Patents

Literature

172results about How to "Reduce the number of workers" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method and system for diagnosing and flashing electronic control unit of vehicle

ActiveCN106375175AImprove offline production efficiencyIncrease productivityBus networksUser Datagram ProtocolEthernet

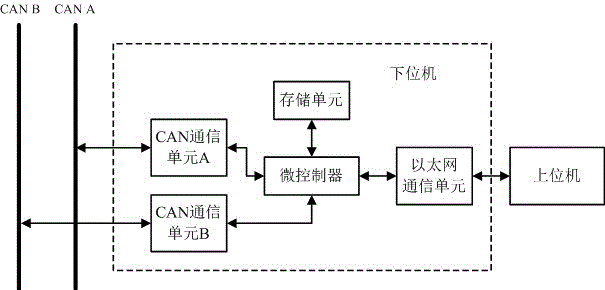

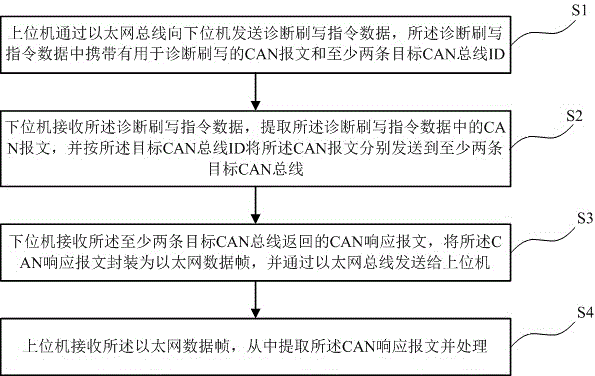

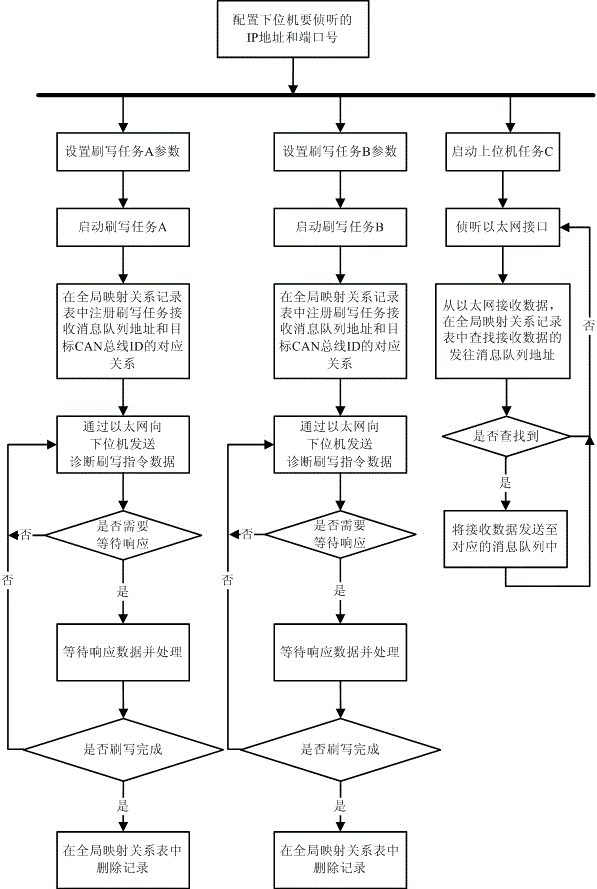

The invention provides a method and a system for diagnosing and flashing the electronic control unit of a vehicle. The method comprises the following steps: an upper computer sends diagnosing and flashing instruction data to a lower computer via an Ethernet bus, wherein the diagnosing and flashing instruction data carries a CAN message for diagnosing and flashing and at least two target CAN bus IDs; the lower computer receives the diagnosing and flashing instruction data, extracts a CAN message in the data, and sends the CAN message to at least two target CAN buses according to the target CAN bus IDs; the lower computer receives a returned CAN response message, packages the CAN response message into an Ethernet data frame, and sends the Ethernet data frame to the upper computer via the Ethernet bus; the upper computer receives the Ethernet data frame, extracts the CAN response message from the Ethernet data frame, and processes the CAN response message; and the upper computer and the lower computer communicate via a user datagram protocol UDP. The electronic control units on multiple CAN buses can be flushed at the same time, and thus, the production efficiency is improved.

Owner:GUANGZHOU AUTOMOBILE GROUP CO LTD

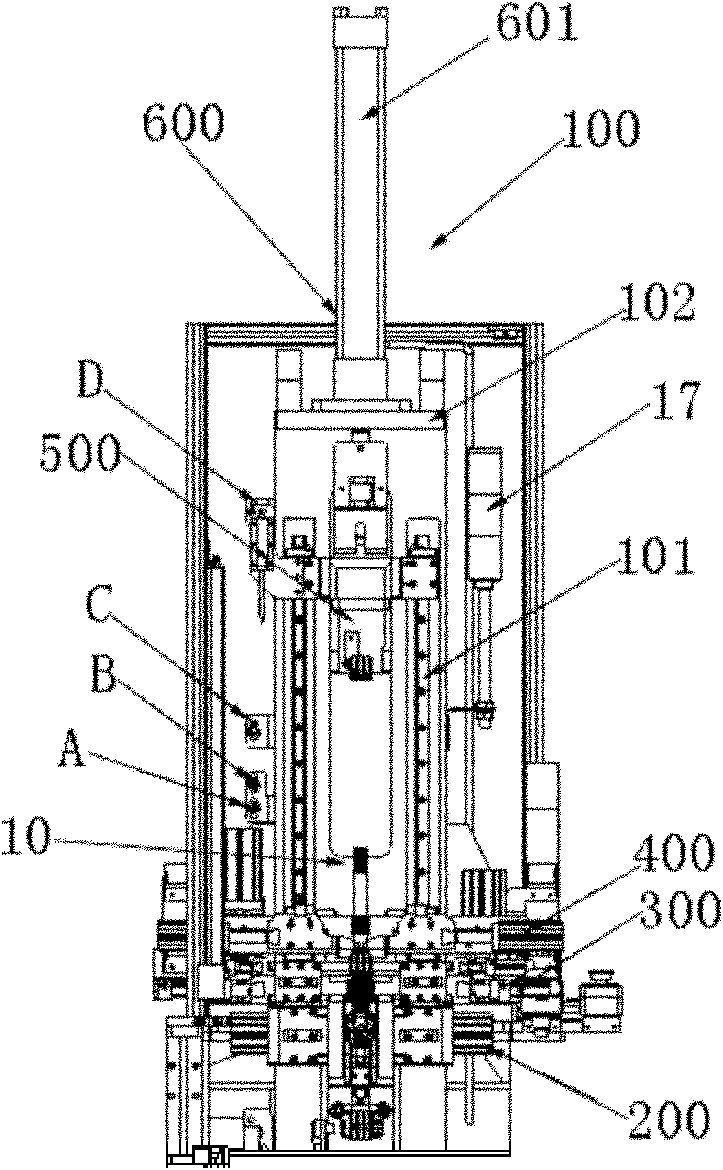

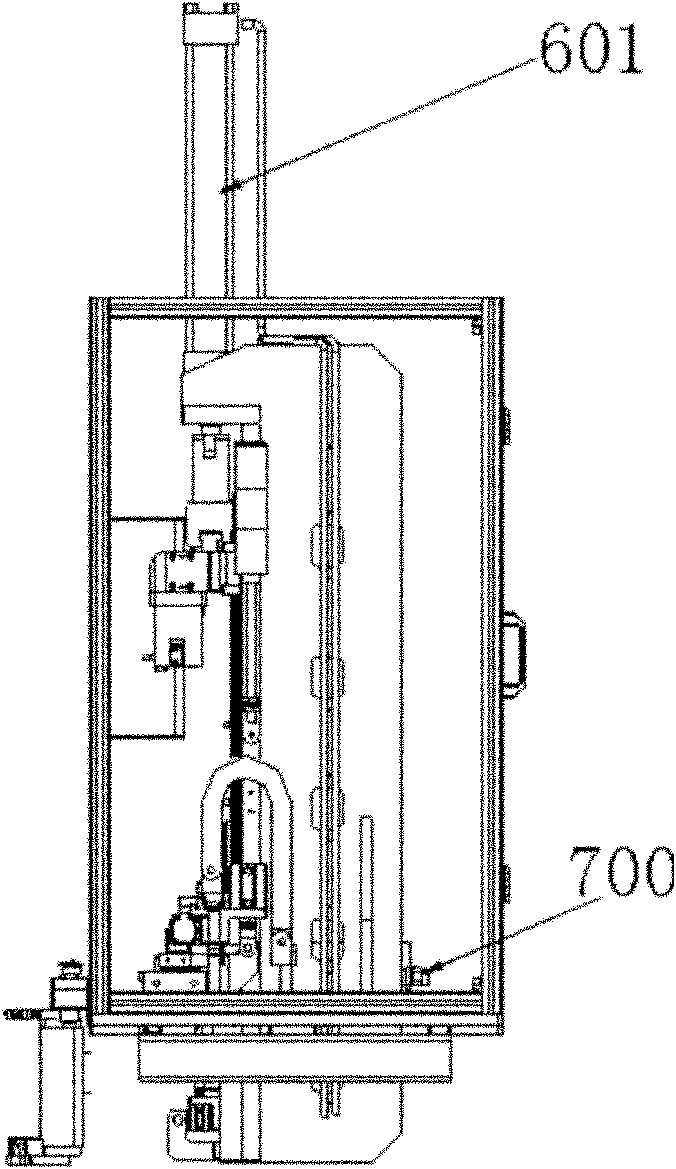

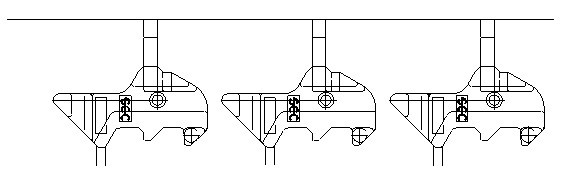

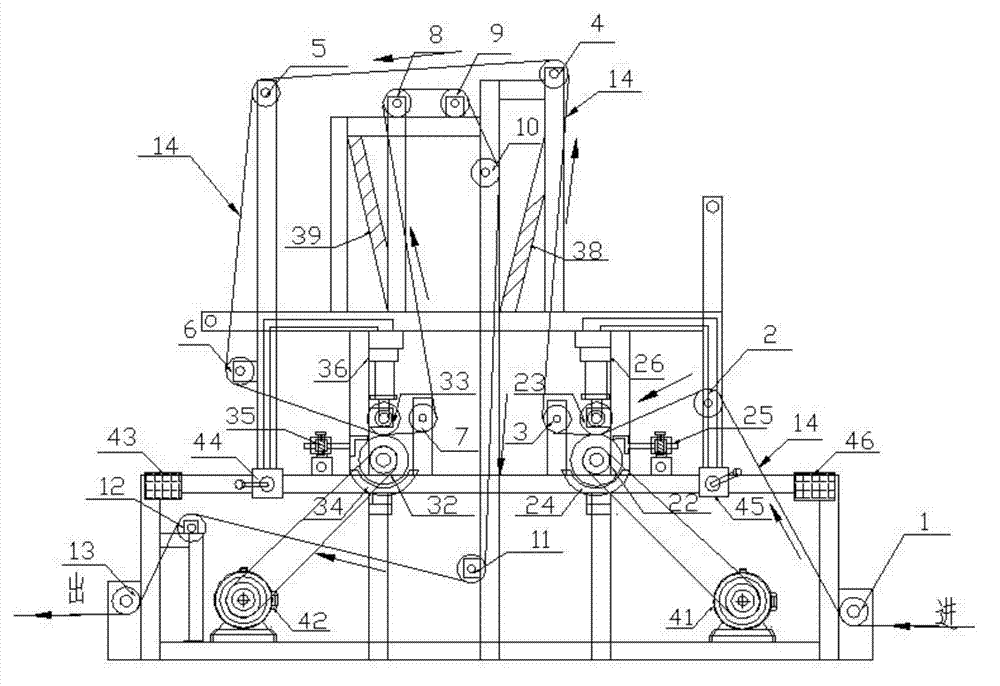

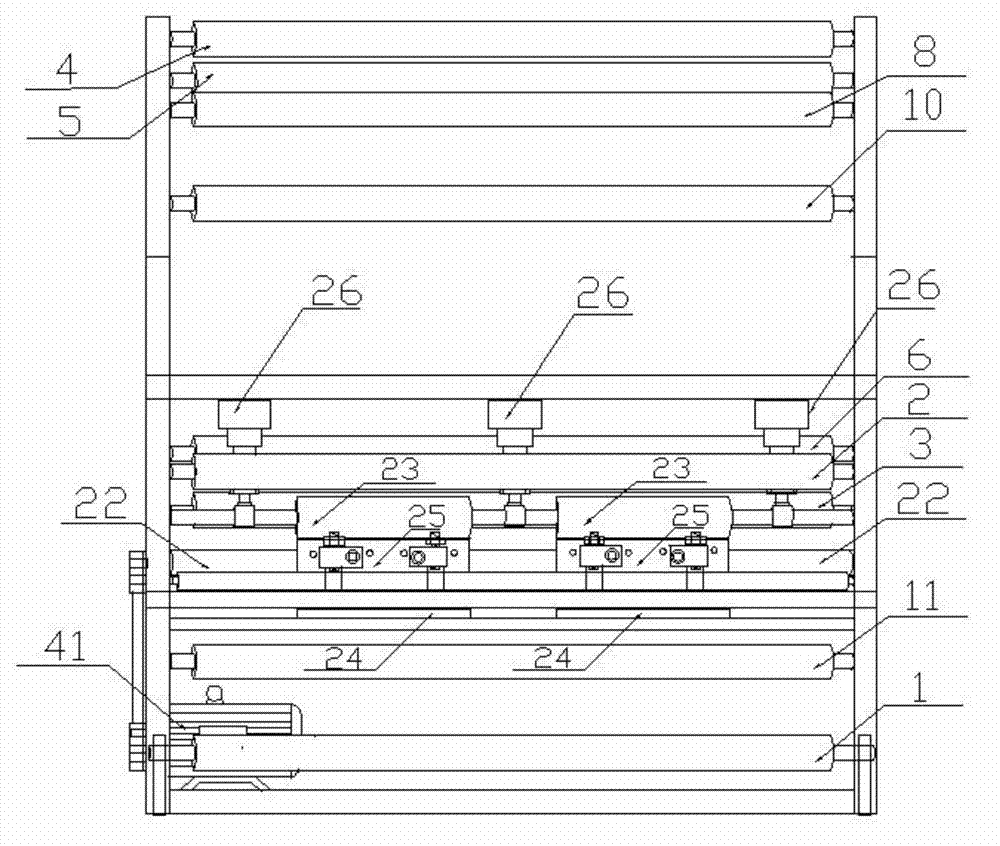

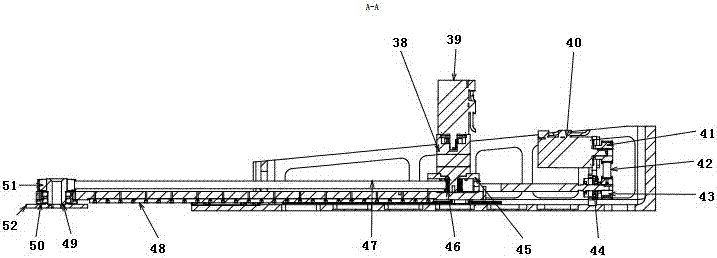

Press-mounting device for automobile steering column fittings and press-mounting method thereof

ActiveCN102107353AReduce in quantityShorten the timeMetal working apparatusSteering columnSteering wheel

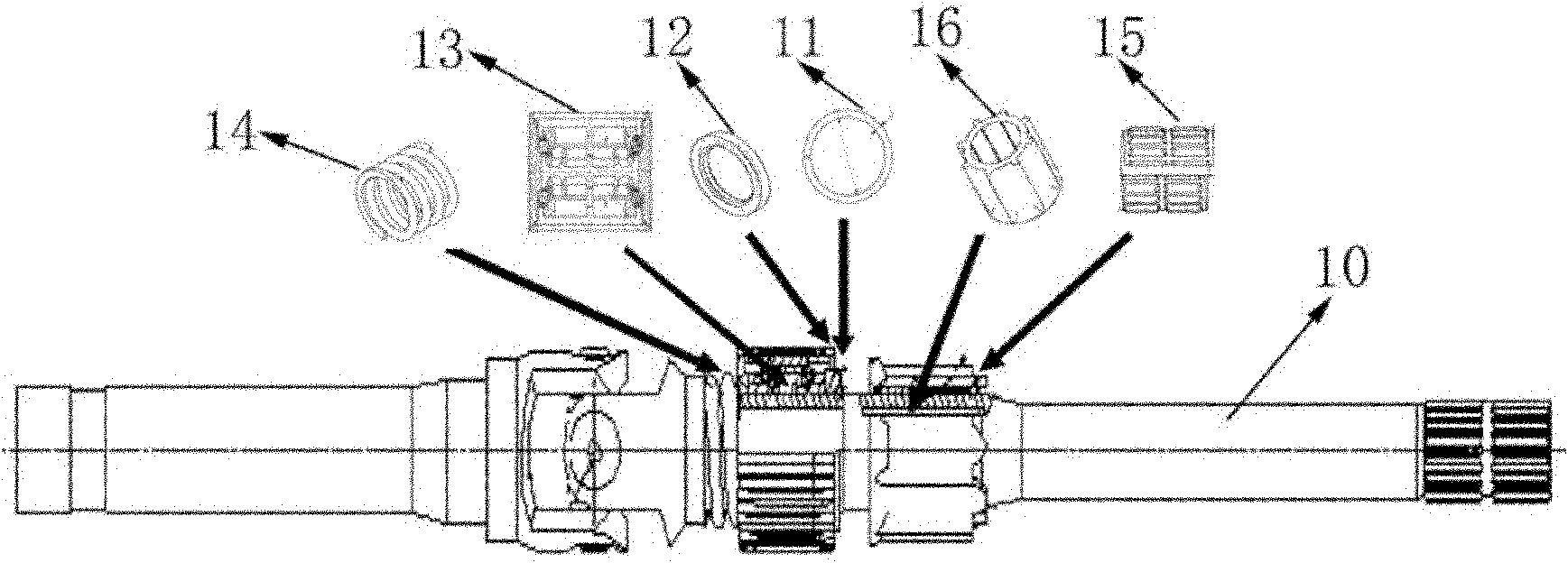

The invention discloses a press-mounting device for automobile steering column fittings and an application method thereof, and according to the invention, the assembling of components such as lower bearings, clamp springs and lock sleeves of automobile steering wheel shafts can be completed once. The press-mounting device disclosed by the invention comprises a rack, an assembly positioning mechanism, a clamp spring / lower bearing press-mounting mechanism, a positioning-ring press-mounting mechanism, a lock-sleeve press-mounting mechanism and a press-mounting mechanism, wherein the assembly positioning mechanism is arranged at the lower part of the rack, and used for fixing and positioning the axial position of a steering column; the clamp spring / lower bearing press-mounting mechanism is arranged at the upper part of the assembly positioning mechanism, and used for fixing and assembling clamp springs, check rings, lower bearings and compressed springs; the positioning-ring press-mounting mechanism is arranged at the upper part of the clamp spring / lower bearing press-mounting mechanism, and used for fixing a positioning ring and moving the positioning ring to an assigned position; the lock-sleeve press-mounting mechanism is arranged at the upper part of the positioning-ring press-mounting mechanism, and used for carrying out fixing and press mounting on lock sleeves; and the press-mounting mechanism is arranged at the upper part of the rack, and connected with the lock-sleeve press-mounting mechanism. The device and the method disclosed by the invention have the technical effect that the assembling of components such as lower bearings, clamp springs and lock sleeves can be completed once.

Owner:BOSCH HUAYU STEERING SYST CO LTD

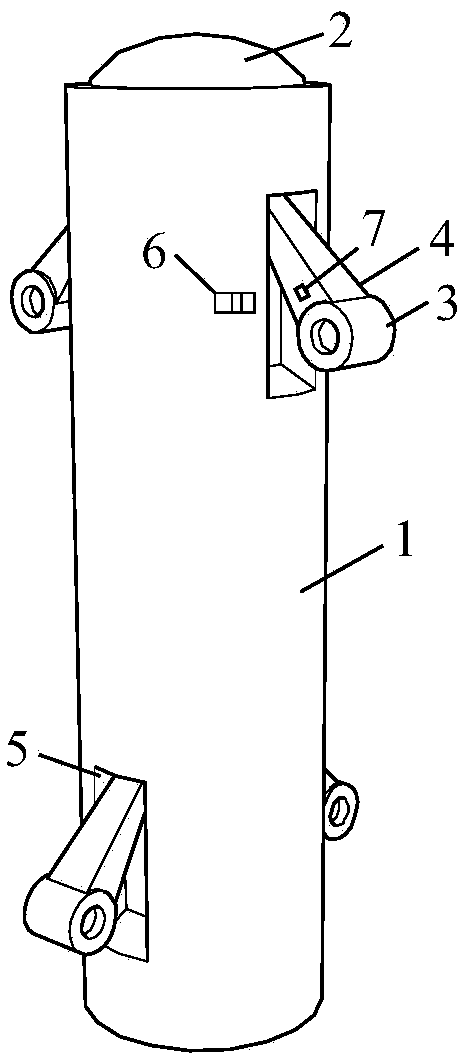

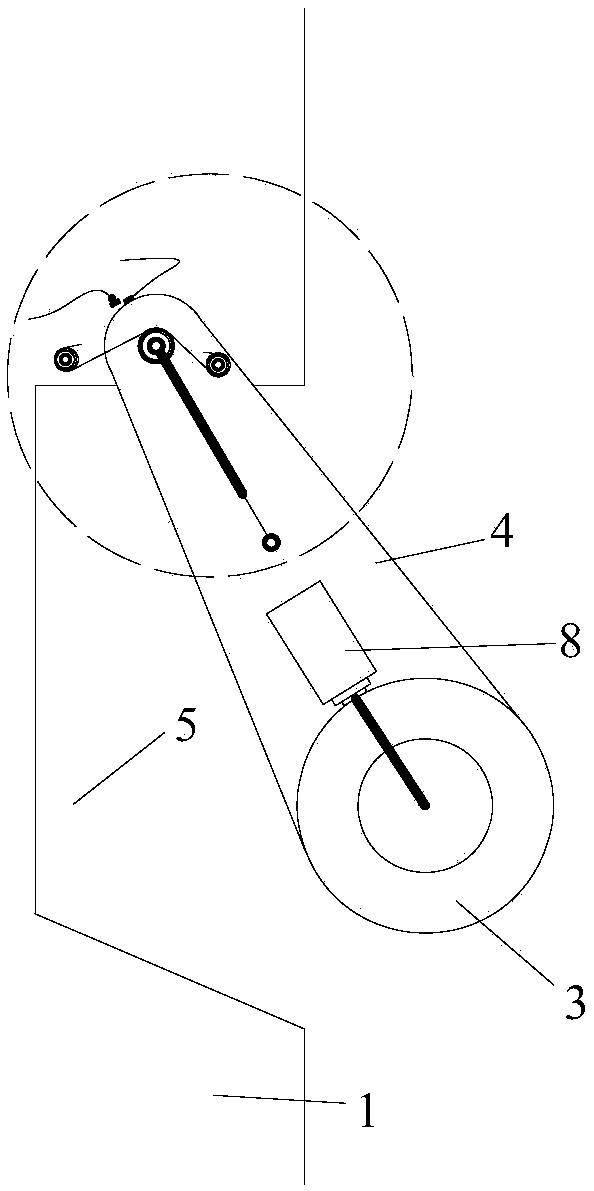

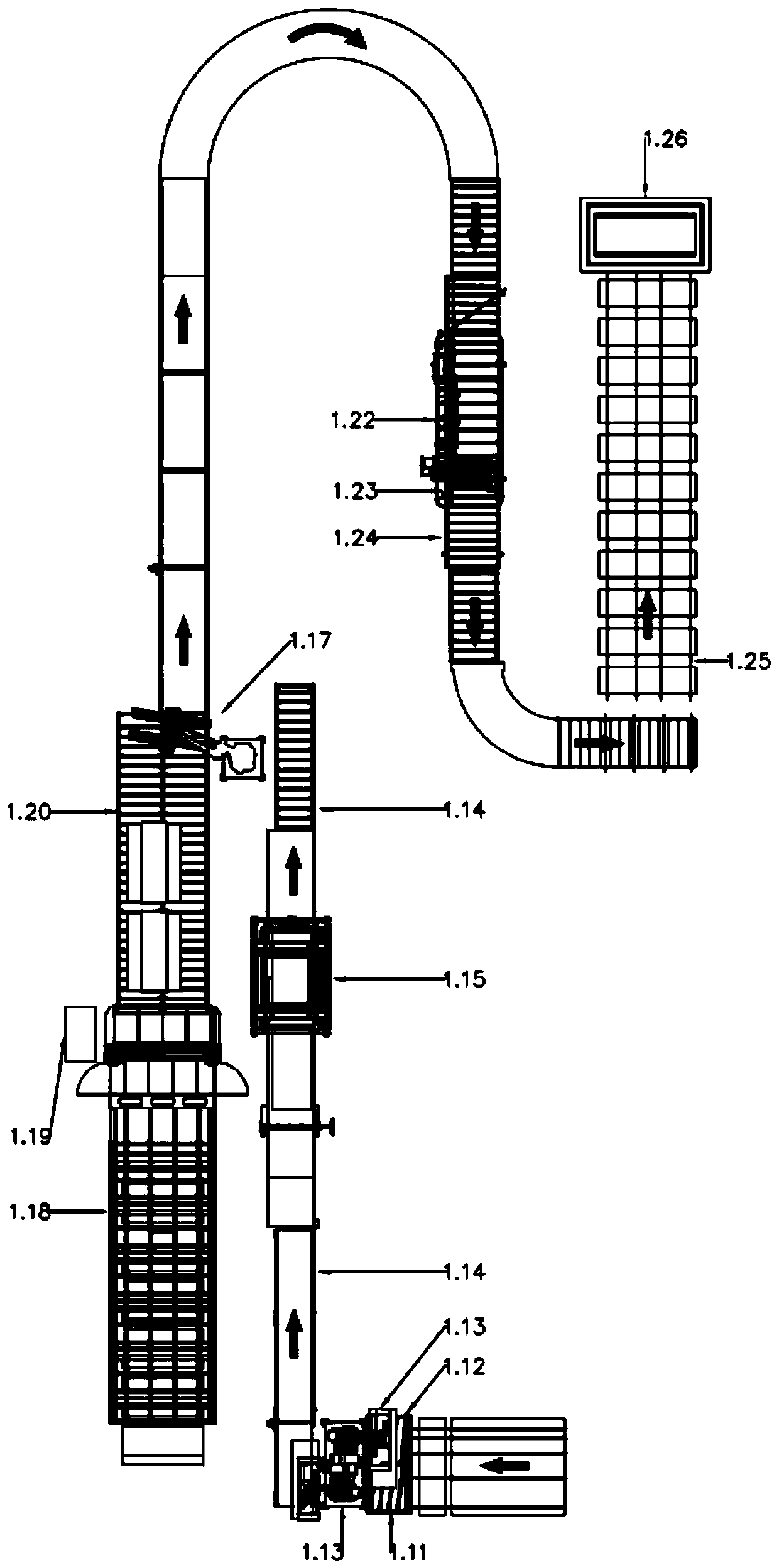

Self-propelled peeping probe adapted to different diameters of drill holes and peeping method thereof

