Checking device and method for continuous materials

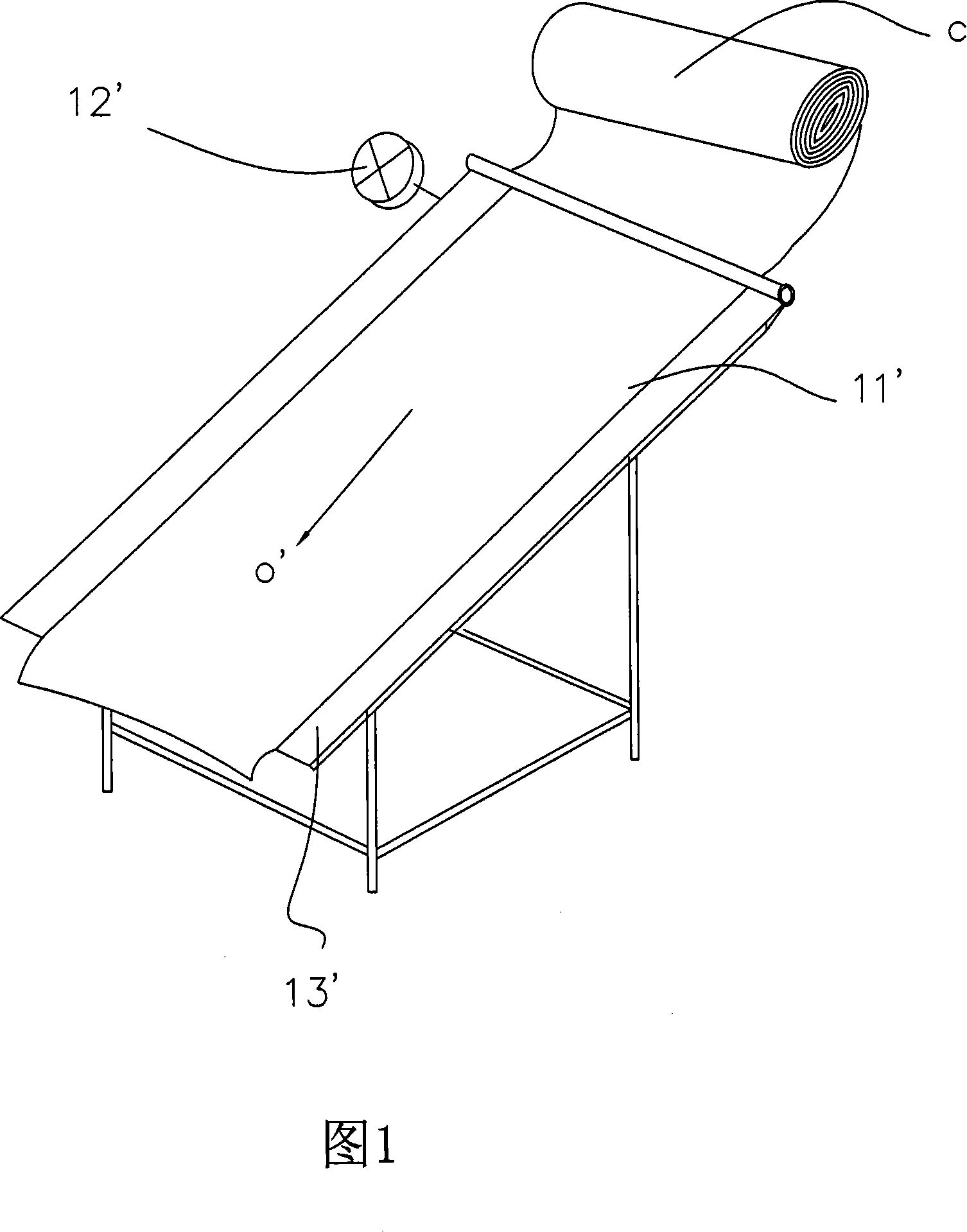

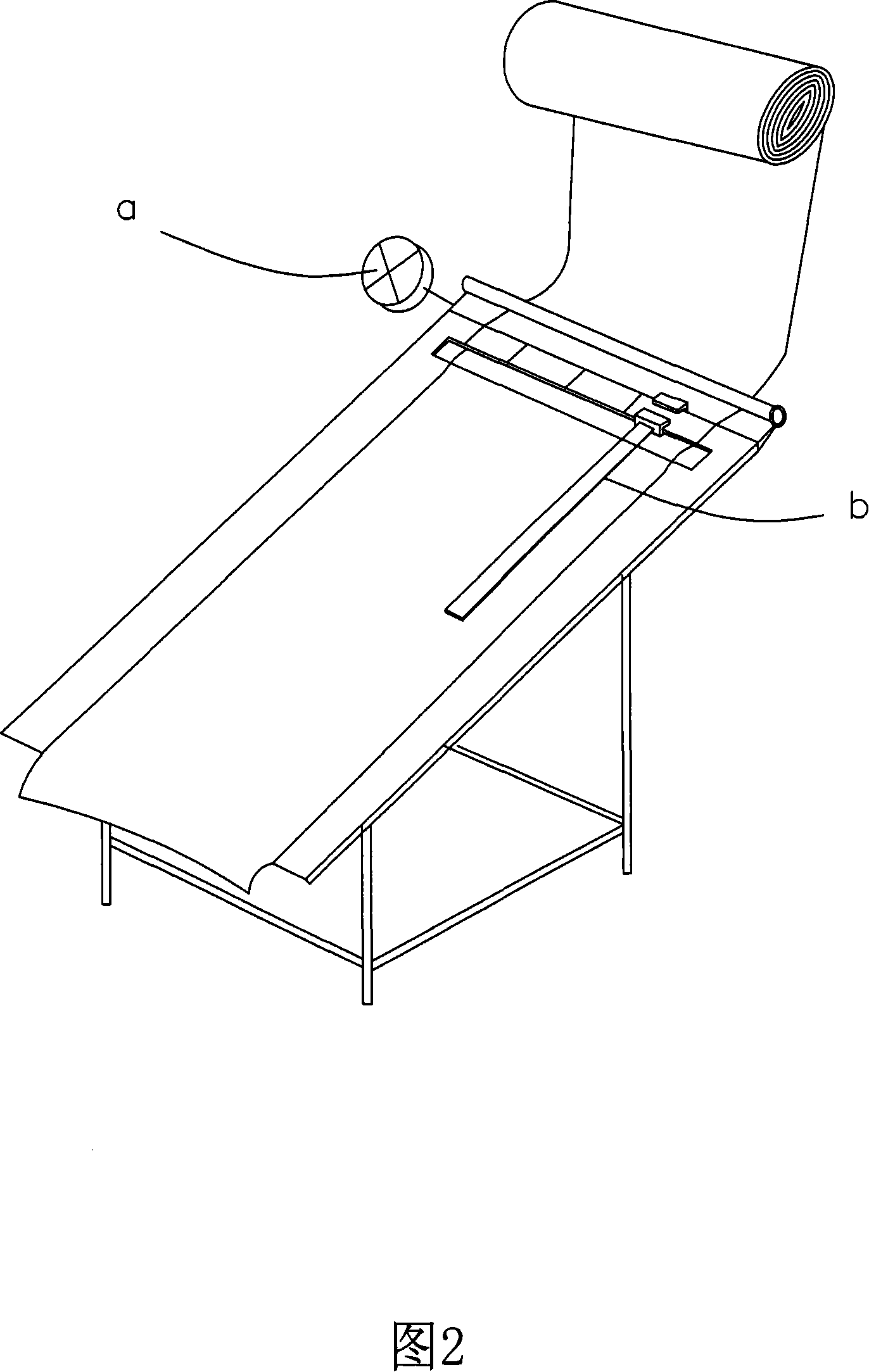

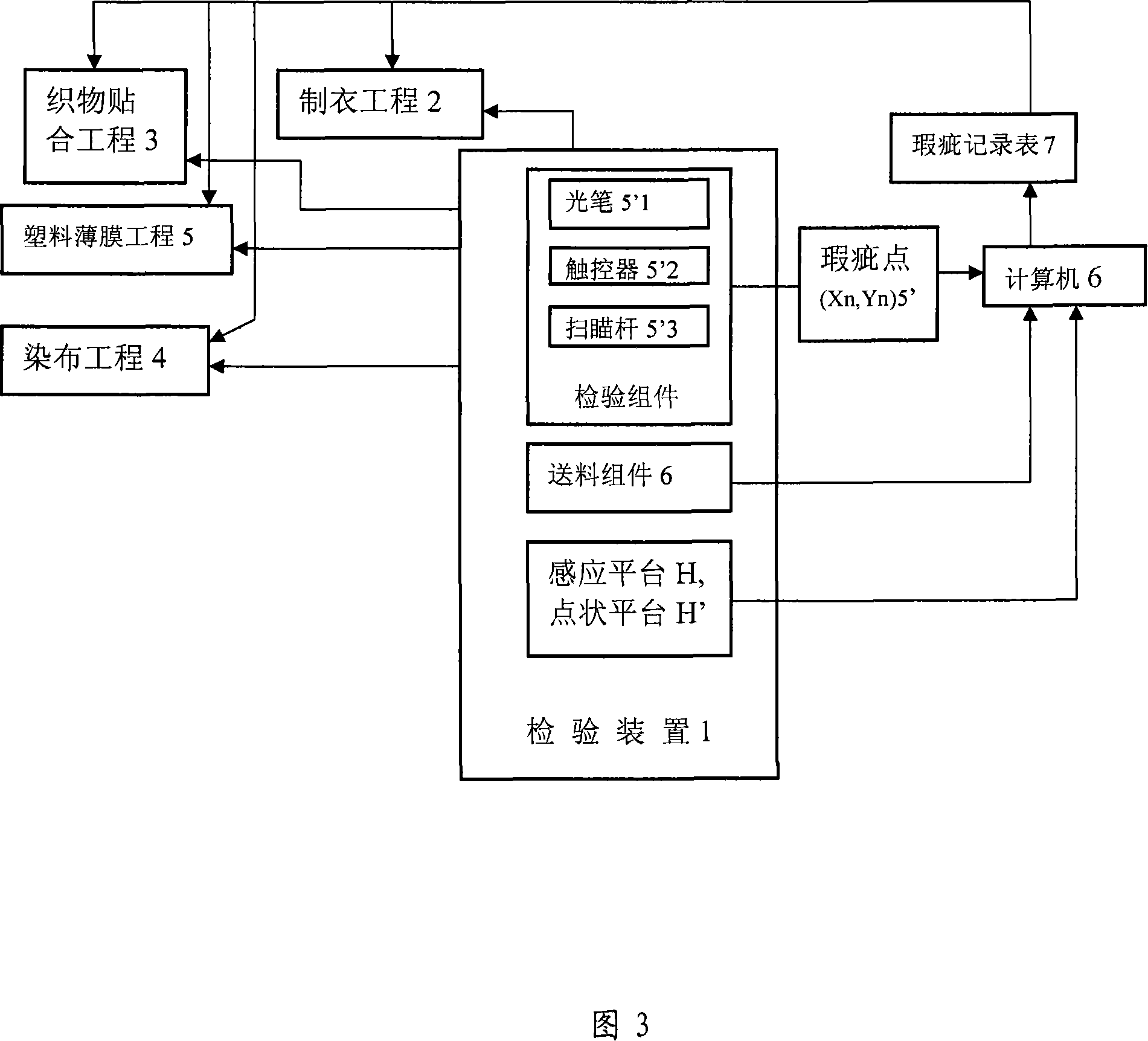

A technology of inspection device and inspection method, which is applied to the inspection of textile materials, material inspection products, and analysis of materials, etc., which can solve the problem of increased loss rate in garment processing, the inability to accurately know the 11' flawed block cloth on the cloth surface, and the inability to Mark the defects of the horizontal position of the cloth surface and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] Take a batch of cloth (PL0001) and install it on the inspection device 1 with the feeding component for inspection. The PL0001 cloth is sent out by the feeding component