Patents

Literature

77results about How to "Improve high temperature thermal stability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

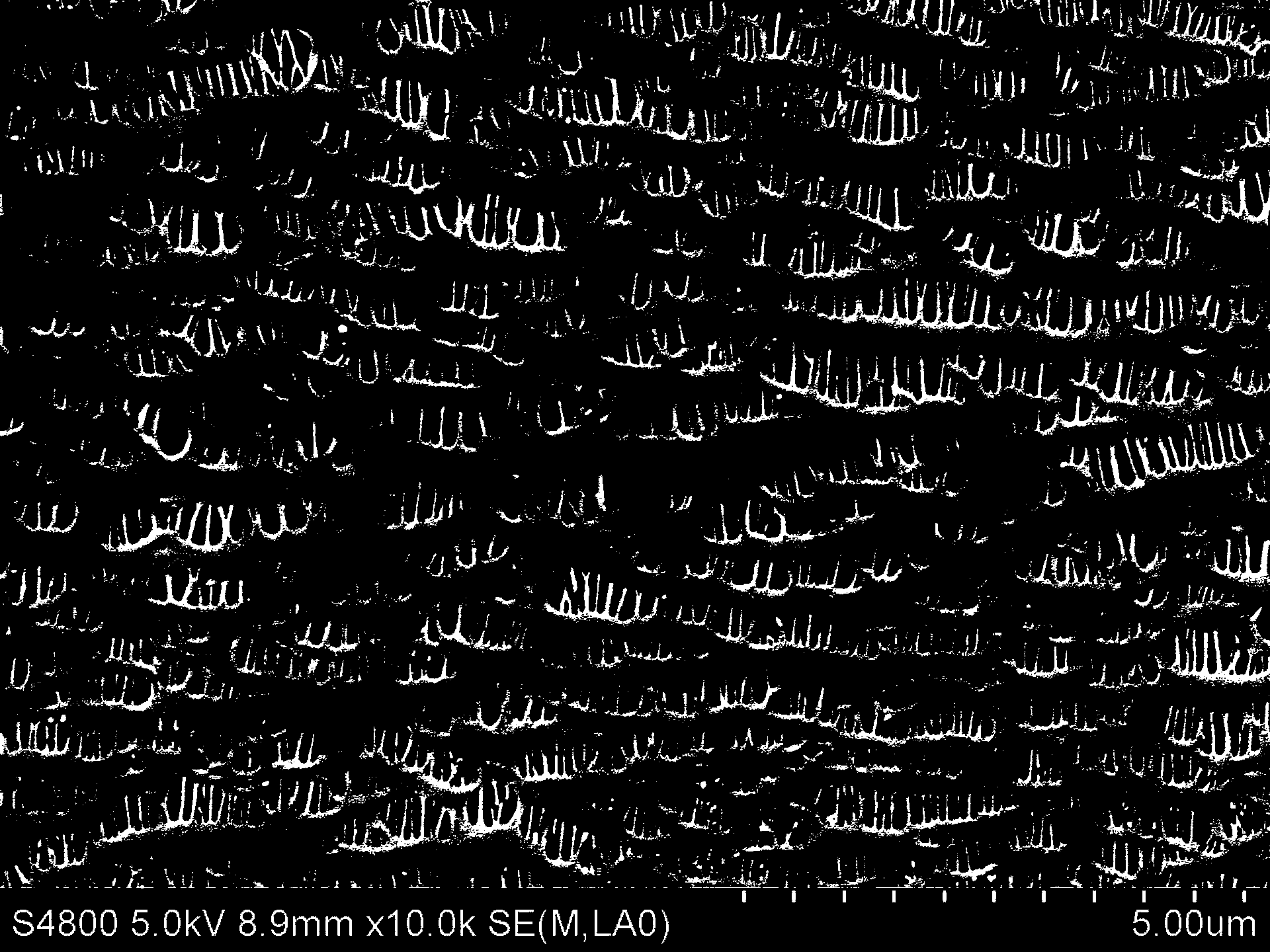

Composite ceramic membrane for lithium ion batteries and preparation method thereof

ActiveCN103956451AAvoid thermal runawayImprove high temperature thermal stabilityCell component detailsElectrolytic agentCeramic coating

The invention discloses a composite ceramic membrane for lithium ion batteries and a preparation method thereof, including a ceramic coating modification method and a ceramic lithium battery membrane. The ceramic protective layer is mainly prepared from a ceramic-adhesive mixture subjected to graft modification by a sodium-sulfonate / sodium-carboxylate-group-containing anionic surfactant. The grafting is completed by using a grafting-on process under the action of a coupling agent; the grafting ratio of the ceramic is higher; the high-temperature-resistant large-surface-area nano ceramic is introduced to the conventional PP (polypropylene) membrane surface, the insulativity and electrolyte wettability of the modified ceramic membrane are greatly enhanced; and the membrane has excellent high-temperature heat stability especially at the high temperature of 130 DEG C, 150 DEG C and 180 DEG C. The lithium battery composite membrane avoids the thermal shrinkage of the convention membrane, thereby avoids the thermorunaway in the battery due to thermal shrinkage, and further enhancing the safe reliability of the lithium ion battery.

Owner:中国东方电气集团有限公司

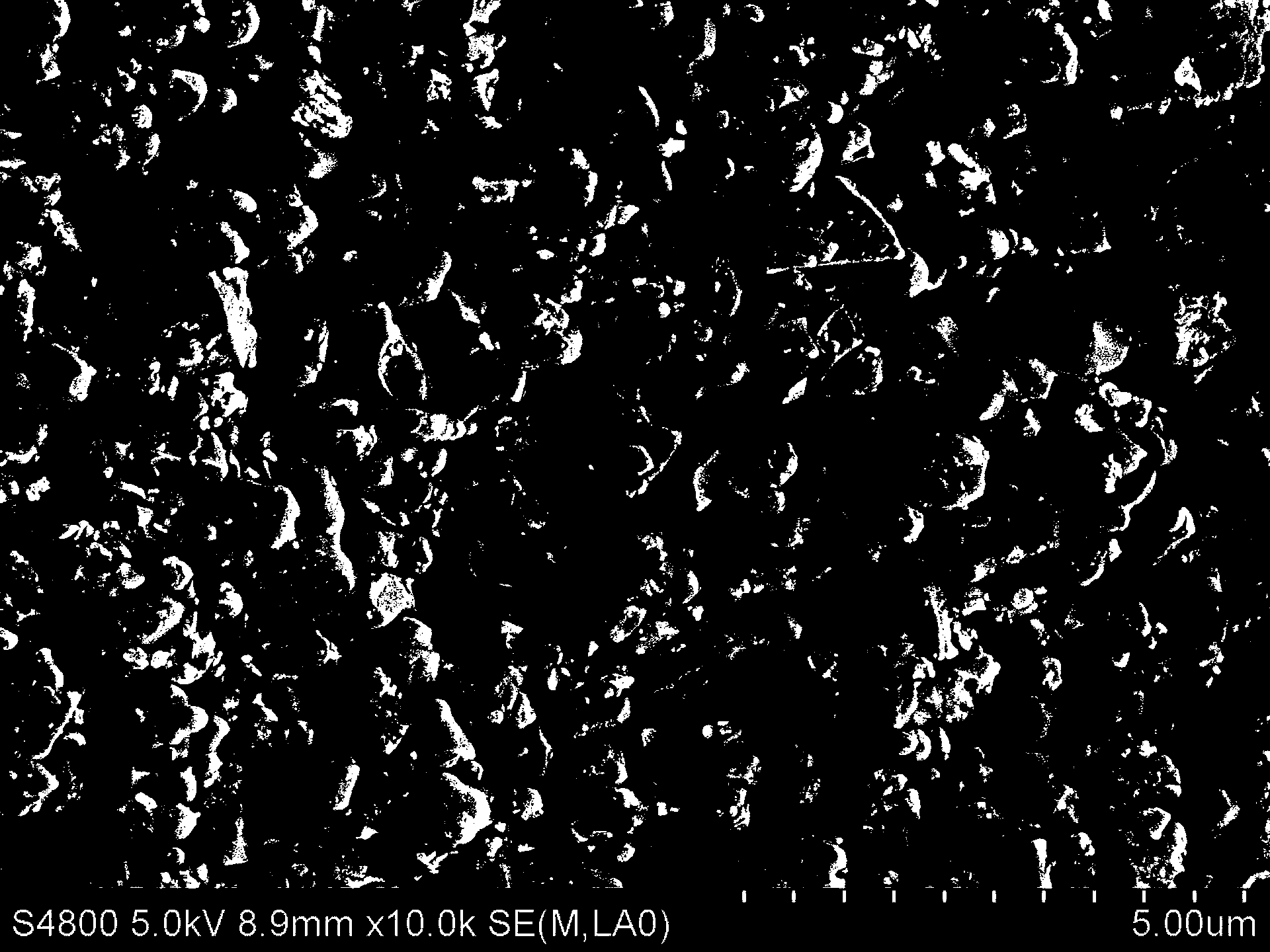

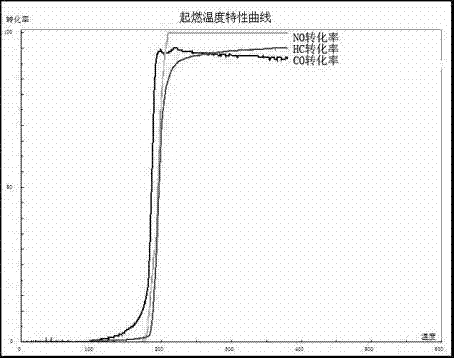

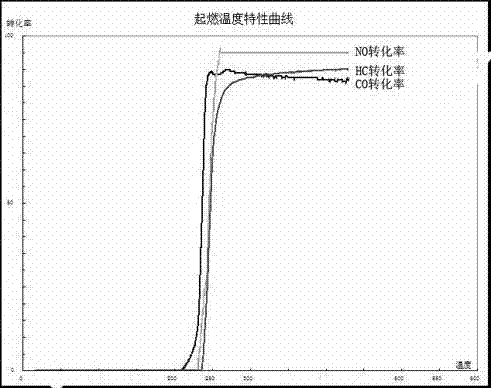

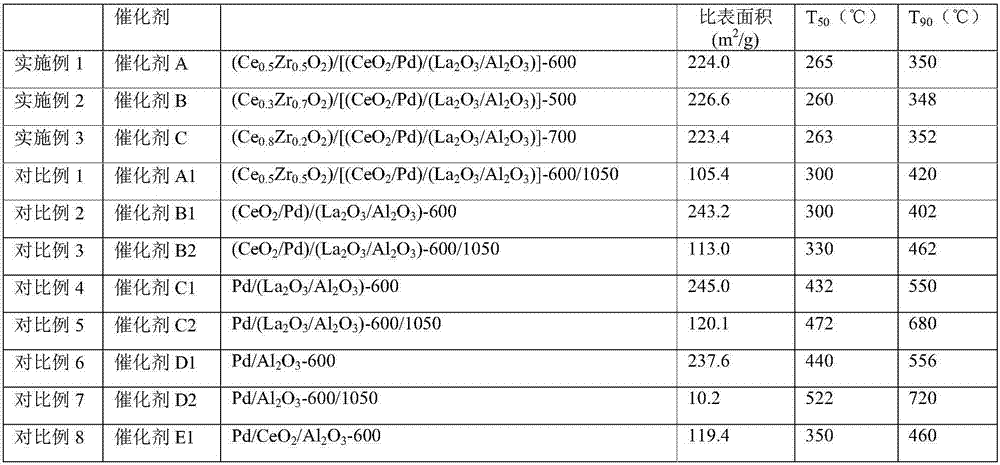

Internal combustion engine tail gas purifying ternary catalyst and preparation method thereof

InactiveCN103877975AImprove conversion efficiencyLow ignition temperatureDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsCeriumCordierite

The invention relates to the field of internal combustion engine tail gas treatment, in particular to a ternary catalyst for purifying the tail gas of an internal combustion engine and a preparation method thereof. The preparation method is characterized in that cordierite ceramic honeycomb is used as a carrier, precious metals such as platinum, palladium and rhodium are adopted as active components, the bottom layer catalyst contains the palladium active component with the active component concentration of 0.1 to 6g / L, the content of cerium of a cerium-containing oxygen storage material is 15-30 percent by weight, the top catalyst contains palladium and / or rhodium active component with the concentration of 0.01 to 0.6g / L, the content of cerium of the cerium-containing oxygen storage material is 40 to 80 percent by weight, a heat-resisting oxide is aluminum oxide consisting of gamma-aluminum oxide or theta-aluminum oxide, the aluminum oxide is stabilized by 3 to 8 percent by weight of lanthanum, the specific surface area is 120 to 300 m<2> / g, the weight ratio of the aluminum oxide to cerium-containing oxygen storage material to additive is 100: (40-80): (11-30). By adopting the catalyst based on the technical scheme, the conversion efficiency of the pollutants in tail gas of the internal combustion engine is high, the ignition temperature is lower, and the thermal stability in high temperature is high.

Owner:CHONGQING TONGQING ENVIRONMENTAL PROTECTION TECH

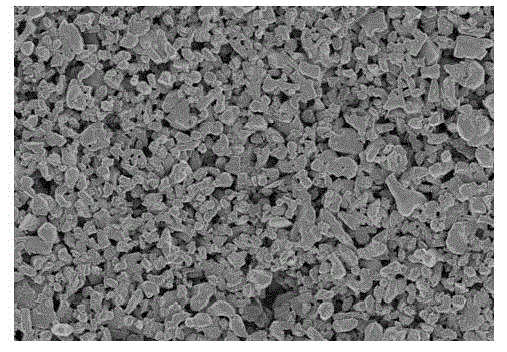

Synthesis technique of high-grade self-sharpening polycrystalline diamond

InactiveCN103521132ALow oxygenGuaranteed synthetic yieldUltra-high pressure processesIn situ polymerizationPolycrystalline diamond

The invention relates to a synthesis technique of a high-grade self-sharpening polycrystalline diamond, which comprises the following steps: metering and mixing the raw materials for synthesizing the diamond according to percentage by mass, granulating, and pressing into a synthetic stick; putting the synthetic stick into a synthesis block, and drying in a vacuum drying oven at constant temperature for later use, wherein the synthesis block is synthesized at high temperature under superhigh pressure with a cubic press; and taking out the synthetic stick, carrying out after-treatment to obtain a self-sharpening polycrystalline diamond, carrying out in-situ polymerization by a sol-gel process, and applying a zirconia coating on the diamond surface to form the high-grade self-sharpening polycrystalline diamond. The product has the advantages of favorable impact toughness, favorable thermal stability and favorable comprehensive properties, can obviously enhance the holding force of the self-sharpening polycrystalline diamond in a grinding tool, can keep the self-sharpness in the grinding process, and finally, is beneficial to prolonging the service life of th grinding tool and enhancing the machining efficiency of the grinding tool.