The invention discloses a self-propelled peeping probe adapted to different diameters of drill holes and a peeping method thereof. The probe comprises a peeping probe body, a camera, walking wheels, rocker arms connected to the walking wheels, and an operating host. The rock arms can achieve a certain angle of damping opening and closing under the effects of internal torsion springs and gas springs and have alarm functions, and the rocker arms can be fixed in grooves of a peeping probe side through locking holes and locking blocks. The self-propelled function of the peeping probe in a drill hole can be achieved through an internal power supply, a driving motor, a video processing module, a control module, a WIFI module and the external operating host. The peeping probe has the advantages of centered drill hole, self-propelling and less workers in operation in a drilling peeping operation process, the complexity in a conventional drilling peeping operation is reduced, a push rod and a video transmission line are removed, auxiliary accessories are greatly reduced, and a new solution is provided for determining the fracture of a rock mass through drilling peeping in underground engineering.

Owner:CHINA UNIV OF MINING & TECH

Wood tray manufacture method

InactiveCN101417452AThe nailing position is uniform and beautifulImprove the stabilityWood working apparatusProduction lineUltimate tensile strength

The invention relates to a manufacturing method of wood trays, including the following steps of: forming front components of wood trays; turning over the front components of the wood trays; forming back components of the wood trays at back sides of the front components of the wood trays to produce the wood trays; postprocessing procedures; lining up and stacking the wood trays into a block; and exporting and carrying the whole block of wood trays stacked well into a warehouse. Compared with the prior art, the invention has the advantages that only 4 to 6 operators are needed in the whole production line, which equals the production efficiency of 20 operators with manual operation; the amount of labor can be saved by 70 percent and the production efficiency can be increased by more than 5 times; the labor intensity of workers can be reduced; the wood trays are lined up in order and can be staggered positively and negatively to save space; and single-deck trays can save space by more than 40 percent, site and space can be saved, and all processing equipment can be installed on the production line.

Owner:吴继荣

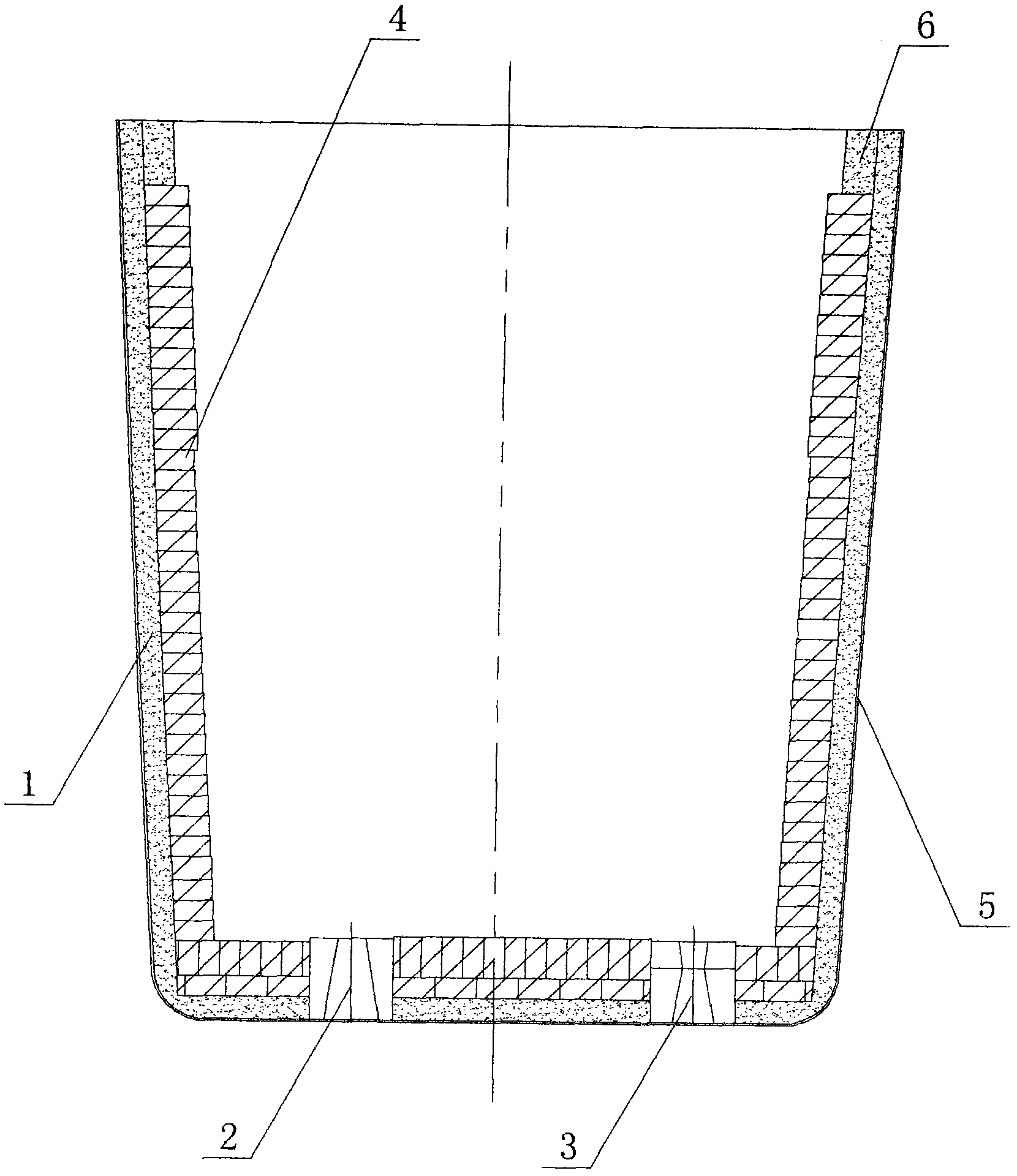

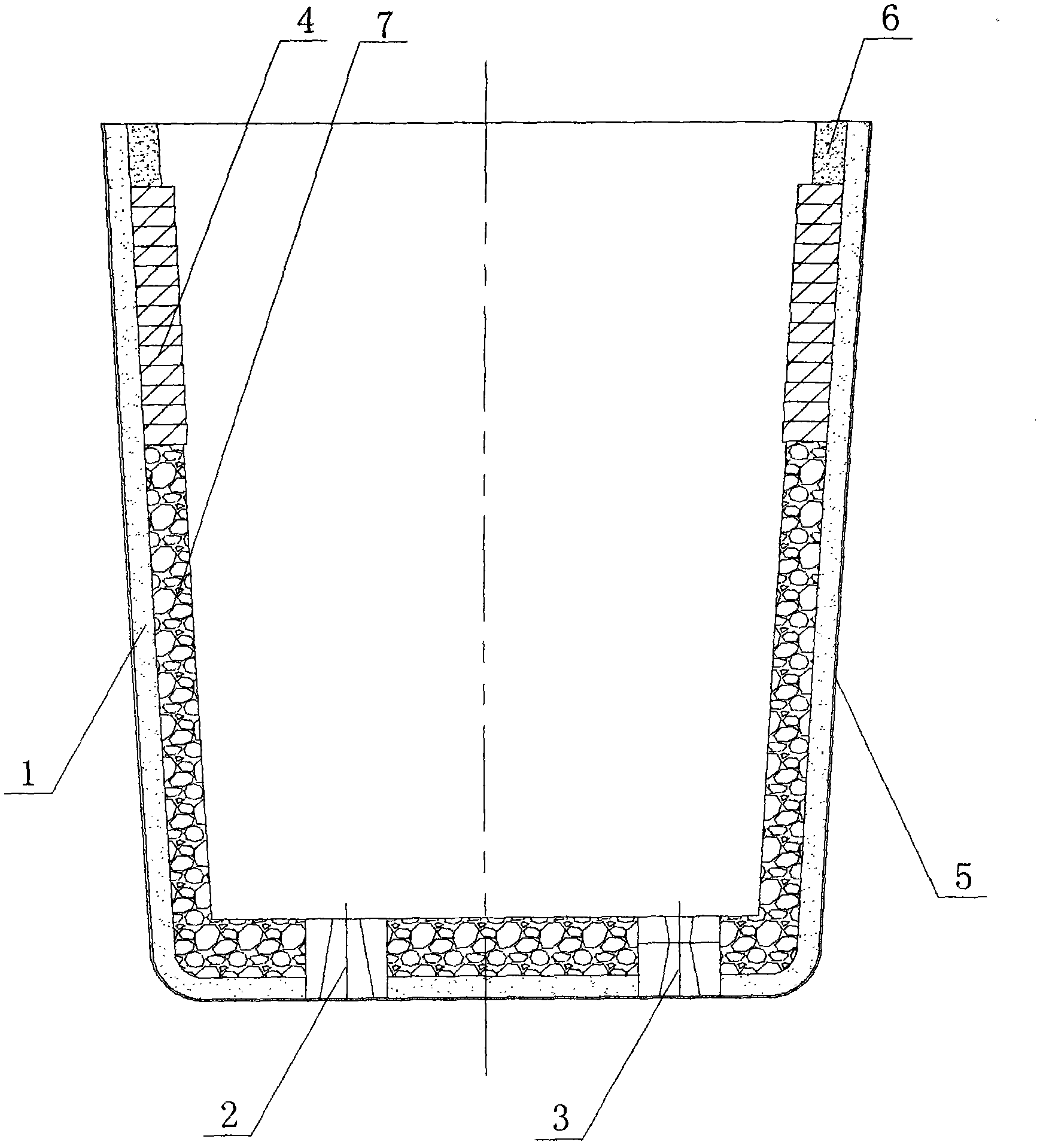

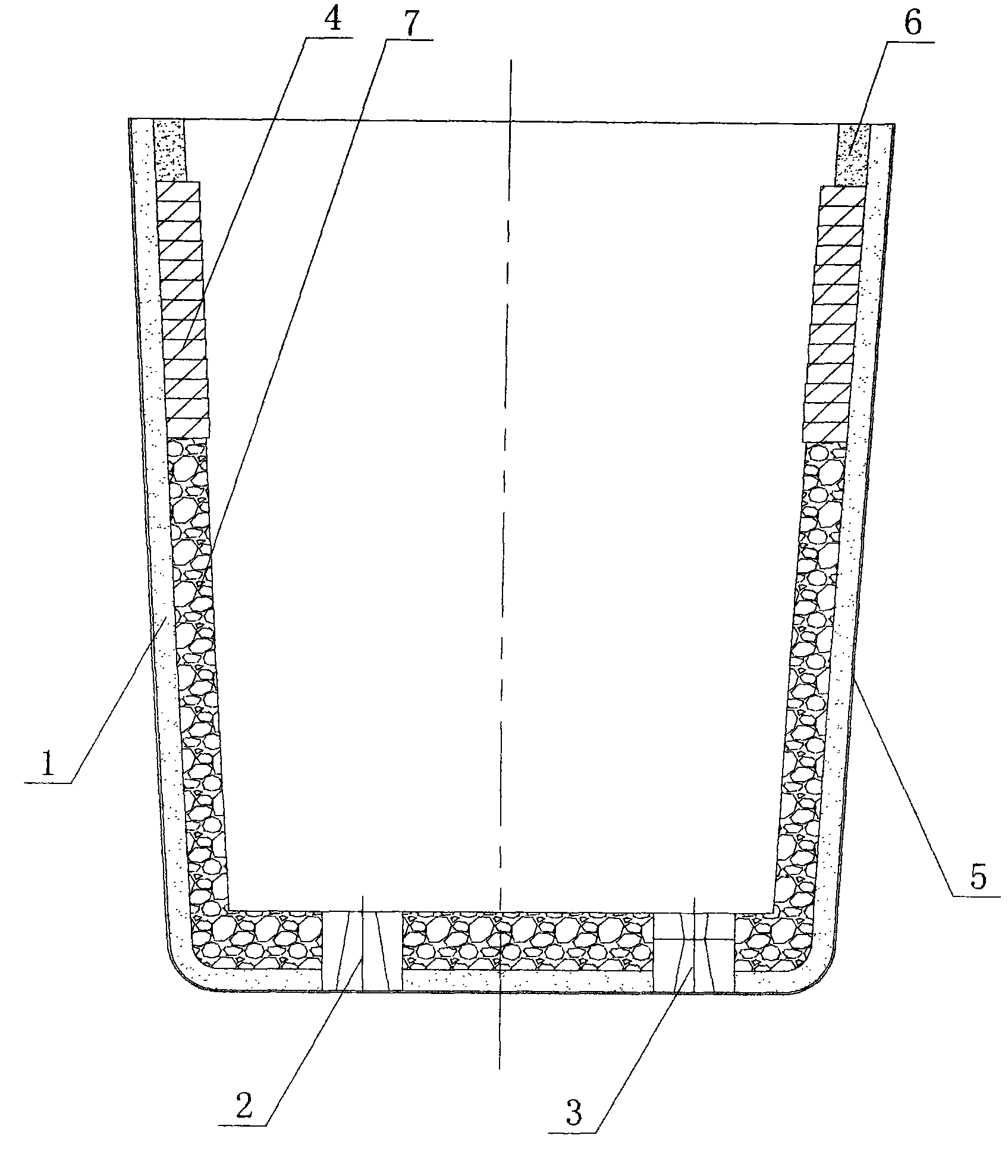

Large steel ladle and manufacturing method for same

The invention discloses a large steel ladle, which comprises a ladle body with a top opening. An air brick and a tapping nozzle are arranged at the bottom of the ladle body, the ladle body sequentially comprises a steel shell, a permanent layer and a lining layer from outside to inside, the permanent layer is cast with aluminum-magnesium casting materials, the lower half portions of the bottom surface and the lateral surface of the lining layer are cast with corundum spinel casting materials, the upper half portion of the lateral surface of the lining layer is built with magnesia carbon bricks or built with mixed magnesia carbon bricks and carbon-free precast blocks, and a seal is arranged at the top of the lining layer. The manufacturing method for the large steel ladle includes the steps: 1 casting the permanent layer; 2 manufacturing the lining layer; 3 baking; and 4 mounting the air brick and arranging the tapping nozzle at the bottom of the ladle body. The large steel ladle has the advantages that (1) the lining layer is high in strength and resistant to corrosion of molten steel, so that the service cycle of the lining layer is longer than original service cycle and frequent repair for the lining layer is omitted, and (2) when the lining layer is repaired, material consumption is low, construction efficiency is high, labor intensity is low, and manpower and material resources are saved.