in a fixed-length 1 / 4 yard for inspection, and is inspected by the touch sensor platform. For the defective part of the cloth, the coordinates of the defective points will be sent to the computer screen and some defective point A coordinates (30, 175), defective point B coordinates (75, 225), defective point C coordinates (60, 300 ), the defect point D coordinates (90, 350) as shown in Figure 7, the table is as follows:

[0044] Coordinate unit (yard, centimeter)

[0045]

[0046] 200

[0047] As mentioned above, according to the position of the defect point displayed on the screen E of the computer 6, the fabric defect record table is made and can be sent to the downstream processing industry.

Embodiment 2

[0049]Take a batch of plastic cloth (FL0001), 25μ thickness, 60m / min line speed, and produce it under the conditions of coiling and inspection device 1 equipped with a feeding assembly. Control the fixed length to be inspected, and press the point-shaped platform with a light pen to inspect the defective part of the plastic cloth, and the coordinates of the defective points will be sent to the screen E of the computer 6 and the coordinates of some defective points a (15, 160), defect point b coordinates (60, 190) and defect point c coordinates (90, 230) are listed in the following table:

[0050] Coordinate unit (yard, centimeter)

[0051]

[0052] As mentioned above, according to the position of the defect point displayed on the screen E of the computer 6, a plastic cloth defect record table is made and can be sent to the downstream processing industry.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com