High-precision five-axis intelligent robot for stamping part carrying

An intelligent robot and high-precision technology, applied in the direction of conveyor objects, transportation and packaging, etc., can solve problems such as reduced work efficiency, fatigue and negligence of stamping workers, and prone to accidents, so as to avoid potential safety hazards, improve production efficiency, reduce The effect of the number of workers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

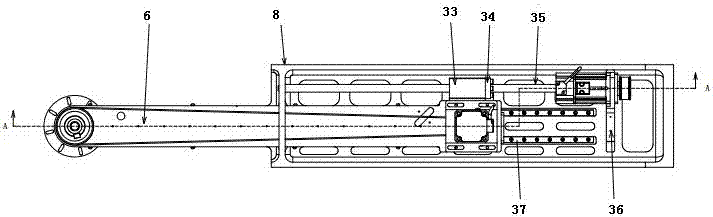

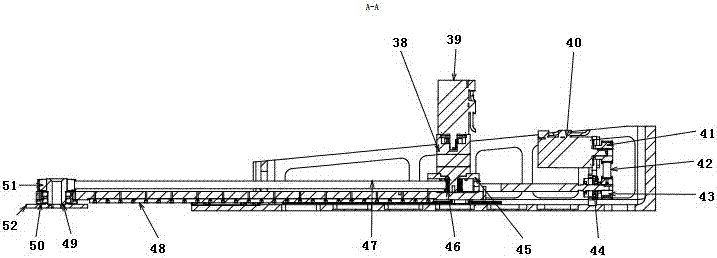

[0027] Combine below Figure 1 to Figure 6 , to further illustrate the present invention.

[0028] A high-precision five-axis intelligent robot for carrying stamping parts, including a main shaft rotation mechanism 3, a main shaft lifting movement mechanism 11, a swing arm flip movement mechanism 12, a swing arm horizontal telescopic movement mechanism 9, and an end rotation movement mechanism 7, wherein The main shaft rotary motion mechanism 3 is fixedly connected with the fixed frame 4, the main shaft lifting motion mechanism 11 is fixedly connected with the main shaft rotary motion mechanism 3 on the lifting frame 5, and the swing arm turning motion mechanism 12 is fixedly connected with the main shaft lifting motion mechanism 11 on the turning frame 10 , the swing arm horizontal telescopic movement mechanism 9 and the swing arm flipping movement mechanism 12 are fixedly connected to the telescopic frame 8, the end rotation movement mechanism 7 and the swing arm horizontal ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com