Owner:JINAN IRON & STEEL GRP REFRACTORY CO LTD

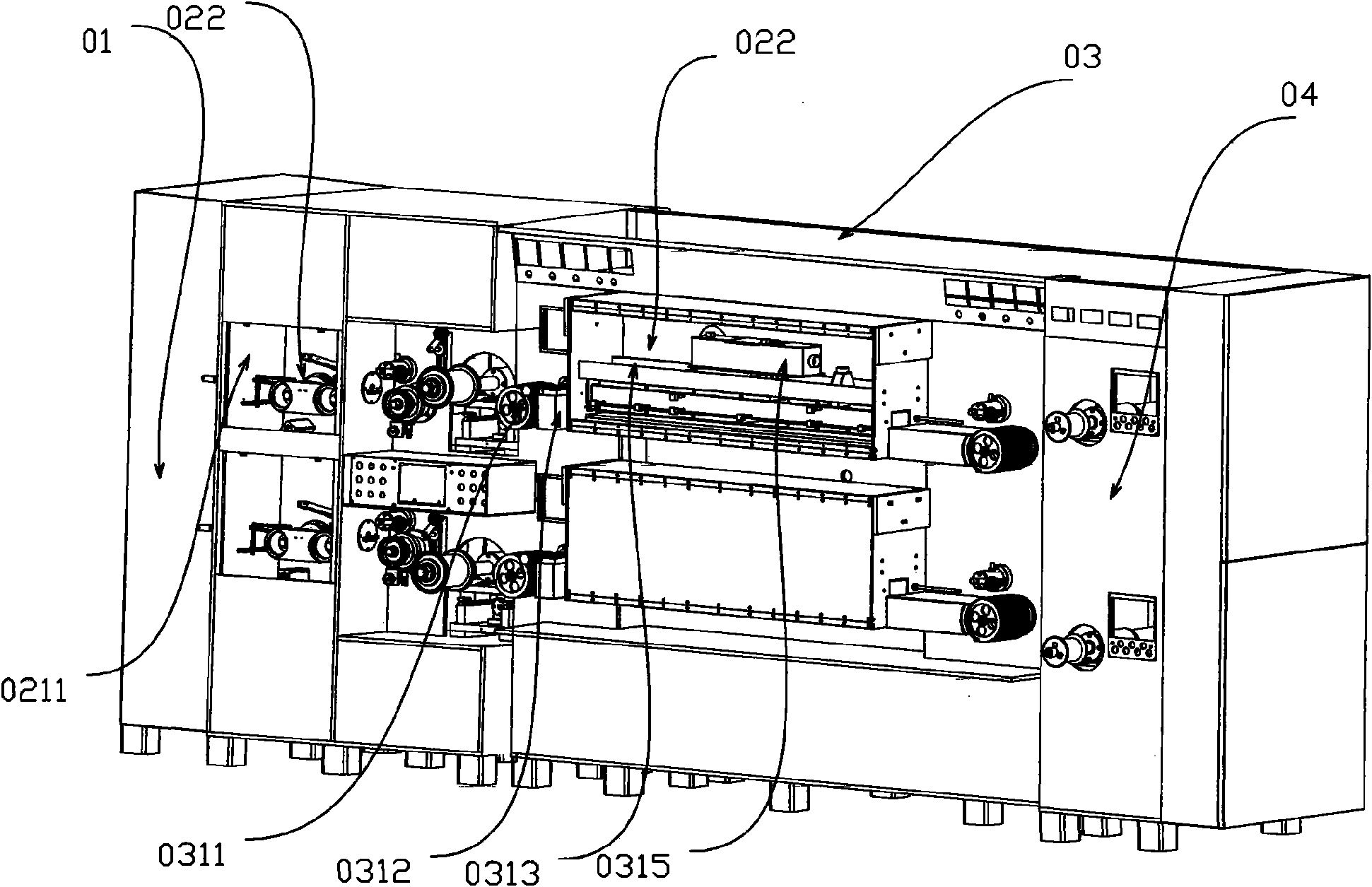

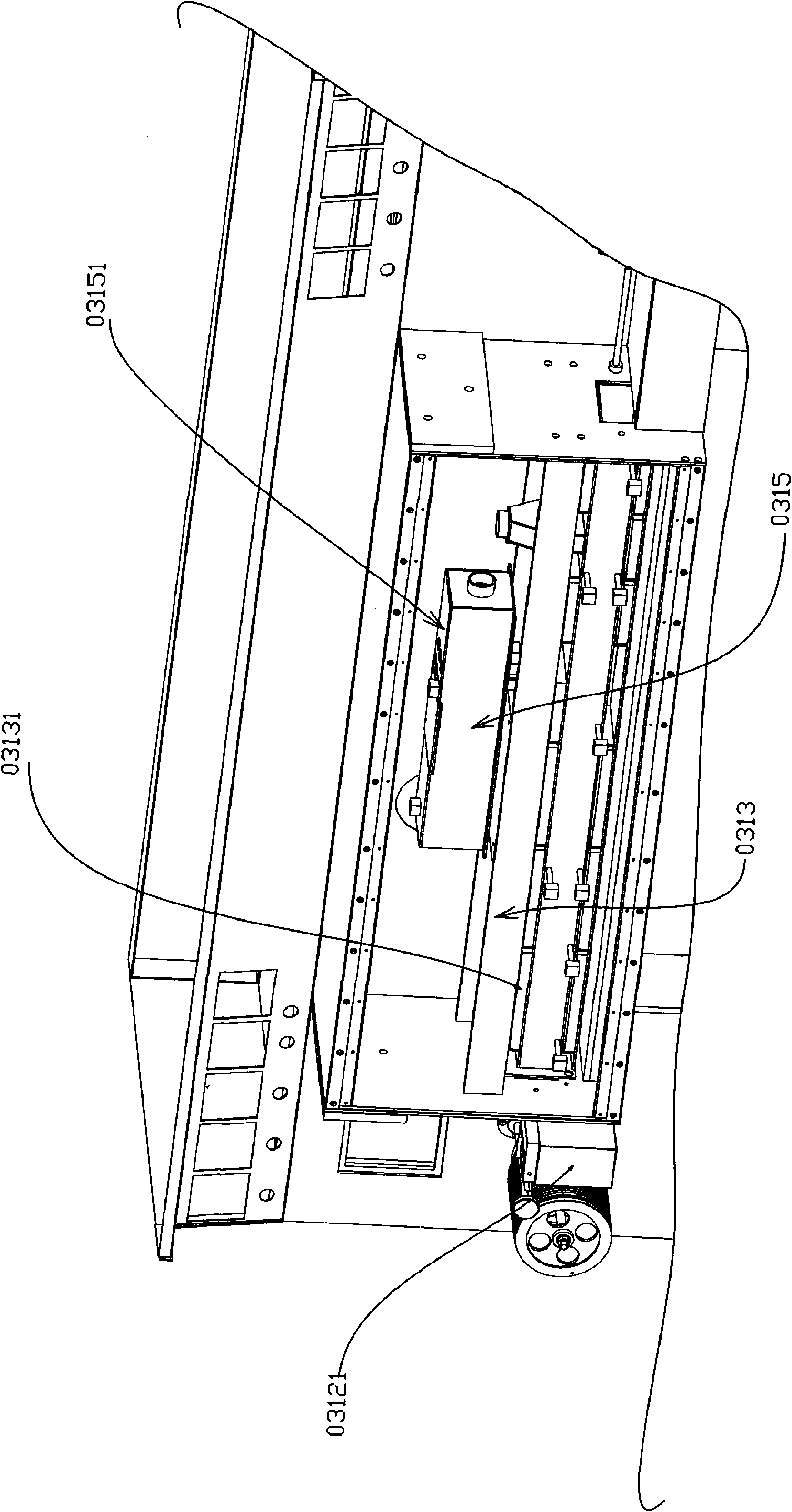

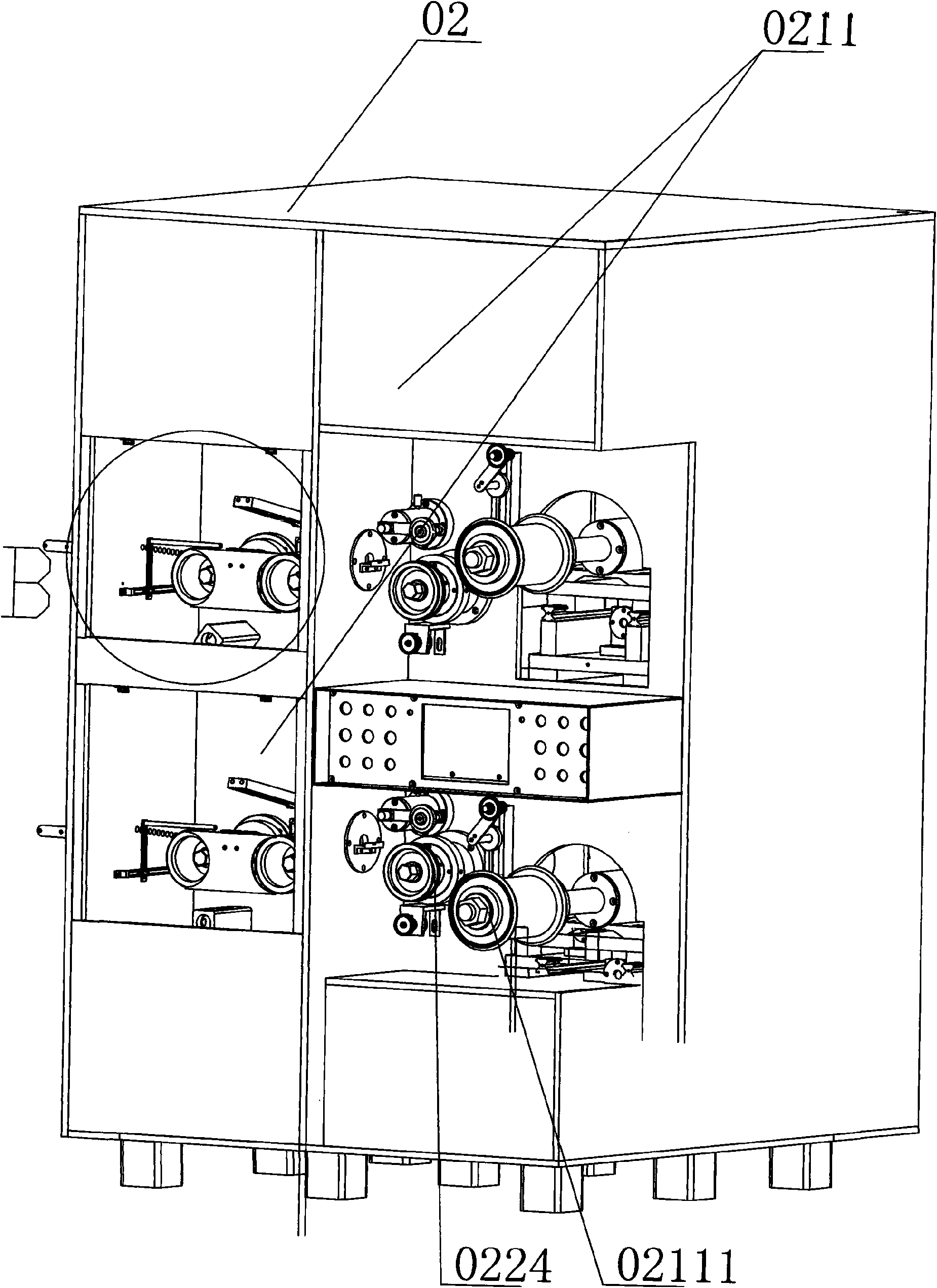

Equipment for producing bonding wire for packaging semiconductor

InactiveCN101572135AReduce volumeCompact structureLine/current collector detailsSemiconductor/solid-state device manufacturingThin metalSemiconductor package

The invention discloses equipment for producing a bonding wire for packaging a semiconductor, which comprises a wire releasing device, a wire-drawing machine, a quenching and tempering device and a take-up device, wherein a metal wire in the wire releasing device is sent to the wire-drawing machine through a leading mechanism; the wire-drawing machine is arranged on one side of a wire outlet of the wire releasing device and comprises a wire-drawing component; the metal wire led out of the leading mechanism of the wire releasing device is connected to a wire-drawing component capable of gradually drawing the outer diameter of the metal wire small; the quenching and tempering device is arranged on one side of a wire outlet of the wire-drawing machine and comprises a wire sending device, a washing device, a coating device, an annealing device and a roasting oven; a thin metal wire conforming to specifications and pulling out of the wire-drawing machine is sent to the washing device through the wire sending device; the washed metal wire enters the annealing device for annealing; the annealed metal wire enters the coating device for coating; the coated metal wire enters the roasting oven for drying and then enters a cooling device for cooling; the wire take-up device is provided with a wire containing tray for collecting a finished wire, and the wire containing tray is connected with a driving device and driven by the driving device.

Owner:袁毅

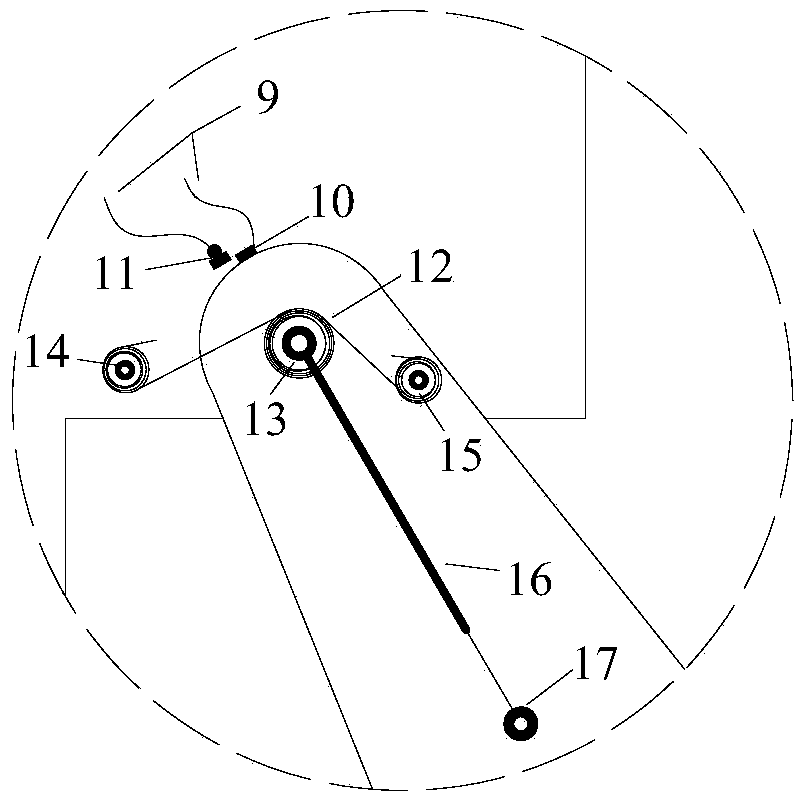

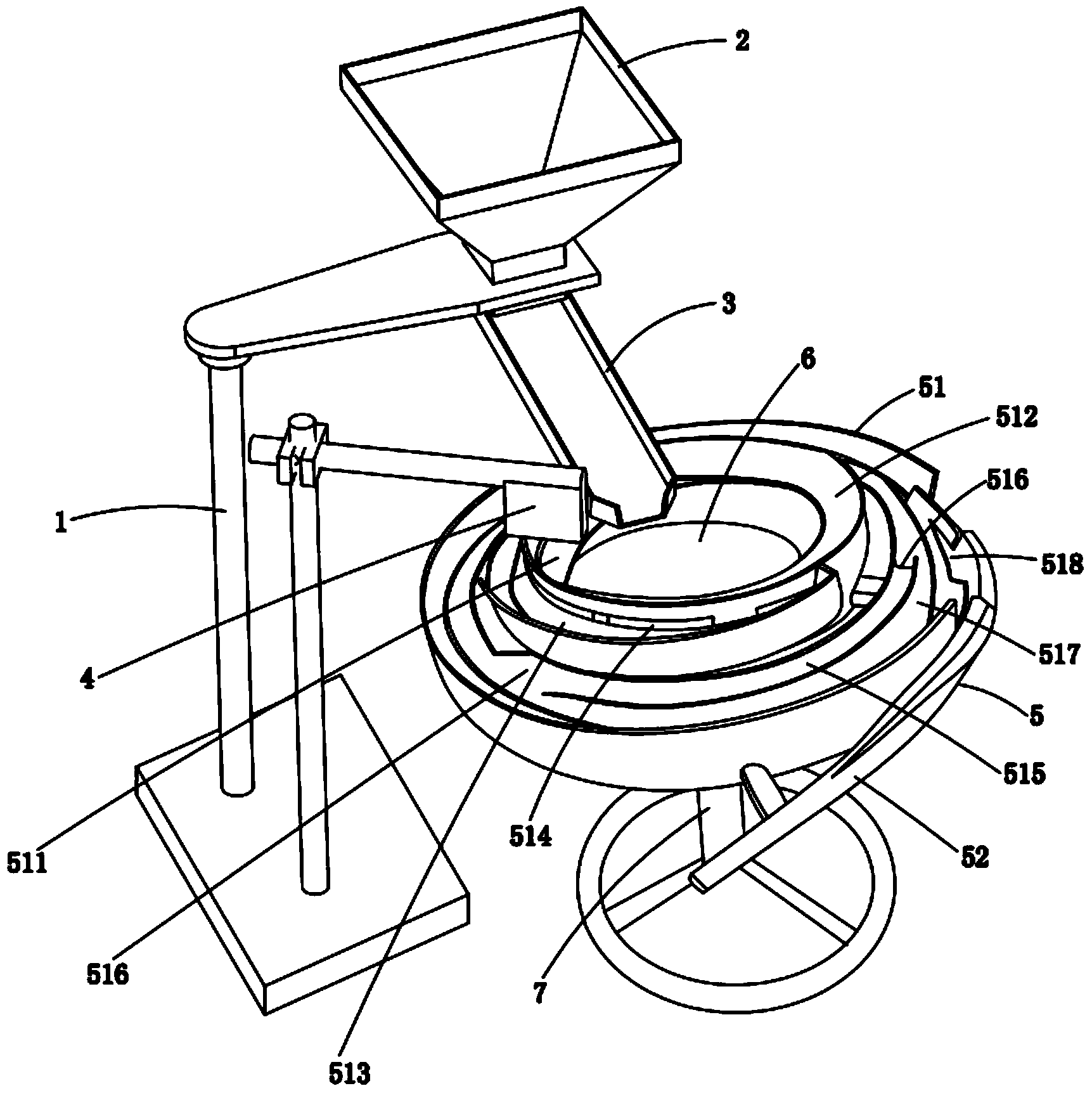

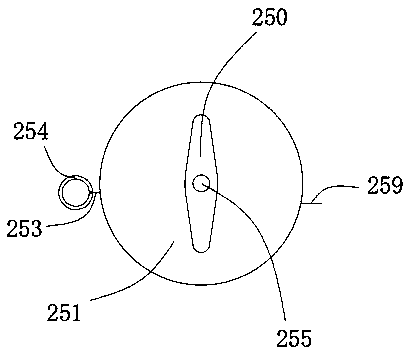

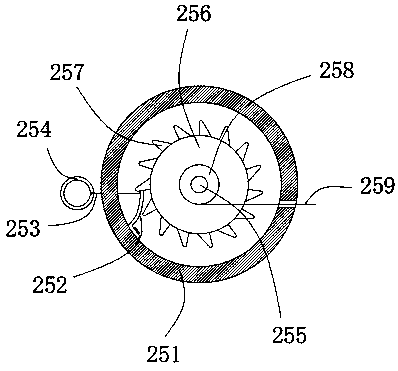

Automatic-arranging detecting device

ActiveCN103910187AAvoid damageReduce workloadControl devices for conveyorsRotary conveyorsAutomationMagnetic core

The invention relates to an automatic-arranging detecting device which comprises a frame, a feed hopper, a slide groove, a detecting device body and a screen plate. The feed hopper is mounted on the frame. The oblique slide groove is connected to the bottom of the feed hopper. The screen plate is located right below the tail end of the slide groove. The detecting device body is disposed above the screen plate. The screen plate comprises a magnetic core rail and a movable rotary plate. The magnetic core rail comprises a circular rail and a linear rail. The circular rail comprises a plurality of channels. The movable rotary plate is disposed in the middle of the circular rail and fixed on a rotating mechanism. The movable rotary plate is driven by the rotating mechanism to rotate clockwise. By the automatic-arranging detecting device, disordered to-be-machined magnetic core blanks can be automatically neatly arranged one by one in the linear rail to prepare for the next work procedure after being detected by the detecting device body and being screened and sorted by the multiple channels. In addition, the automatic-arranging detecting device is ingenious in structural design, high in automation level and intelligent in detecting, number of operators is reduced, blank damage is reduced, and work efficiency is increased effectively.

Owner:广州特创电子有限公司

Road bridge asphalt pavement crack detection restoration device

The invention discloses a road bridge asphalt pavement crack detection restoration device comprises a vehicle body. The top surface of the vehicle body is, from left to right, sequentially provided with a control device, a correction device, a collection device, a driving device, and a fusion device. The left end of the bottom surface of the vehicle body is provided with a universal wheel, and theright end of the bottom surface of the vehicle body is provided with a walking wheel, and the bottom surface of the vehicle body is provided with a transmission device between the universal wheel andthe walking wheel. By adopting the cooperation among the control device, the correction device, the driving device, and the fusion device, the device can be used for blowing and sweeping sundries, pouring the asphalt, and correcting the asphalt at the same time, and then the restoration speed is additionally provided, and then the amount of used machine equipment and the amount of workers can bereduced, the asphalt recycling of the workers can be facilitated, the consumption amount of the asphalt can be reduced, the restoration costs can be reduced, and the practicability of the road bridgeasphalt pavement crack detection restoration device can be improved.

