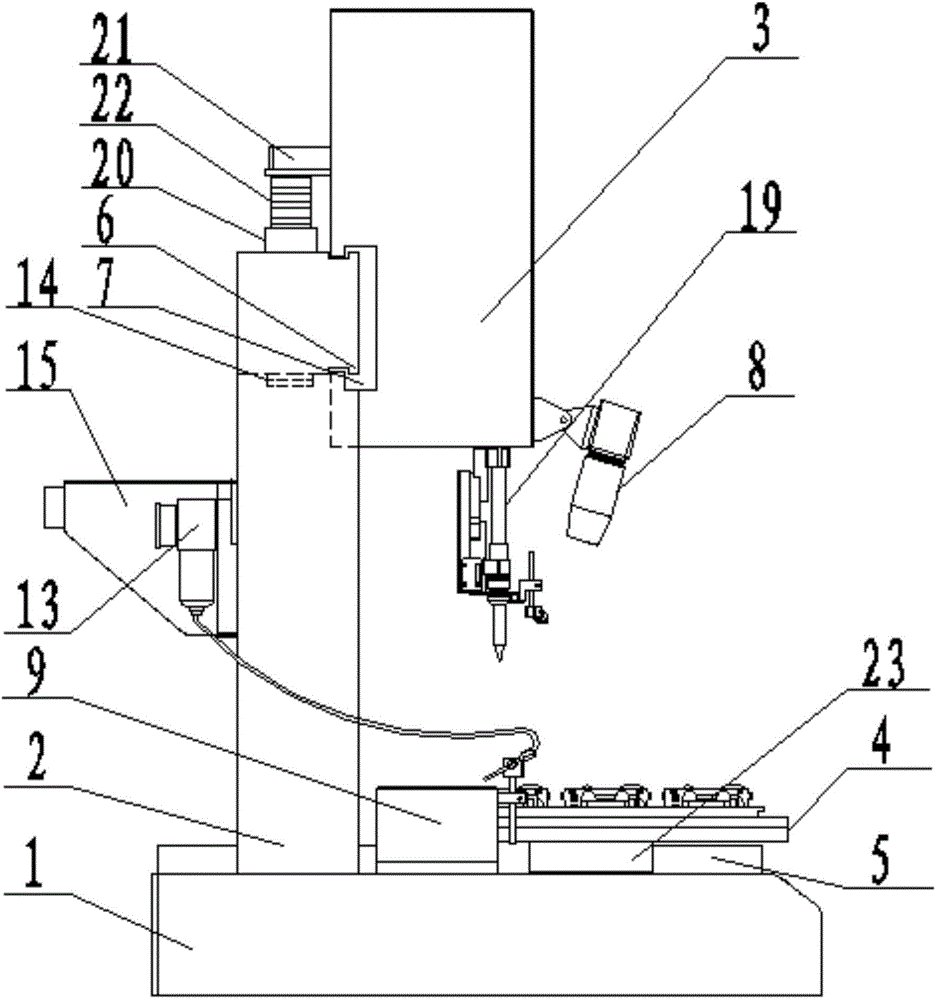

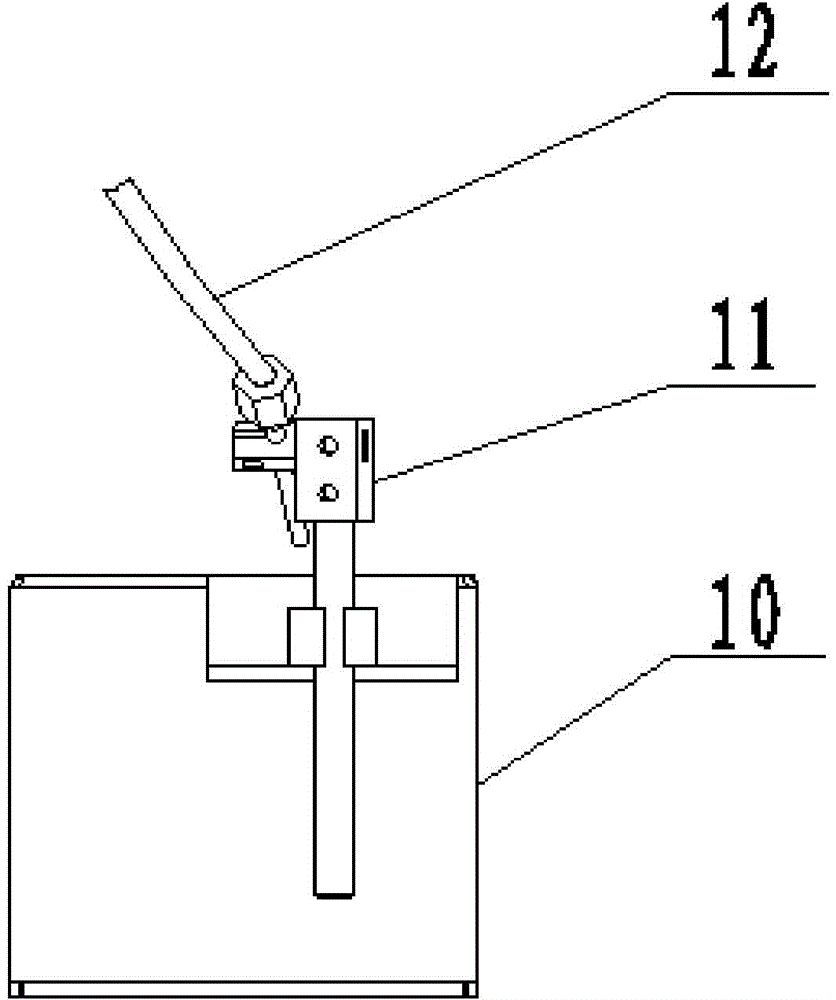

[0020] A method for detecting solder joints and replenishing solder on a complete electronic product. The method is implemented by an automatic soldering machine with a CPU. The structure of the automatic soldering machine includes a workbench 1, an X axis, and a Y axis. A four-axis numerical control system consisting of a Z axis and a rotation axis around the Z axis, the welding head is fixed on the Z axis, and an industrial camera is fixed on the Z axis. On this basis, the method includes the following steps:

[0021] A. Collect the standard image data of the whole machine and store it in the data memory of the CPU: fix each part of the electronic product machine on the workbench 1 of the automatic soldering machine, such as figure 1 with figure 2 As shown, the four-axis linkage of the movement of the X-axis guide rail 6, the movement of the Y-axis guide rail 5, the movement of the vertical guide post 3 in the Z-axis direction and the rotation of the welding gun around the Z-axi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com