Mobile shear type lifting multi-stage belt ship loader with traveling crane

A belt conveyor and mobile technology, which is applied to the field of bag loading devices at the inner port terminal, can solve the problems of incapable of 24-hour bag packing ship operation and the limited operating area of the bag ship loader, so as to improve operation efficiency and reduce ship loading. Cost, effect of coverage expansion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

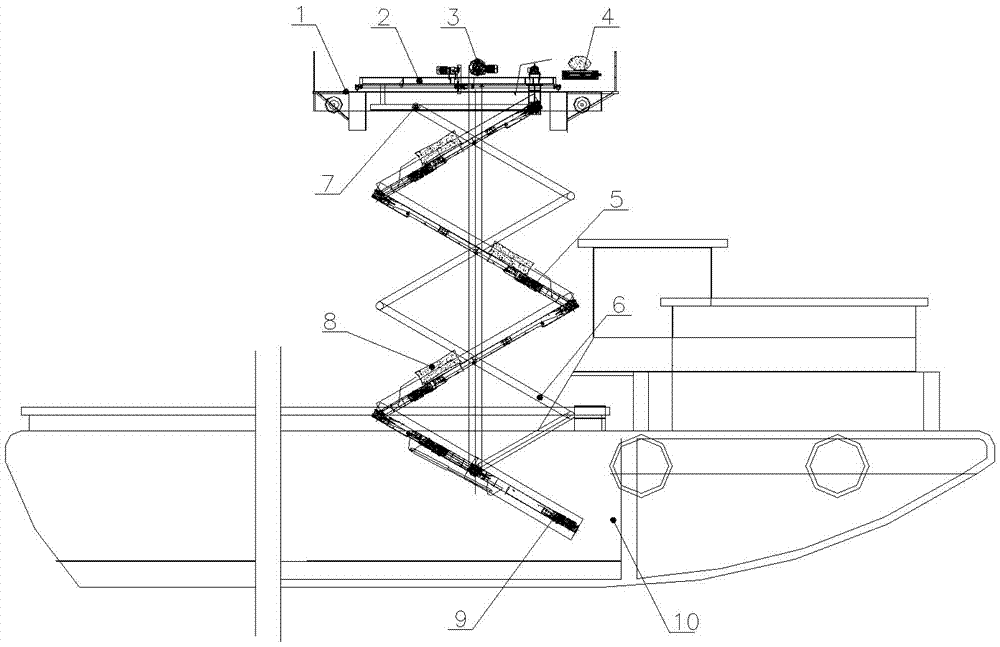

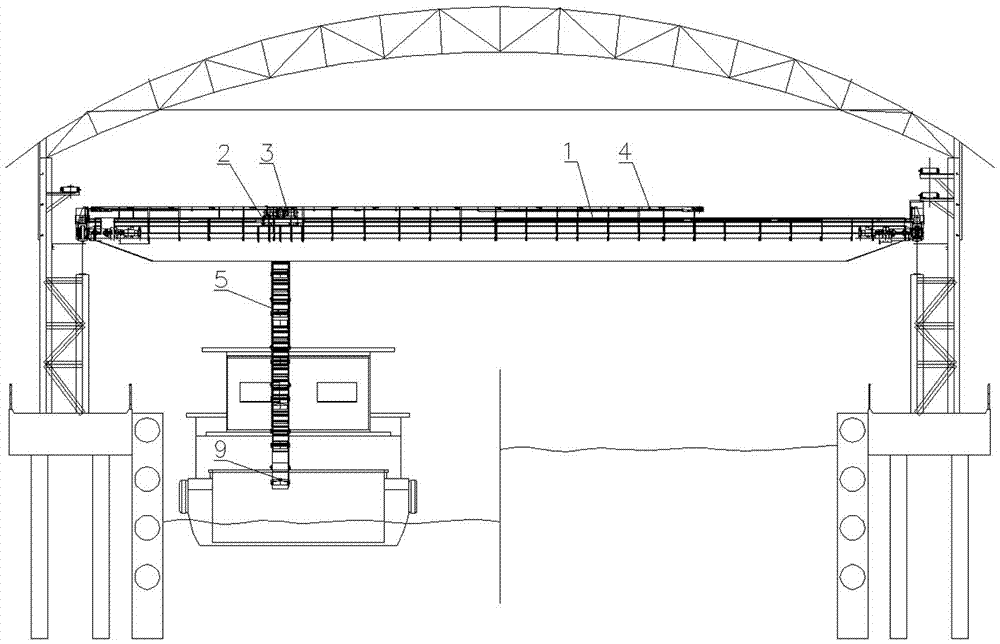

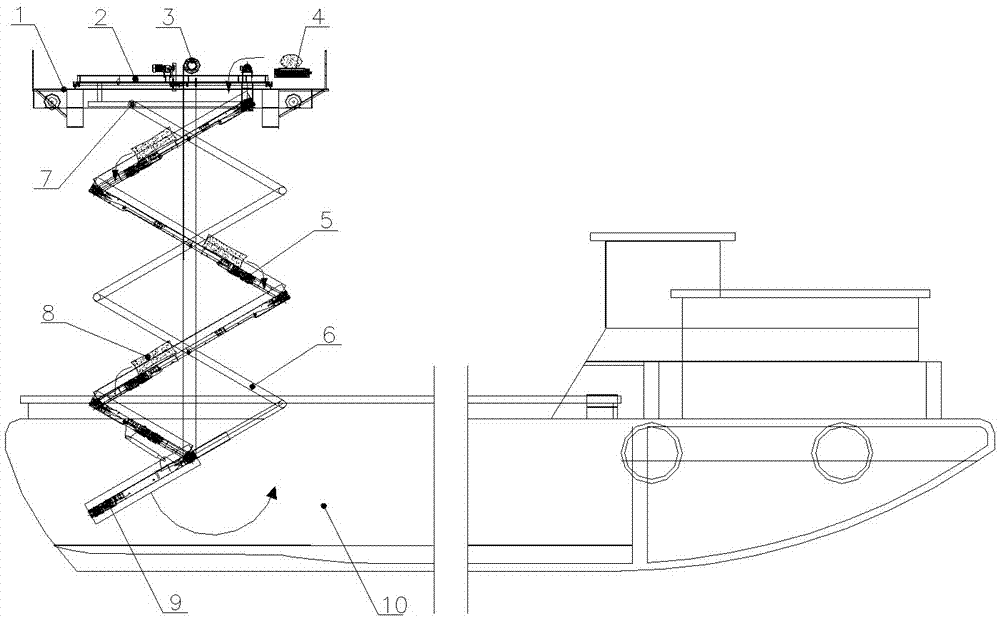

[0022] The specific embodiment of the present invention is as follows: the bag is sent into the transfer belt 4 on the mobile double-beam crane 1 through the belt conveyor feeding system, and then slides into the multi-stage folding belt conveyor 5 through the blocking bag chute on the mobile trolley 2 On the track, through multiple transfers on the multi-stage folding belt conveyor 5, it finally falls on the tail cloth belt conveyor 9, and then the bags are stacked on the ship through the tail cloth belt conveyor 9 to realize the entire loading operation.

[0023] After the ship is docked, the lifting mechanism 3 drives the multi-stage folding belt conveyor 5 to lift and fold to a certain height. Allow the tail fabric belt conveyor 9 to cross the side of the ship and enter the cabin, then through the hoisting mechanism 3, cooperate with the double beam traveling vehicle 1 and the mobile trolley 2 to move the tail fabric belt conveyor 9 to the yard bag position, start the belt ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com