Owner:ZHONGYUAN ENGINEERING COLLEGE +1

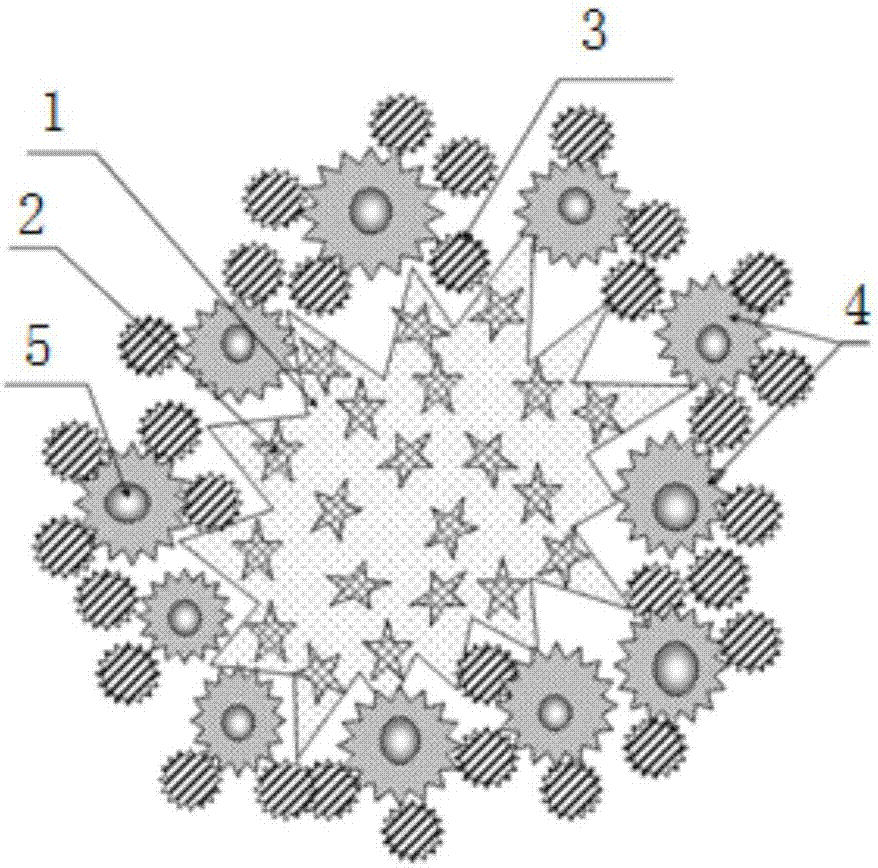

Catalyst for catalyzing methane combustion and preparation method thereof

ActiveCN107262093AGuaranteed high temperature stabilityImprove high temperature thermal stabilityHeterogenous catalyst chemical elementsDispersed particle separationActive componentOxygen vacancy

The invention provides a catalyst for catalyzing methane combustion and a preparation method thereof. The catalyst comprises a carrier, and an active component which is loaded on the carrier, wherein the active component is wrapped with a wrapping layer for providing oxygen vacancy. The catalyst further comprises a catalyst promotor which is a ceria-zirconia solid solution. According to the catalyst, the wrapping layer wraps the active component, so that oxygen molecule stored in the wrapping layer can be timely conveyed to the active component, so that the high-temperature stability of the active component of the catalyst is maintained; in addition, the catalyst further comprises the catalyst promotor which is the ceria-zirconia solid solution capable of generating more oxygen vacancies and timely effectively storing and discharging oxygen, so that the high-temperature stability of the active component of the catalyst is improved; in addition, the wrapping layer, the ceria-zirconia solid solution and the carrier are mutually dispersed and in contact, so that the mutual insulation effect is achieved, and the sintering of the carrier is inhibited, and as a result, the high-temperature thermal stability and the catalyzing activity of the catalyst can be improved.

Owner:FUZHOU UNIV +1

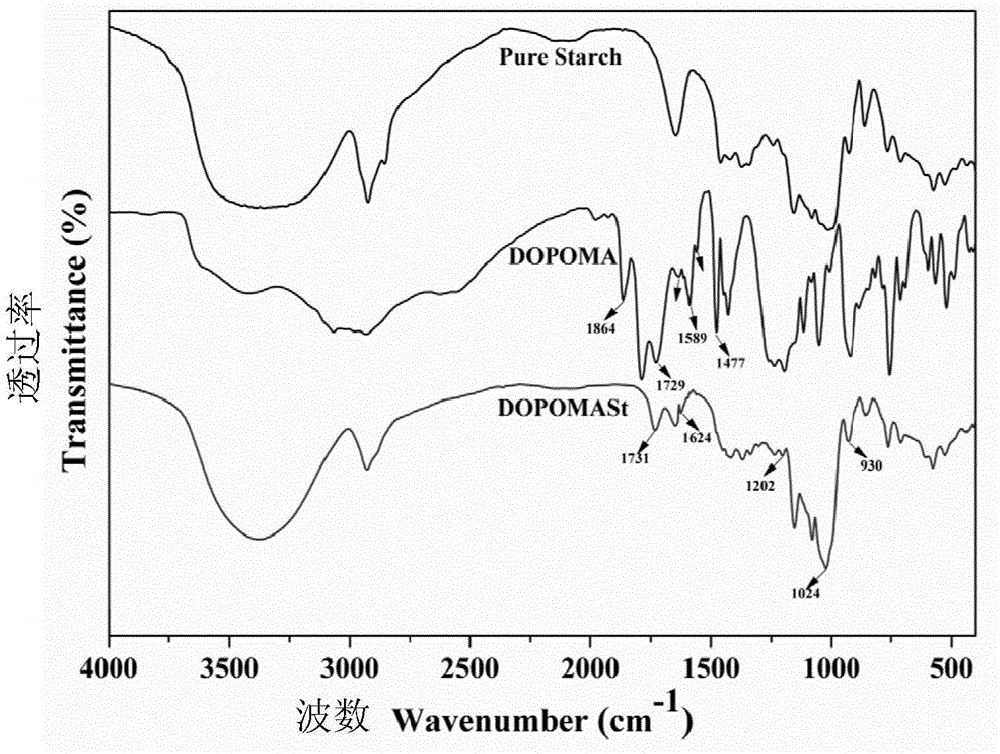

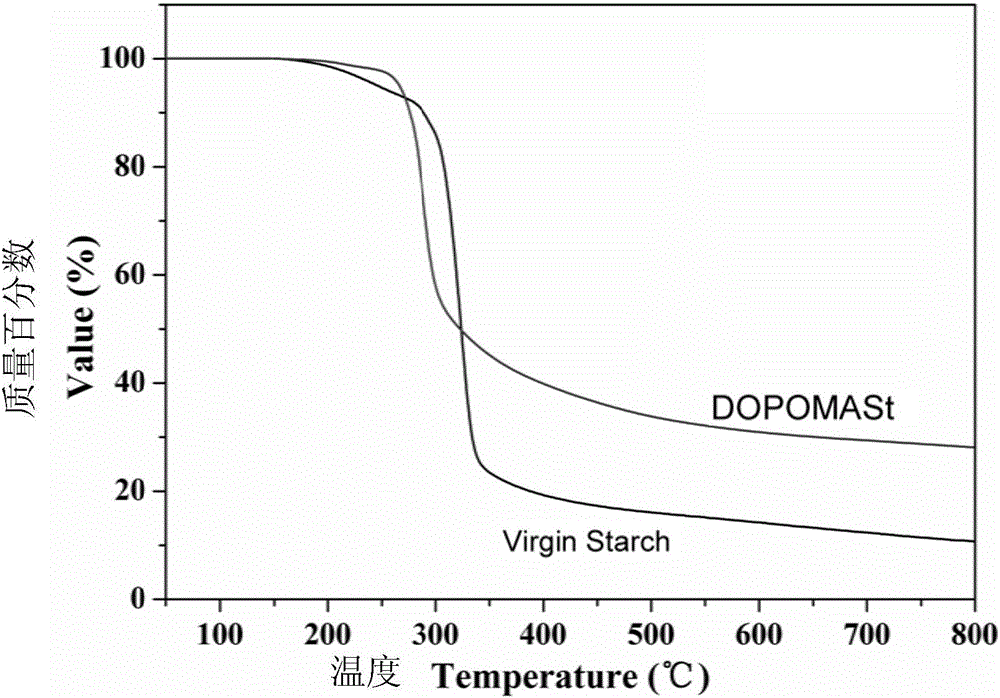

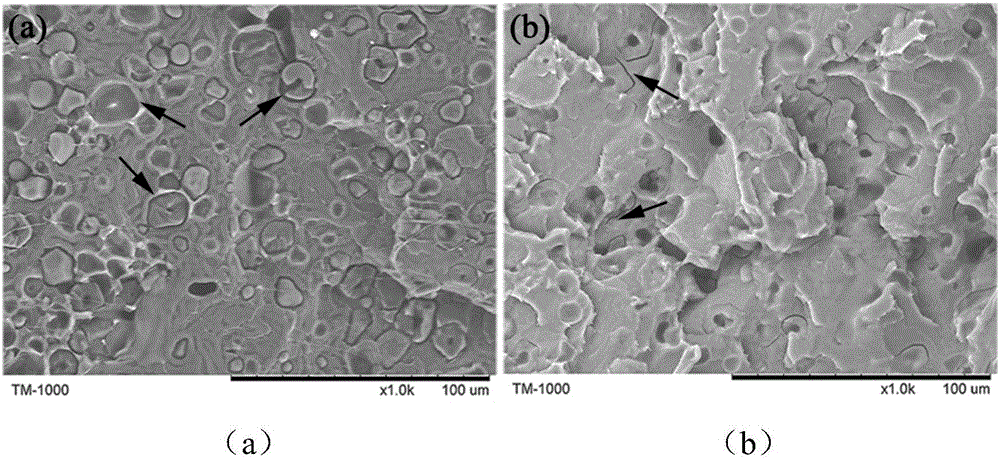

Polylactic acid/starch expansion flame-resistant composite material, and preparation method thereof

ActiveCN106496975AImprove charcoal abilityImprove high temperature thermal stabilityMaleic anhydrideChemistry

The invention discloses a polylactic acid / starch expansion flame-resistant composite material with excellent flame resistance, and a preparation method thereof. The polylactic acid / starch expansion flame-resistant composite material is composed of, by weight, 60 to 89% of polylactic acid, 5 to 30% of an acid source, 5 to 30% of a modified starch, and 1 to 15% of a gas source. In a preferred embodiment, the modified starch is phosphorized maleic anhydride grafting modified starch (bio-based phosphorus containing starch). According to the preparation method, polylactic acid possesses excellent compatibility with the modified starch; synergistic effect of the acid source, the carbon source (the modified starch), and the gas source is capable of improving charring forming capability of the polylactic acid matrix, and improving high temperature stability and flame resistance of polylactic acid greatly. According to the preparation method, adoption of an existing double-screw extruder is enough for production; preparation is simple and convenient; and the preparation method is convenient for industrial production.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

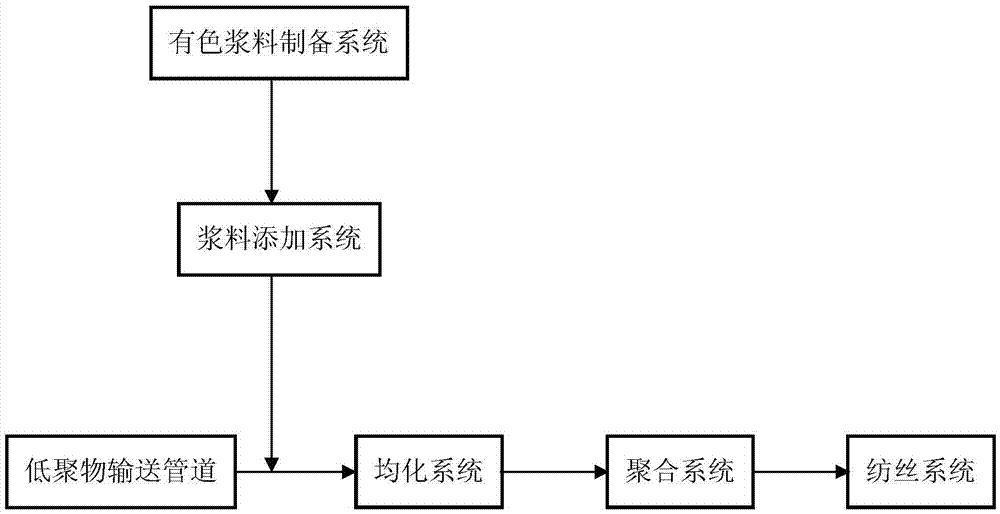

Method for preparing colored polyester fibers through stock solution coloring

ActiveCN105442078AEvenly dispersedHigh color fastnessPigment addition to spinning solutionMonocomponent polyesters artificial filamentPolyesterFiber

The invention discloses a method for preparing colored polyester fibers through stock solution coloring. The method comprises steps as follows: organic pigments are added to liquid-state dispersion media containing a stabilizer and sufficiently dispersed, and uniformly dispersed colored slurry is obtained; the colored slurry is added to polyester oligomer, the mixture is uniformly mixed for prepolymerization and final polycondensation reactions, polyester melts are obtained and subjected to direct spinning through a spinning manifold, and the colored polyester fibers are prepared; or colored polyester chips are firstly prepared, single-color polyester chips or various polyester chips with different colors are mixed and then subjected to indirect spinning according to demands, and the colored polyester fibers with the required color are prepared. The prepared colored slurry is stable at the normal temperature and has good compatibility with polyester; the pigments are uniformly dispersed in a polymerization system; after spinning and forming of the melts, a coloring agent is fixed in the fibers, and the color fastness of the product is high; different batches of the colored polyester fibers or the same batch of the colored polyester fibers basically don't have color difference, and the method is particularly suitable for large-scale continuous production.

