Automatic-arranging detecting device

A detection device and automatic arrangement technology, applied in the direction of conveyor control devices, transportation and packaging, conveyors, etc., can solve the problems that the arrangement speed cannot keep up with the processing speed, unfavorable mass production, high production cost, etc., and achieve ingenious structural design , reduce the number of operators, and achieve a high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

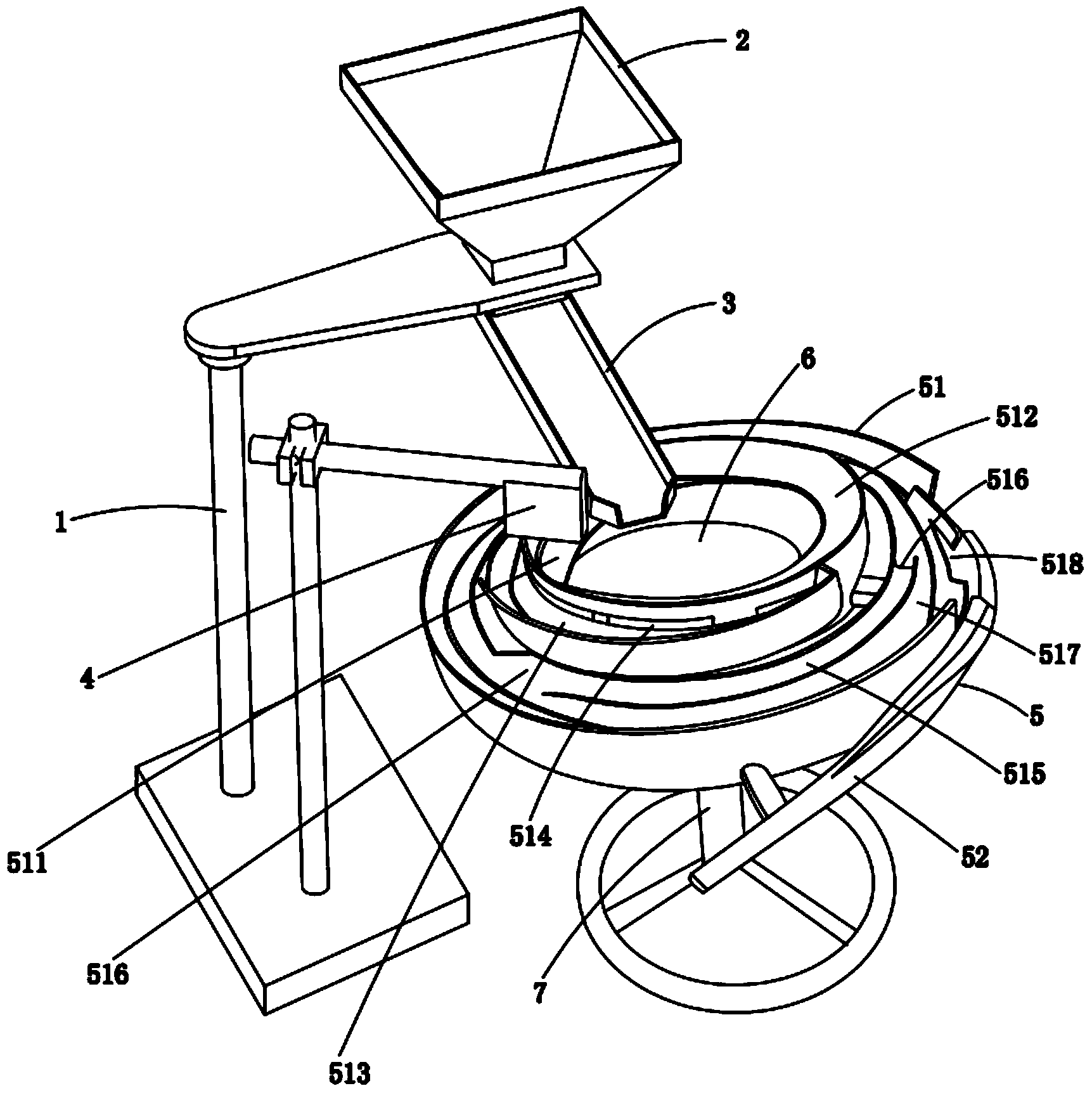

[0015] See attached figure 1 , an automatic arrangement detection device, including a frame 1, a feed hopper 2, a chute 3, a detection device 4 and a screening plate, the feed hopper 2 is installed on the frame 1, and the bottom of the feed hopper 2 is connected to a Inclined chute 3, the screening disc is placed directly below the end of the chute 3, and the detection device 4 is arranged above the screening disc; the screening disc includes a magnetic core track 5 and a movable turntable 6, and the magnetic core track 5 includes a circular track 51 and a linear track 52, the circular track 51 includes a plurality of grooves, the grooves are spirally arranged in a clockwise direction, the width of the grooves narrows from the inside to the outside and the inner side of each groove is slightly higher than the outer side, The magnetic core is moved along the outer wall, and the width of the groove is at least greater than the width of a magnetic core; the linear track 52 is arr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com