Owner:大冶市德晟公路工程有限公司

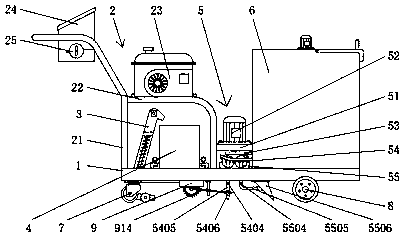

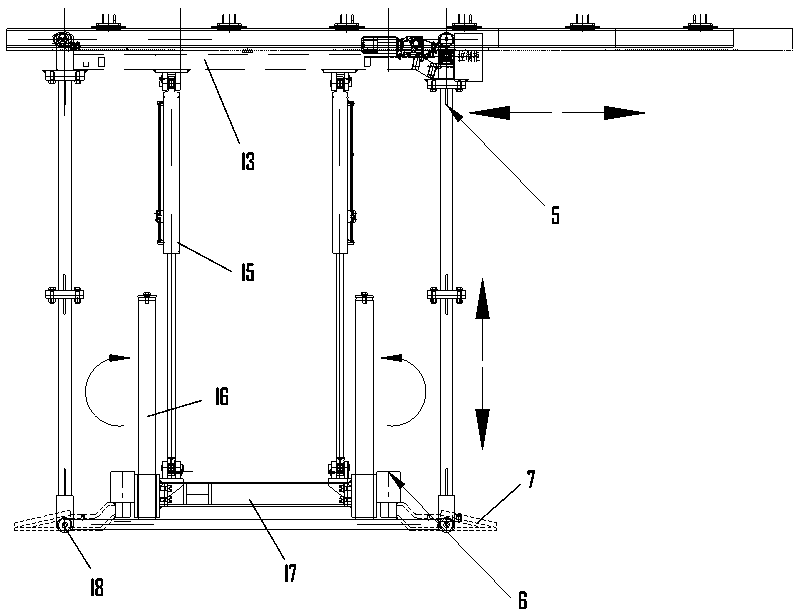

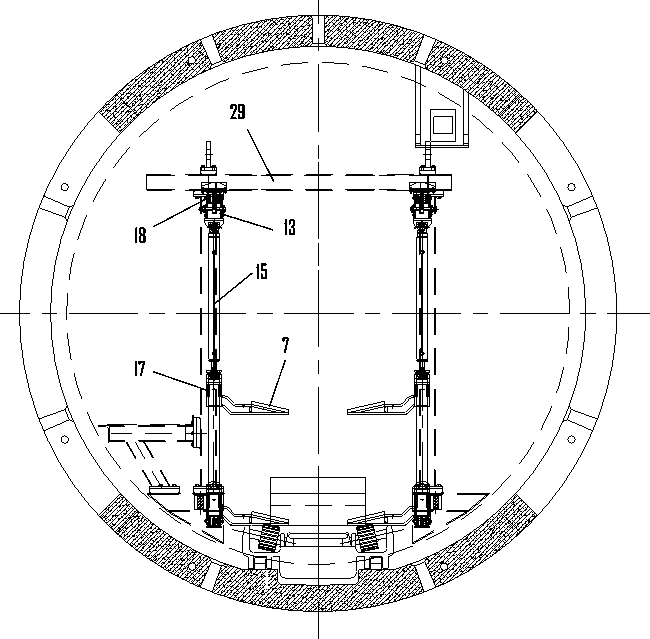

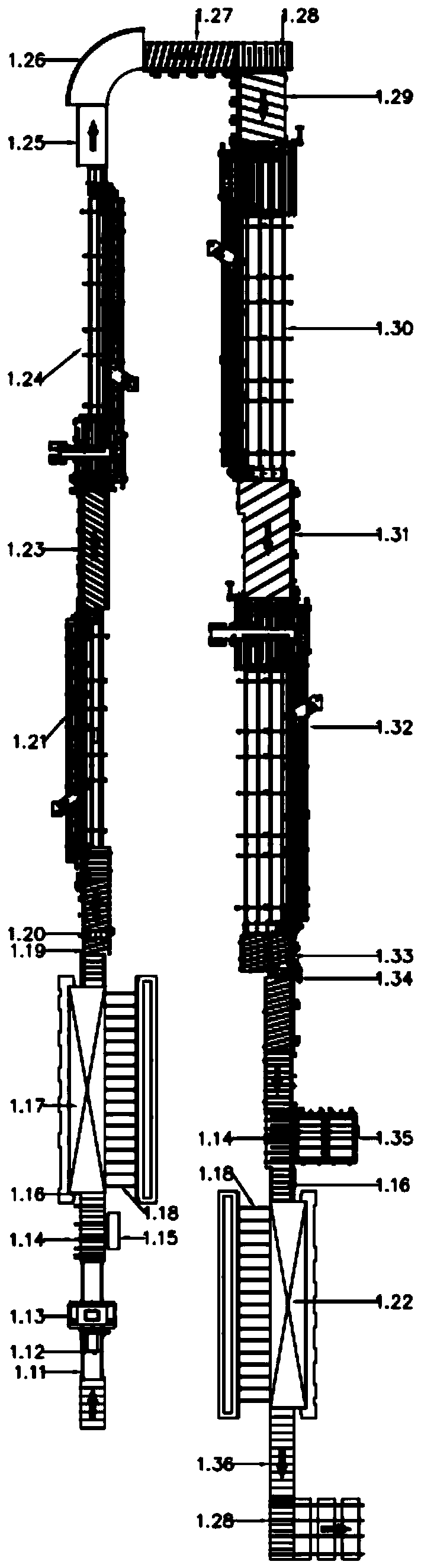

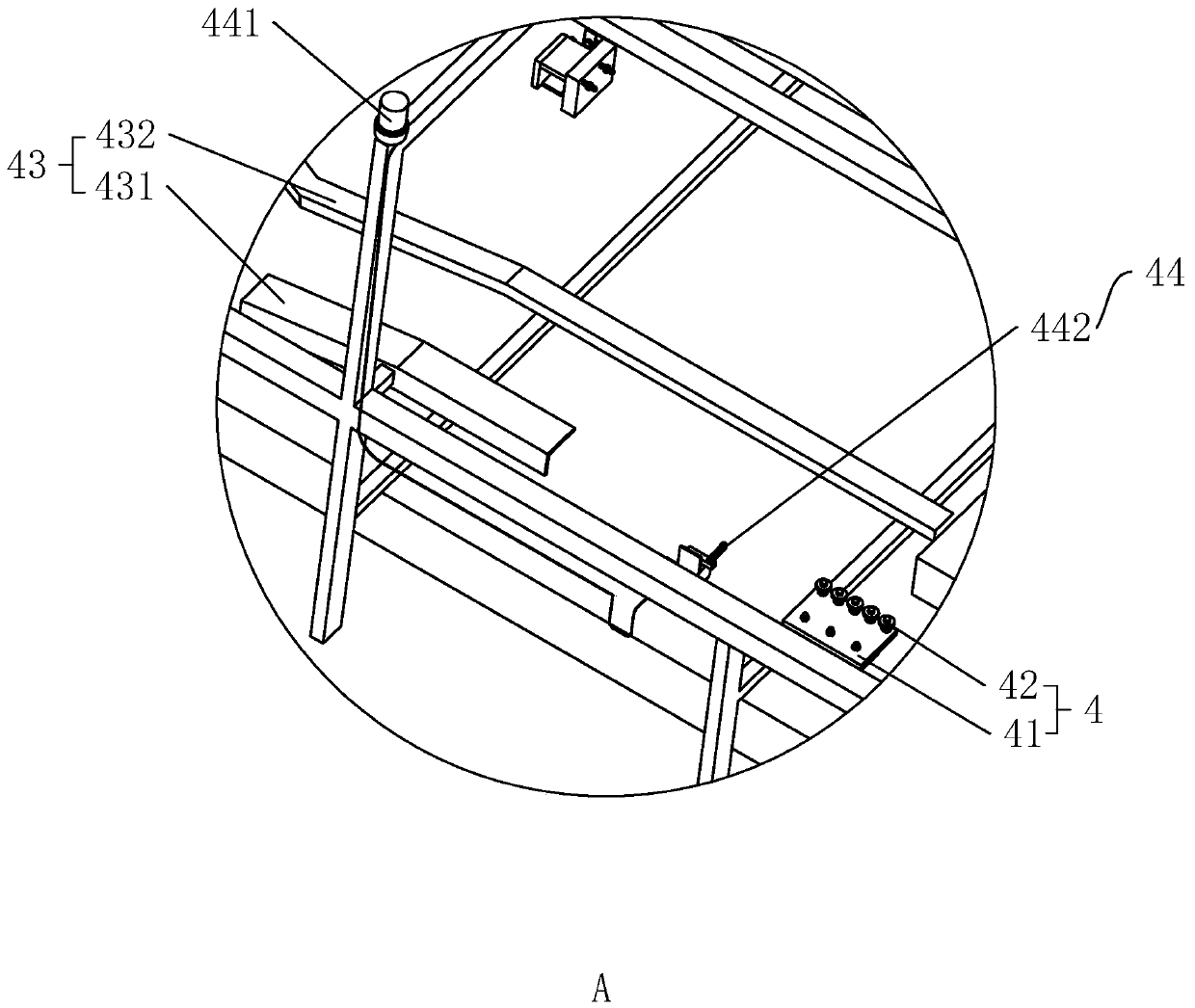

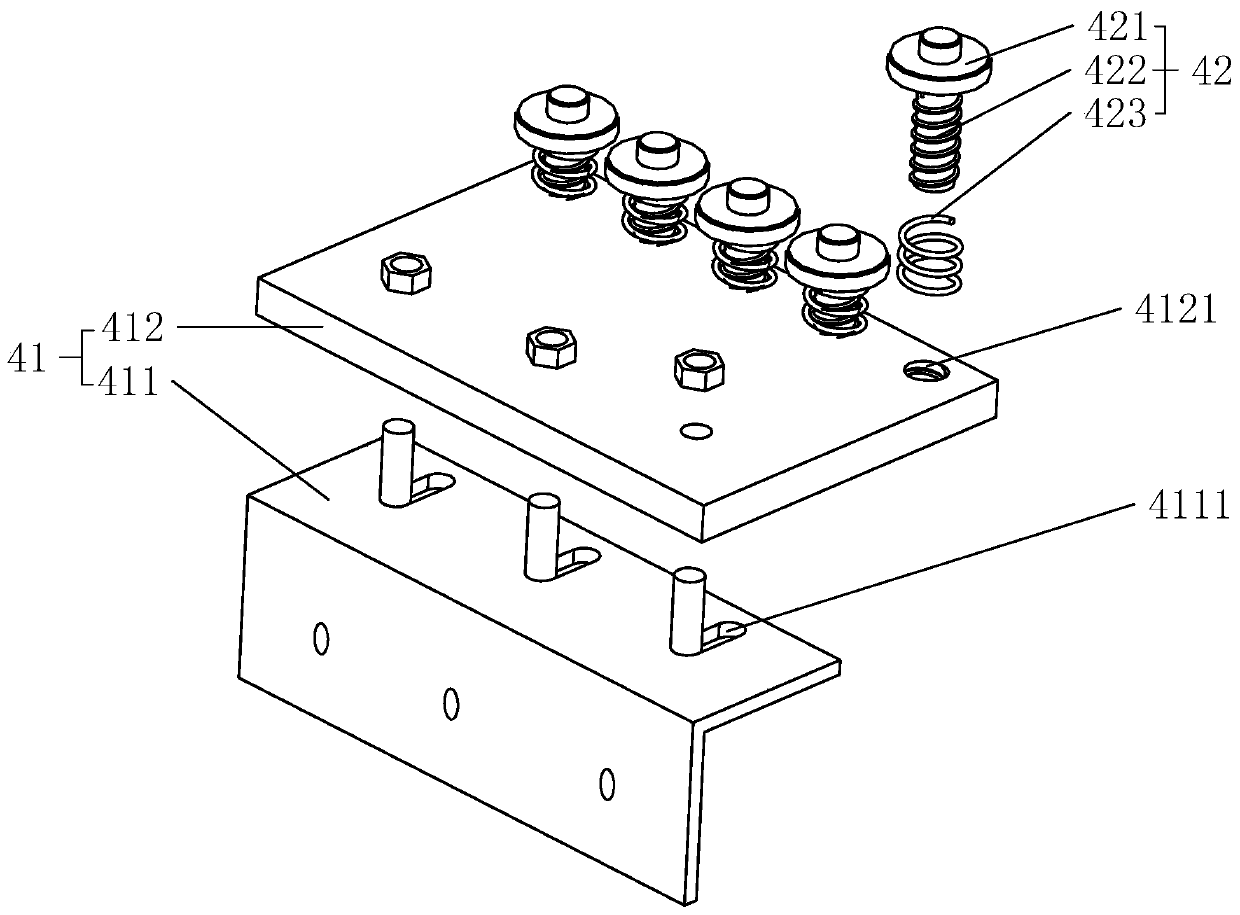

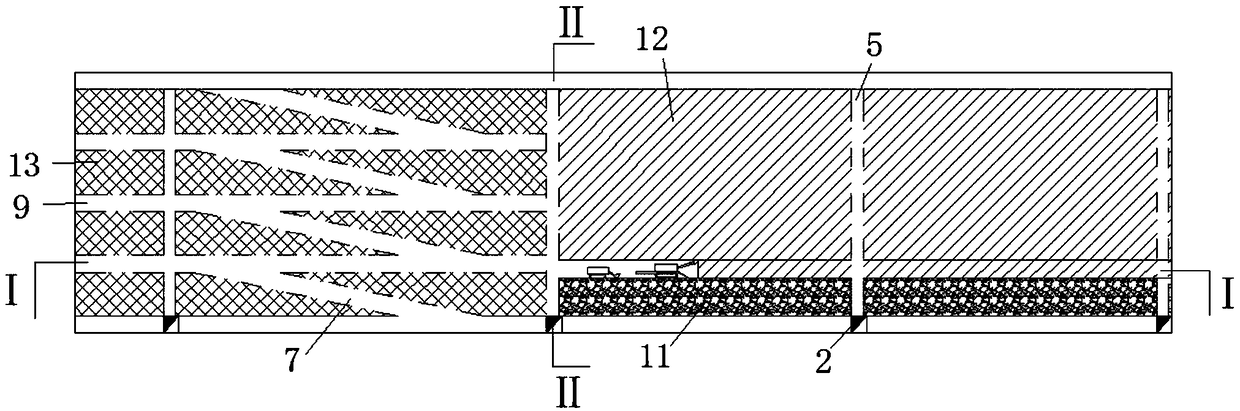

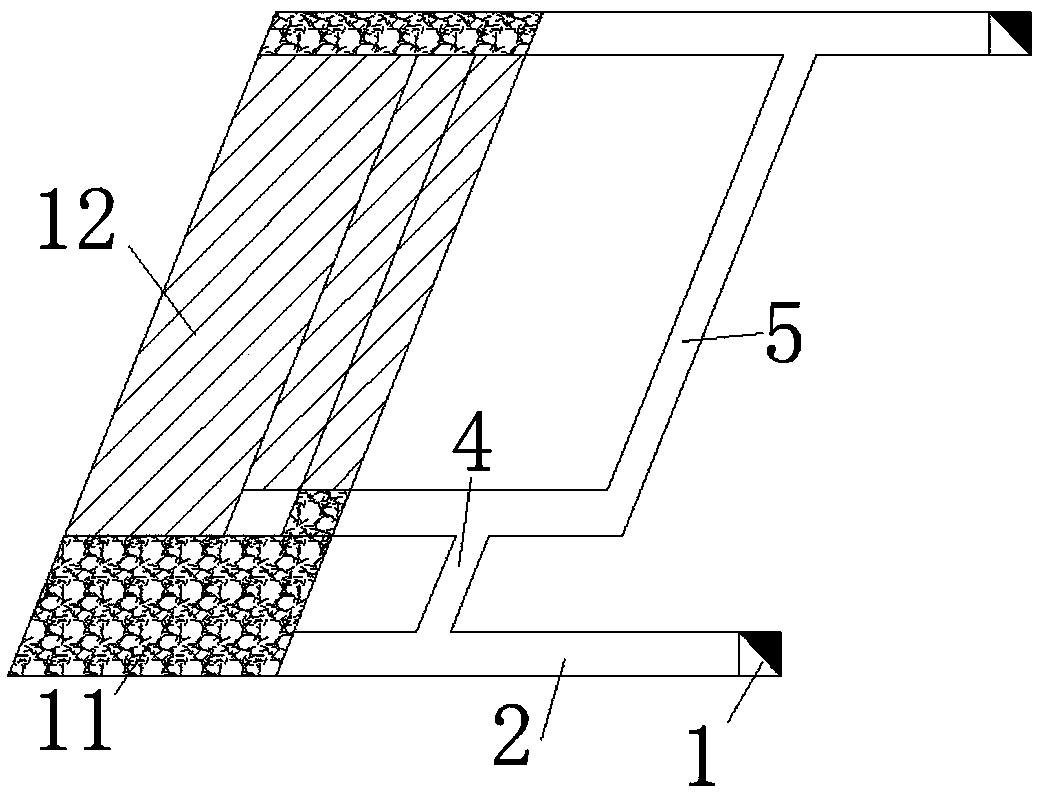

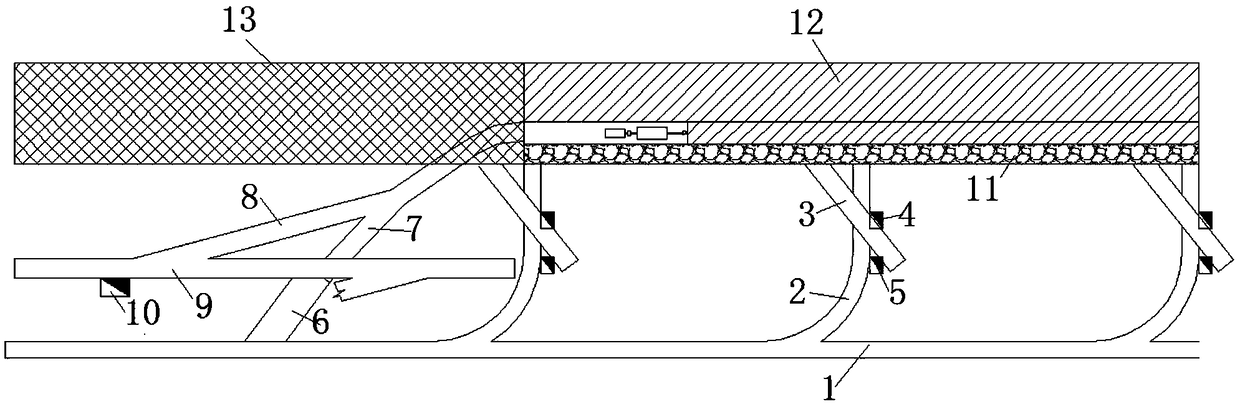

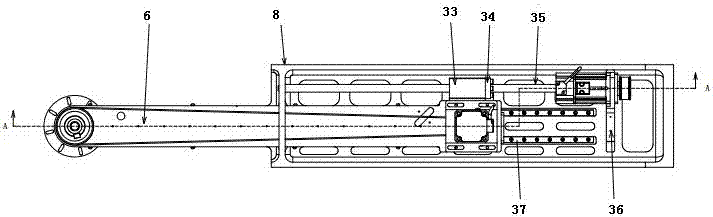

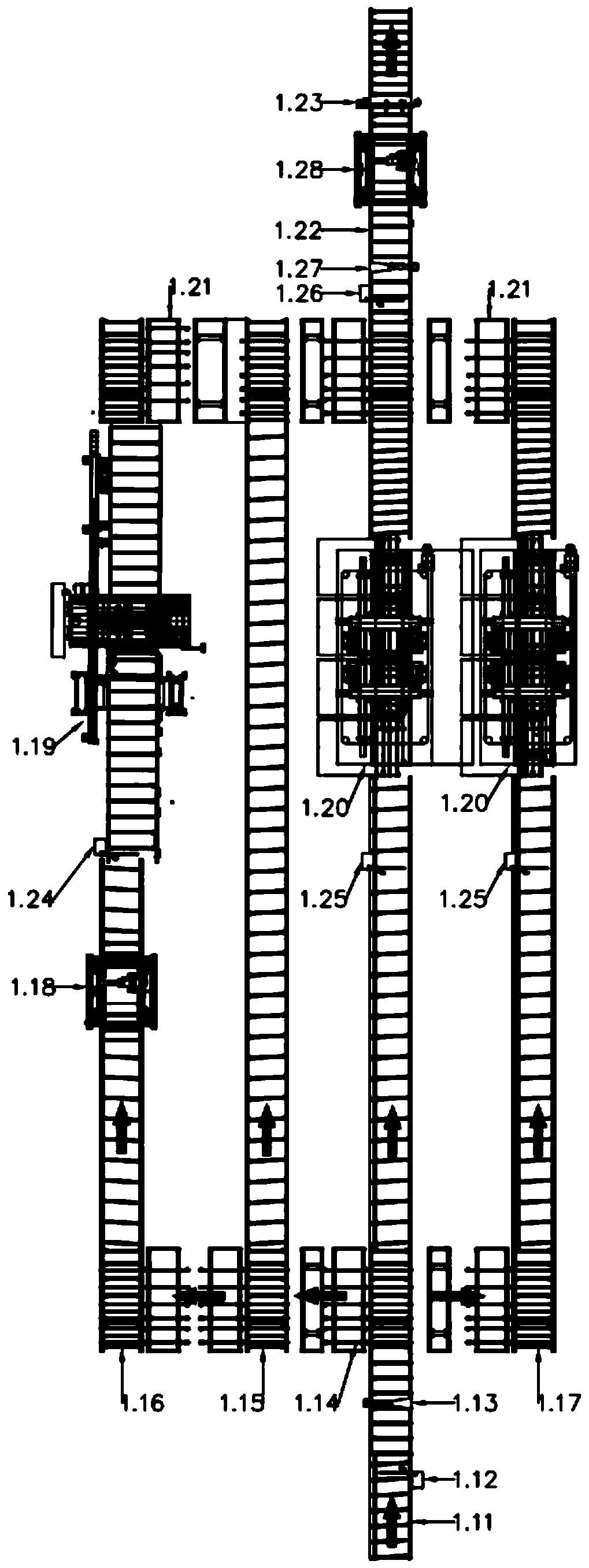

Automatic segment conveying system

ActiveCN110985073AStable delivery cycleReduce the number of workersUnderground chambersTunnel liningDelivery systemAutomation

The invention provides an automatic segment conveying system. The automatic segment conveying system comprises a front-end transfer device and a rear-end transfer device, a moving unloader is arrangedbetween the front-end transfer device and the rear-end transfer device, the moving unloader comprises an unloading frame which can walk, a telescopic guide frame is arranged on the walking unloader,and a rotary bending and lifting head is arranged on the guide frame. The automatic segment conveying system has the advantages that a stable segment conveying period can be ensured; the safety is improved and the number of people for operating of segment conveying is reduced; the automatic segment conveying system is matched with an automatic segment assembly system, and the unmanned performanceand automation of shield type TBM construction are promoted; and the shield type TBM construction period is shortened, and the shield type TBM construction cost is saved.

Owner:CHINA RAILWAY ENGINEERING EQUIPMENT GROUP CO LTD +1

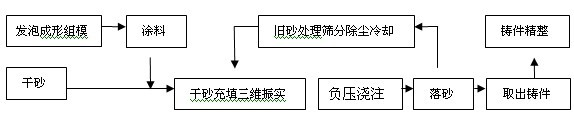

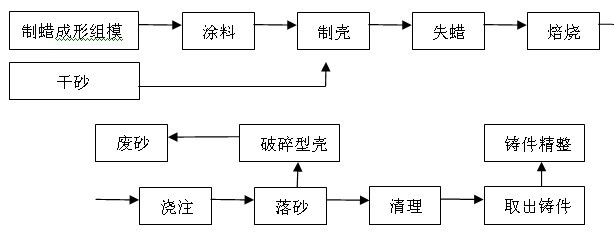

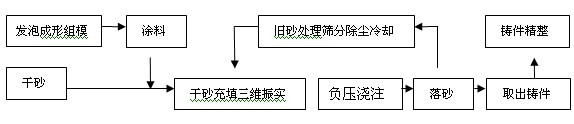

Lost foam casting method of casing of full-automatic lock for container

InactiveCN102366818AReduce process stepsReduce labor intensityFoundry mouldsFoundry coresDry sandProcess engineering

The invention discloses a lost foam casting method of a casing of a full-automatic lock for a container. The lost foam casting method comprises the following steps of preparing a casting-shaped model from a foaming material, building a model cluster, putting the model cluster into a sandbox, carrying out vibration molding by binder-free dry sand, carrying out improvement on strength of the binder-free dry sand filling a cavity by vacuum negative pressure so that the binder-free dry sand has enough strength, carrying melting and pouring, taking out a casting from the binder-free dry sand without residual strength, carrying out normalizing, and then carrying out shot blast to obtain finished products. Through the lost foam casting method, a foam gas generation amount can be centralizedly controlled by a vacuum system; a casting is easy to be taken out from a sandbox; modeling sand can be recycled; multiple processes of production are suitable for mechanized production; paint use amounts can be controlled according to product conditions; and a total production cost can be reduced.

Owner:WUXI KAIJIE CASTING

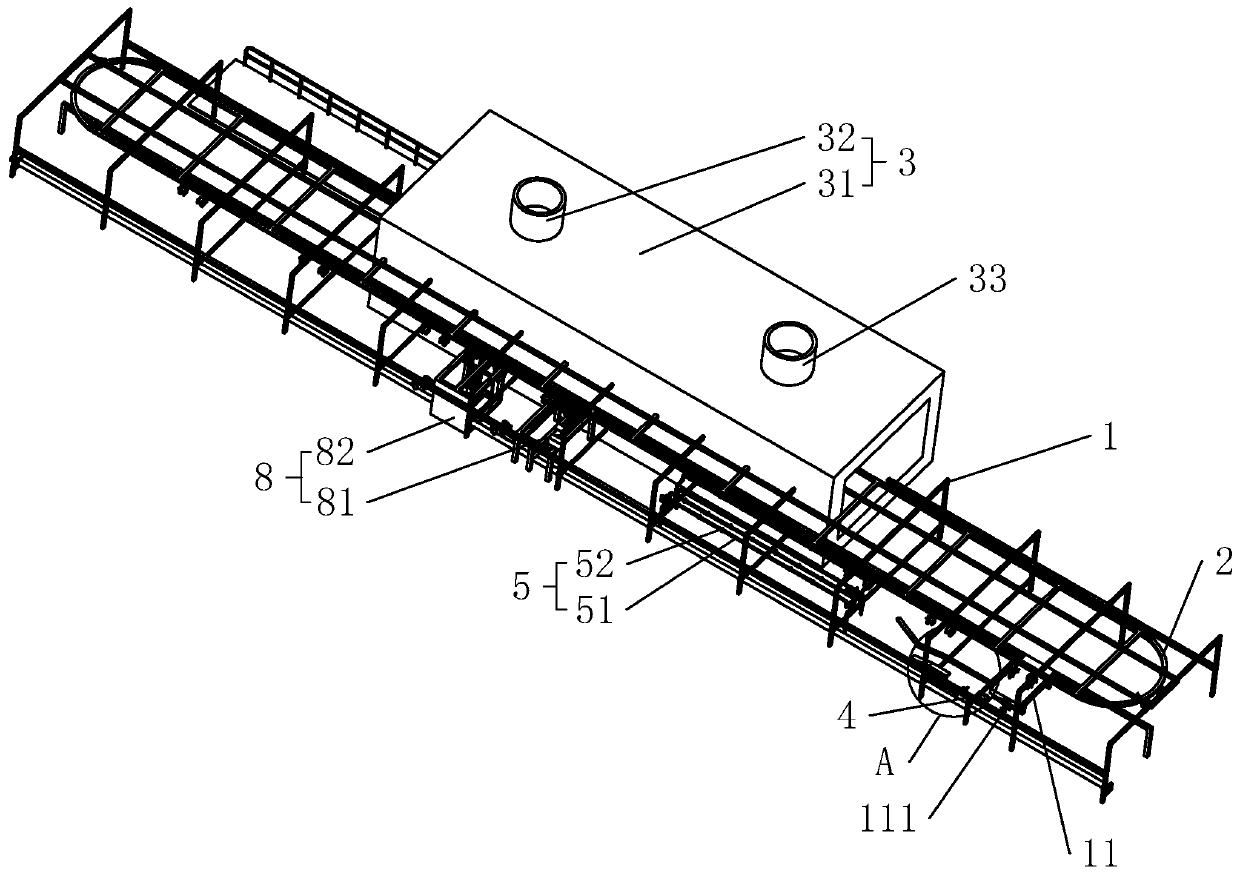

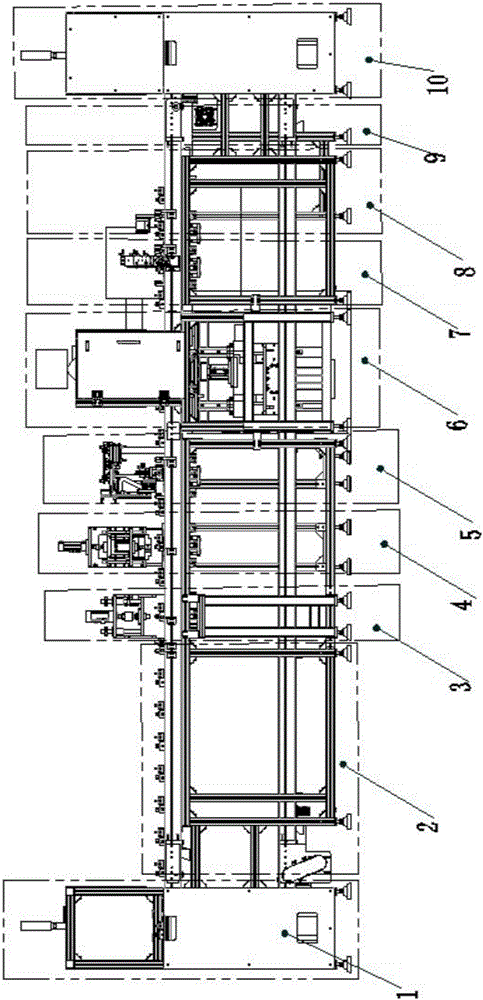

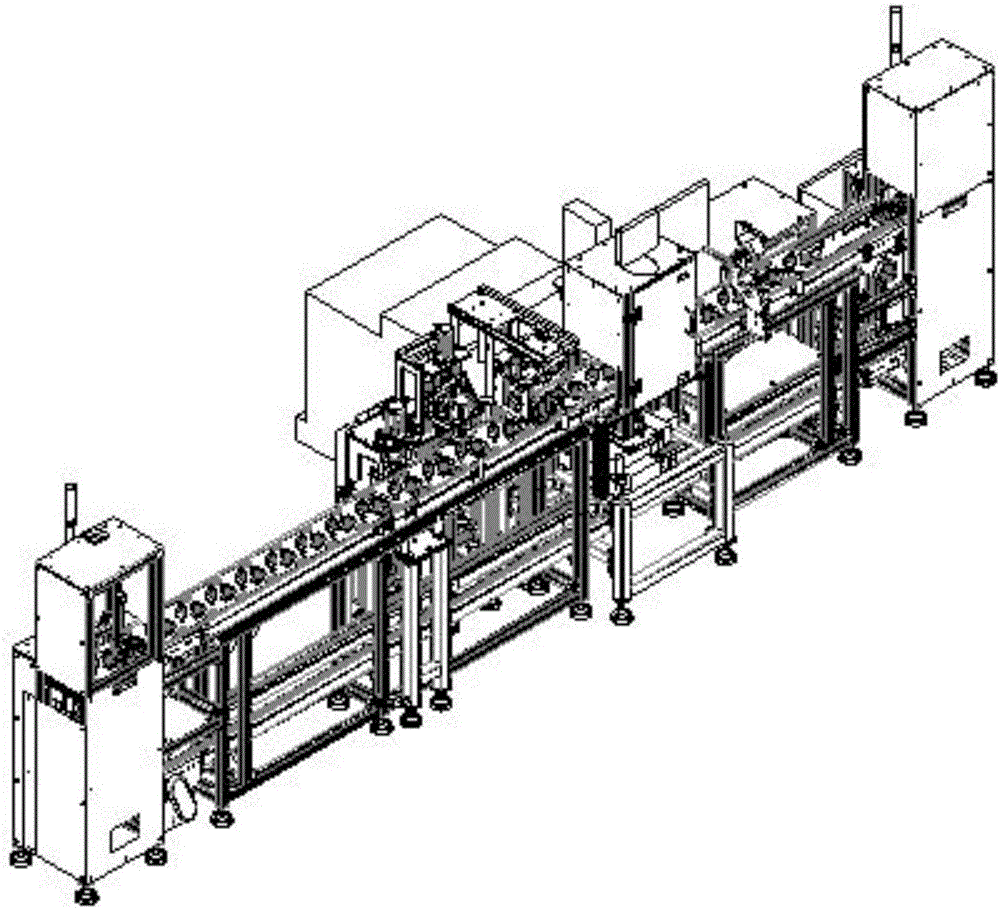

Automatic packaging production line for customized furniture boards and control method of automatic packaging production line

PendingCN109720671AReduce the number of workersMeet the needs of mass productionPackaging automatic controlPackaging machinesPaper cutManipulator

The invention relates to an automatic packaging production line for customized furniture boards. The automatic packaging production line comprises a packaging control device, a packaging conveying line, a stacking mechanical arm, a stack grabbing mechanical arm, an automatic paper cutting device and a plurality of board position detection sensors located on the packaging conveying line, wherein the packaging conveying line comprises a feeding conveying line, a board stack conveying line and a packaging line; the stacking mechanical arm is located at the position between the feeding conveying line and the board stack conveying line, a code scanning device A for scanning an identification code on a board is arranged on the feeding conveying line, and a measuring and rectifying device is arranged on the board stack conveying line; the automatic paper cutting device is located on the upper stream of the packaging line, and the stack grabbing mechanical arm is located at the down stream ofthe automatic paper cutting device and is close to the down stream of the measuring and rectifying device; and the packaging control device is connected with the packaging conveying line, the code scanning device A, the stacking mechanical arm, the measuring and rectifying device, the stack grabbing mechanical arm, the automatic paper cutting device and the board position detection sensors. The number of needed workers is small, continuous production can be carried out, and the large-scale production requirement can be met.

