Lost foam casting method of twist lock shell for containers

A lost foam casting and container technology, which is applied to casting molding equipment, molds, mold components, etc., can solve the problems of high labor intensity, waste of resources, and low safety factor in mold making, so as to improve labor productivity and reduce resource consumption. , the effect of improving product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

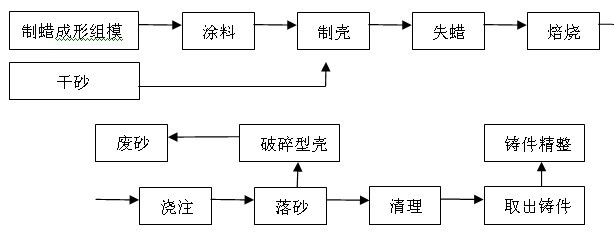

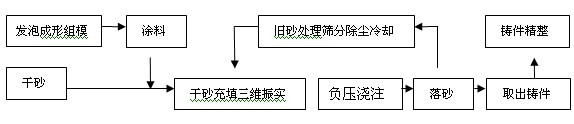

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] 1. Use EPS foamed plastic pellets specially used for lost foam casting with a diameter of φ0.2mm. The EPS foamed material is XJ501 produced by Wuxi Xingda Foam Plastic New Material Co., Ltd.

[0042] 2. Use a pre-foaming machine with a foaming multiple of 38 for pre-foaming, and the foaming diameter is controlled within the range of 23-25 grams / 500ml. The preheating temperature of the system is about 100°C, the preheating time is suitable for the temperature of the barrel of the hand-feeling foaming machine to be uniform, the steam pressure of the incoming steam is controlled between 0.2-0.3MPa, and the cycle time is 1.5 minutes.

[0043] 3. Mature the pre-foamed foamed beads in the curing chamber for 8 hours, the ambient temperature is 25-30°C, the ventilation is good, and the humidity in the air is controlled below 40-45%.

[0044] 4. Inject the foamed beads into the mold with compressed air of about 0.6 MPa, expand the white mold through steam expansion again, pass...

Embodiment 2

[0060] 1. Use EPS foamed plastic pellets with a diameter of 0.3mm for lost foam casting.

[0061] 2. Use a pre-foaming machine with a foaming multiple of 50 for pre-foaming, and the foaming diameter is controlled within the range of 20-23 grams / 500ml. The preheating temperature of the system is about 120°C. The preheating time is suitable for the temperature of the barrel of the hand-feeling foaming machine to be uniform. The steam pressure of the incoming steam is controlled between 0.2-0.3MPa, and the cycle time is 1.5 minutes.

[0062] 3. Mature the pre-foamed foamed beads in the curing chamber for 15 hours, the ambient temperature is 25-30°C, the ventilation is good, and the humidity in the air is controlled below 45-50%.

[0063] 4. Use 0.65 MPa compressed air to inject the foamed beads into the mold, expand the steam again, pass water to cool the white mold, and then use compressed air to blow the white mold out of the mold. The steam pressure is between 0.2 and 0.3 MPa...

Embodiment 3

[0079] 1. Use EPS foamed plastic pellets specially used for lost foam casting with a diameter of φ0.4mm.

[0080] 2. Use a pre-foaming machine with a foaming multiple of 60 for pre-foaming, and the foaming diameter is controlled within the range of 20-23 grams / 500ml. The preheating temperature of the system is about 100°C, the preheating time is suitable for the temperature of the barrel of the hand-feeling foaming machine to be uniform, the steam pressure of the incoming steam is controlled between 0.2-0.3MPa, and the cycle time is 1.5 minutes.

[0081] 3. Mature the pre-foamed foamed beads in the curing chamber for 24 hours, the ambient temperature is 25-30°C, the ventilation is good, and the humidity in the air is controlled below 40-50%.

[0082] 4. Use 0.7MPa compressed air to inject the foamed beads into the mould, expand again with steam, cool with water to form the white mold, and then use compressed air to blow the white mold out of the mould. The steam pressure is b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com