Bicycle completely prepared from basalt-fiber-reinforced resin-based composite and preparation method thereof

A technology based on basalt fiber and reinforced resin, which is applied in the field of bicycles and its preparation, can solve the problems of complex preparation process, long assembly line, and poor impact resistance of carbon fiber bicycles, shorten the preparation time and the number of workers required, and improve product performance , the effect of enhancing the mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

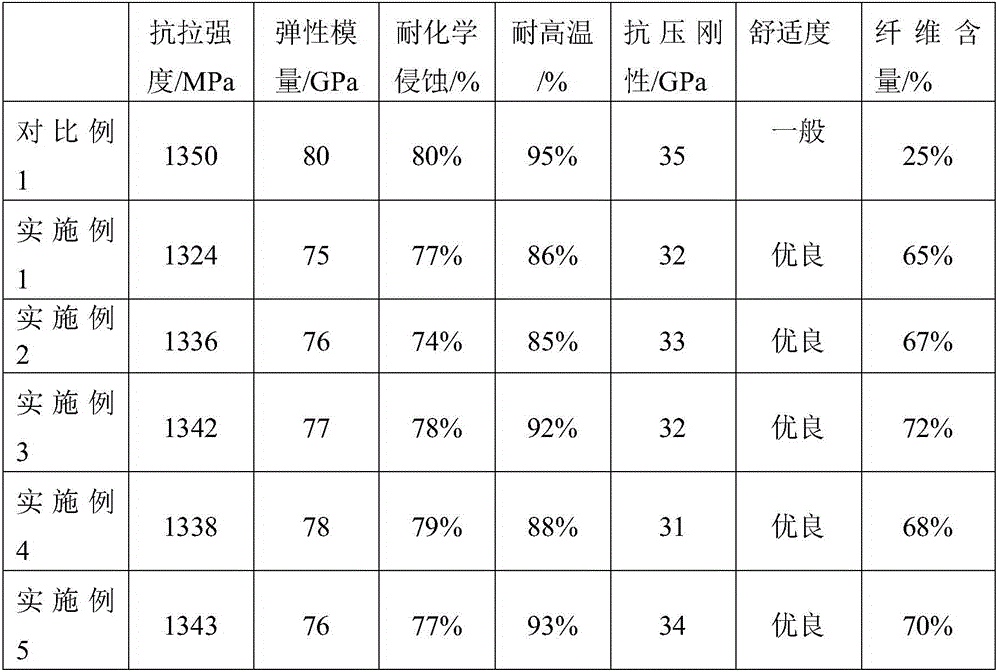

Examples

Embodiment 1

[0027] Party:

[0028] Bicycle handlebar: 70 parts of continuous basalt fiber yarn, 25 parts of vinyl resin;

[0029] Frame and front fork parts: 70 parts of basalt fiber cloth, 25 parts of epoxy resin;

[0030] Hub: 60 parts of basalt fiber cloth, 10 parts of basalt fiber powder, 25 parts of polyurethane resin;

[0031] Crank: 60 parts of continuous basalt fiber yarn, 10 parts of basalt fiber powder, 25 parts of vinyl resin;

[0032] Pedal: 60 parts of continuous basalt fiber yarn, 10 parts of basalt fiber powder, 25 parts of nylon.

[0033] Preparation:

[0034] (1) Prepare basalt fiber-reinforced thermosetting resin prepreg by impregnating basalt fiber with thermosetting resin; pass basalt fiber and thermoplastic resin through a fiber-reinforced thermoplastic molding machine to prepare basalt fiber-reinforced thermoplastic resin plastic;

[0035] (2) According to the requirements of bicycle parts, select basalt fiber reinforced thermosetting resin prepreg or basalt fibe...

Embodiment 2

[0040] Party:

[0041] Bicycle handlebar: 75 parts of continuous basalt fiber yarn, 30 parts of epoxy resin;

[0042] Frame and front fork parts: 75 parts of basalt fiber cloth, 30 parts of vinyl resin;

[0043] Hub: 65 parts of basalt fiber cloth, 10 parts of basalt fiber powder, 30 parts of vinyl resin;

[0044] Crank: 65 parts of continuous basalt fiber yarn, 10 parts of basalt fiber powder, 30 parts of polyurethane resin.

[0045] Pedals: 65 parts of continuous basalt fiber yarn, 10 parts of basalt fiber powder, and 30 parts of nylon.

[0046] Preparation:

[0047] (1) Prepare basalt fiber-reinforced thermosetting resin prepreg by impregnating basalt fiber with thermosetting resin; pass basalt fiber and thermoplastic resin through a fiber-reinforced thermoplastic molding machine to prepare basalt fiber-reinforced thermoplastic resin plastic;

[0048] (2) According to the requirements of bicycle parts, select basalt fiber reinforced thermosetting resin prepreg or basalt...

Embodiment 3

[0053] Party:

[0054] Bicycle handlebar: 72.5 parts of continuous basalt fiber yarn, 27.5 parts of vinyl resin;

[0055] Frame and front fork parts: 72.5 parts of basalt fiber cloth, 27.5 parts of epoxy resin;

[0056] Hub: 62.5 parts of basalt fiber cloth, 10 parts of basalt fiber powder, 27.5 parts of polyurethane resin;

[0057] Crank: 62.5 parts of continuous basalt fiber yarn, 10 parts of basalt fiber powder, 27.5 parts of vinyl resin.

[0058] Pedal: 62.5 parts of continuous basalt fiber yarn, 10 parts of basalt fiber powder, 27.5 parts of polypropylene.

[0059] Preparation:

[0060] (1) Prepare basalt fiber-reinforced thermosetting resin prepreg by impregnating basalt fiber with thermosetting resin; pass basalt fiber and thermoplastic resin through a fiber-reinforced thermoplastic molding machine to prepare basalt fiber-reinforced thermoplastic resin plastic;

[0061] (2) According to the requirements of bicycle parts, select basalt fiber reinforced thermosetting ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com