Owner:索菲亚家居湖北有限公司 +2

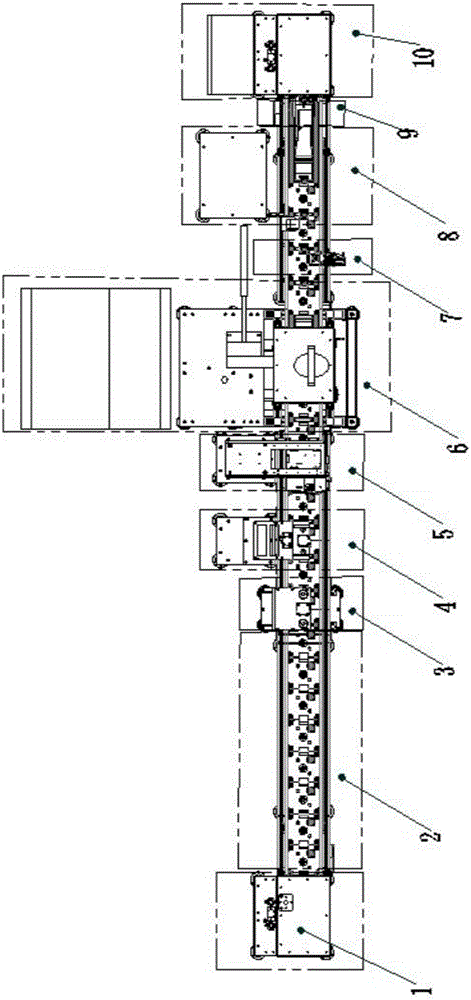

Automatic board edge banding system and control method thereof

PendingCN109748071ASmooth connectionReduce the number of workersOther plywood/veneer working apparatusDomestic articlesEngineeringTemporary storage

The invention discloses an automatic board edge banding system and a control method thereof. The system comprises an edge banding control device, edge banding conveying lines, a code scanning device A, an edge banding machine, a feeding temporary storage bin and a discharging temporary storage bin. The edge banding conveying lines include the feeding conveying line and the discharging conveying line and are provided with a plurality of board position detection sensors, wherein the feeding conveying line, the feeding temporary storage bin, the code scanning device A, the edge banding machine, the discharging temporary storage bin and the discharging conveying line are arranged in the board conveying direction in sequence; and the edge banding control device is electrically connected with the board position detection sensors, the edge banding conveying lines, the code scanning device A, the edge banding machine, the feeding temporary storage bin and the discharging temporary storage bin.The method comprises the steps that firstly, the feeding conveying line conveys boards to be subjected to edge banding to the code scanning device A, and identification codes on the boards are scanned; secondly, the boards recognized by the code scanning device A are conveyed to the edge banding machine for edge banding; and thirdly or finally, the discharging conveying line conveys the boards subjected to edge banding to the next working section.

Owner:索菲亚家居湖北有限公司 +2

Latex pillow production line

InactiveCN109795061AFewer preparation stepsReduce the number of workersManufacturing engineeringProduction line

The invention discloses a latex pillow production line, and relates to a pillow production technology. The latex pillow production line is used for solving the problem of low production efficiency ofthe prior art, and comprises an annular support, an endless conveyor belt disposed on the annular support and a pillow die fixed to the endless conveyor belt in a hanging mode. The pillow die is provided with a press-opening type die assembly lock, and a latex curing device, a die opening device, a die cleaning device and a die drying device are sequentially arranged on the annular support in theconveying direction of the pillow die. The latex pillow production line has the following advantages and effects that the latex pillow production line can integrate the entire process of pillow production on one piece of equipment, reduces a lot of preparation steps in the latex pillow production process, reduces the number of workers required in the latex pillow production process, and optimizesthe process of pillow production, thereby being capable of achieving improvement of production efficiency.

Owner:浙江舒慕思乳胶科技有限公司

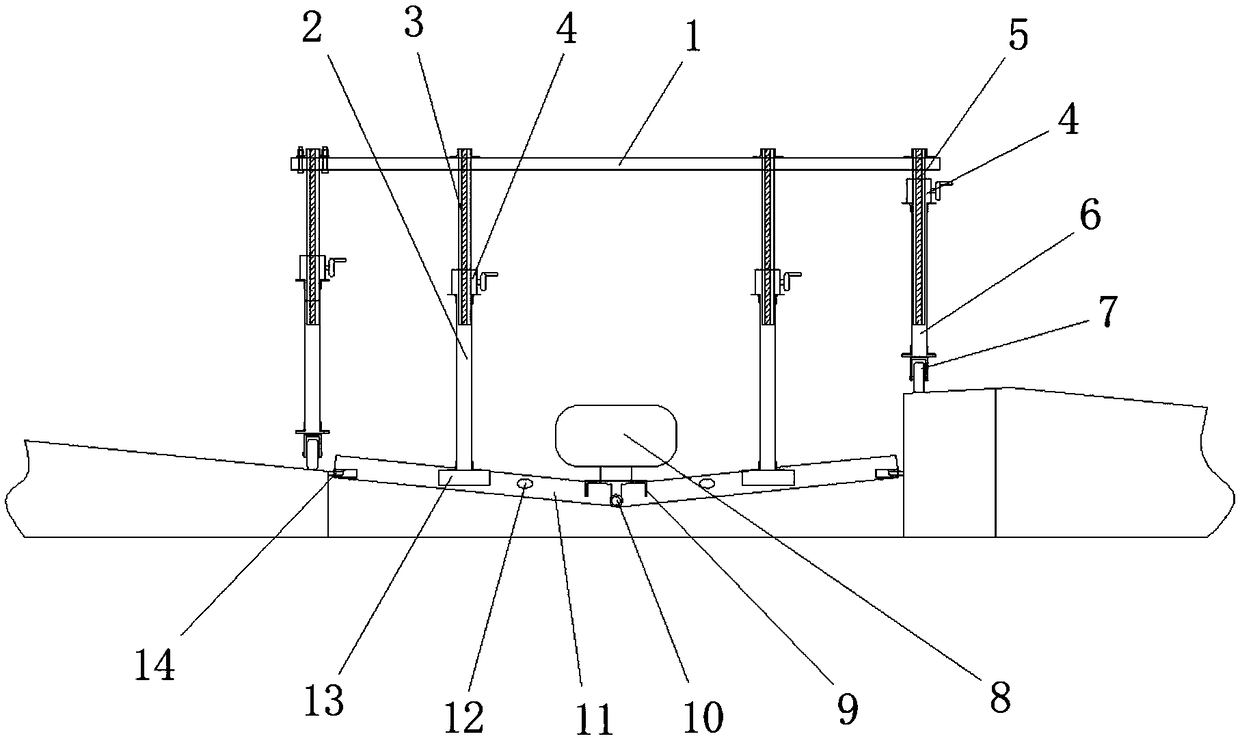

Railway track closing layer concrete leveling machine

PendingCN108660898AImprove drainage capacityEasy to operateBridge structural detailsRoads maintainenceEngineeringUltimate tensile strength

The invention discloses a railway track closing layer concrete leveling machine. The machine comprises second telescopic rods fixedly connected to the two ends of a crossbeam and is characterized in that first telescopic rods fixedly connected to the crossbeam are arranged between the second telescopic rods and are in sliding connection with first rod pieces, the second telescopic rods are in sliding connection with second rod pieces, the bottoms of the first rod pieces are rotationally connected with a leveling board through rotary pieces, the leveling board is used for adjusting the levelingangle and provided with a vibrator, and second rolling wheels used for limitation are horizontally installed on the edge portions on the two sides of the leveling board. The surface of a concrete closing layer is highly leveled through the vibrator and the leveling board capable of rotating at a certain angle, meanwhile, the leveling angle is adjustable, the drainage effect of a drainage surfaceis remarkably improved, meanwhile the machine is easy and convenient to operate, the number of operation personnel is small, and labor intensity is greatly reduced.

Owner:THE FIFTH ENG CO LTD OF CHINA TIESIJU CIVIL ENG GRP +1

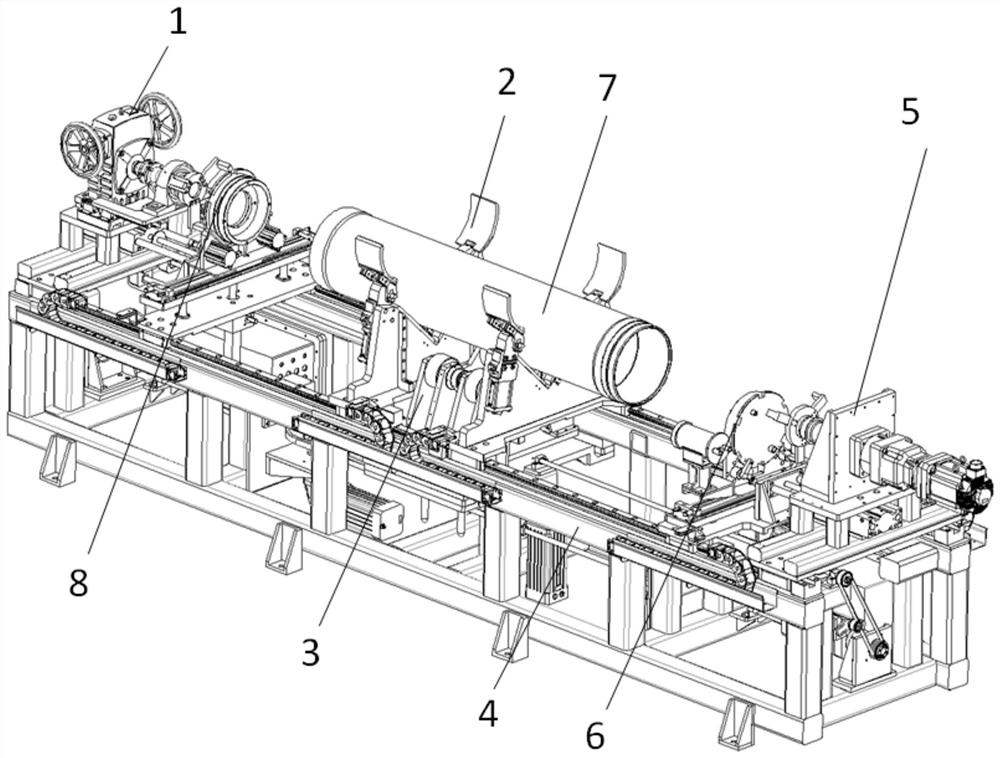

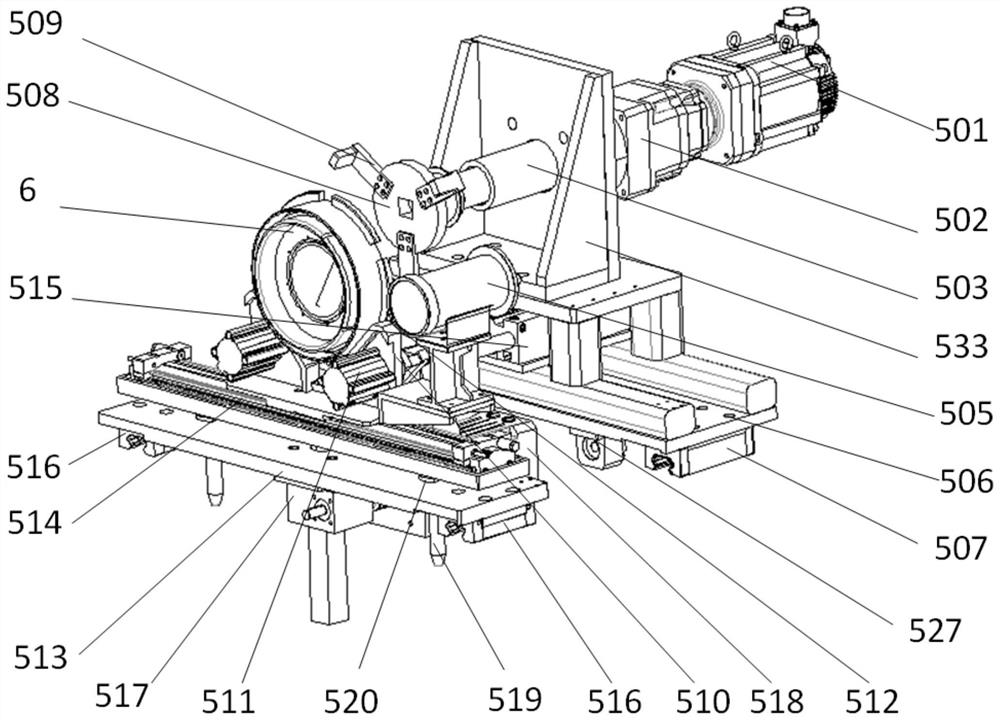

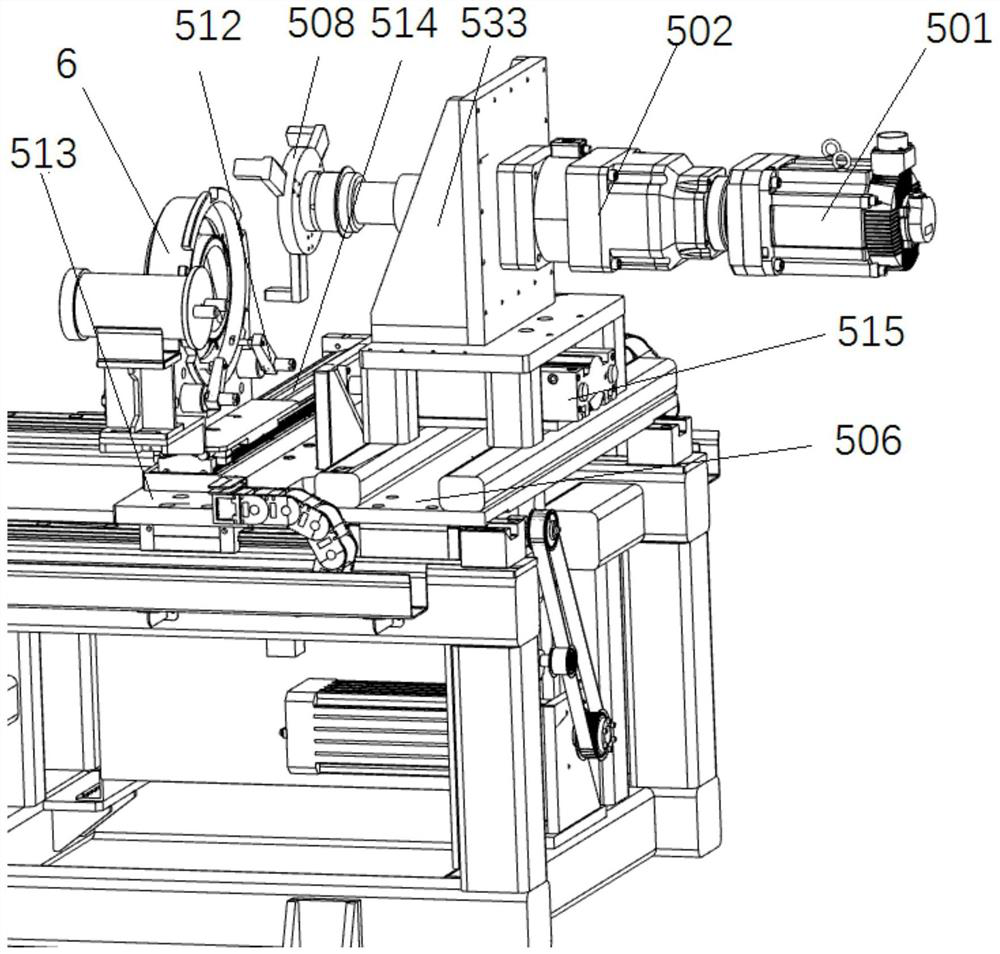

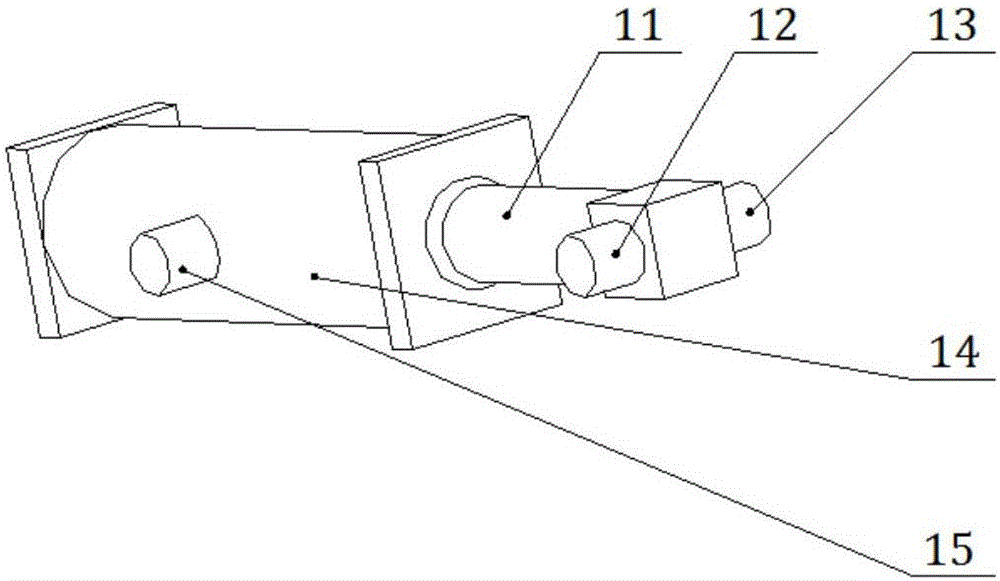

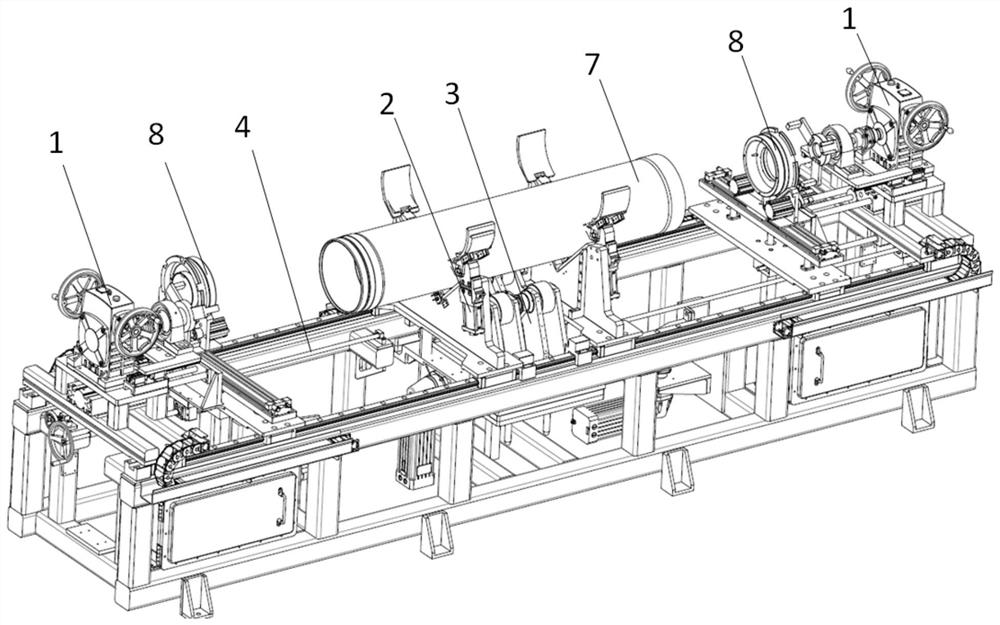

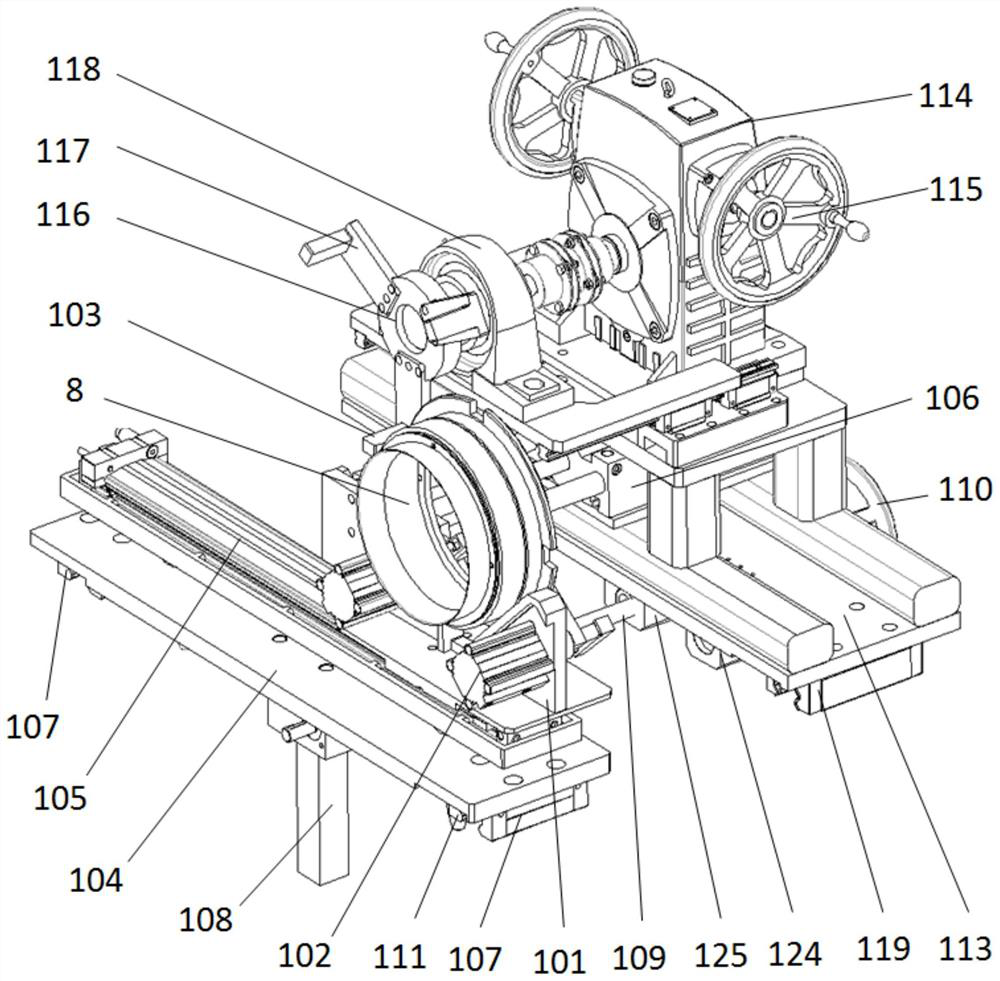

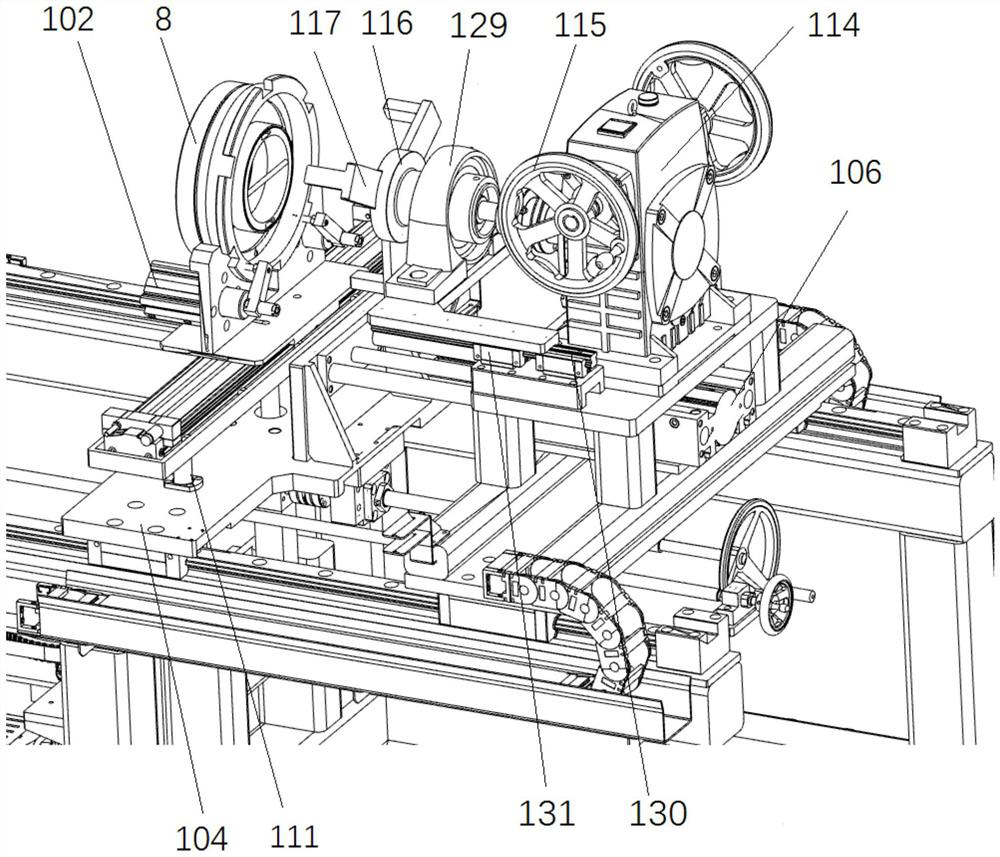

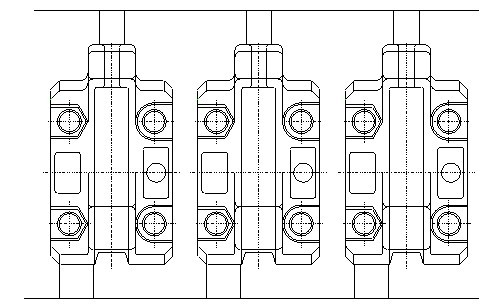

Equipment for installing and disassembling large-diameter non-standard threads

ActiveCN111775113ARealize assembly and disassemblyRealize automatic tighteningMetal-working hand toolsScrew threadPressure pipe

