Latex pillow production line

A latex pillow and production line technology, applied in the field of pillow production, can solve the problems of high time cost, low production efficiency, cumbersome transportation and preparation processes, etc., achieve good drying effect, realize production efficiency, and reduce the effect of preparation steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be described in further detail below in conjunction with the accompanying drawings.

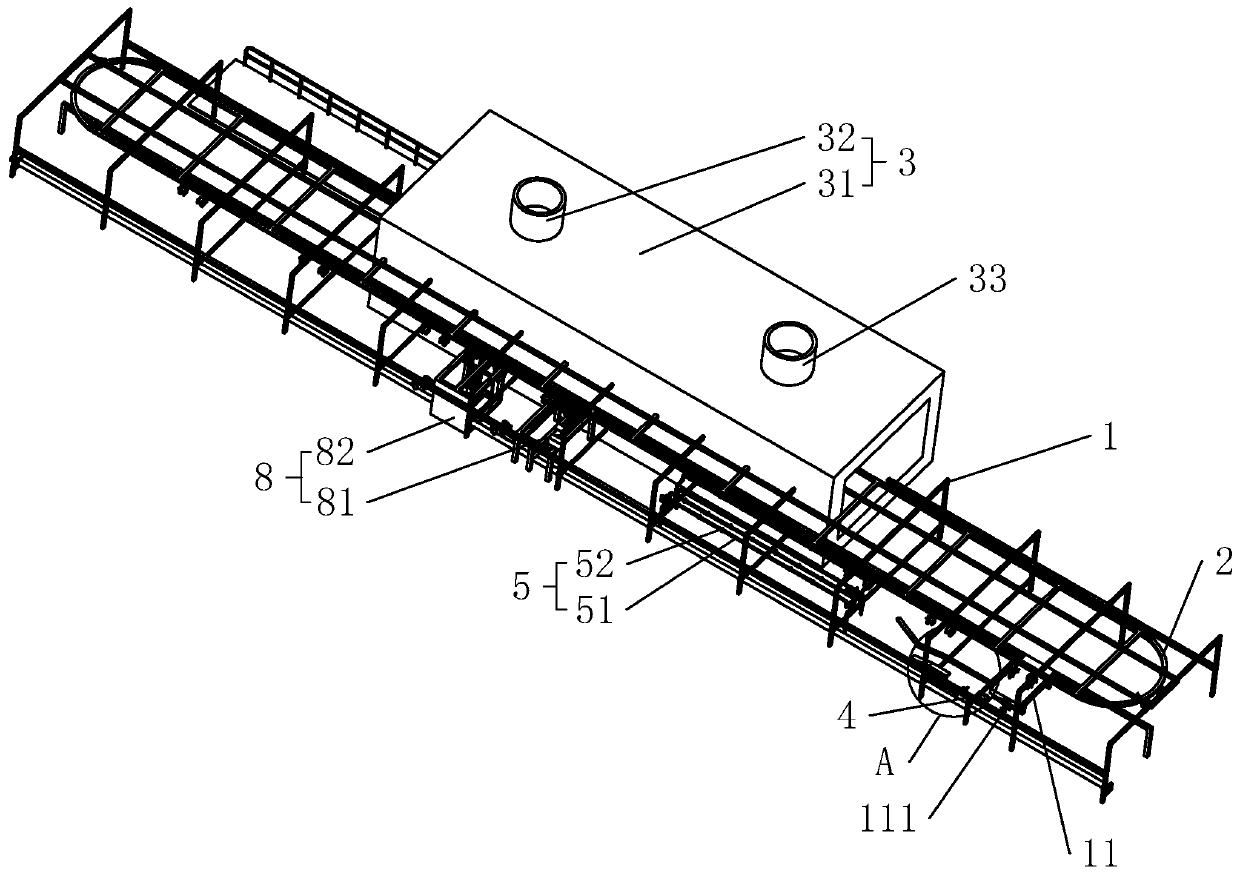

[0041] Such as figure 1 Shown, a kind of latex pillow production line, comprises annular support 1, endless conveyor belt 2, pillow mold 11, and annular support 1 is main supporting structure, and endless conveyor belt 2 is installed on the annular support 1, and is annular circulation motion; Pillow mold 11 It is fixed on the endless conveyor belt 2 by hanging, and moves along the circular route driven by the endless conveyor belt 2 .