Owner:SHANGHAI JUYOU CHEM ENG

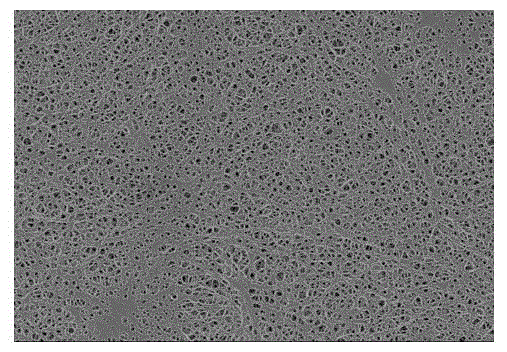

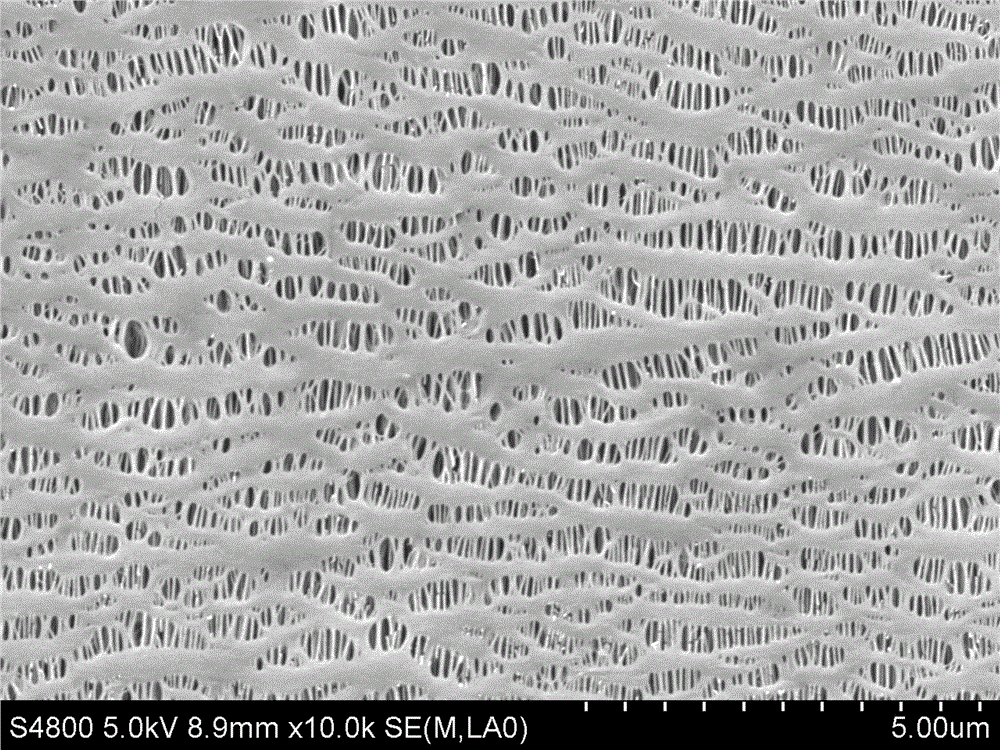

Porous inorganic coating/polyolefin microporous membrane compound diaphragm and preparation method thereof

InactiveCN102977394ADimensional stabilityImprove the safety of useCell component detailsCoatingsPolyolefinPre treatment

The invention relates to a porous inorganic coating / polyolefin microporous membrane compound diaphragm and a preparation method thereof. The preparation method provided by the invention comprises the following steps of: carrying out plasma surface pre-treatment on a polyolefin microporous membrane, so that multiple polar groups are connected to the surface of the polyolefin microporous membrane; coating the polyolefin microporous membrane subjected to the plasma surface pre-treatment by adopting an inorganic coating masking liquid to form a porous inorganic coating; and curing the inorganic coating. The compound diaphragm provided by the invention still has the characteristics and thermal closing function of a lithium ion transport channel as well as basic performances such as air permeability, ionic conductivity, acupuncture strength and tensile strength required by a lithium ion battery diaphragm, and high temperature thermal stability of the compound diaphragm is obviously improved.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

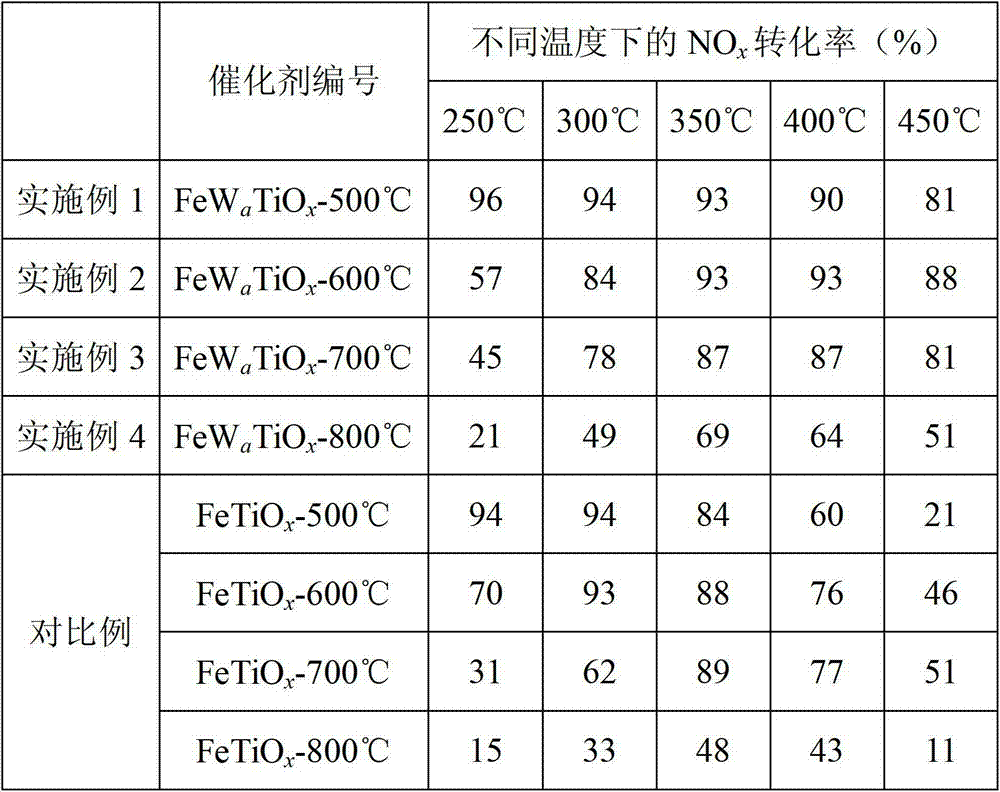

Iron-tungsten-titanium composite oxide catalyst, and preparation method and purpose thereof

ActiveCN103028420AGood dispersionOvercome CorrosivityDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsFiltrationComposite oxide

The invention relates to iron-tungsten-titanium composite oxide catalyst. The catalyst has the chemical composition of FeWaTiOx, wherein a is greater than 0 and less than or equal to 1.6. The invention further discloses a preparation method of the catalyst, which comprises the following steps: (1), preparing the solutions of Fe source, W source and Ti source in the presence of oxalic acid, and mixing the solutions of Fe source, W source and Ti source to obtain a mixed solution; and (2), adding excessive urea precipitation agent into the mixed solution to ensure that ions can be fully deposited, and carrying out suction filtration, washing, drying and baking to obtained sedimentation products to obtain the iron-tungsten-titanium composite oxide catalyst. Compared with iron-tungsten-titanium composite oxide catalyst without adulteration, the iron-tungsten-titanium composite oxide NH3-SCR catalyst has an obviously improved high-temperature thermal stability, and is easier to apply to catalysis and decontamination of NOx in heavy duty diesel exhaust.

Owner:RES CENT FOR ECO ENVIRONMENTAL SCI THE CHINESE ACAD OF SCI

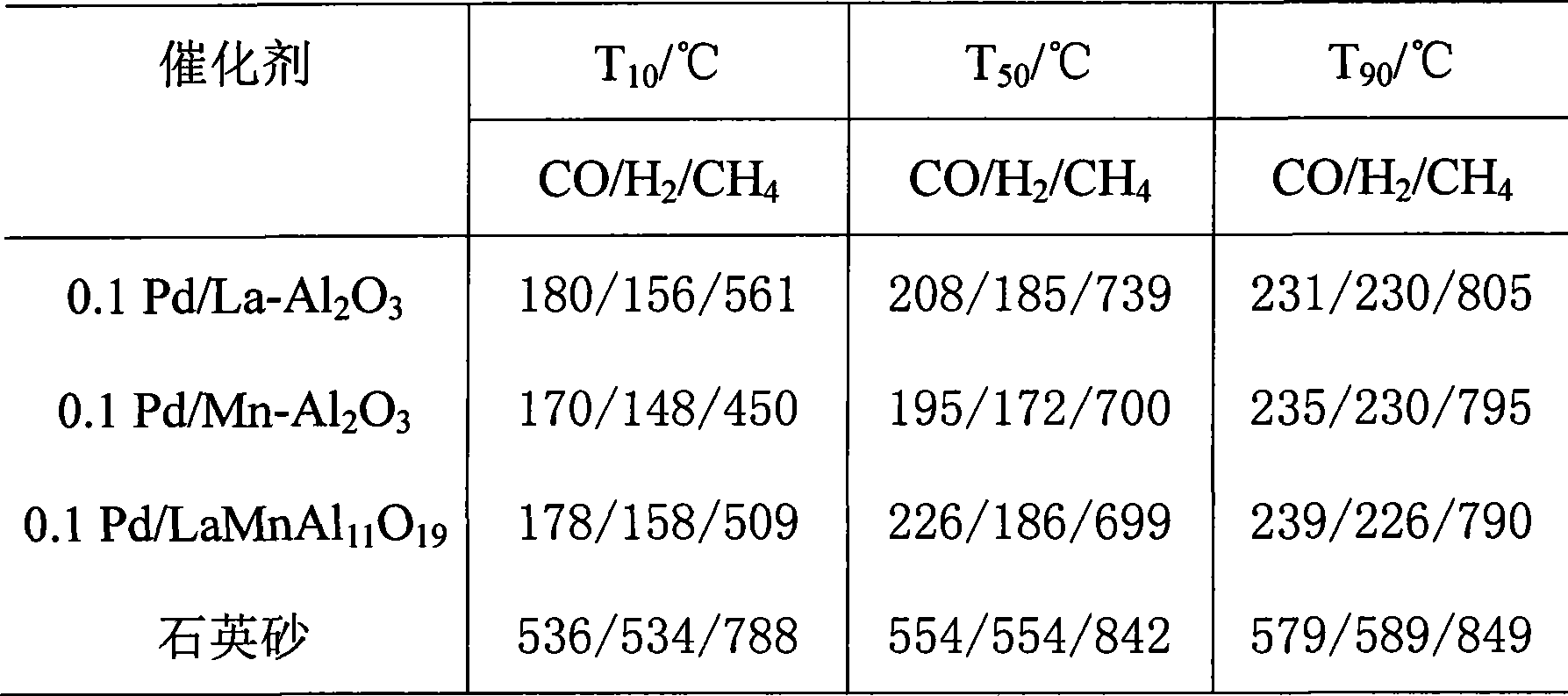

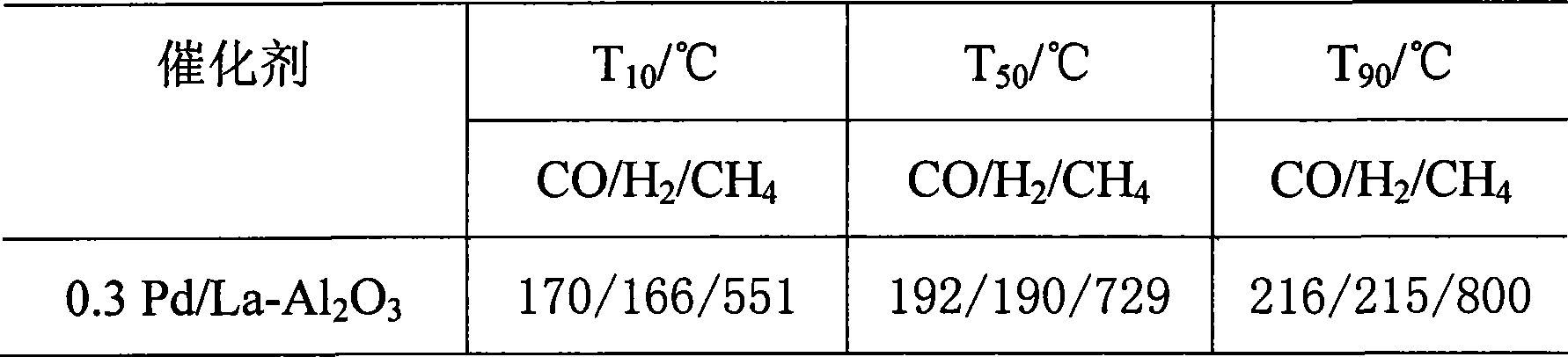

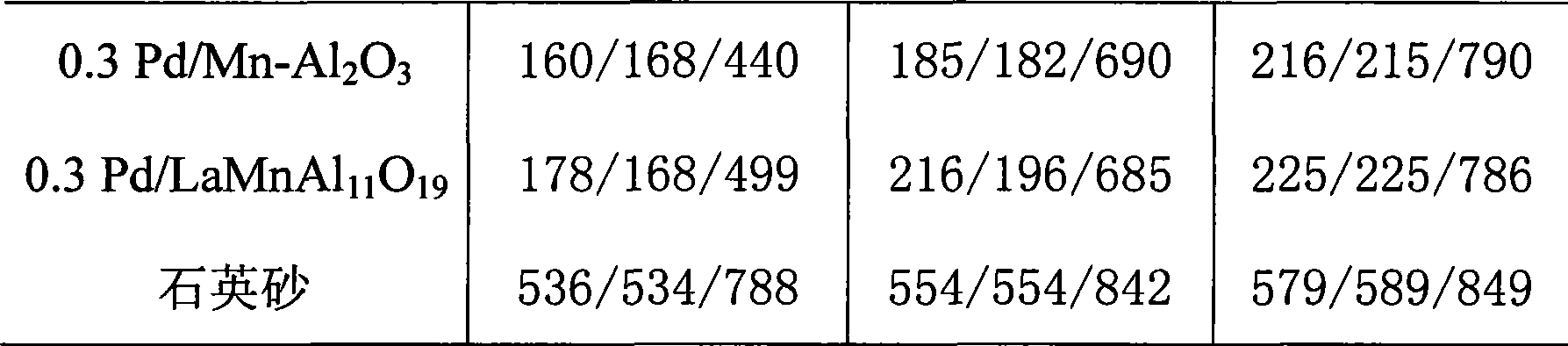

La, Mn modified Pd/gamma-Al2O3 catalyst and preparation method thereof

InactiveCN101518734AReduce loadLarge specific surface areaFuel additivesMetal/metal-oxides/metal-hydroxide catalystsNitrateManganese

The invention provides a La, Mn modified Pd / gamma-Al2O No.[3] catalyst. The catalyst comprises the following components by mass percentage: 60 to 80 percent of gamma-Al2O3, 19.9 to 39.5 percent of La or Mn or the combination of the La and the Mn, and the balance of noble metal Pd. The invention also provides a method for preparing the catalyst. The method comprises the following steps: evenly mixing manganese nitrate or lanthanum nitrate or a mixed solution of the manganese nitrate and the lanthanum nitrate with the gamma-Al2O3, and drying and baking the mixture to obtain an intermediate catalyst; and immersing the intermediate catalyst by a H2PdCl4 solution, then cleaning the intermediate catalyst until the intermediate catalyst does not contain Cl ions, and drying and baking the intermediate catalyst again to obtain the catalyst. The prepared catalyst has better low temperature activity and can be widely and industrially applied to the catalytic combustion of low heat value gas.