The invention provides equipment for installing and disassembling large-diameter non-standard threads. By means of the equipment, the problems existing in installing of existing thread tools that production efficiency is low, larger operation space is needed and tool threads are extremely easy to damage are solved. The equipment for installing and disassembling the large-diameter non-standard threads comprises a supporting device, an automatic clamping device, a jacking rolling device, a manual tightening device and an automatic tightening device. The automatic tightening device is arranged onthe right side of the supporting device and used for achieving automatic installing or disassembling of a first thread tool. The manual tightening device is arranged on the left side of the supporting device, capable of moving along the supporting device and used for achieving manual installing or disassembling of a second thread tool. The automatic clamping device is arranged on the supporting device, located between the manual tightening device and the automatic tightening device, capable of moving on the supporting device and used for achieving clamping of a pressure pipe. The jacking rolling device is arranged on the supporting device, located between the manual tightening device and the automatic tightening device and used for achieving jacking and rolling of the pressure pipe.

Owner:XIAN AEROSPACE PRECISION ELECTROMECHANICAL INST

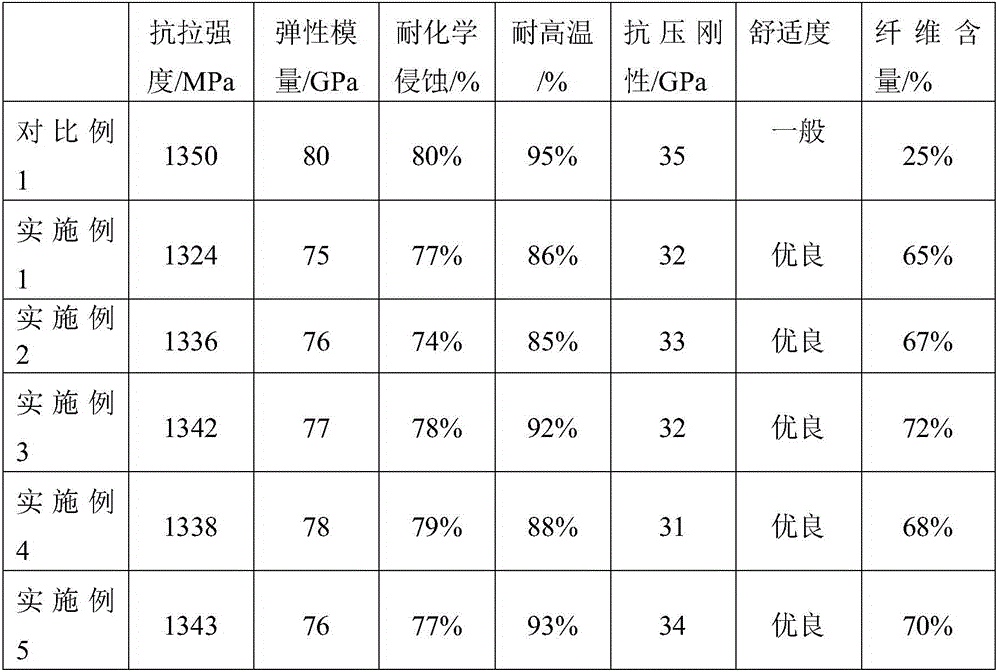

Bicycle completely prepared from basalt-fiber-reinforced resin-based composite and preparation method thereof

The invention discloses a bicycle completely prepared from a basalt-fiber-reinforced resin-based composite. Such components of the bicycle as a handlebar, a front fork, a vehicle frame, wheel hubs, a crank and pedals are prepared from the basalt-fiber-reinforced resin-based composite. The basalt-fiber-reinforced resin-based composite is mainly prepared from the following raw materials by weight: 70 to 75 parts of basalt fiber, 25 to 30 parts of resin, 0.5 to 15 parts of a curing agent, 0.25 to 3 parts of a mold lubricant and 0.125 to 3 parts of a promoter. According to the invention, the basalt fiber used in the invention is much lower in price compared with carbon fiber, so the cost for the bicycle is reduced; basalt fiber materials of different forms and resin are used for different components of the bicycle, so the mechanical properties of each component of the bicycle is maximally improved; a preparation method provided by the invention enables the content of the fiber to be increased to 60 to 70%, so product performance is greatly improved and product weight is low; and the preparation method is rapid in molding and saves cost.

Owner:JURONG BASTEP COMPOSITE MATERIALS

Flue-cured tobacco mulching film row spacing marking device

The invention discloses a flue-cured tobacco mulching film row spacing marking device comprising a rack, a motor group and a roller shaft assembly, wherein the roller shaft assembly comprises a guide roller group, a steering roller group and a reversing roller group, the marking device further comprises a printing assembly, the printing assembly comprises a marking roller and a pressing roller, the marking roller is externally tangent to the pressing roller, the marking roller is connected with a printing ink box, and a printing ink scraping knife is arranged on the outer side of the marking roller; and the flue-cured tobacco mulching film row spacing marking device disclosed by the invention marks the common polyethylene (PE) agricultural mulching film by printing at one time online to greatly relieve the labor intensity of farmers and reduce 2 / 3 of labors, the device can be used for accurately and clearly marking the mulching film so as to improve the accuracy of the line spacing and the row spacing during the transplanting process, the location of the row spacing is accurate to guarantee the plants to uniformly grow, so that the fertilization uniformity is large during the fertilization process and the non-fertilization phenomenon is unlikely to happen, thereby further improving the agricultural yield and the crop quality.

Owner:中国烟草总公司贵州省公司 +1

Working method of magnetic core test line body

ActiveCN106392450AImprove stabilityReduce the number of workersWelding/cutting auxillary devicesAuxillary welding devicesMagnetic coreManipulator

The invention discloses a working method of a magnetic core test line body. The working method comprises the following specific steps: a magnetic core is placed in a jig at an operation station; and a transmission device conveys the jig to a press-in station, presses in the jig and conveys the jig to a sweeping station, a sweeping device starts to sweep, after the sweeping is concluded, the transmission device conveys the jig to a turnover station, a manipulator turns over the magnetic core a certain angle and then places the magnetic core, the transmission device conveys the jig to a welding station, after the welding is concluded, the transmission device conveys the jig to an on-off detection station, the on-off detection station starts to work and judges good products and defective products, after the detection is completed, the transmission device conveys the jig to a code scanning station, after code scanning is completed, the transmission device conveys the jig to a manual unloading station, and the magnetic core is manually taken away. The working method disclosed by the invention is capable of automatically pressing in, sweeping, turning over, welding and judging the good products and defective products, and improving the stability and high efficiency of working performance.

Owner:DALIAN YUN MING AUTOMATION TECH

Method for mining broken thick ore body through coal roadway heading machine

ActiveCN109252863AContinuous operationReduce the number of workersUnderground miningSurface miningContinuous operationCoal

The invention discloses a method for mining a broken thick ore body through a coal roadway heading machine. The method comprises the steps that a vein external middle-section haulage roadway is arranged in the traveling direction of the ore body, a plurality of vein-crossing roadways are arranged perpendicular to the traveling direction of the ore body, ore chutes, pedestrian ventilation systems and filling chutes are arranged in the vein-crossing roadways, and a Z-shaped layer transfer equipment contacting road is arranged at the end of the ore body; stoping is conducted through the coal roadway heading machine, and road-entering-type stoping or successive stoping roadway by roadway or stoping at intervals is conducted in the direction of a vein; a carry-scraper follows the coal roadway heading machine to load and transport ore, and then the ore is transferred to the ore chutes; and meanwhile, waste ore cemented filling is conducted on a stoping space through the carry-scraper, filling and stoping are simultaneously conducted, and stoping and filling are balanced. The mechanization degree of the method is high, stope preparation engineering is reasonably designed, the processes ofstoping and filling are optimized, ore mining and filling continuous operation is achieved, the number of operators is decreased, the labor intensity is lowered, and thus the production efficiency isimproved greatly.

Owner:湖南黄金洞矿业有限责任公司

High-precision five-axis intelligent robot for stamping part carrying

InactiveCN107381035AReduce the number of workersAvoid safety hazardsConveyor partsMovement controlMotor drive

The invention discloses a high-precision five-axis intelligent robot for stamping part carrying. The intelligent robot comprises a motor driving movement control assembly, a main shaft rotating mechanism, a main shaft lifting movement mechanism, a swing arm turnover movement mechanism, a swing arm horizontal stretching movement mechanism and a tail end rotating movement mechanism, wherein the main shaft rotating mechanism is connected with the main shaft lifting movement mechanism for controlling rotation of the main shaft lifting movement mechanism, the main shaft lifting movement mechanism is connected with the swing arm turnover movement mechanism for controlling lifting of the swing arm turnover movement mechanism, the swing arm turnover movement mechanism is connected with the swing arm horizontal stretching movement mechanism for controlling turnover of the swing arm horizontal stretching movement mechanism, the swing arm horizontal stretching movement mechanism is connected with the tail end rotating movement mechanism for controlling stretching of the tail end rotating movement mechanism, and a material taking and placing device is fixedly connected to the tail end rotating movement mechanism. According to the high-precision five-axis intelligent robot for stamping part carrying, not only can the number of workers on a stamping production line be decreased, but also potential safety hazards caused by manual operation can be avoided; and meanwhile, the production efficiency is improved, and the purpose of flexibly placing workpieces is achieved.

Owner:TONGLING FUSHI SANJIA MACHINE

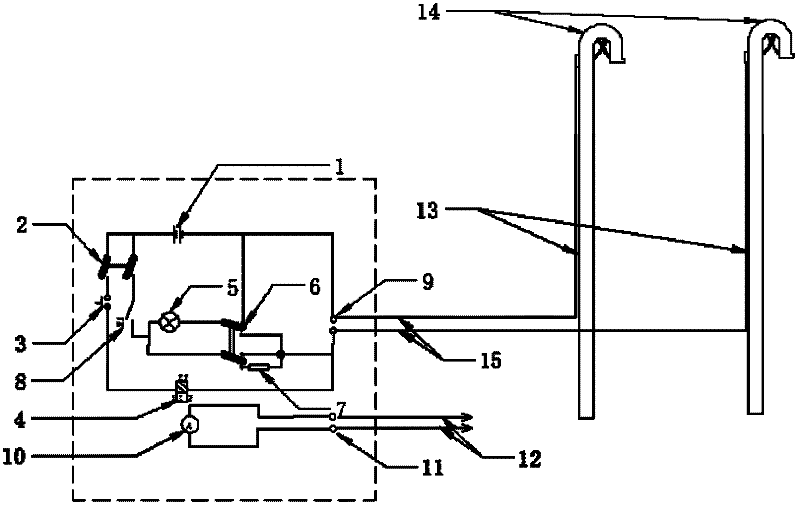

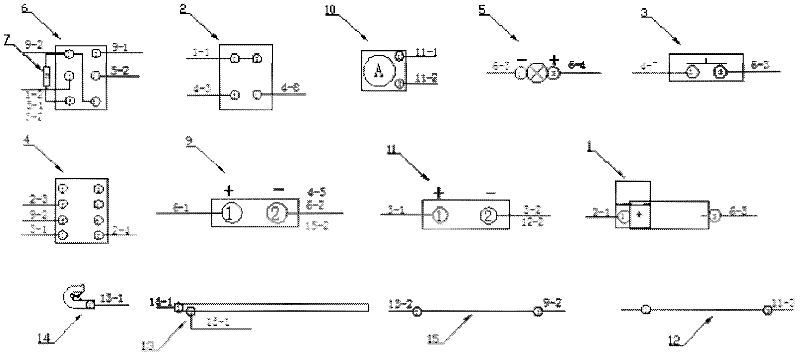

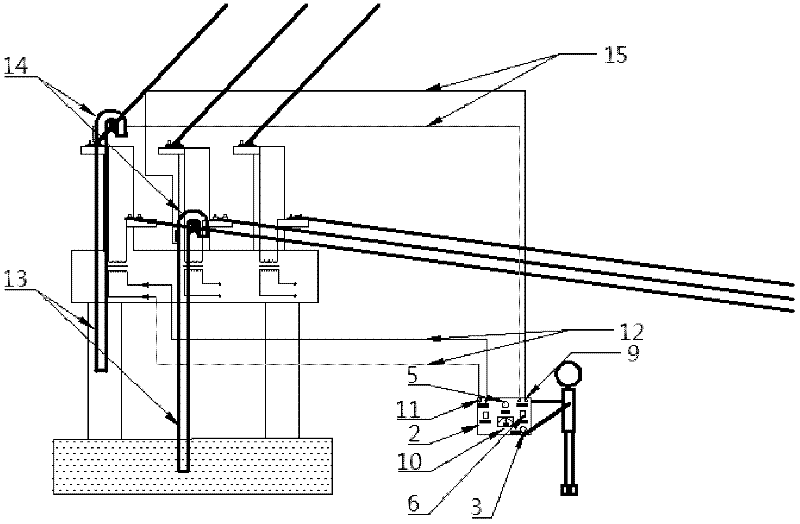

Ascending-free tester for current transformer (TA) polarity of switch

ActiveCN102435906AImprove reliabilityIncrease carrying capacityElectrical testingElectrical batteryPower switching

The invention discloses an ascending-free tester for current transformer (TA) polarity of a switch. A group of normally open contacts of the power switch is connected with a testing button and a positive pole current terminal of a relay, a negative pole current terminal of the relay is connected with a positive pole of a primary output terminal, and a negative pole of the primary output terminal is connected with a negative pole of a battery to form a loop. According to the invention, the ascending-free tester for the current transformer (TA) polarity of the switch is used for testing the polarity, and the ascending-free operation is completely realized; original four testers are reduced to be one, so that a communication link is avoided, and the reliability of working is improved; and the portability of a test device is greatly improved.

Owner:西安供电局 +1

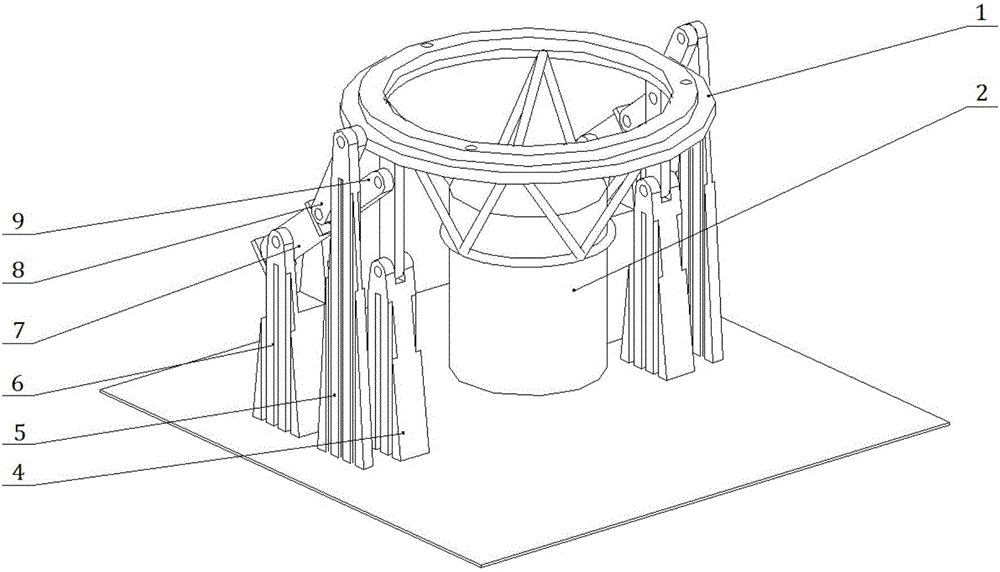

Turnover mechanism for assembling of large parts

ActiveCN106826157AEven by forceSmooth rotationWork benchesMetal working apparatusEngineeringWork time

Owner:SHANGHAI JIAO TONG UNIV

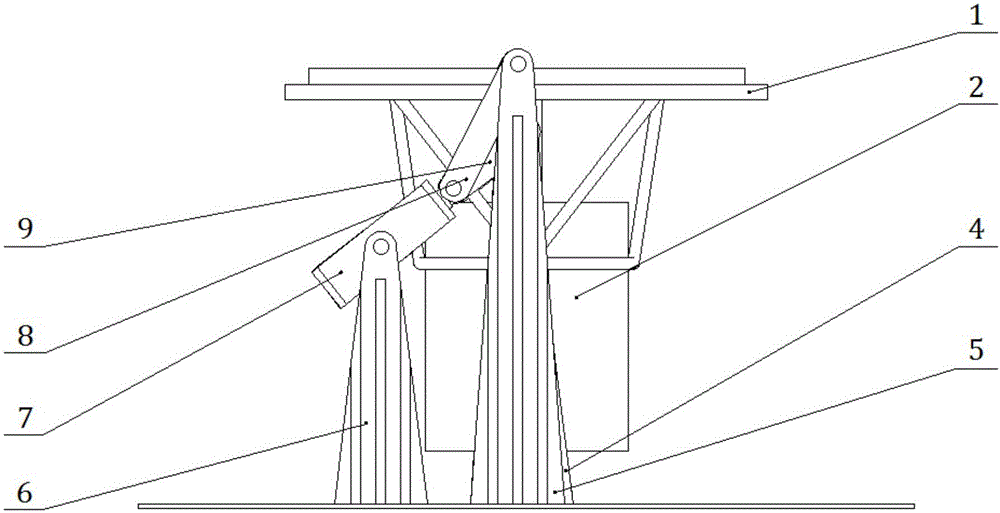

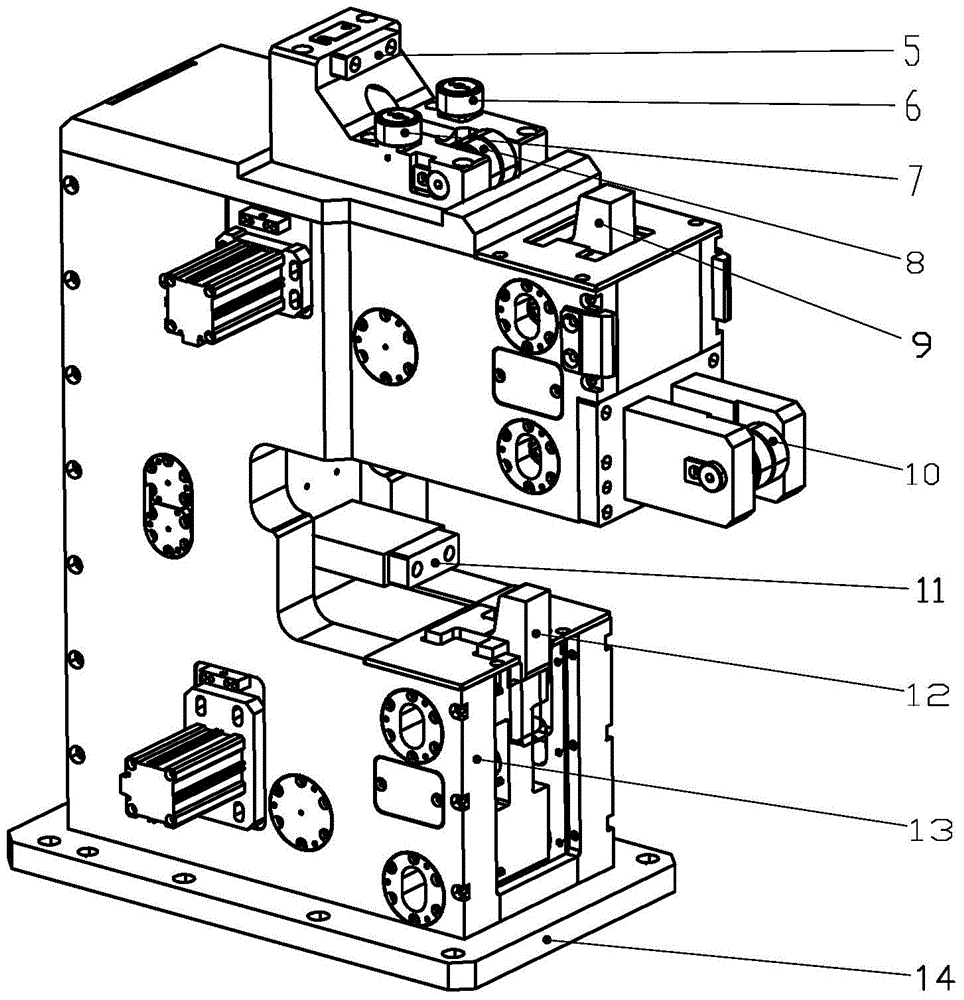

Manual tightening device and large-caliber non-standard threaded manual mounting and demounting equipment

ActiveCN111775112AAvoid damageReduce the number of workersMetal-working hand toolsRotational axisReduction drive

The invention provides a manual tightening device and large-caliber non-standard threaded manual mounting and demounting equipment. The problems that when an existing threaded tool is mounted, the production efficiency is low, a large operation space is needed, and threads of the tool are extremely likely to be damaged are solved. The manual tightening device comprises a threaded tool grabbing unit, a threaded tool adjusting unit, a manual tightening unit and a manual driving unit. The threaded tool grabbing unit comprises a tool V-shaped support, tool clamping cylinders and tool clamping arms. The tool V-shaped support is arranged on the threaded tool adjusting unit, and the threaded tool adjusting unit is used for achieving three-dimensional position adjustment of the tool V-shaped support. The two tool clamping cylinders are arranged on the two sides of the tool V-shaped support correspondingly, and rotary shafts of the tool clamping cylinders are connected with the tool clamping arm. The tool clamping arms are used for clamping the threaded tool. The manual tightening unit is used for achieving clamping of the threaded tool and comprises a tightening frame, a worm reducer, a rotary disc, a clamping finger, a tightening hand wheel and a follow-up assembly. The manual driving unit is used for driving the manual tightening unit to move front and back.

