Equipment for producing bonding wire for packaging semiconductor

A technology for producing equipment and bonding wire, which is applied in semiconductor/solid-state device manufacturing, metal processing equipment, cleaning equipment for metal extrusion, etc. , increase the probability of wire surface damage, etc., to achieve the effect of shortening the process, reducing management staff, and improving processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

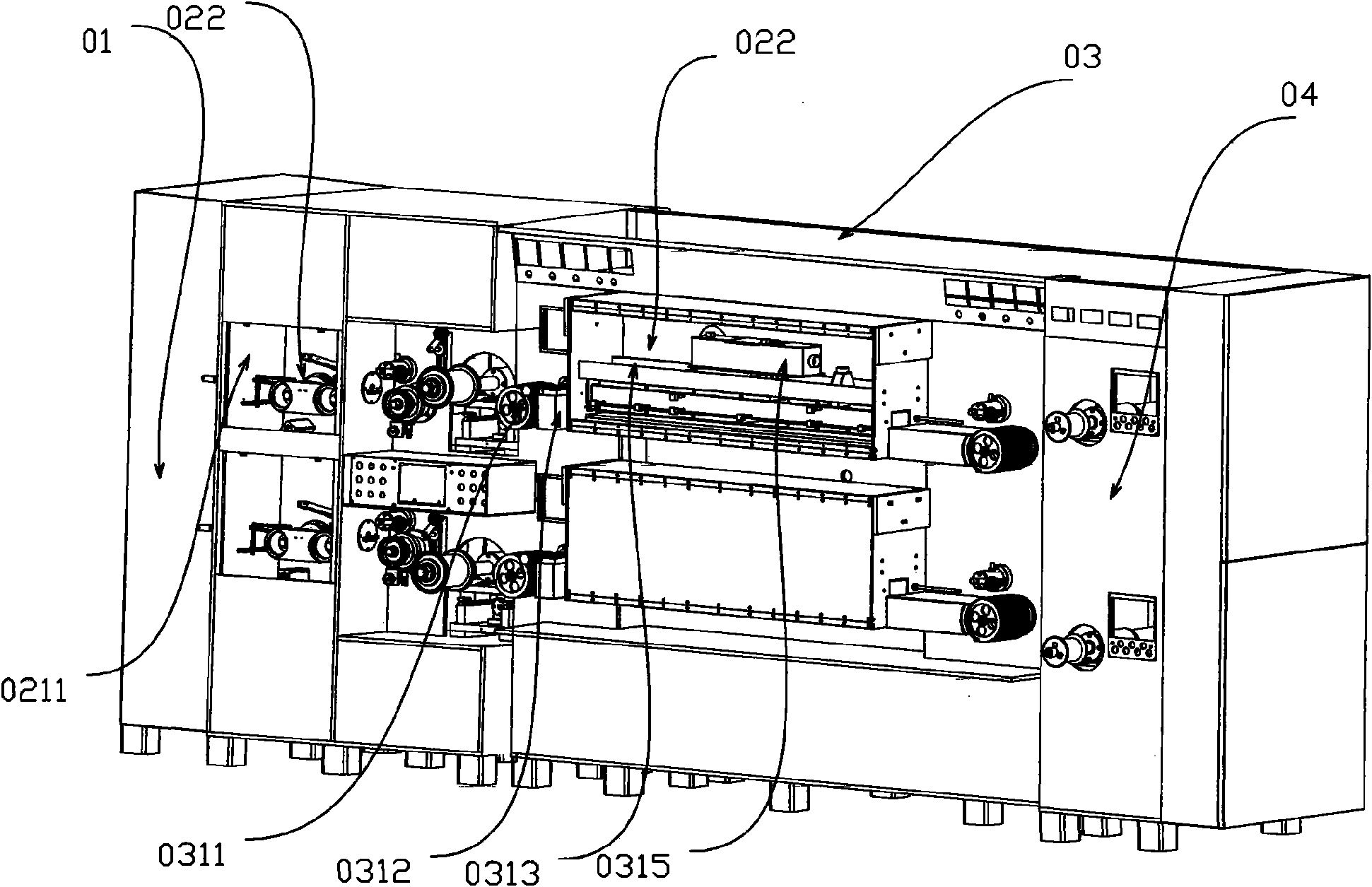