Owner:HUAZHONG UNIV OF SCI & TECH

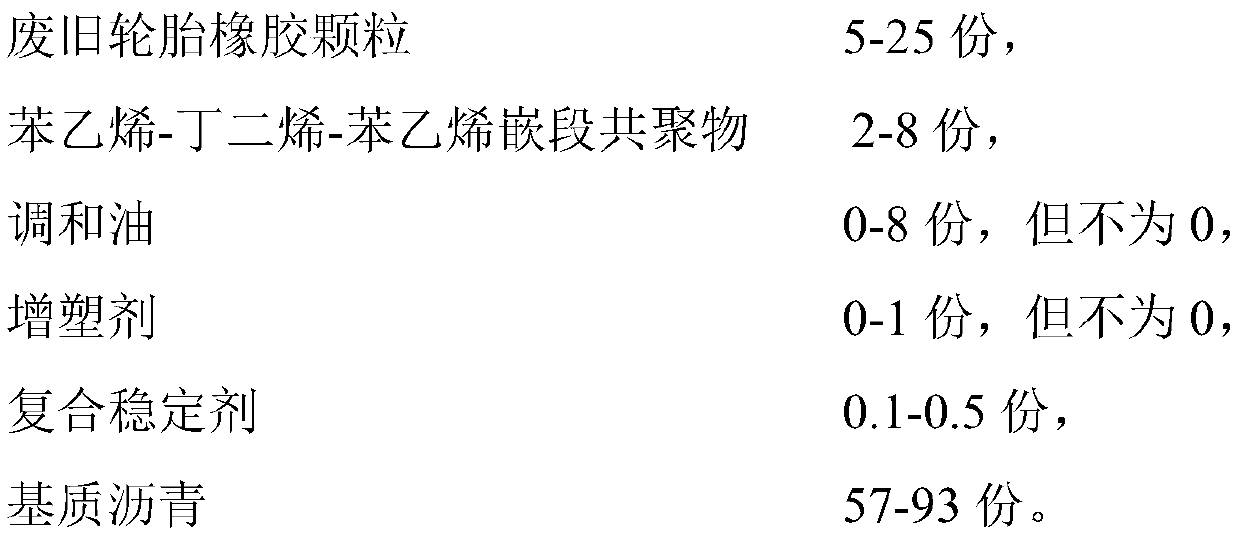

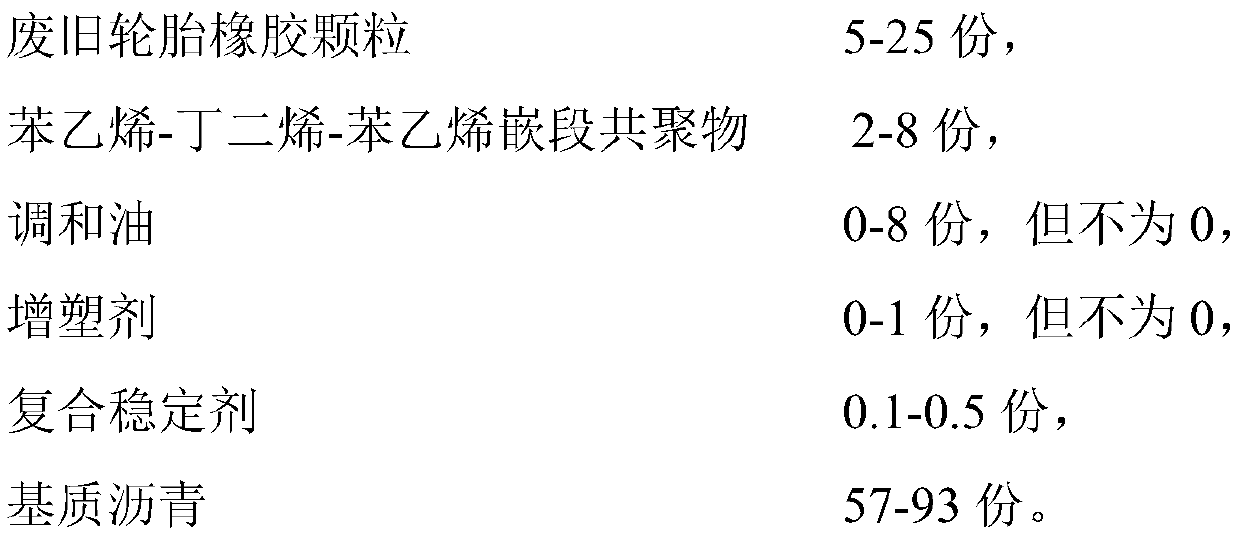

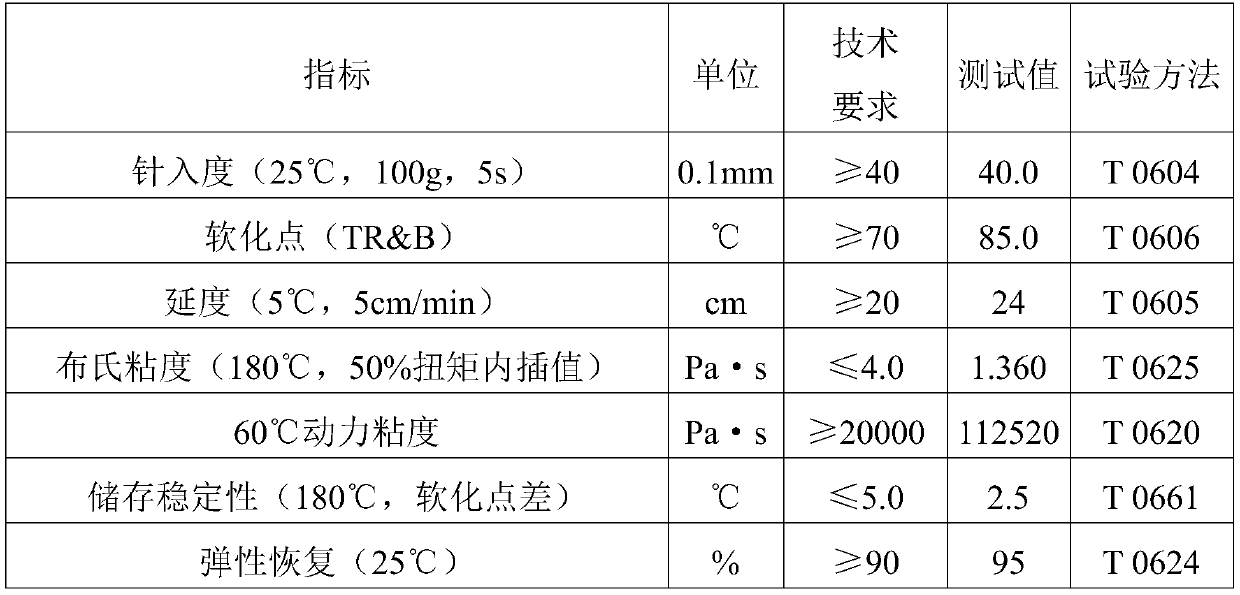

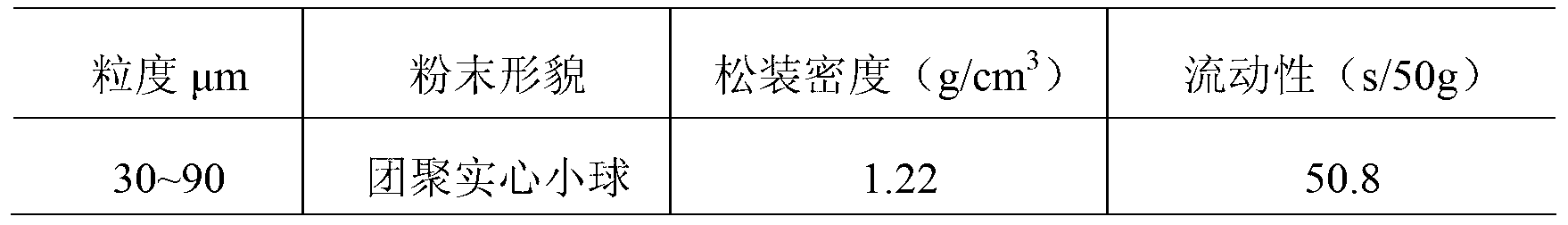

Compounded high-viscosity high-elasticity asphalt material and preparation method therefor

InactiveCN110452550AHigh viscosityIncreasing the thicknessBuilding insulationsPlasticizerBituminous materials

The invention relates to a compounded high-viscosity high-elasticity asphalt material and a preparation method therefor. The asphalt material is prepared from the following ingredients in parts by weight: 5-25 parts of waste tire rubber granules, 2-8 parts of styrene-butadiene-styrene block copolymer, 0-8 (but 0 is exclusive) parts of blend oil, 0-1 (but 0 is exclusive) part of plasticizer, 0.1-0.5 part of composite stabilizer and 57-93 parts of matrix asphalt. Compared with the prior art, the asphalt material prepared by the method has the advantages that the kinetic viscosity at the temperature of 60 DEG C is not smaller than 20,000Pa.s, the recovery of elasticity at the temperature of 25 DEG C is not smaller than 90%, the storage stability at the temperature of 180 DEG C is not greaterthan 4.0 DEG C, the asphalt material has good mechanical properties and storage stability, the high-temperature rut resistance of pervious asphalt concrete can be improved, the low-temperature frost heave resistance of the pervious asphalt concrete can also be improved, the durability of the pervious asphalt concrete is remarkably improved, and the service life of the pervious concrete is prolonged.

Owner:TONGJI UNIV +1

Cable scarfskin and preparation method thereof

InactiveCN103724788AImprove high temperature thermal stabilityLow costInsulated cablesInsulatorsMaleic anhydrideChemistry

The invention discloses a cable scarfskin which comprises the following materials in parts by weigh: ethylene-vinyl-acetate copolymer, magnesium hydroxide, aluminum hydroxide, maleic anhydride grafted ethylene- vinyl-acetate copolymer, maleic anhydride grafted polyethylene, silicone, silane, fillers, antioxygen 1010, zinc oxide, ferric oxide, epoxidized soybean oil, toner and polyethylene. The cable scarfskin has the characteristics of good flexibility, high impact resistance, high environmental stress resistance, and the like, by compounding EVA and PE. A flaw which can cause crack can not appear. Meanwhile, in order to overcome the defects of flammability, a plurality of auxiliaries, such as aluminum hydroxide and magnesium hydroxide, are added, thereby improving the fire resistance of the cable scarfskin. Materials comprising halide are not added, which makes the cable scarfskin have no halogen. The fillers are added to make the heat stability of the cable scarfskin good. The cable scarfskin can be used at 105 DEG C.

Owner:福建福硕线缆股份有限公司

Composite micro-nanometer zirconia-based high temperature abradable sealed coating material and preparation method thereof

InactiveCN103319920AImprove deposition efficiencyRelieve local stressPowdery paintsSpray GranulationHardness

The invention relates to a composite micro-nanometer zirconia-based high temperature abradable sealed coating material and a preparation method thereof, and the material is made by compositing a base-phase component A, a base-phase component B, a bonding component, a solid lubrication component and a poring component, wherein the content of each component, based on weight percentage, are as following: 60-70 wt% of base-phase component A, 15-20 wt% of base-phase component B, 5-15 wt% of bonding component, 1-3 wt% of solid lubrication component and 5-8 wt% of poring component; the coating material is obtained through fixing, spraying granulation and screening the components. The coating prepared by the invention has high deposition efficiency, strong high-temperature thermal stability, appropriate coating thickness and hardness, good abrasivity and bonding strength etc.

Owner:WUHAN UNIV OF TECH

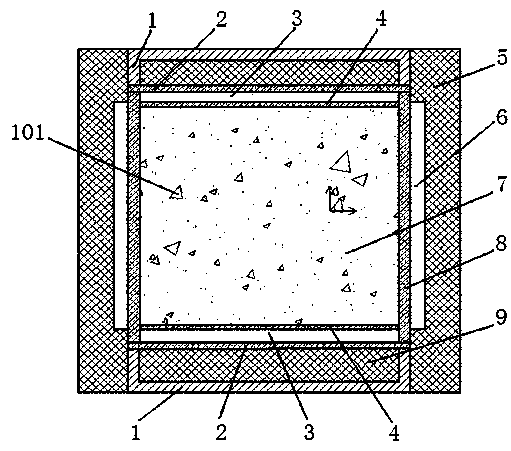

Non-loaded type deep-hydrogenation catalyst and preparation method thereof

ActiveCN105363460AEvenly dispersedImprove high temperature thermal stabilityMetal/metal-oxides/metal-hydroxide catalystsRefining to eliminate hetero atomsReactive siteActive component

The invention relates to a non-loaded type deep-hydrogenation catalyst and a preparation method thereof, and belongs to the field of catalyst preparation. The catalyst takes Ni and Mo as main active components and one or more of Zr, Zn, Al and Fe as an auxiliary active component; through BET-method determination, the catalyst has a mesoporous structure, and has the mesoporous diameter of 5.0-7.0 nm and the specific surface area of 100-300 m<2> / g. With combination of characteristics of simple operation of a precipitation method and catalyst thermal stability improvement of a hydrothermal synthesis method, the defects of long period, low metal utilization rate and high cost are overcome, the obtained catalyst not only has more metal active sites, but also has the hydrothermal stability improved. In the preparation process of the catalyst, no other binders are used, the preparation process is simplified, and the cost of the catalyst is reduced.

