Automatic packaging production line for customized furniture boards and control method of automatic packaging production line

An automatic packaging and production line technology, applied in the field of plate processing, can solve the problems of high processing cost, low production capacity, and difficulty in meeting large-scale production needs, and achieve the effect of fewer workers and meeting large-scale production needs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The boards in the present invention are all pasted with identification codes, such as two-dimensional codes or barcodes, and the information corresponding to the boards, such as order information, design parameters, processing information, etc., can be queried by scanning the identification codes with a code scanning device. Such information may specifically include the quantity of plates in the order, the shape and size of each plate, the position, quantity, size, and shape of the holes on the plates, and the packing box to which each plate belongs.

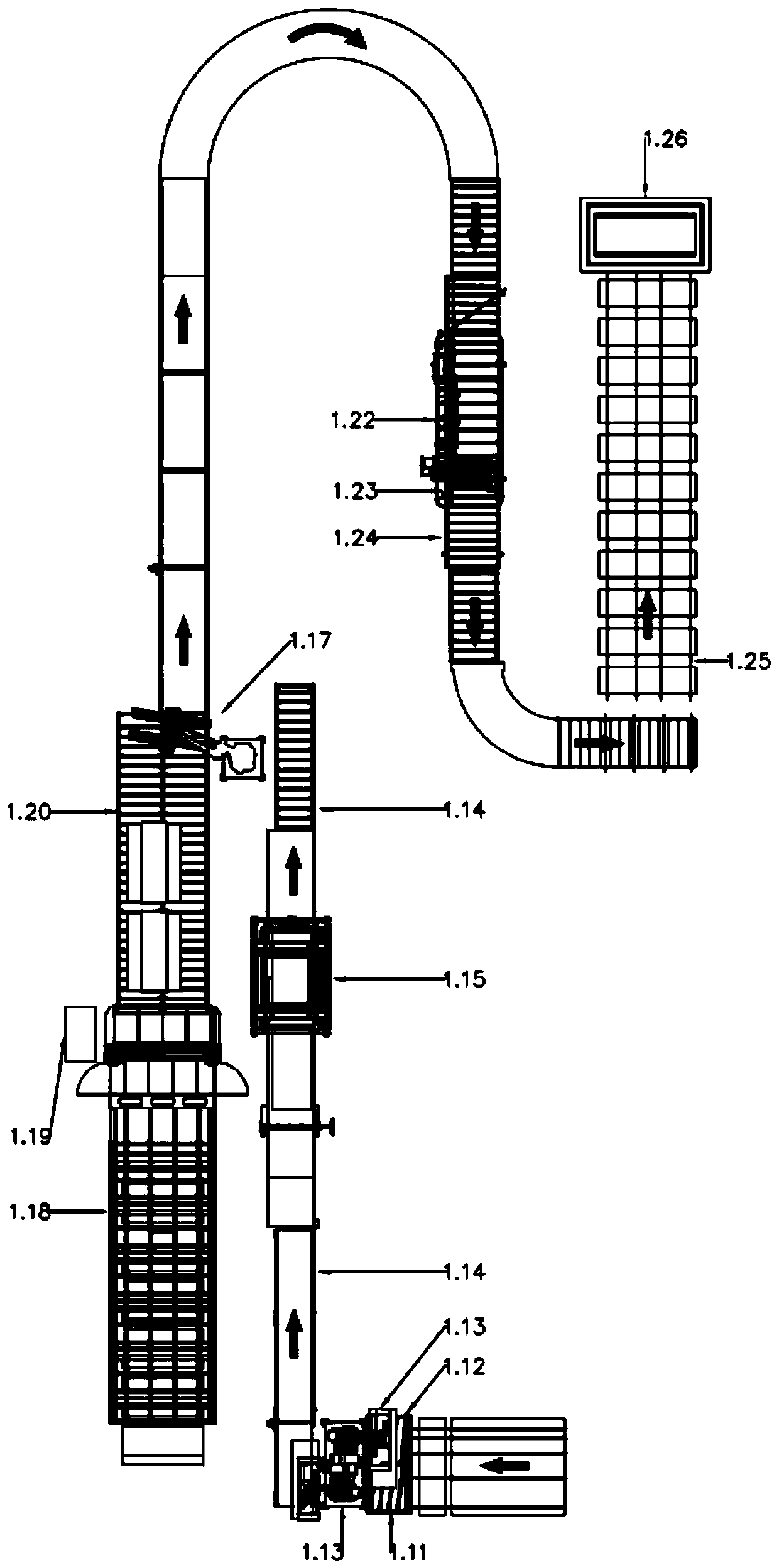

[0024] figure 1 It shows an automated packaging production line for customized furniture panels, including packaging control devices, packaging transmission lines, stacking manipulators 1.13, grabbing manipulators 1.17, automatic paper cutting equipment 1.18, and multiple board position detection sensors on the packaging transmission line.

[0025] The packaging transmission line is equipped with plate position detection ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com