Owner:XIAN AEROSPACE PRECISION ELECTROMECHANICAL INST

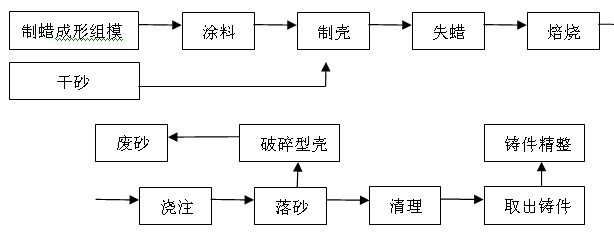

Lost foam casting method of twist lock shell for containers

InactiveCN102363201AReduce process stepsReduce labor intensityFoundry mouldsFoundry coresDry sandProcess engineering

The invention discloses a lost foam casting method of a twist lock shell for containers, comprising the following steps of: firstly making a foaming material into a casting shape, forming a die cluster, putting into a sandbox and using binder-free sand for vibrating compaction, making the dry sand for filling a cavity to possess enough strength by the utilization of vacuum negative pressure, melting and pouring, taking out the cast from the modeling sand without residual strength, normalizing, and carrying out shot peening treatment to obtain the finished product. According to the invention, gas forming amount can be processed in a vacuum system; the cast is easy to take out from the sandbox; the modeling sand is repeatedly usable; a plurality of links during the production process are suitable for mechanized production; the application amount of a paint can be controlled according to the case of the product; and the total production cost can be reduced.

Owner:WUXI KAIJIE CASTING

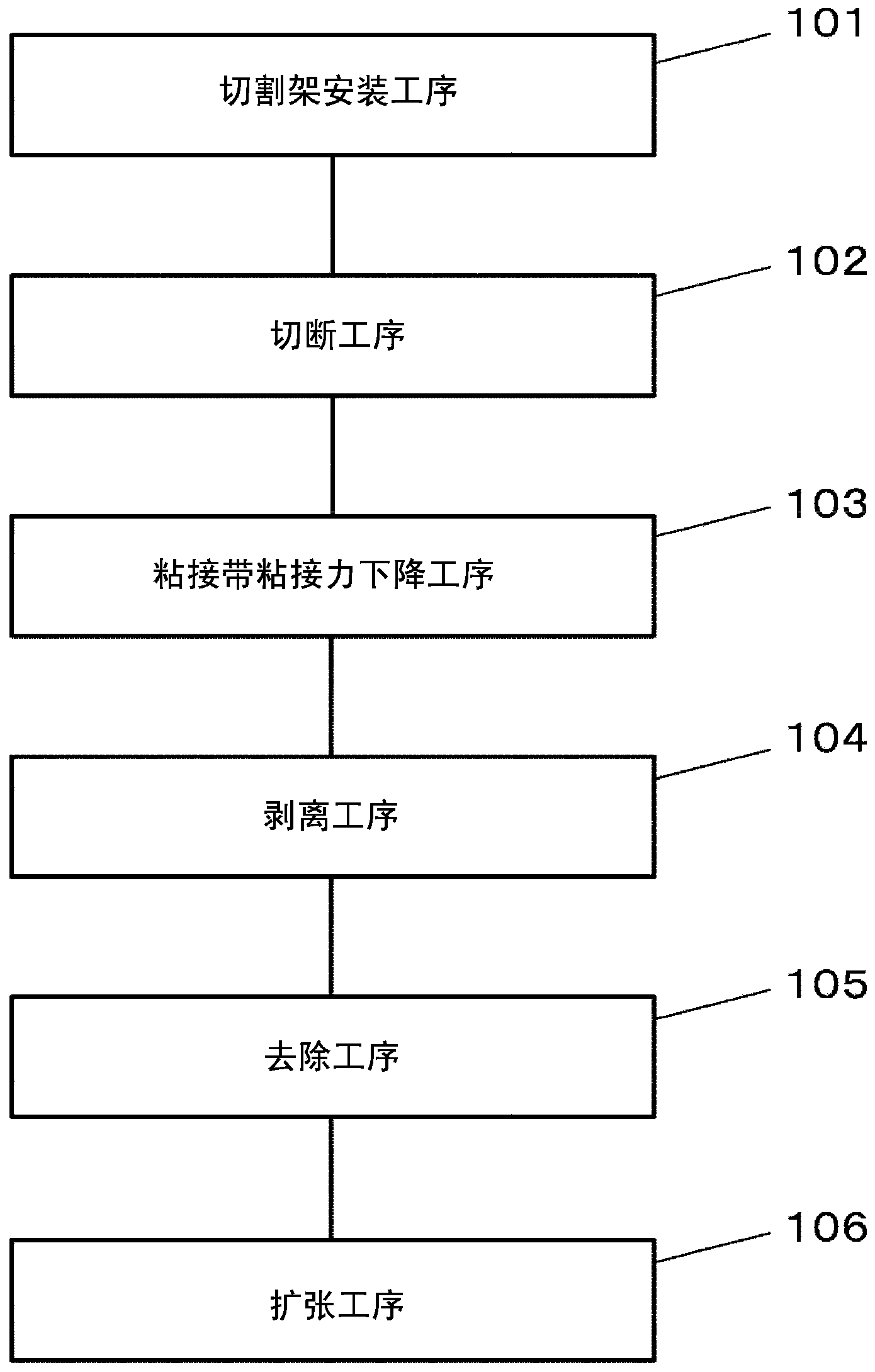

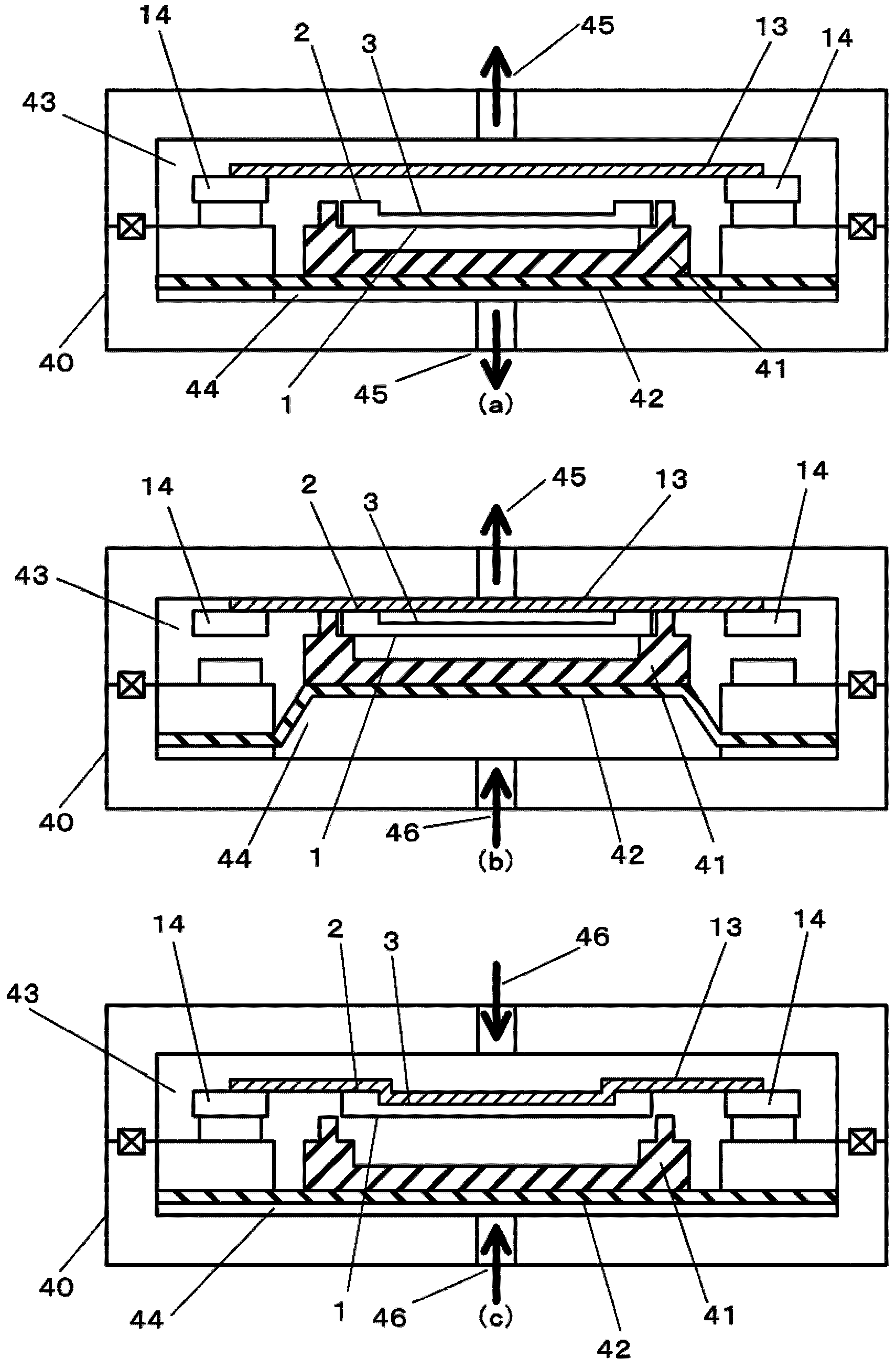

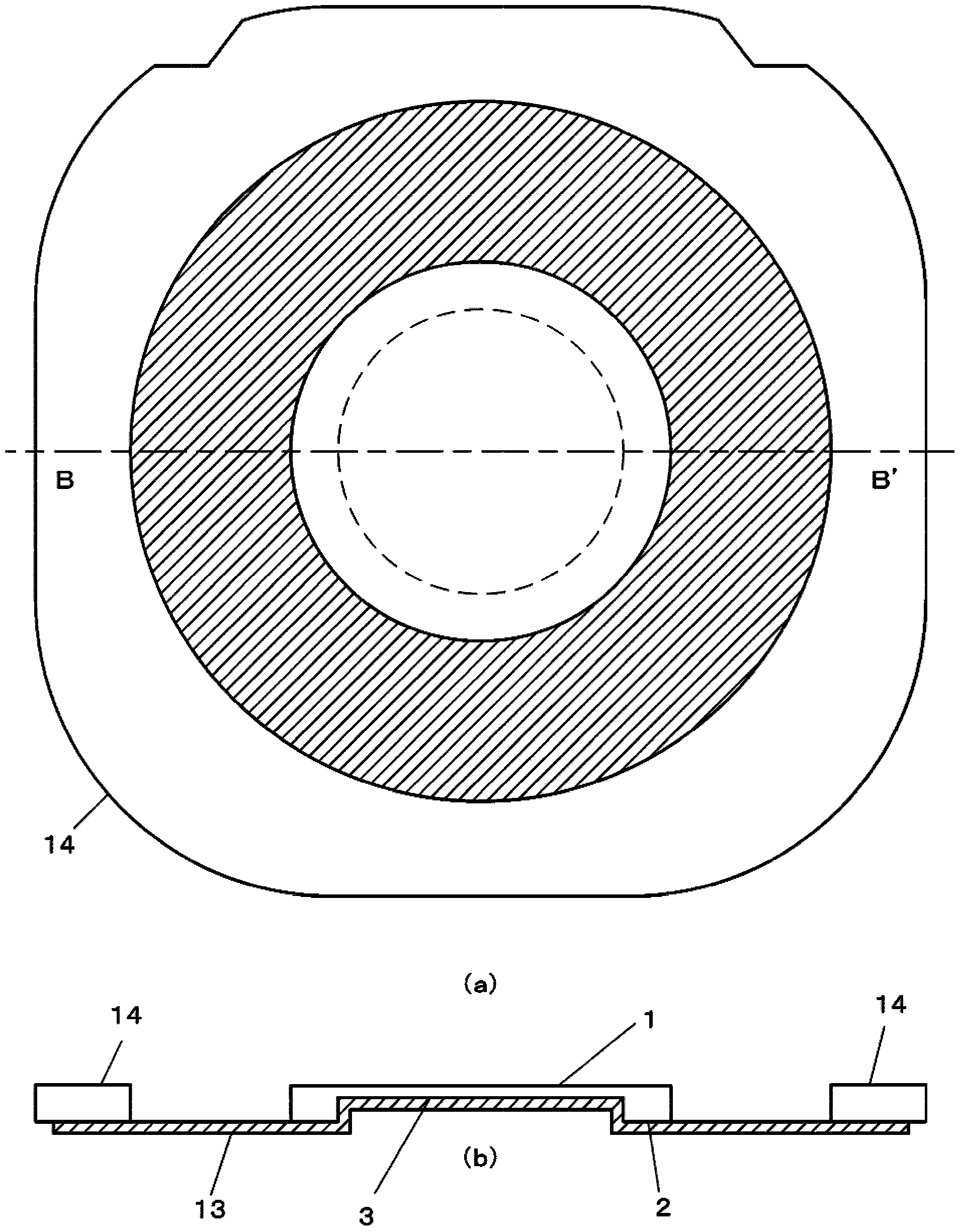

Method of manufacturing semiconductor device

InactiveCN104253018AReduce dropReduce the number of workersSolid-state devicesSemiconductor/solid-state device manufacturingMan-hourSemiconductor chip

The invention provides a device for manufacturing a semiconductor device, which can reduce man-hour used for removing a circular enhancement part of a semiconductor chip and reduce cracks or drop of debris. According to the method, a semiconductor chip is divided into a plurality of semiconductor devices; a central section on the back of the semiconductor chip is provided with a recess thinner than the periphery; the periphery is provided with a circular enhancement part; the recess is provided with a semiconductor element area used for forming a plurality of semiconductor devices, and a residual area formed by the recess except the semiconductor element area. The method comprises an installation process in which the back of the semiconductor chip is installed to a cutting support through a bonding belt; a cutting process in which the back of the semiconductor chip on the cutting support is placed to a workbench of a snug smaller than the recess, and a semiconductor element forming area is cut from a front side of the semiconductor chip to cut a plurality of semiconductor devices one by one; a bonding force decline process in which bonding force of the bonding belt is declined; a stripping process in which the circular enhancement part is stripped from the bonding belt; and a removing process in which the circular enhancement part and the residual area are removed.

Owner:FUJI ELECTRIC CO LTD

Automatic plate drilling system and control method thereof

PendingCN109794992ARealize refined managementReduce the number of workersDrilling machinesMeasurement/indication equipmentsPunchingDrilling system

The invention relates to an automatic plate drilling system and a control method thereof. The plate drilling system comprises a drilling section control device, a drilling section transmission line and a plurality of plate position detection sensors positioned on the drilling section transmission line. The drilling section transmission line comprises a feeding transmission line, a non-porous platetransmission line, a double-faced porous plate transmission line, a single-faced porous plate transmission line and a discharging transmission line, wherein the feeding transmission line is positioned at the upstream to transmit plates with identification codes to the non-porous plate transmission line, the double-faced porous plate transmission line and the single-faced porous plate transmissionline; and the discharging transmission line is positioned at the downstream to receive processed plates. The feeding transmission line is provided with a code scanning device A and a first plate rotating device, the double-face porous plate transmission line is provided with a plate buffer device, a code scanning device B and double-face punching equipment, the single-faced porous plate transmission line is provided with a code scanning device C and a single-faced punching equipment, and the discharging transmission line is provided with a code scanning device D and a second plate rotating device.

Owner:索菲亚家居湖北有限公司 +2

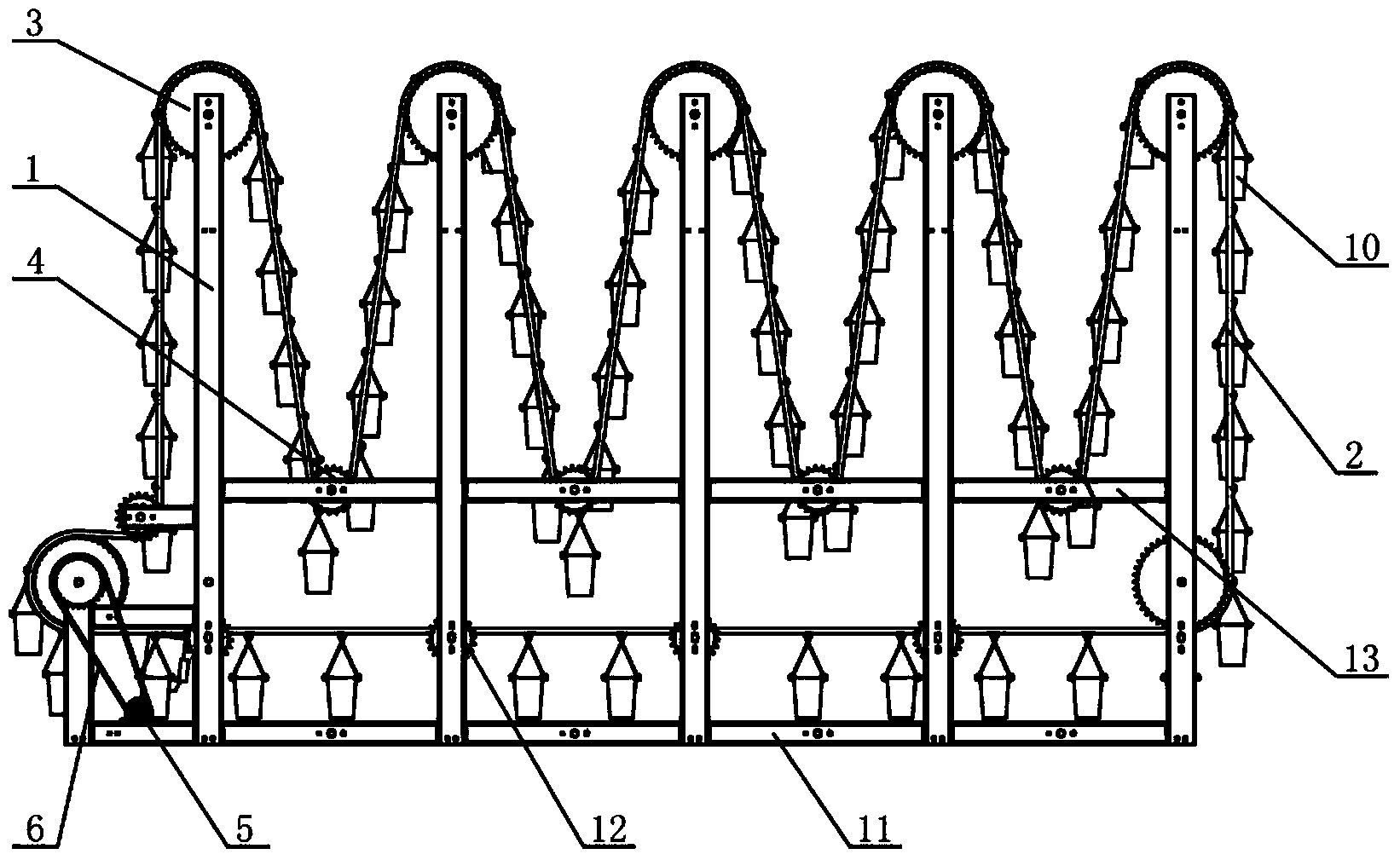

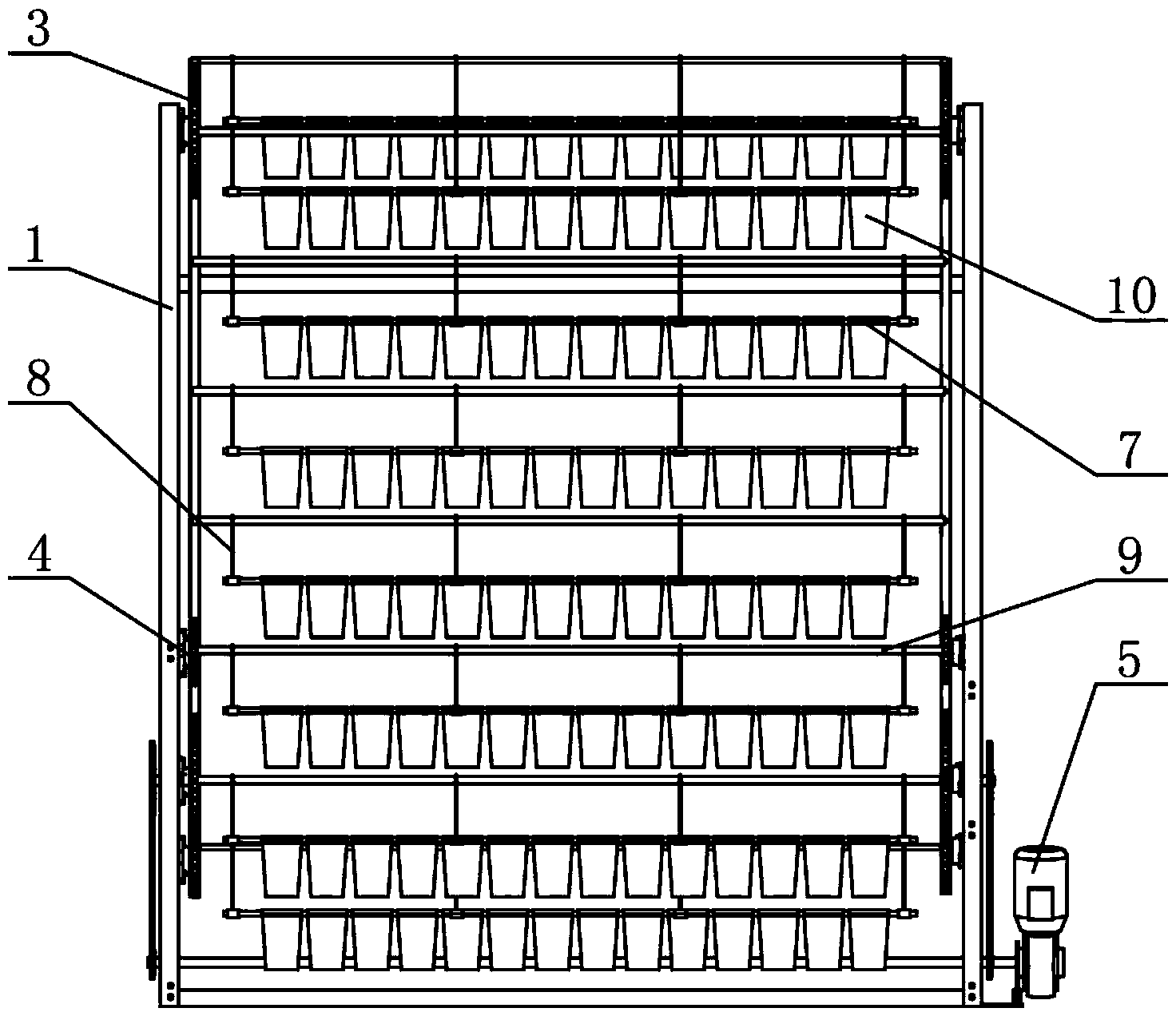

Vegetable cycle production line

ActiveCN103477892AImprove space utilizationImprove light energy utilizationAgriculture gas emission reductionCultivating equipmentsProduction lineChain type

The invention relates to the technical field of agricultural production, in particular to a vegetable cycle production line, and particularly relates to a leaf vegetable chain type automatic cycle production line. The vegetable cycle production line disclosed by the invention adopts a power unit to drive a transmission chain so as to pull vegetable cultivation units to move, a control unit is used for enabling the production line to move according to a set program, the whole production line space can adopt relatively closed management, diseases, pests and infectious microbes introduced by manual operation or from entrances and exits can be avoided, and unmanned management of the production process can be realized. With the adoption of the vegetable cycle production line, the space utilization ratio and the optical energy utilization ratio are improved, the yield and water and fertilizer use ratio of unit area are improved, labor force is greatly reduced, the labor intensity is reduced, the labor productivity is improved, high-quality vegetables can be produced, and the production line is suitable for popularization and use in the urban agriculture and the modern agricultural management system.