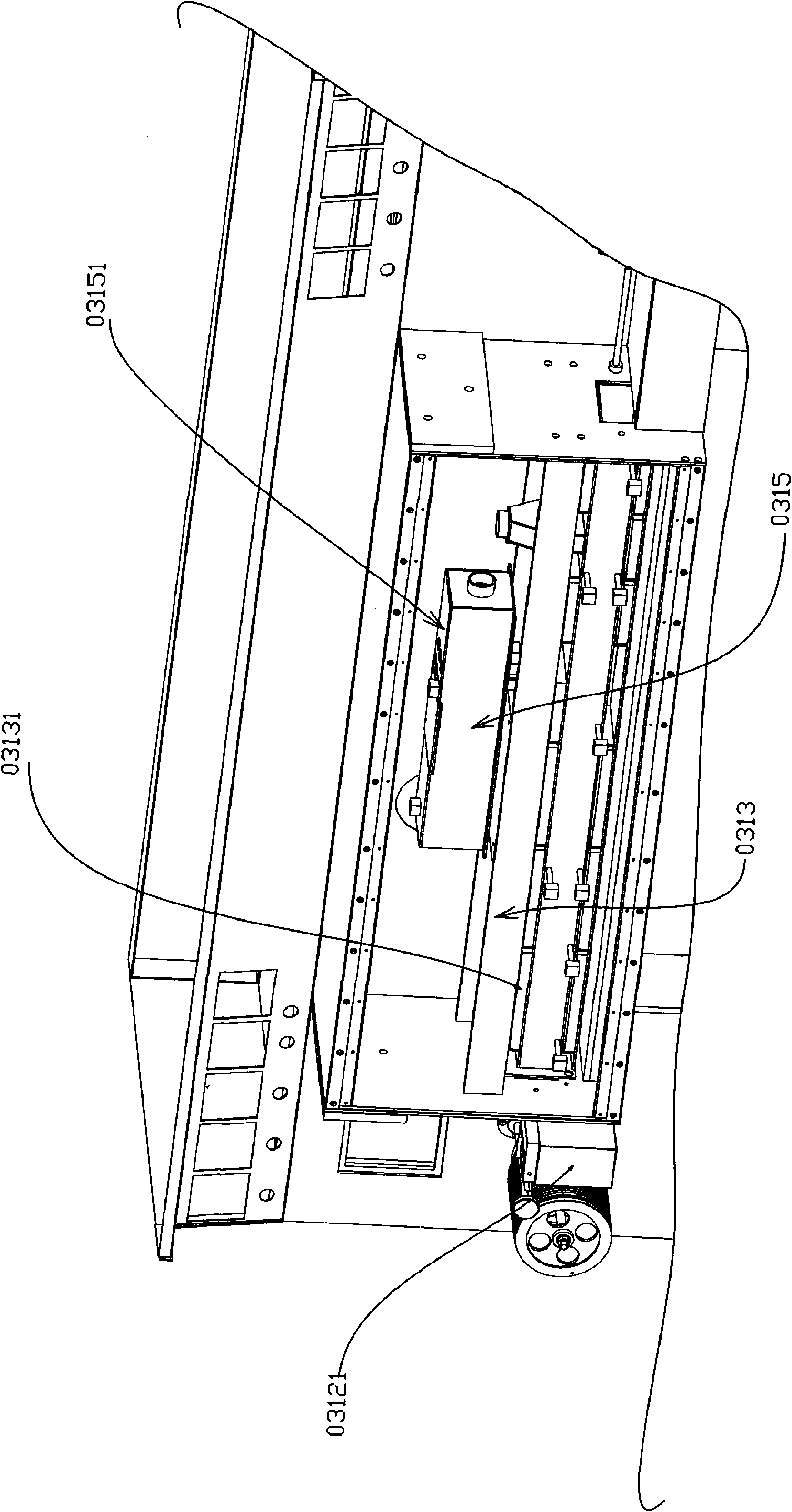

[0034] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments: As shown in the figure, the bonding wire equipment for semiconductor packaging is to perform functions such as wire-drawing, wire drawing, quenching and tempering (annealing), cleaning, coating, and winding. It is integrated in a horizontal and straight line, and the fine bonding wire or insulated bonding wire can be directly obtained from the small bare metal wire, which includes:

