Flue-cured tobacco mulching film row spacing marking device

A technology of plant distance marking and mulching film, applied in printing, rotary printing machines, printing machines, etc., can solve problems such as difficult to control tension, waste of time, manpower and money, and affect yield, so as to improve agricultural output and crop quality, and reduce labor. Strength, Accuracy-enhancing Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with accompanying drawing:

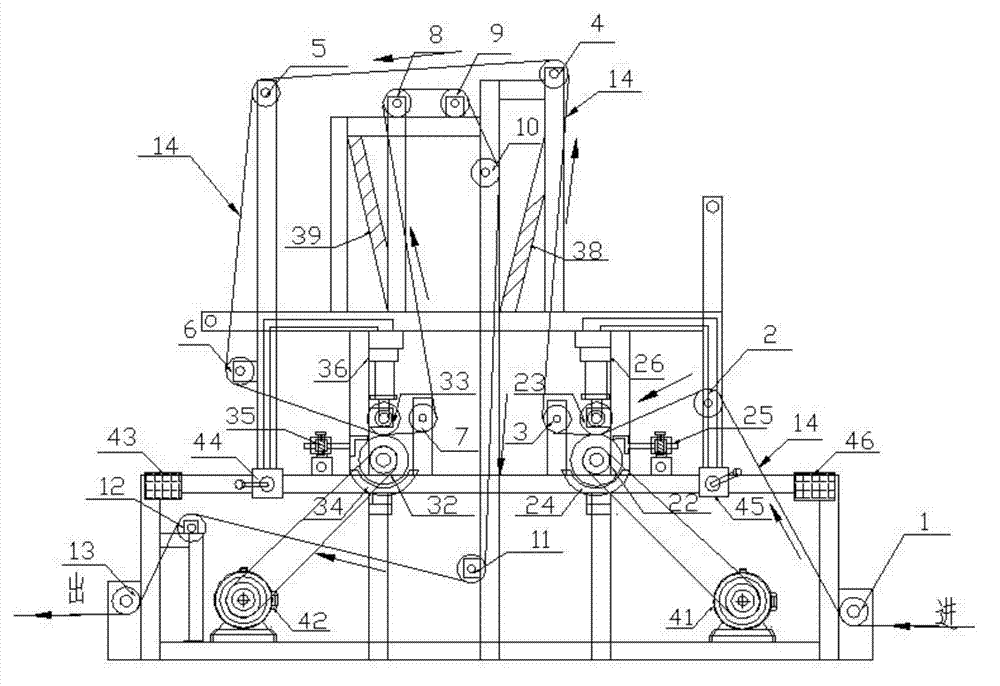

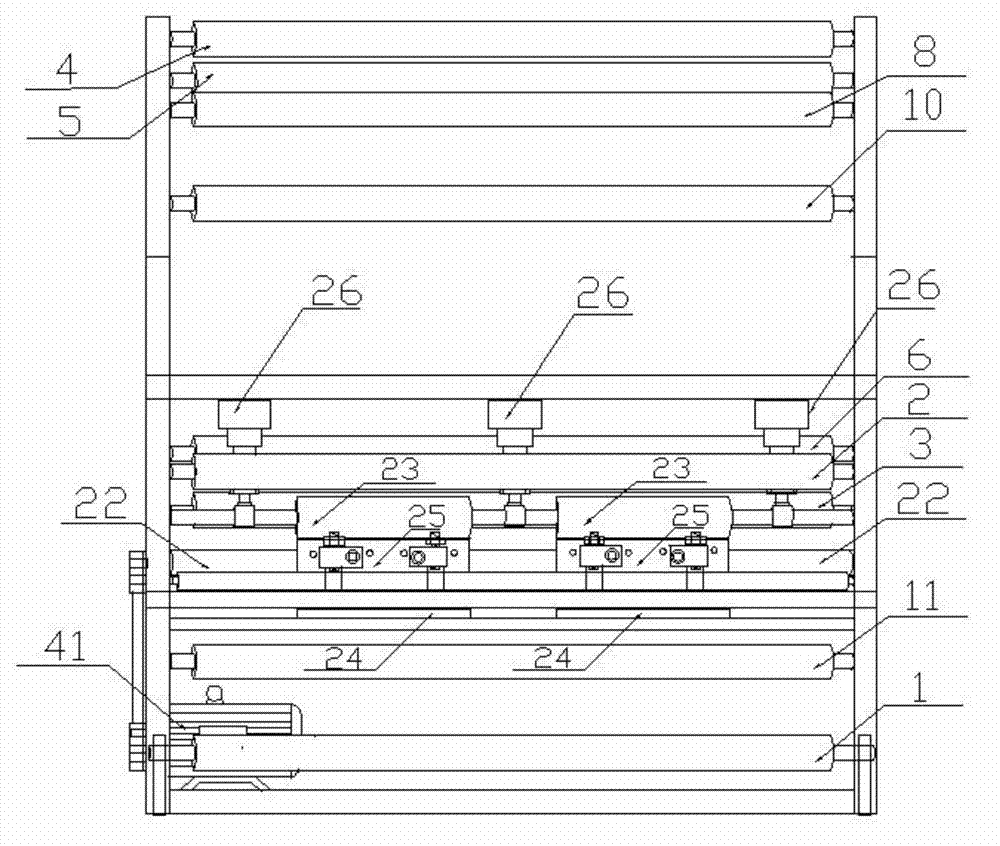

[0016] Such as figure 1 , figure 2 As shown, a flue-cured tobacco mulch film spacing marking device includes a frame, a motor unit and a roller assembly, the roller assembly includes a guide roller group, a steering roller group, and a reverse roller group, and the marking device also includes a printing assembly; The printing assembly includes a first printing assembly and a second printing assembly; the first printing assembly includes a first marking roller 22, a first pinch roller 23, the first marking roller 22 and the first pinching roller 23 are circumscribed, and the first The marking roller 22 is connected to the first ink cartridge 24, and the first ink scraper 25 is arranged outside the first marking roller 22; the second printing assembly includes a second marking roller 32, a second pinch roller 33, a second marking roller 32 and a second pressing The tight ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com