Owner:农芯(南京)智慧农业研究院有限公司

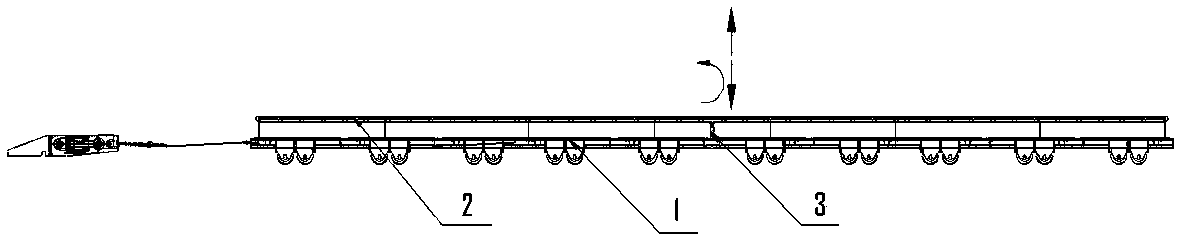

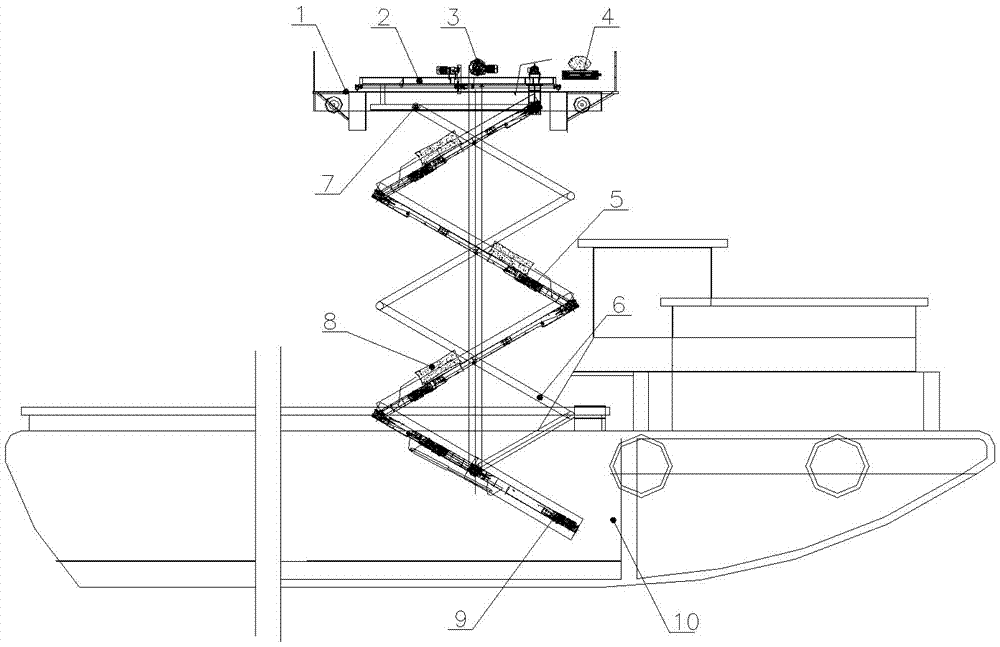

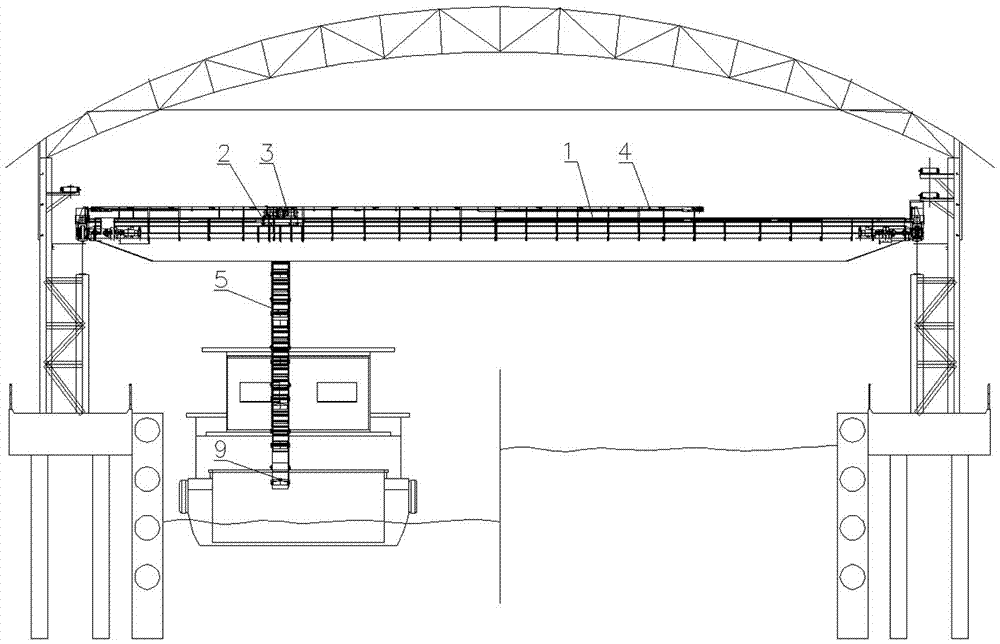

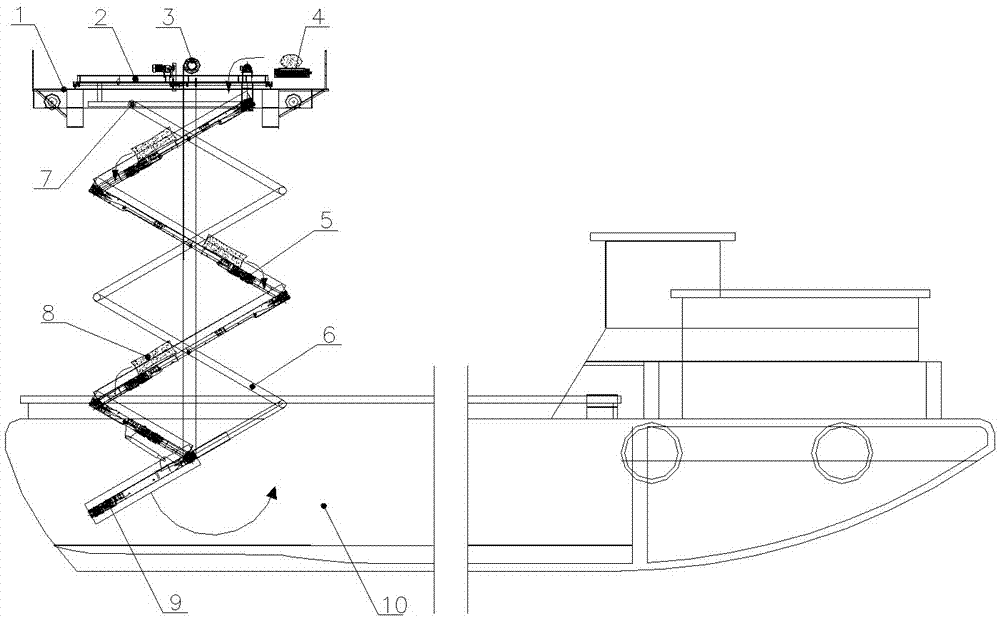

Mobile shear type lifting multi-stage belt ship loader with traveling crane

ActiveCN105438853ALarge coverageImprove work efficiencyLoading/unloadingMarine engineeringBelt conveyor

The invention relates to a mobile shear type lifting multi-stage belt ship loader with a traveling crane. The mobile shear type lifting multi-stage belt ship loader with the traveling crane comprises a two-beam traveling crane cart (1), a moving trolley (2), a lifting reel (3) and an adapter belt (4); the moving trolley (2) is mounted on a track of the two-beam traveling crane cart (1); the lifting reel (3) is mounted on the moving trolley (2); the adapter belt (4) is fixed on one end of the traveling crane cart (1); a multi-stage folding belt conveyor (5) and a multi-stage folding connecting rod (6) are mounted below the moving trolley (2); the multi-stage folding connecting rod (6) is crosswise hinged with the multi-stage folding belt conveyor (5) to form a shear type structure; and a tail distribution belt conveyor (9) is arranged on the lower end of the multi-stage folding belt conveyor (5). The mobile shear type lifting multi-stage belt ship loader with the traveling crane is capable of realizing increase of coverage of ship loading operations and avoiding the shifting of a ship; as a result, the operation efficiency is greatly improved, and meanwhile, the labor intensity is reduced, the number of operators is reduced and the ship loading cost is reduced.

Owner:JIANGSU TONGHUI MACHINERY & ELECTRICAL EQUIP

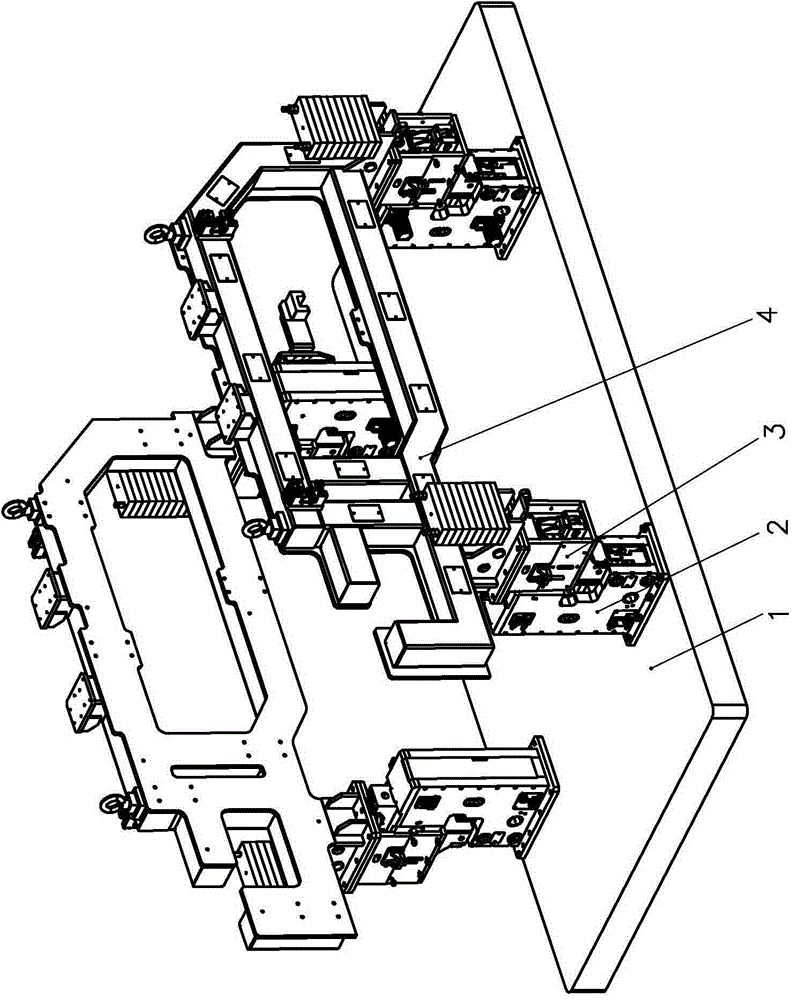

Locating and clamping system for body-in-white welding total-splicing clamp

ActiveCN104002078AReduce the number of spatial singularitiesReduce purchasesWelding/cutting auxillary devicesAuxillary welding devicesEngineeringSoldering gun

The invention discloses a locating and clamping system for a body-in-white welding total-splicing clamp. The locating and clamping system comprises a system installation base plate, two locating and clamping mechanisms capable of fixing the clamp are installed on the system installation base plate, each locating and clamping mechanism comprises a clamp installation unit and clamping and locating units arranged at the two ends of the clamp installation unit, clamp supporting units are installed between the clamping and locating units and the clamp installation units, the clamping and locating units are fixed on the system installation base plate through bolts, each clamp installation unit comprises an installation cavity, and one end of the clamp can be fixed in the installation cavity. The locating and clamping system is small in size, only small space at the bottom of the total-splicing clamp is occupied, space in the upper portion of the total-splicing clamp is not occupied, more space is reserved for movement of a welding gun, the number of space singular points of a welding robot is decreased, the welding space scope of a welding total-splicing station is accordingly expanded, and the number of welding points at the total-splicing station is increased.

Owner:GUANGZHOU MINO AUTOMOTIVE EQUIP CO LTD +1

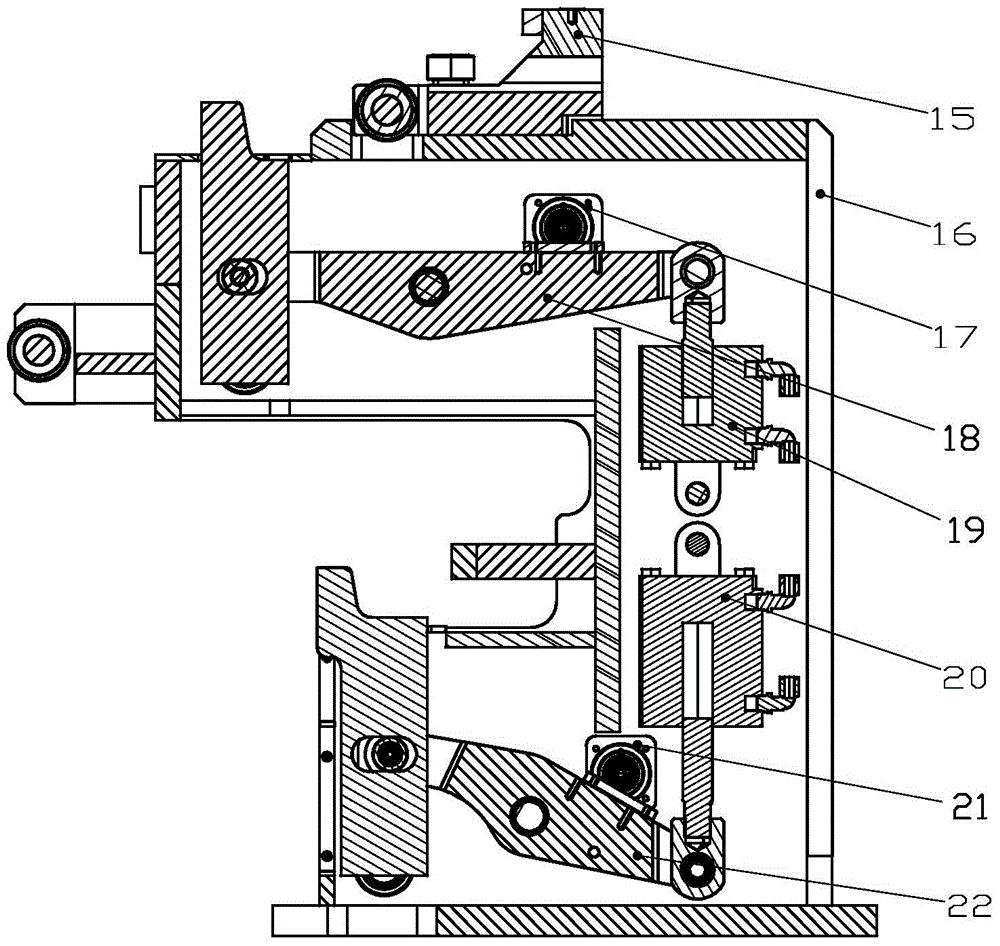

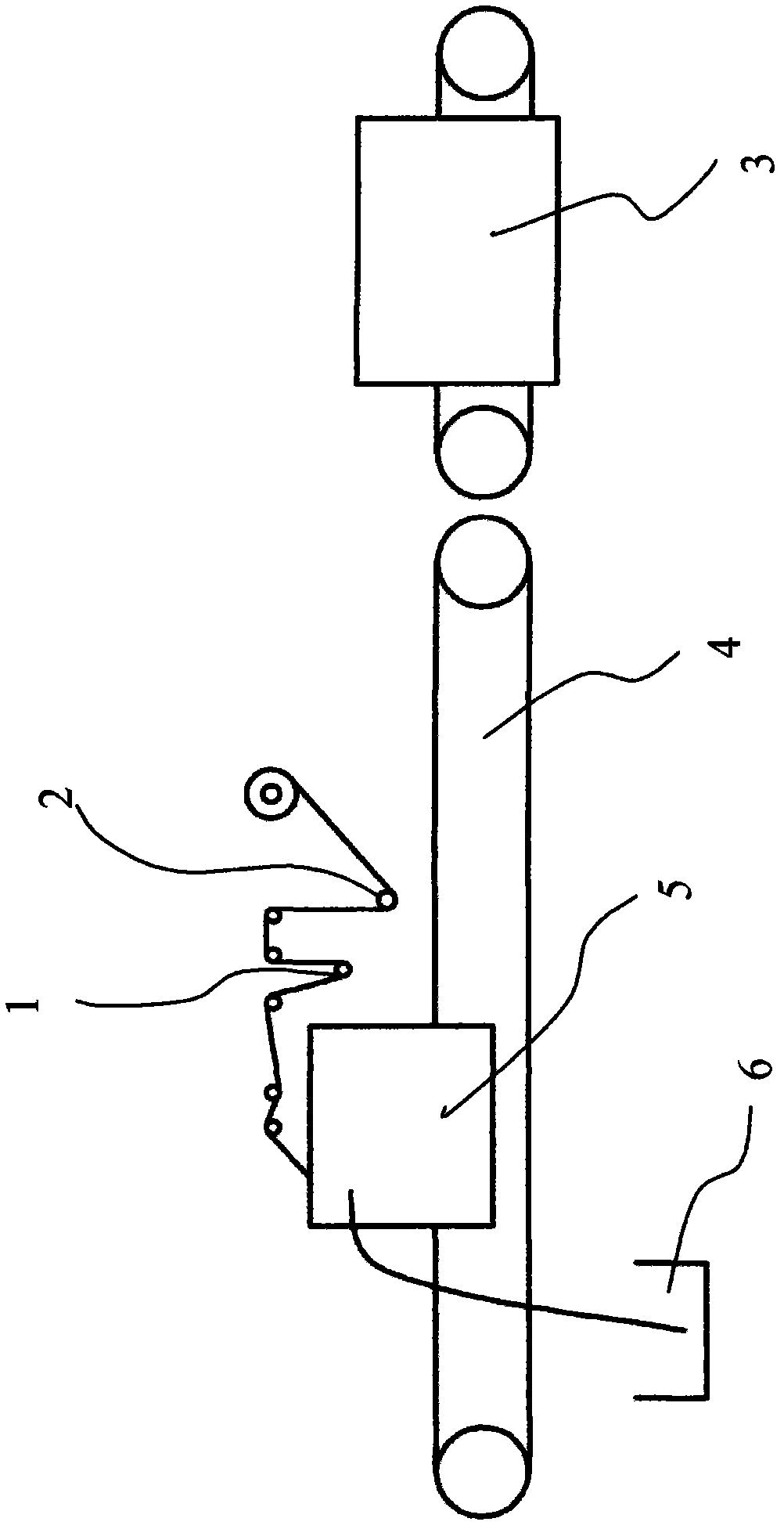

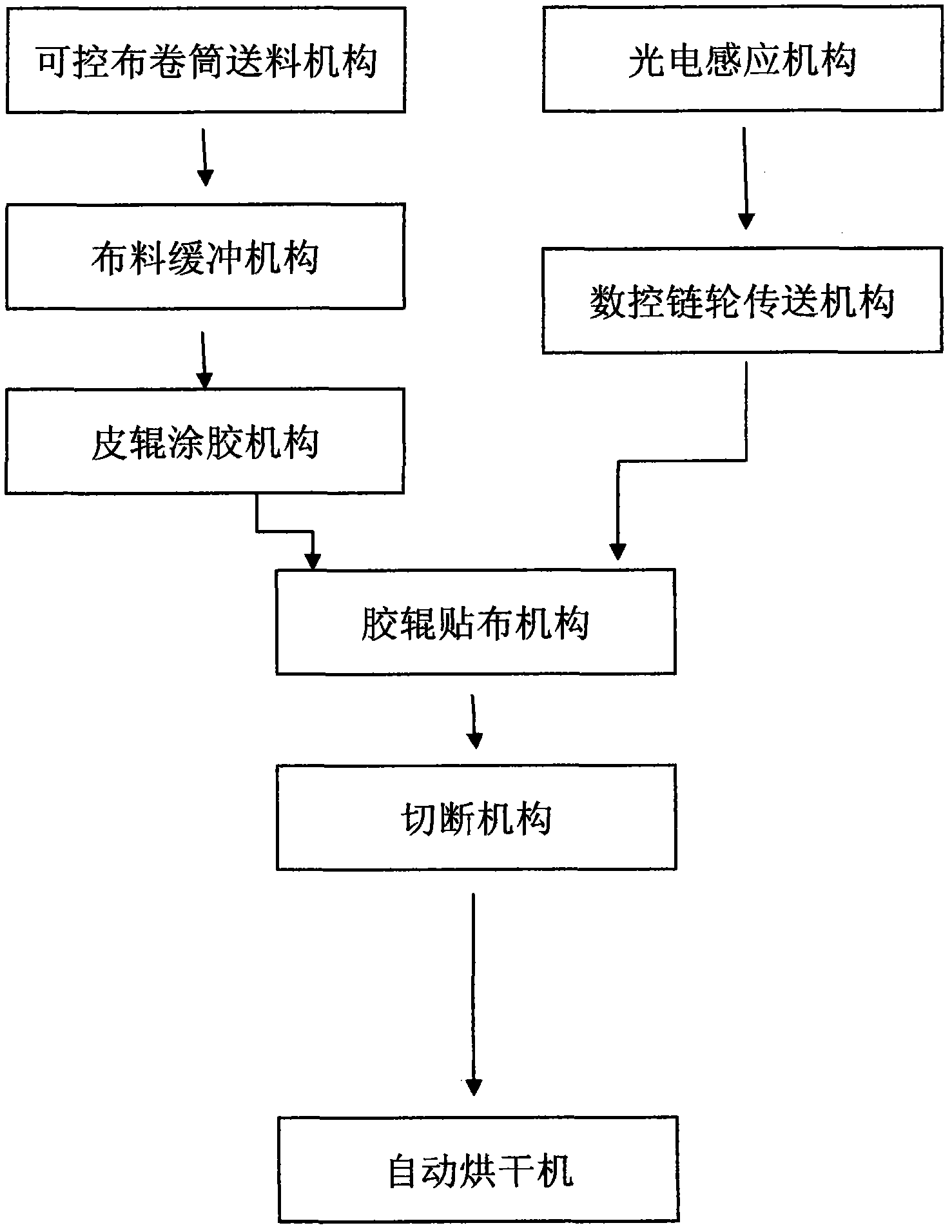

Full-automatic cloth-applying and drying unit, and working method thereof

InactiveCN103203945AReduce the number of workersShorten process timeLamination ancillary operationsLaminationSprocketEngineering

The invention discloses a full-automatic cloth-applying and drying unit comprising a cloth-applying machine assembly and a drying machine assembly. The cloth-applying machine assembly comprises a cloth delivery mechanism, a sheet material delivery mechanism, a rubber roller cloth-applying mechanism, and a cutting mechanism. The cloth delivery mechanism is composed of a controllable cloth roll feeding mechanism, a cloth buffering mechanism, and a leather roller adhesive-applying mechanism. A numerical-control sprocket transmission mechanism is fixed on a frame. The rubber roller cloth-applying mechanism is arranged above the numerical-control sprocket transmission mechanism. The numerical-control sprocket transmission mechanism is docked with a delivery device of the drying machine. A drying box is arranged above the delivery device of the drying machine. With the unit and the method provided by the invention, cloth-applying process flow full automation can be realized, worker number can be greatly reduced, process working time can be shortened, land occupation is low, flexibility is high, product quality is stable, production efficiency can be effectively improved, and cost can be effectively reduced.

Owner:杨锦泉

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com