Owner:CHAMBROAD CHEM IND RES INST CO LTD

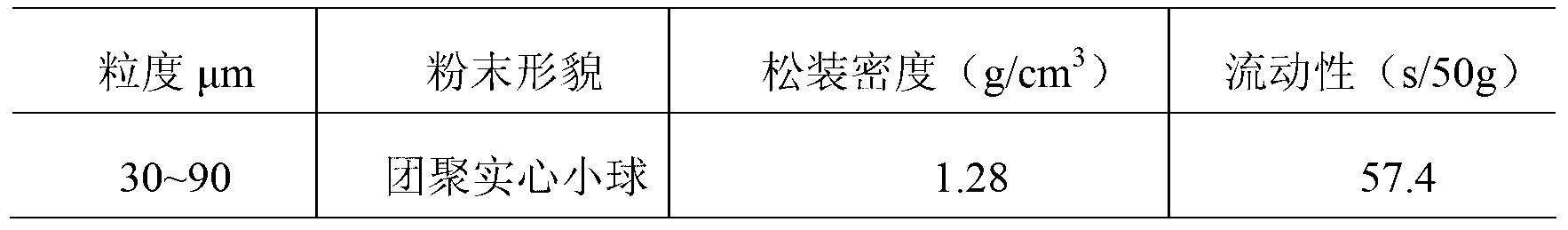

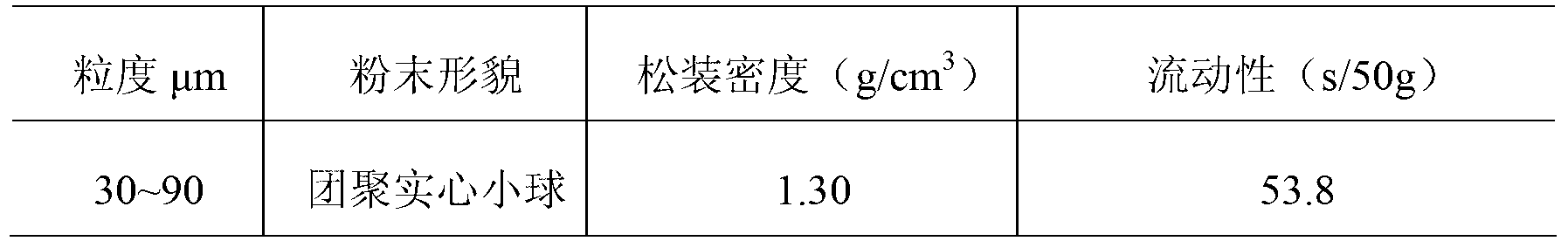

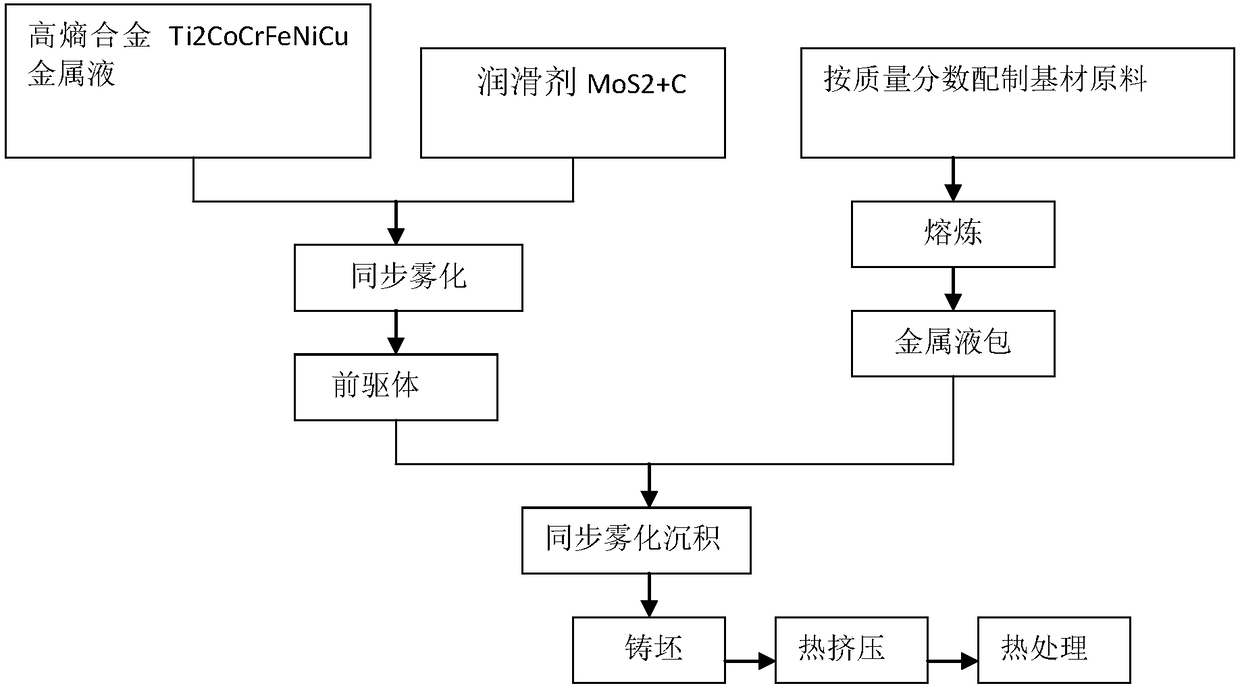

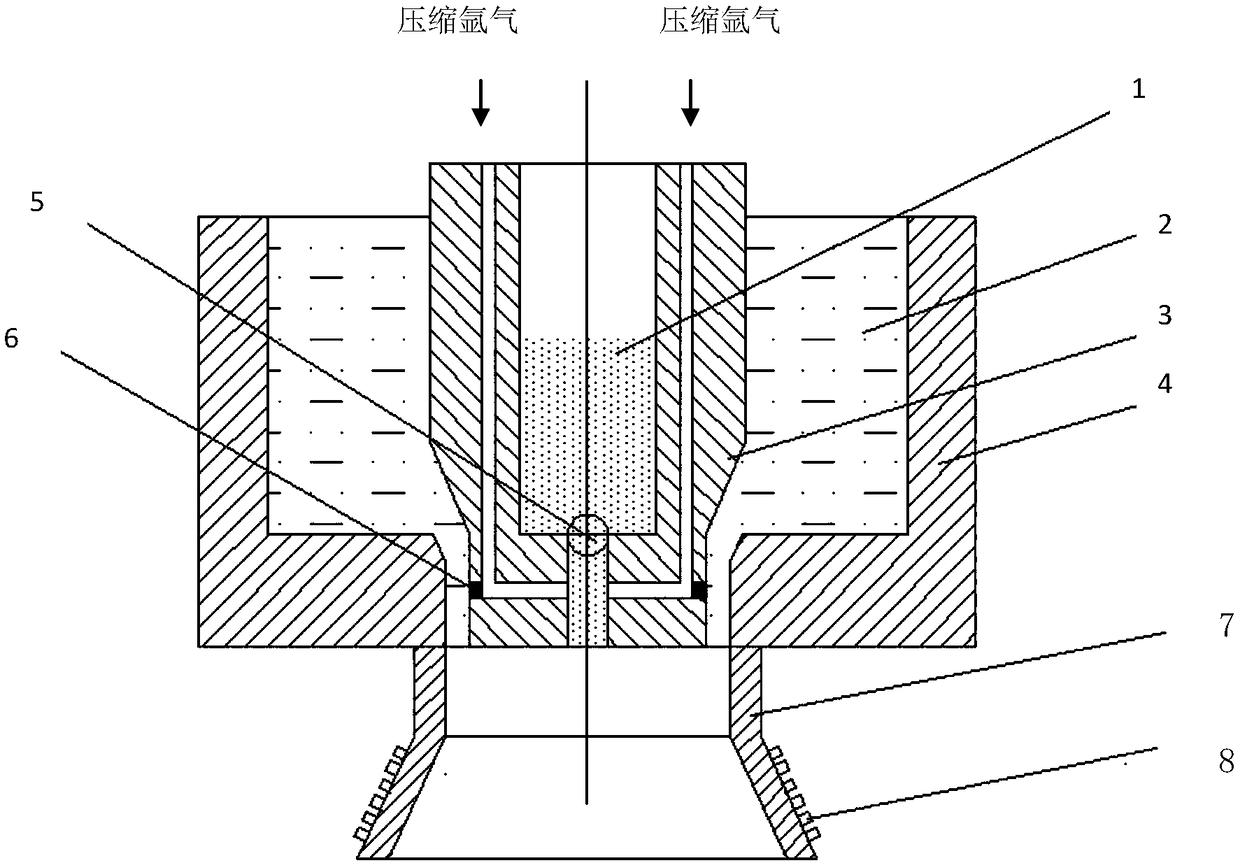

Aluminum alloy composite material with solid self-lubrication and preparation method thereof

ActiveCN108588501AImprove wear resistanceImprove the lubrication effectAdditive manufacturing apparatusDrilling rodsHigh entropy alloysAlloy composite

The invention discloses an aluminum alloy drill rod composite material with solid self-lubrication and a preparation method. The composite material consists of two parts: a substrate and a precursor,wherein the substrate comprises the following components in percentage by mass: 3.8-4.9% of Cu, 1.2-1.8% of Mg, 0.30-0.90% of Mn, and the balance of Al. The precursor is 20-30% of the substrate by mass; and the precursor is formed by a high-entropy alloy Ti2CoCrFeNiCu coating MoS2+C particles. The preparation method comprises the following steps: the precursor is prepared; the raw materials of thesubstrate are prepared; then, the precursor is injected in a solid particle fluidizing conveyor of spraying deposition equipment; finally, the raw materials of the substrate are molten by a cruciblesmelting furnace for flowing to a metal liquid pocket; and metal liquid and the precursor are synchronously atomized to form a solid-liquid atomization mixture for deposition to obtain a wear-resistance composite material casting blank with self-lubrication for extrusion molding.

Owner:JIANGSU UNIV OF TECH

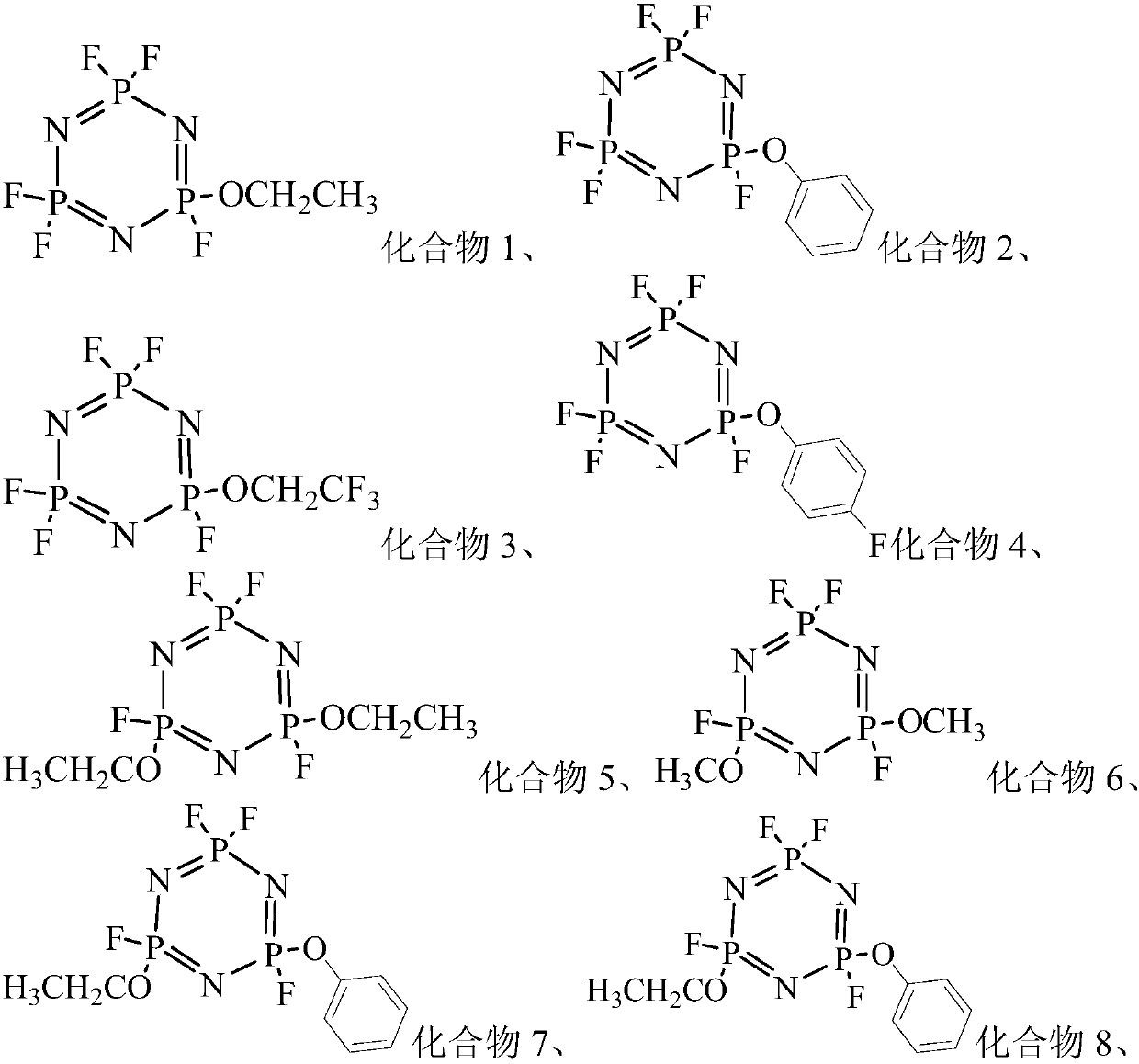

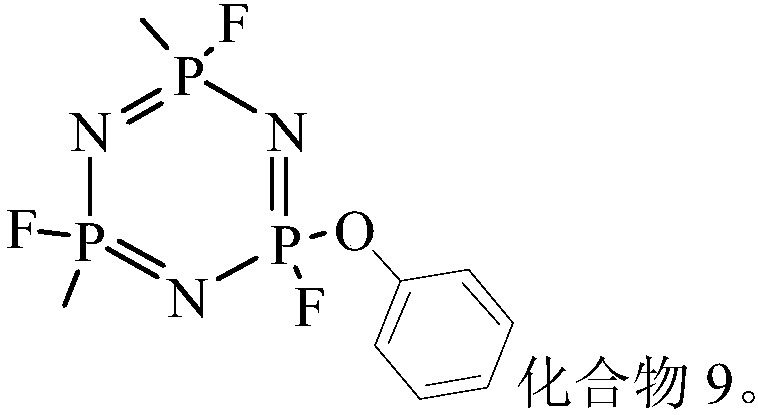

Electrolyte and secondary battery

ActiveCN107871889AImprove normal temperature cycle performanceImprove high temperature storage performanceSecondary cellsOrganic electrolytesOrganic solventEthylene carbonate

The invention provides an electrolyte and a secondary battery. The electrolyte comprises an electrolyte salt, an organic solvent and an additive. The additive comprises a cyclotriphosphazene compoundand vinyl ethylene carbonate. When the electrolyte is applied to a secondary battery, the normal temperature cycle performance, high temperature storage performance and high temperature thermal stability of the secondary battery can be improved simultaneously.

