Method for mining broken thick ore body through coal roadway heading machine

A technology of roadheader and thick ore body, which is applied in surface mining, mining equipment, underground mining, etc., can solve the problems of difficult to achieve safe and efficient mining, ore easily collapsed in large blocks, and a large number of operators, and achieve optimal mining. and filling process, reducing the number of workers, the effect of reducing the number of workers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

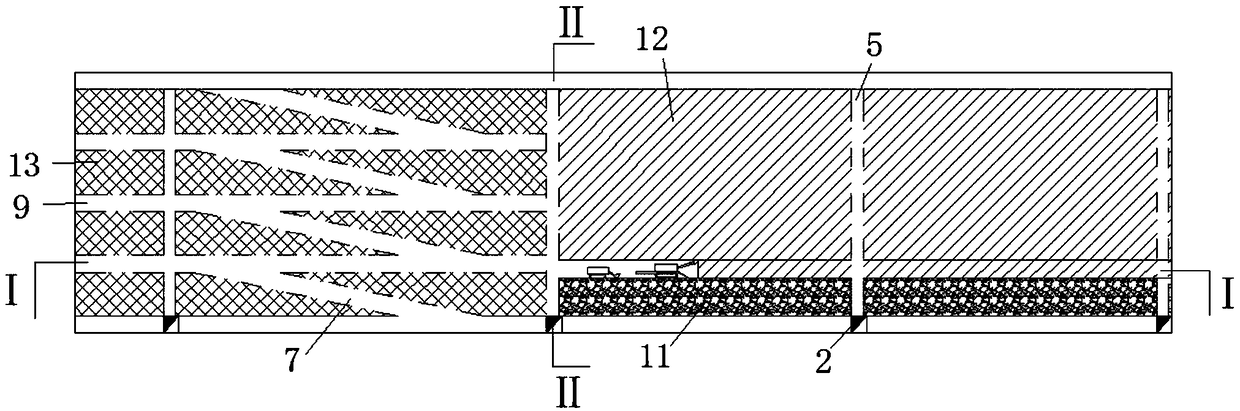

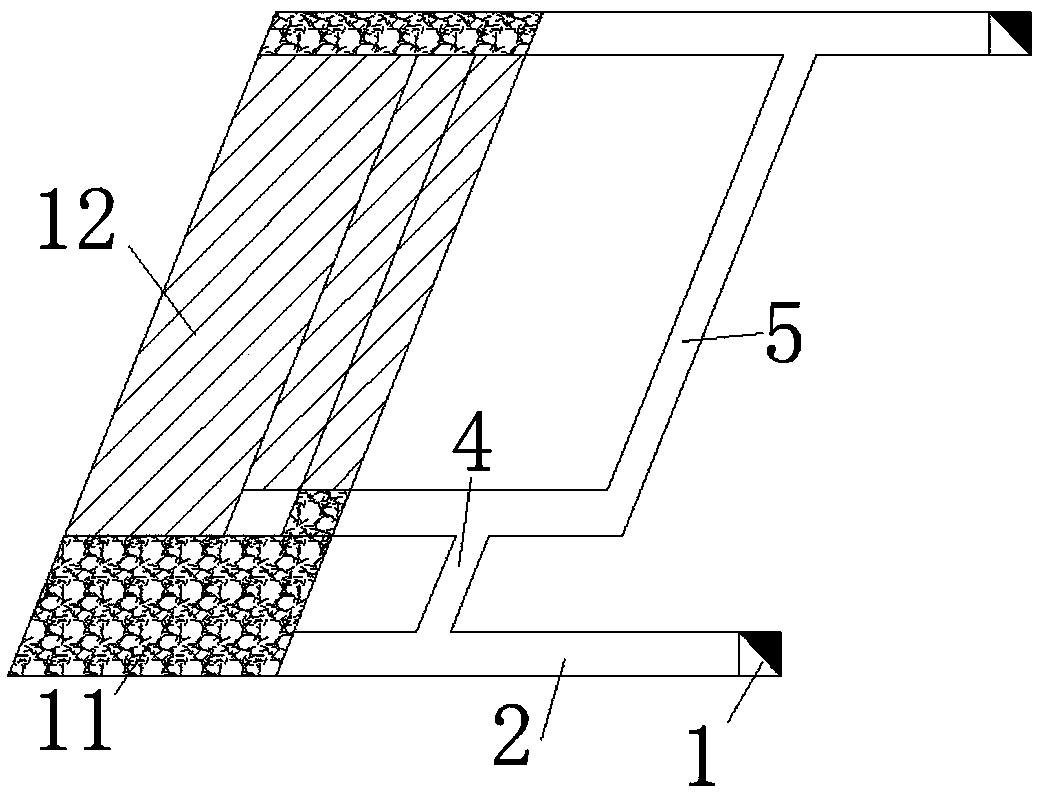

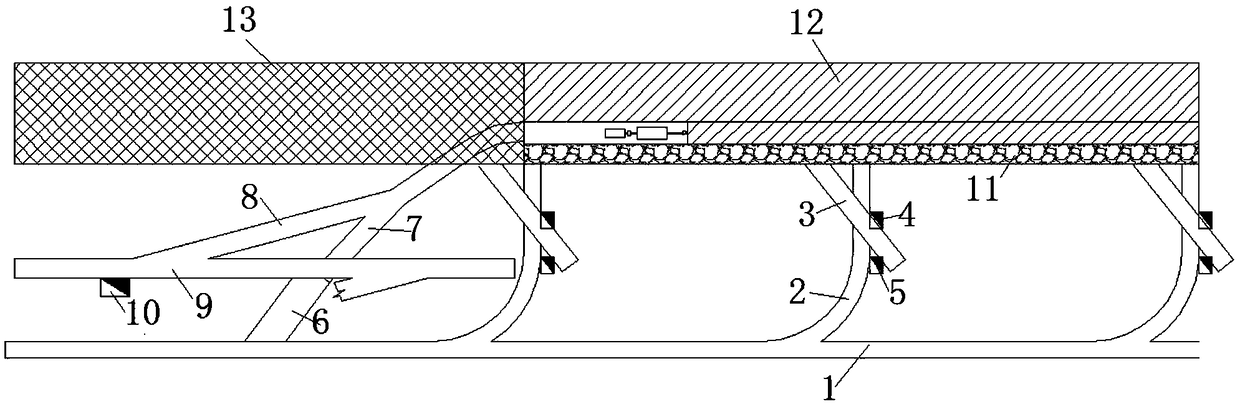

[0030] The specific technical solutions of the present invention will be further described below with reference to the accompanying drawings, so that those skilled in the art can further understand the present invention. Such as figure 1 - Figure 5 Shown, preferred embodiment of the present invention is:

[0031] 1. Equipment

[0032] Coal roadheader 14 is an EBZ160Z roadheader developed by Shanxi Tiandi Coal Machinery Equipment Co., Ltd. for the actual situation of a gold mine. The overall dimensions are length×width×height=11.0m×2.0m×1.85m, and the weight of the whole machine is about 40t. The scraper is a WJD-1 electric scraper produced by Nanchang Kaima Co., Ltd. The overall dimensions are length × width × height = 5.8m × 1.3m × 2.0m, and the bucket capacity is 1.0m³.

[0033] 2. Specific implementation steps

[0034] (1) A gold mine is a typical broken ore body. The average thickness of the ore body 12 is 15 m, the strike length is about 200 m, the dip angle of the o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com