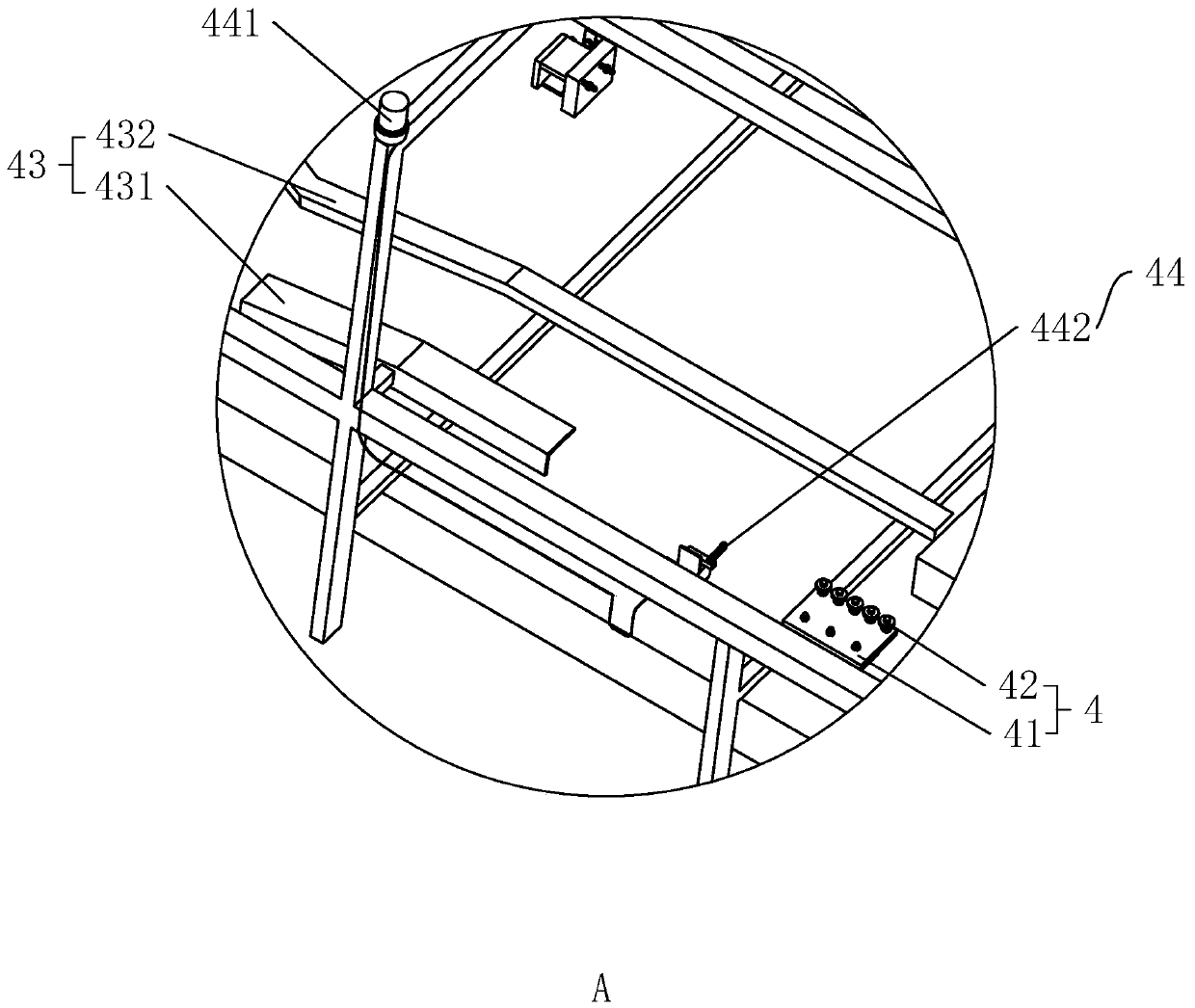

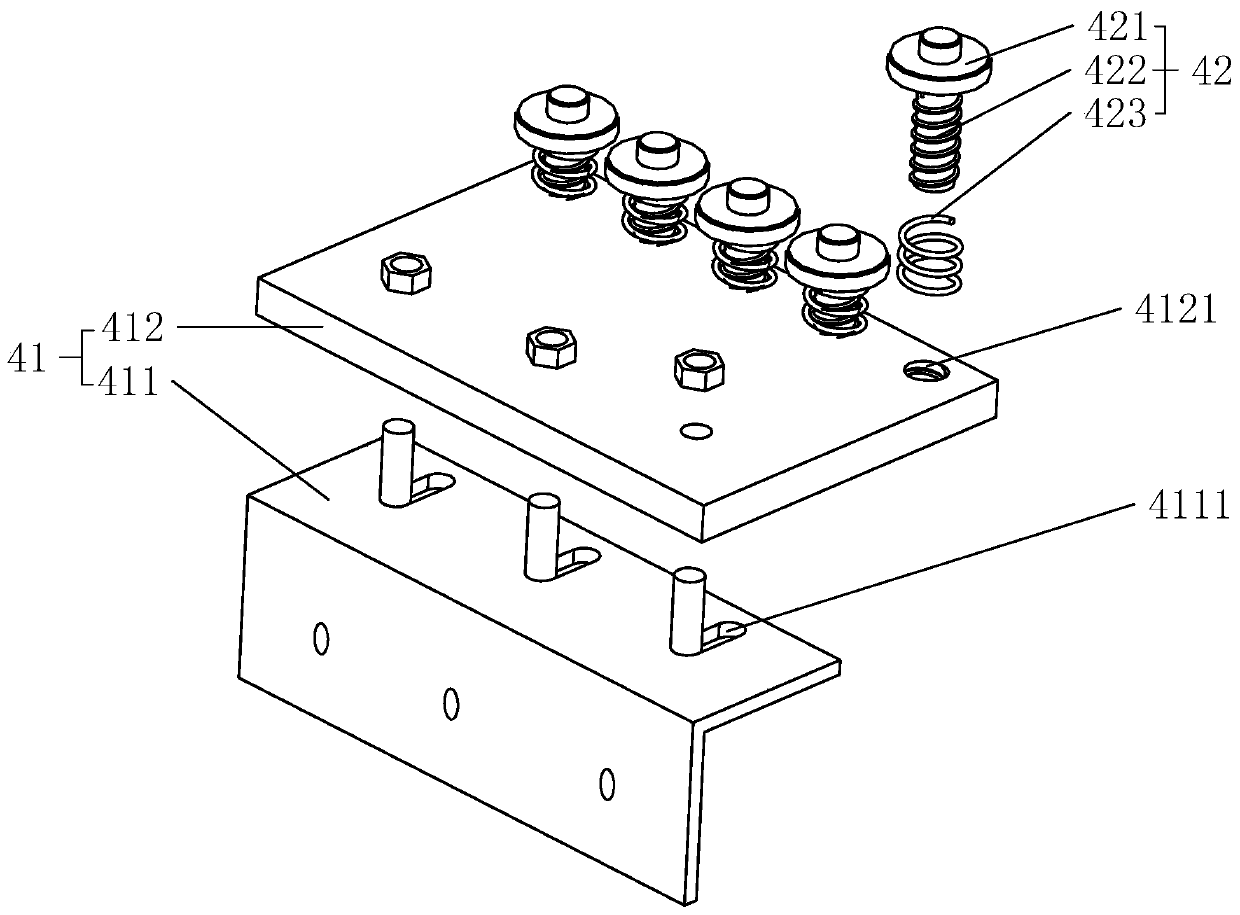

[0042] Latex curing device 3, mold opening device 4, mold cleaning device 5 and mold drying device 8 are sequentially distributed along the transportation route of pillow mold 11 on annular support 1, starting from latex curing device 3 in order, which includes a steam box 31. Heat exchange plate (not shown in the figure), steam inlet 32 and steam outlet 33, the steam box 31 is in the shape of a box, fixed on the ring supp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com