Owner:CONTEMPORARY AMPEREX TECH CO

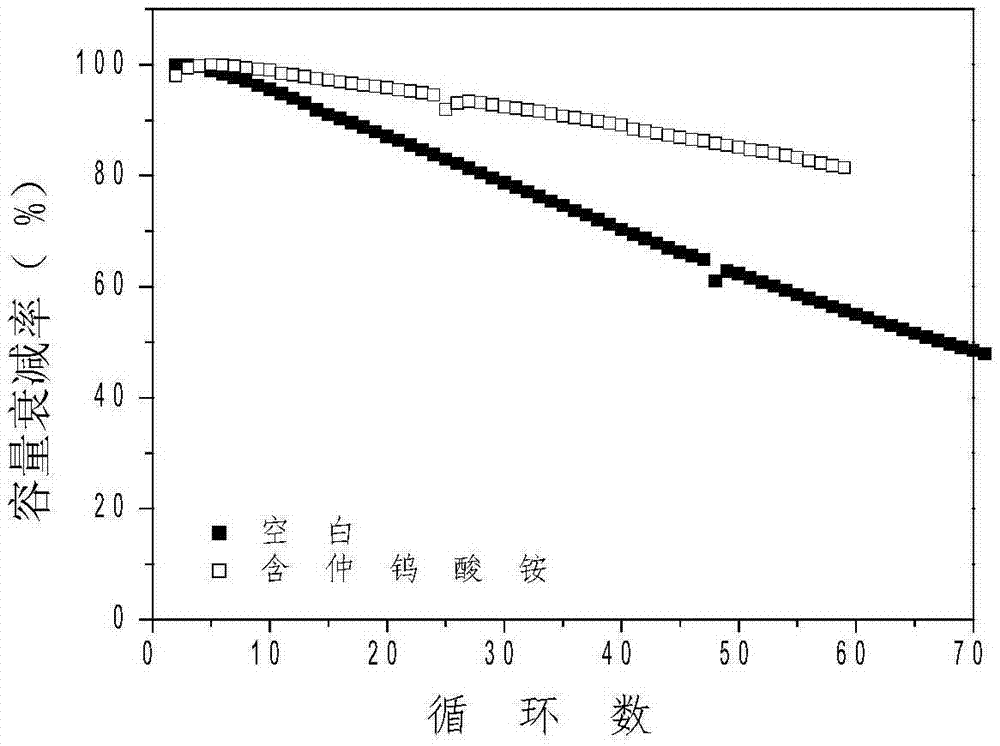

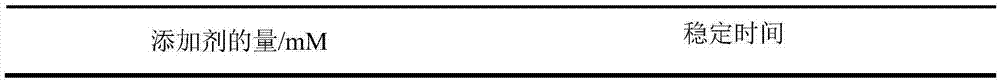

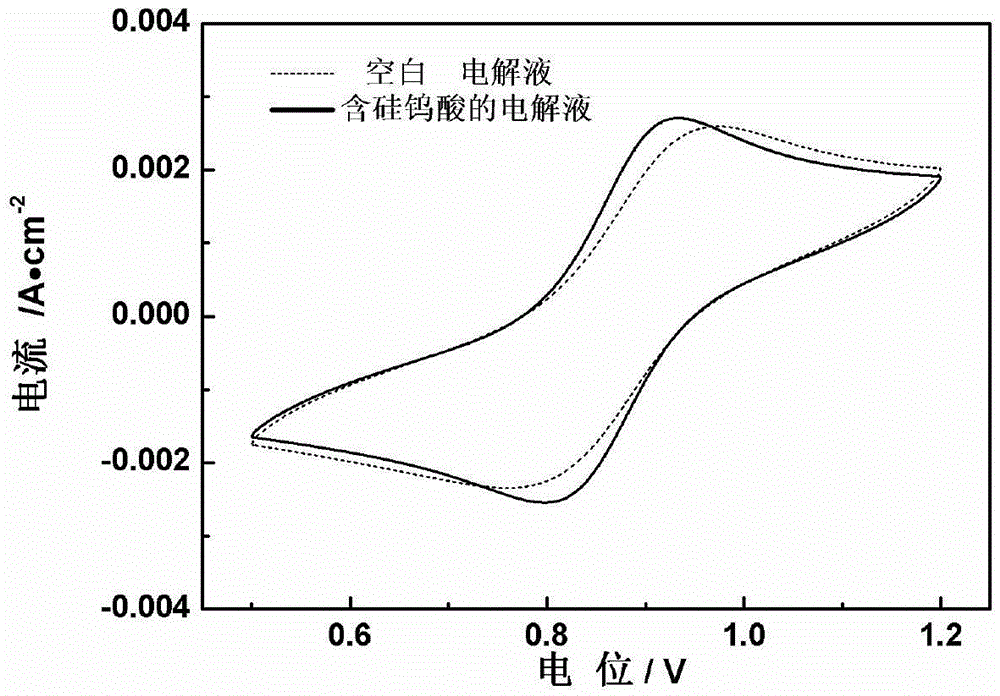

All-vanadium redox flow battery cathode electrolyte containing additive

ActiveCN106876767AImprove high temperature thermal stabilityImprove coordination environmentCell electrodesRegenerative fuel cellsTungstateAmmonium paratungstate

The invention relates to an all-vanadium redox flow battery cathode electrolyte containing additive. The additive is one or more than two of ammonium tungstate, ammonium molybdate, ammonium niobate, ammonium tantalite, ammonium paratungstate, ammonium paramolybdate, ammonium paraniobate, ammonium metatungstate, ammonium metamolybdate, ammonium metaniobate, ammonium dimolybdate, ammonium tetramolybdate and ammonium fluoroniobate. The concentration of the additive is 0.01mol / L-0.5mol / L. According to the electrolyte, salt is taken as the cathode electrolyte additive, so the capacity fading problem generated when a battery operates under a high temperature condition can be effectively suppressed, and the stable operation of the battery is realized. The electrolyte is simple in preparation technology operation and low in cost, is energy-saving and environment-protective and can operate in the battery stably.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

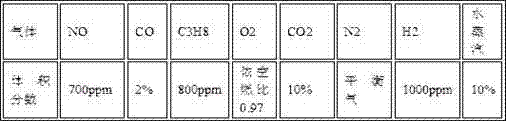

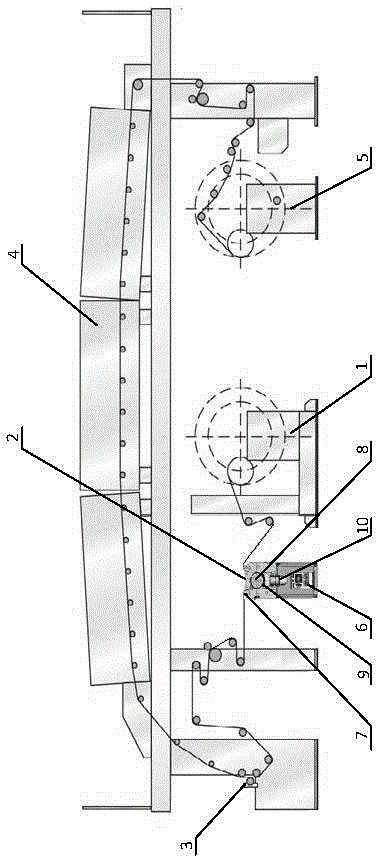

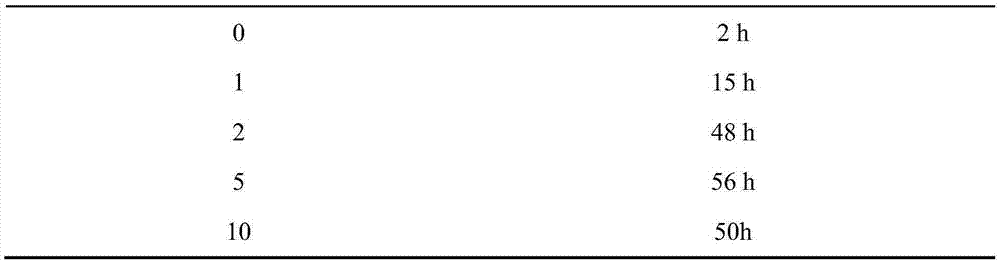

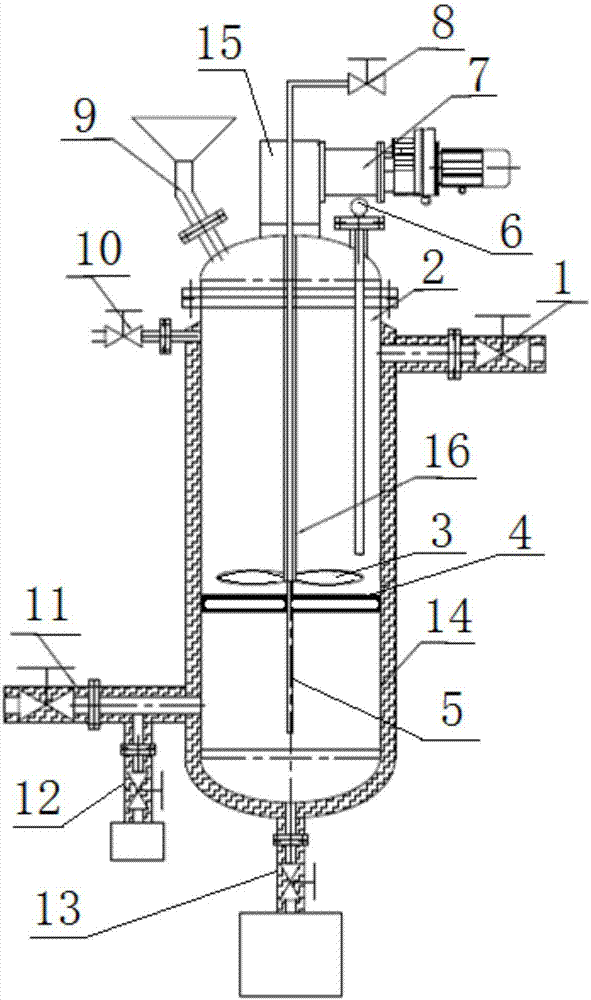

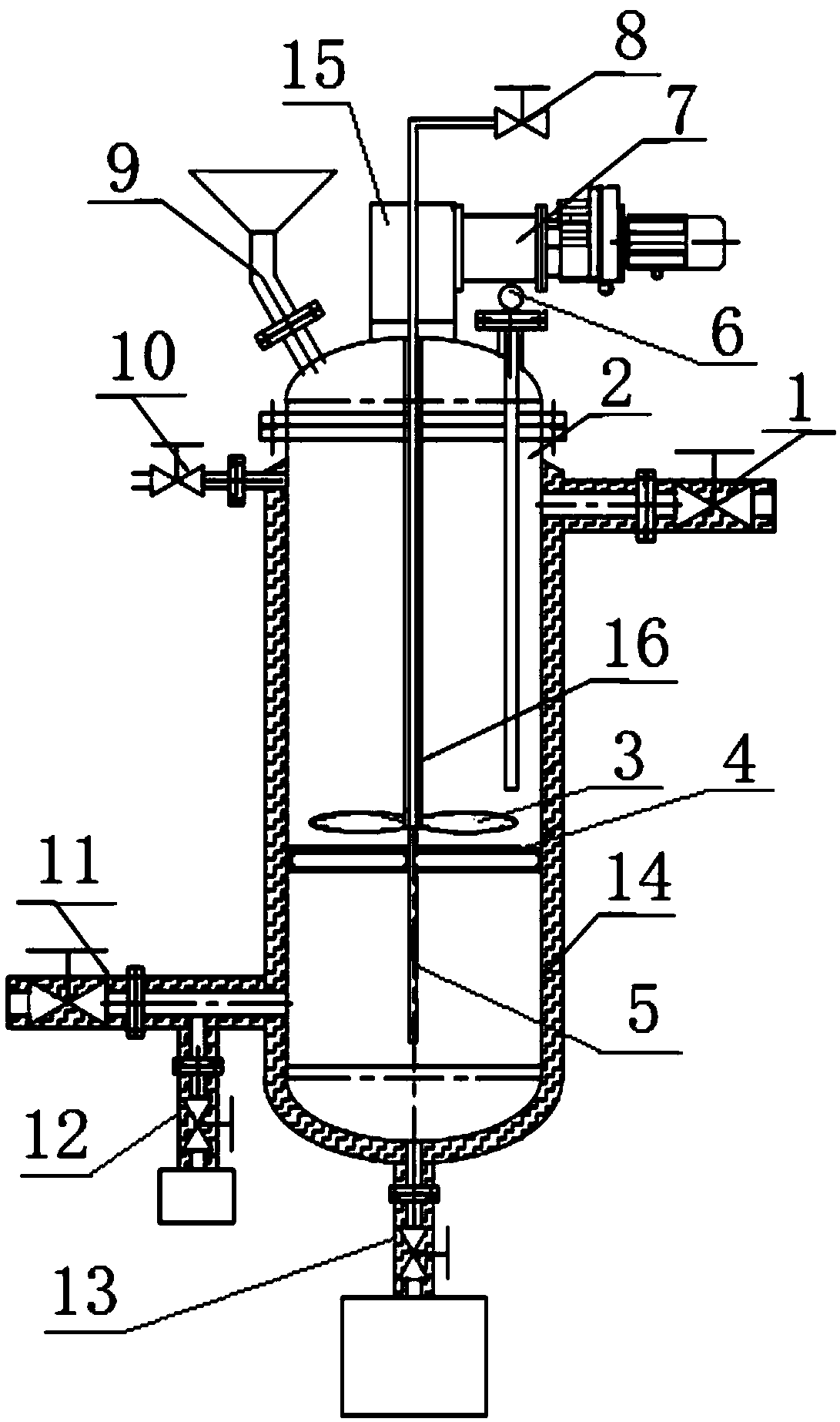

High-temperature liquid-state nitrate purification and performance enhancement fusing tank

ActiveCN106861582AImprove high temperature thermal stabilityLess corrosiveNitrogen compoundsChemical/physical/physico-chemical stationary reactorsNitratePerformance enhancement

The invention relates to a high-temperature liquid-state nitrate purification and performance enhancement fusing tank. A filtering plate (4) is horizontally arranged inside a tank body (2), a hollow stirring rod (16) is arranged in the middle of the top of the tank body (2) towards the tank body (2), the lower end of the hollow stirring rod (16) is positioned on the upper side of the filtering plate (4), a stirring paddle (3) is arranged on the lower end of the hollow stirring rod (16), the lower end of the hollow stirring rod (16) is connected with a bubbler (5) which downwards penetrates through the filtering plate (4). Dry air, carbon dioxide and nitrogen gas are sequentially fed, the stirring paddle (3) is used for stirring while the bubbler (5) conducts gas introduction, and through the coordinated and reasonable structure arrangement of the stirring paddle and the bubbler and by bubbling, stirring, filtering, additive addition and the like under the high-temperature melting state, the purification function of high nitrate can be realized, the impurity removal and purification rate of the fused salt is up to 97%, the high-temperature thermal stability of nitrate can be enhanced, and the corrosivity of nitrate can be reduced. The stirring and homogenization time is short, and the high-temperature liquid-state nitrate purification and performance enhancement fusing tank is energy-saving, environment-friendly, safe and high in efficiency.

Owner:上海煜志科技有限公司

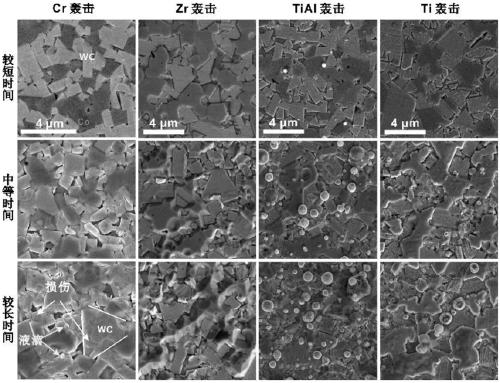

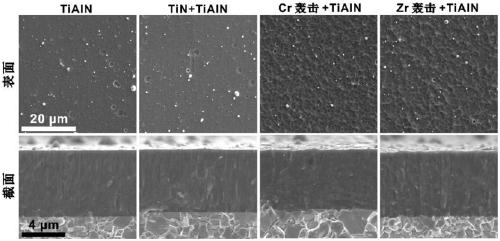

TiAlN hard coating and preparing method and application thereof

ActiveCN109666887AGuaranteed bondingAvoid introducingVacuum evaporation coatingSputtering coatingEtchingPower flow

The invention belongs to the field of coating materials, and discloses a TiAlN hard coating and a preparing method thereof. The method comprises the steps that polishing ultrasonic cleaning is conducted on a hard alloy matrix, after blow-drying and dust removing, the hard alloy matrix is placed in a film plating machine cavity, the cavity is heated, the temperature is increased to 400-600 DEG C, the vacuum degree of the cavity is 1-6 x 10 <-3> Pa, cooling is conducted to 300-400 DEG C, and the temperature is kept constant; inflation of Ar gas is conducted, bias pressure is loaded to a workpiece rotating stand, and the surface of the matrix is subjected to glow cleaning; the flow of the Ar gas is adjusted, the air pressure of the cavity is controlled, a Zr target is ignited through the cathode arc evaporative deposition method, the current of the Zr target and the bias pressure of the workpiece rotating stand are set, and metal ion etching is conducted on the matrix; an Ar gas valve isclosed, inflation of N2 is conducted, the air pressure of the cavity and the bias pressure of the workpiece rotating stand are adjusted, a Ti50Al50 target is ignited, the current of the Ti50Al50 target is adjusted, and the TiAlN hard coating is deposited on the surface of the matrix. The TiAlN hard coating has high heat stability and matrix bonding force.