[0035] A wire pay-off device 01, which is equipped with a supporting frame and a guiding mechanism inside. The wire reel (or bobbin) with the metal wire is placed on the supporting frame, and the metal wire is sent to the wire drawing machine through the guiding mechanism;

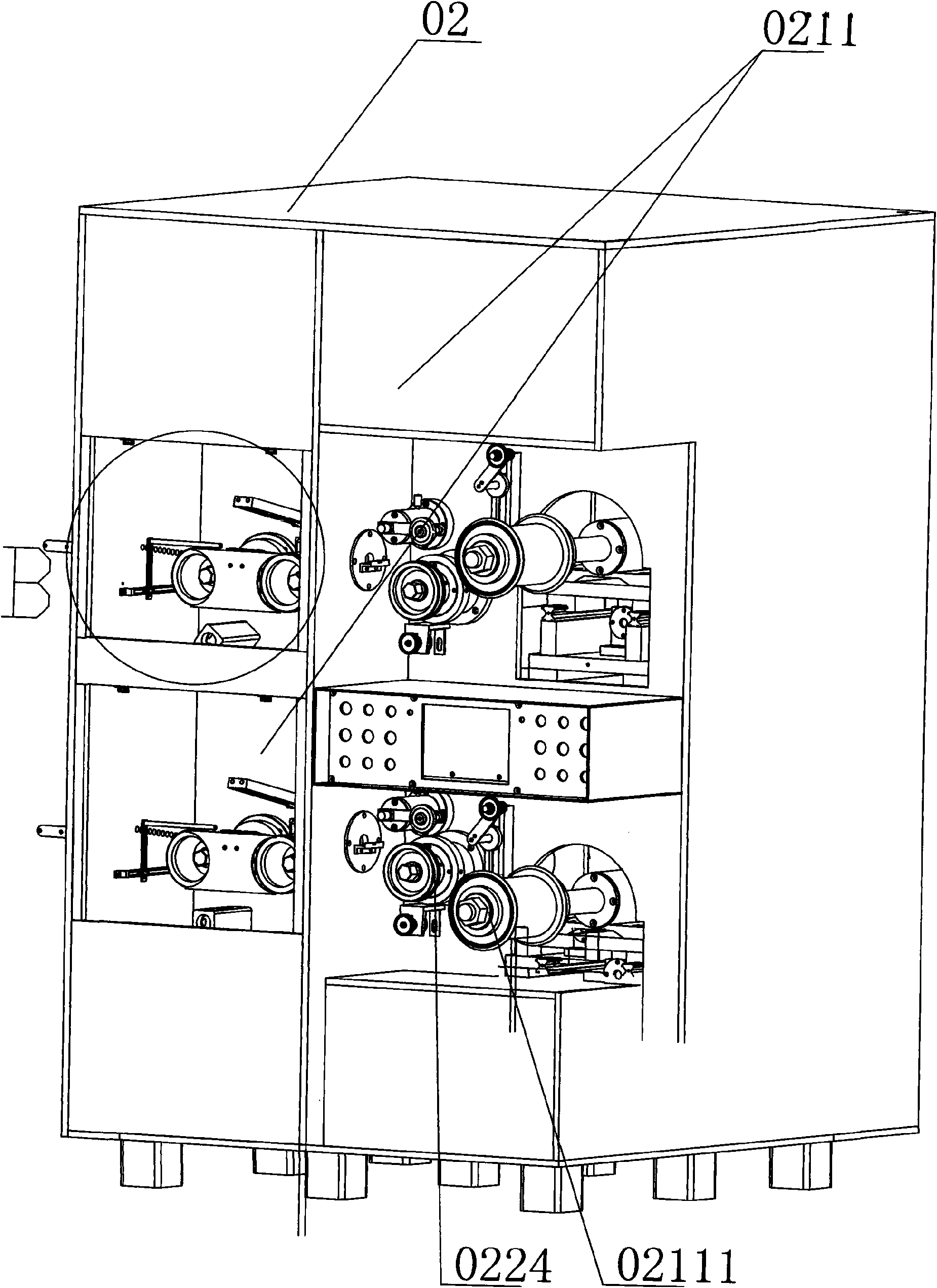

[0036] A wire drawing machine 02, which is arranged on one side of the pay-off device 01, includes a frame 021 and a wire drawing assembly 022, and the wire drawing assembly 022 includes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com