Automatic plate drilling system and control method thereof

A control method and plate technology, applied in the field of plate processing, can solve the problems of high processing cost, discontinuous production, low production capacity, etc., achieve the effect of fewer workers, realize visualization, and meet the needs of large-scale production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

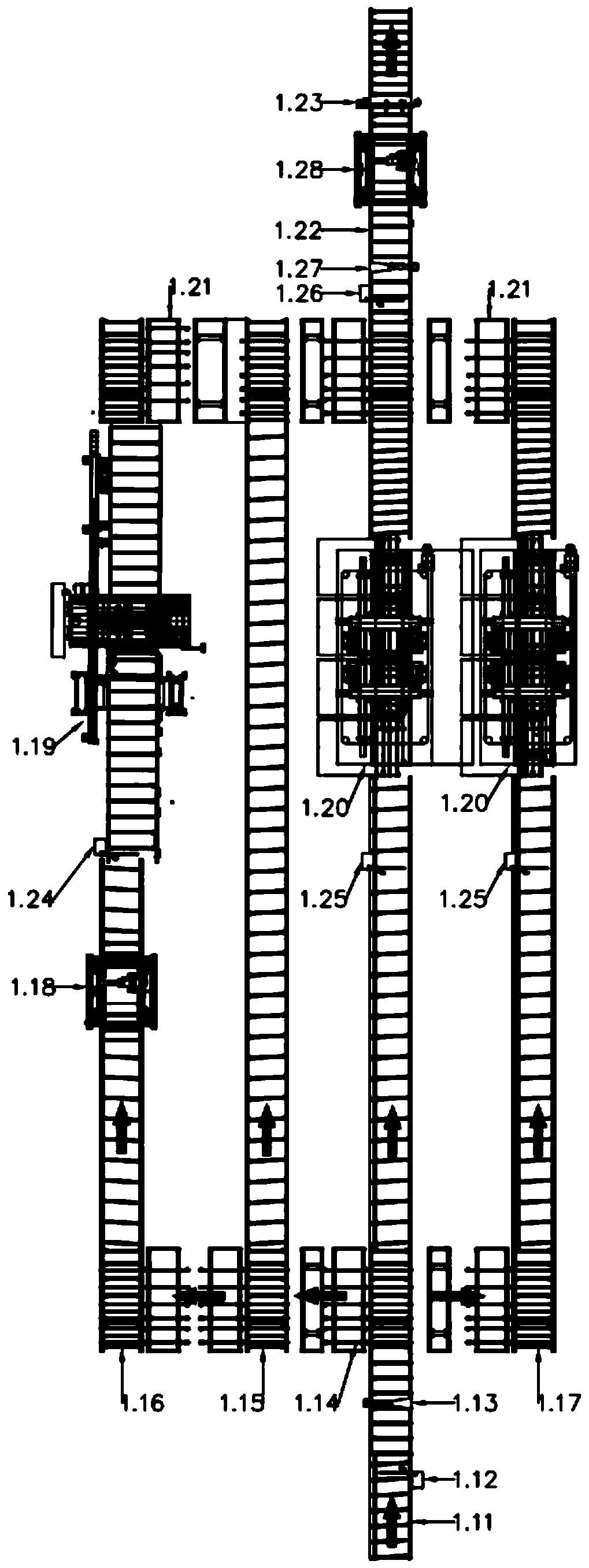

[0019] figure 1 Shows the section structure of the automated plate drilling system, the section is connected to the edge banding section located upstream, and the edge-sealed plate can be punched according to order information, design parameters, processing information, etc., and then the punched holes The plates are transported to the downstream packaging section or sorting section. The order information, design parameters, processing information, etc. in the present invention include the quantity of plates required, the shape and size of each plate, and the position, quantity, size, shape, etc. of the holes on the plates. Each plate is pasted with an identification code identifying the identity of the plate, such as a two-dimensional code or a barcode, and the order information, design parameters, and processing information corresponding to the plate can be queried by reading the identification code.

[0020] The plate drilling system includes a drilling section control dev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com