Owner:GUANGDONG UNIV OF TECH

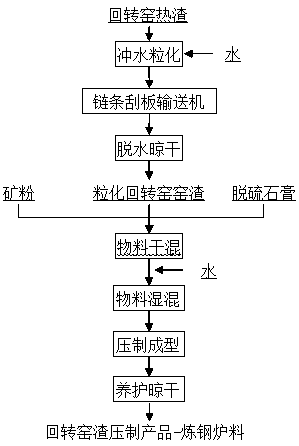

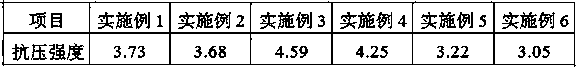

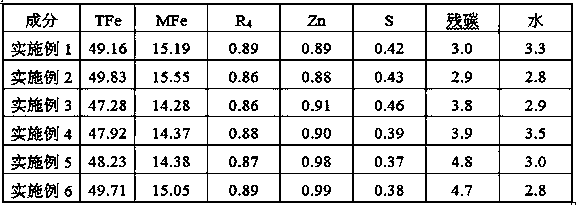

Method for preparing steel-making furnace burden from blast furnace gas dust zinc-extraction kiln slag

ActiveCN111118238AHigh yieldNo increase in steelmaking costsRecycling and recovery technologiesProcess efficiency improvementSteelmakingMixed materials

The invention relates to a method for preparing steel-making furnace burden from blast furnace gas dust zinc-extraction kiln slag. The method comprises the following steps: a, flushing and pelletizing: flushing, flaming out and pelletizing after blast furnace gas dust zinc-extraction rotary kiln hot slag drops from a kiln head, and sinking the slag to the bottom of a slag bath; b, dehydrating anddrying in air: transferring out the pelletized kiln slag cooled on the bottom of the slag bath, and naturally drying the slag after the slag is dehydrated, thereby obtaining the pelletized rotary kilnslag; c, material dry-mixing: weighing the pelletized rotary kiln slag, mineral powder and desulfurized gypsum in a mass ratio being (400-650) to (16-26) to (2-6), and uniformly mixing; d, material wet-mixing: adding water into the uniformly mixed material of the pelletized rotary kiln slag, the mineral powder and the desulfurized gypsum to uniformly mix; and e, pressing and forming, and curing and drying in air: naturally curing after de-moulding, thereby obtaining a rotary kiln slag pressed product, namely steel-making furnace burden. The method can realize cyclic utilization of the blast furnace gas dust zinc-extraction kiln slag, avoids the problems of high energy consumption and secondary pollution of a ball-milling and magnetic-separating process, improves recovery efficiency, and also reduces converter steel-making cost.

Owner:HANDAN IRON & STEEL GROUP +1

Purification and Performance Enhancement of High Temperature Liquid Nitrate Molten Salt Tank

ActiveCN106861582BImprove high temperature thermal stabilityLess corrosiveNitrogen compoundsChemical/physical/physico-chemical stationary reactorsNitratePerformance enhancement

The invention relates to a high-temperature liquid-state nitrate purification and performance enhancement fusing tank. A filtering plate (4) is horizontally arranged inside a tank body (2), a hollow stirring rod (16) is arranged in the middle of the top of the tank body (2) towards the tank body (2), the lower end of the hollow stirring rod (16) is positioned on the upper side of the filtering plate (4), a stirring paddle (3) is arranged on the lower end of the hollow stirring rod (16), the lower end of the hollow stirring rod (16) is connected with a bubbler (5) which downwards penetrates through the filtering plate (4). Dry air, carbon dioxide and nitrogen gas are sequentially fed, the stirring paddle (3) is used for stirring while the bubbler (5) conducts gas introduction, and through the coordinated and reasonable structure arrangement of the stirring paddle and the bubbler and by bubbling, stirring, filtering, additive addition and the like under the high-temperature melting state, the purification function of high nitrate can be realized, the impurity removal and purification rate of the fused salt is up to 97%, the high-temperature thermal stability of nitrate can be enhanced, and the corrosivity of nitrate can be reduced. The stirring and homogenization time is short, and the high-temperature liquid-state nitrate purification and performance enhancement fusing tank is energy-saving, environment-friendly, safe and high in efficiency.

Owner:上海煜志科技有限公司

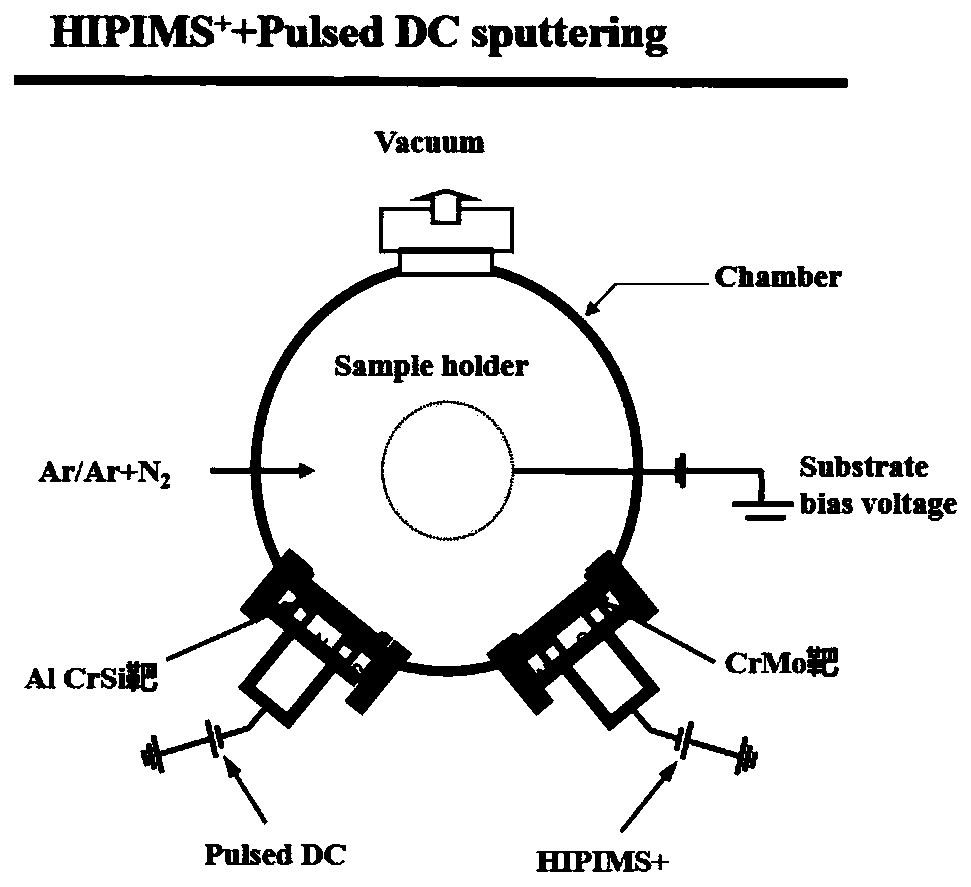

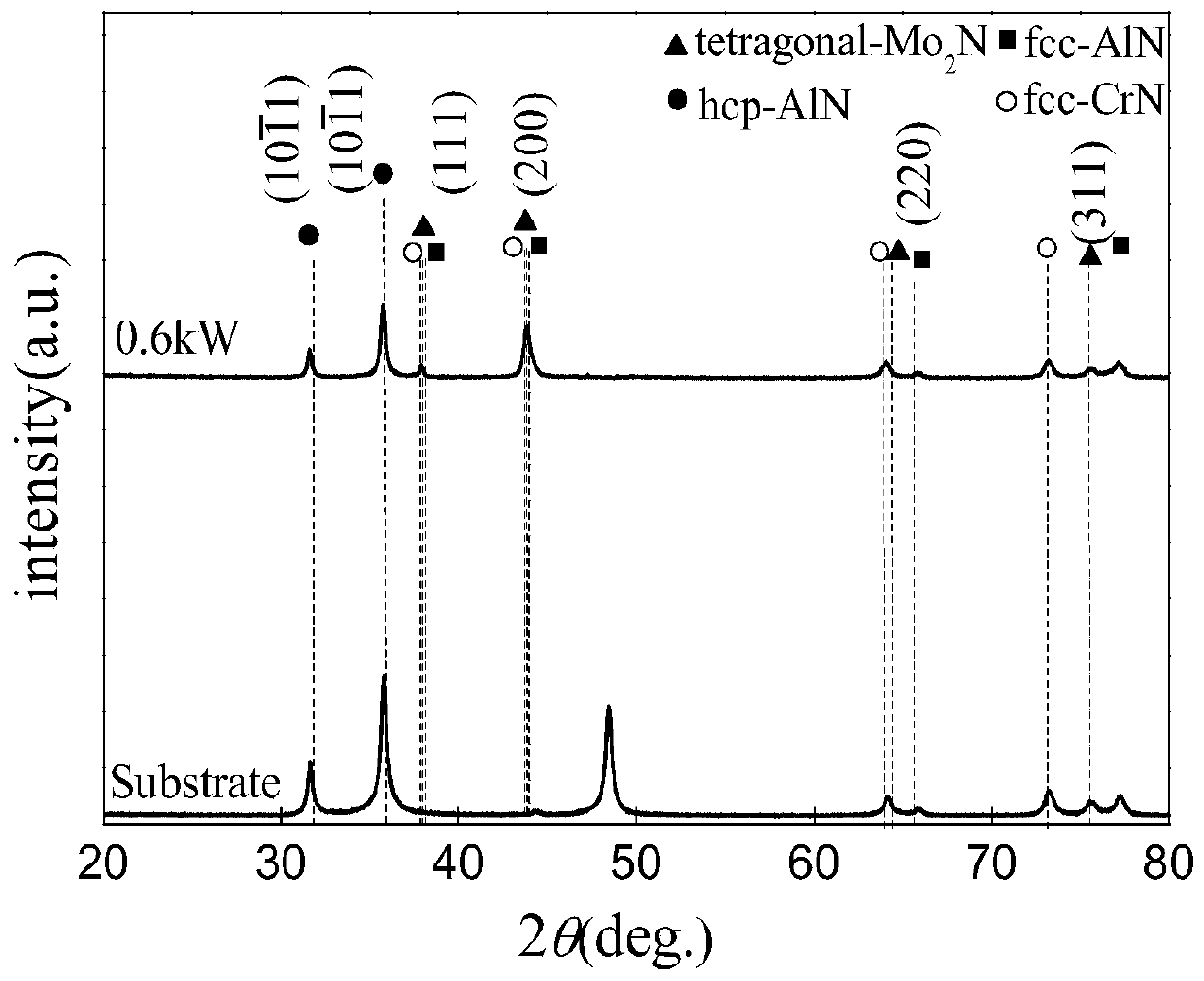

Mo-doped AlCrSiN/Mo self-lubricating film and preparation method thereof

InactiveCN110607499AIncreased resistance to dislocation movementImprove performanceVacuum evaporation coatingSputtering coatingMo elementHardness

The invention discloses a Mo-doped AlCrSiN / Mo self-lubricating film and a preparation method of the Mo-doped AlCrSiN / Mo self-lubricating film, and belongs to the technical field of films and preparation of the films. The AlCrSiN / Mo self-lubricating film is formed by doping Mo elements into a AlCrSiN film, the doping amount of the Mo elements is 0.3-6.3at.%, and the film is prepared on a substrateby adopting a high-power pulse magnetron sputtering technology and a pulse direct current magnetic control coating technology. The prepared AlCrSiN / Mo self-lubricating film is high in hardness, good in toughness, excellent in wear reduction property and capable of remarkably reducing friction between a cutter and chip, and has good chemical stability and easy-to-shear lubricating property.

Owner:TIANJIN UNIV OF TECH & EDUCATION TEACHER DEV CENT OF CHINA VOCATIONAL TRAINING & GUIDANCE

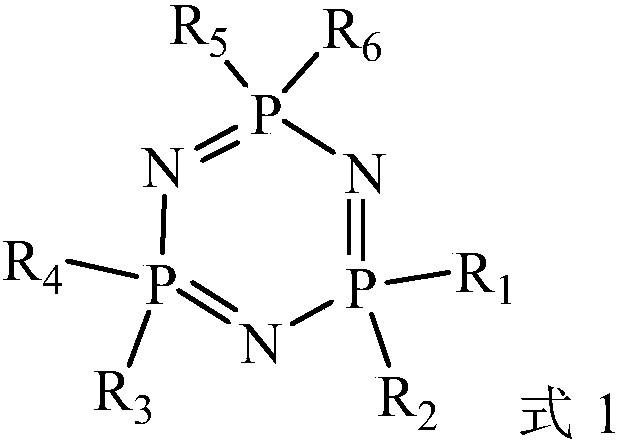

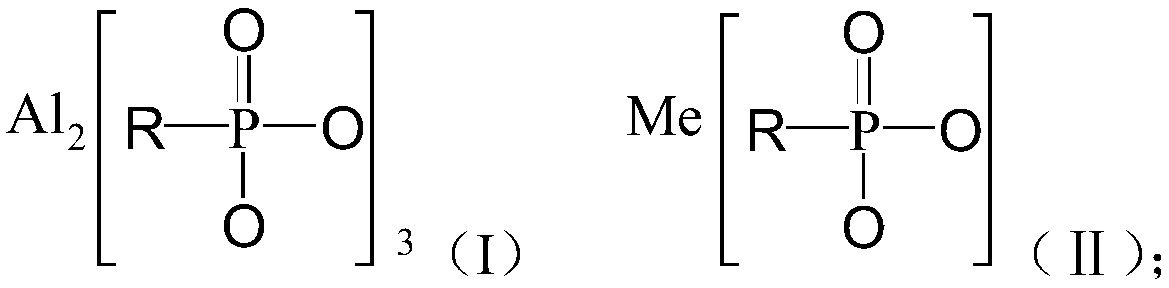

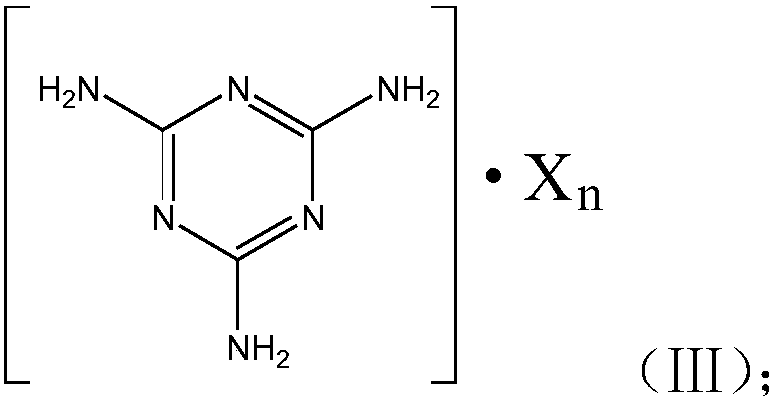

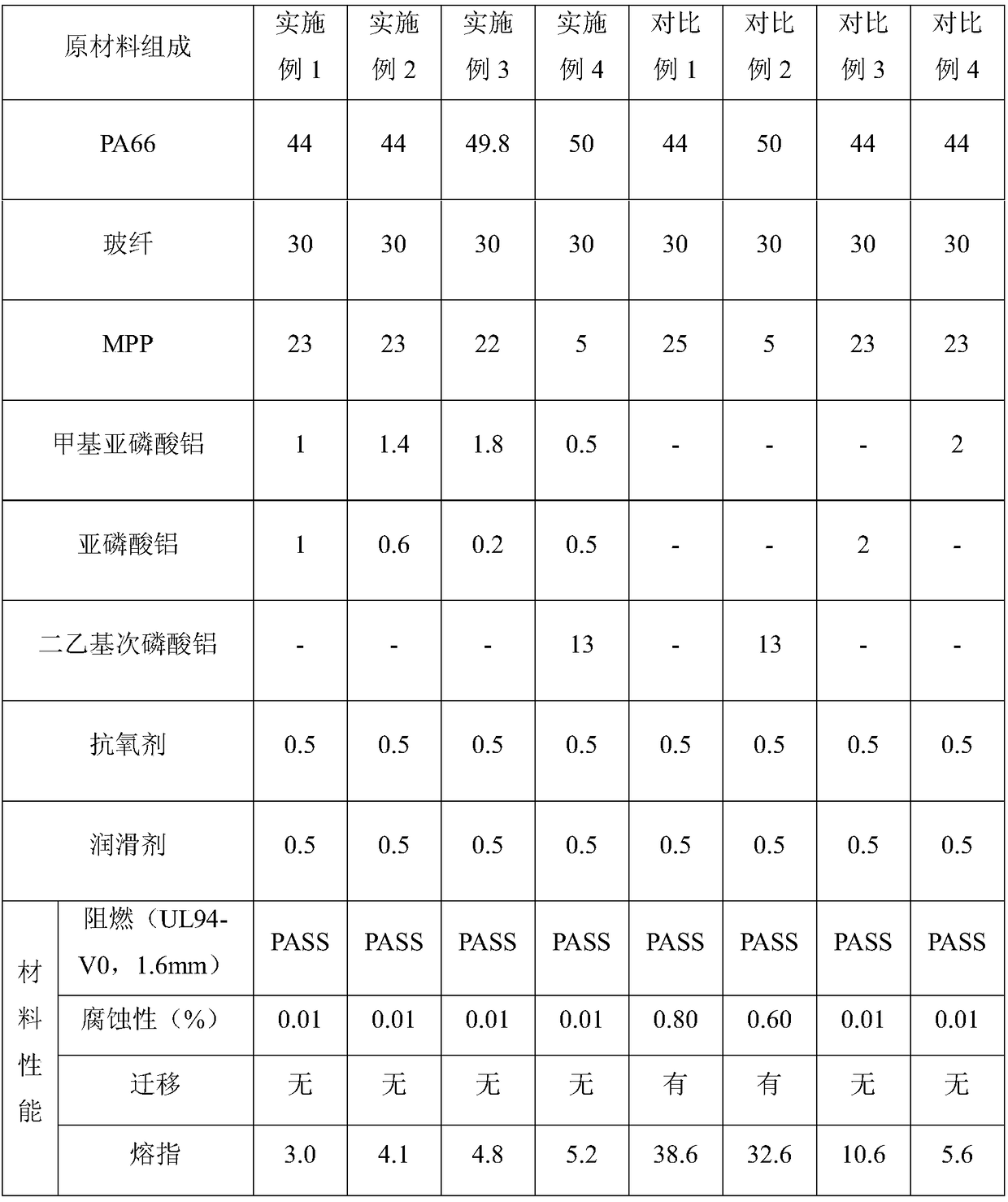

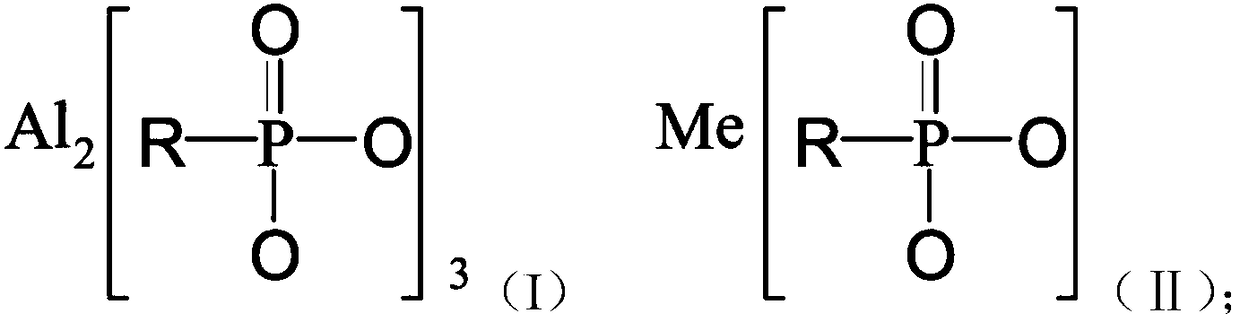

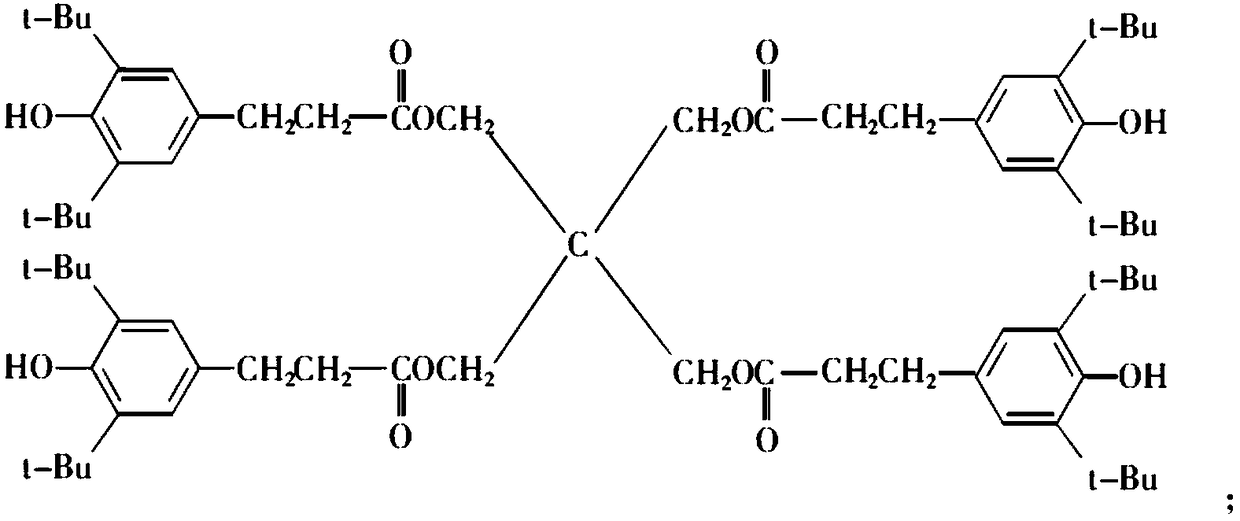

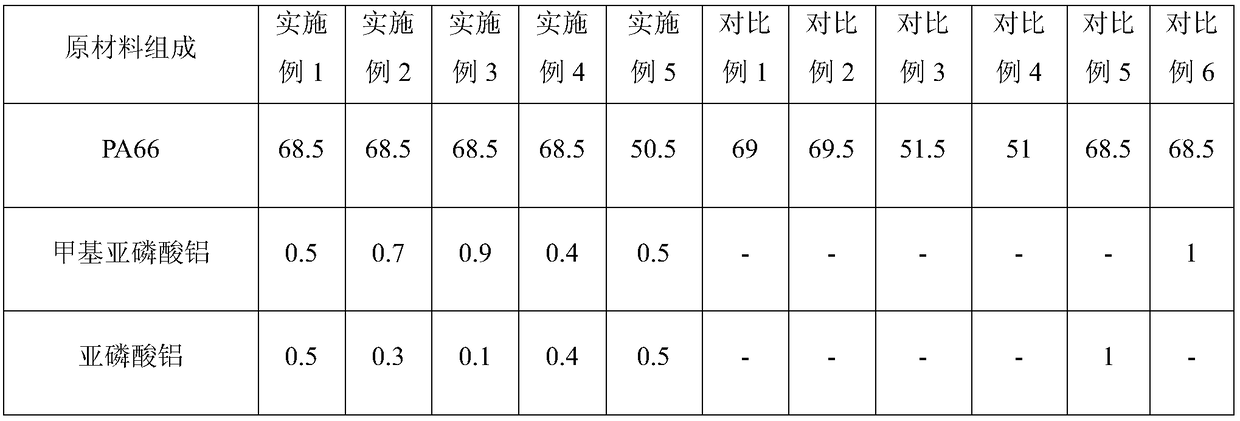

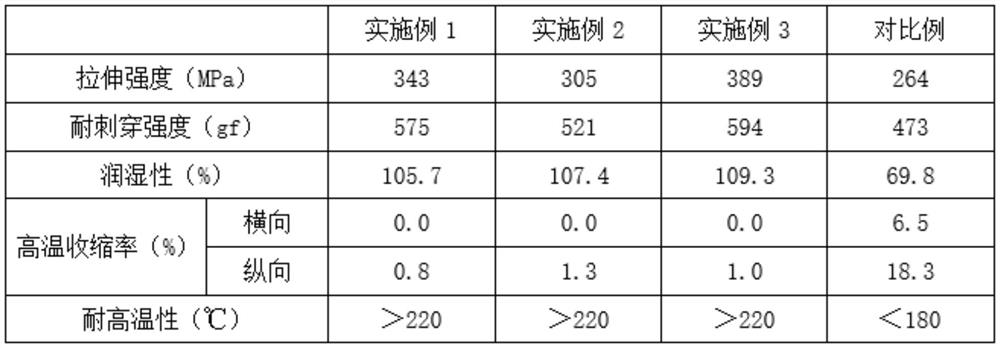

Method for promoting high temperature heat stability of melamine derivative fire retardant by utilizing inorganic and alkyl metallic phosphites, product and application thereof

ActiveCN109181293AImprove high temperature thermal stabilityHigh thermal decomposition temperatureDecompositionHeat stability

The invention discloses a method for promoting high temperature heat stability of a melamine derivative fire retardant by utilizing inorganic and alkyl metallic phosphites. The method comprises the step of adding a compound of inorganic metallic phosphite and alkyl metallic phosphite into raw materials; the addition of the compound is 0.1-40%, on the basis of the total weight of the melamine derivative fire retardant; the weight ratio of inorganic metallic phosphite to alkyl metallic phosphite is at 1:(1-10); the structural formula of alkyl metallic phosphite is shown by formula (I) or (II); Ris selected from straight chain fat alkyl with 1-6 aryl groups or carbons and Me is selected from zinc, calcium or magnesium. According to the method disclosed by the invention, the melamine derivative has high thermal decomposition temperature and can overcome the defects of decomposition and degradation of substrate polymer, migration, corrosion to equipment, and the like, of fire retardant, and meanwhile, the property of fire retardant is maintained, the synergistic anti-flaming effect with other fire retardants is maintained and the application field of fire retardant is widened.

Owner:ZHEJIANG UNIV

A kind of composite diaphragm for lithium ion battery and preparation method thereof

ActiveCN103956450BAvoid thermal runawayImprove high temperature thermal stabilityCell component detailsElectrolytic agentCeramic coating

The invention discloses a composite separator for lithium ion batteries and a preparation method thereof, including a ceramic coating modification method and a ceramic lithium battery separator. The ceramic protective layer is mainly a mixture composed of ceramics graft-modified by anionic surfactants containing sodium sulfonate or sodium carboxylate groups, and a binder. The grafting is completed under the action of dehydrating agent and using the "grafting to" method. The grafting rate of ceramics is relatively high. The modified ceramic separator has greatly improved the performance of the modified ceramic separator due to the introduction of high-temperature-resistant high-specific surface area nanoceramics on the surface of the conventional PP separator. The insulation and electrolyte wettability of the separator are improved, especially at high temperatures of 130°C, 150°C and 180°C, showing excellent high-temperature thermal stability. The lithium battery composite separator avoids the heat shrinkage of conventional separators, thereby avoiding thermal runaway inside the battery caused by heat shrinkage, thereby improving the safety and reliability of lithium-ion batteries.

Owner:DONGFANG ELECTRIC CORP LTD

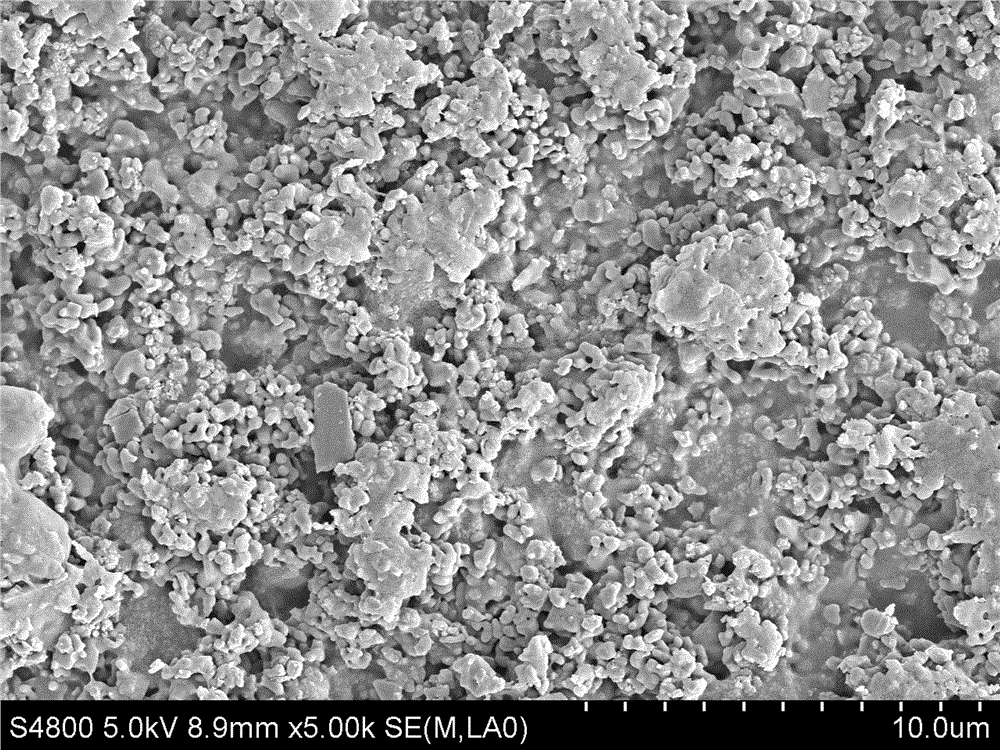

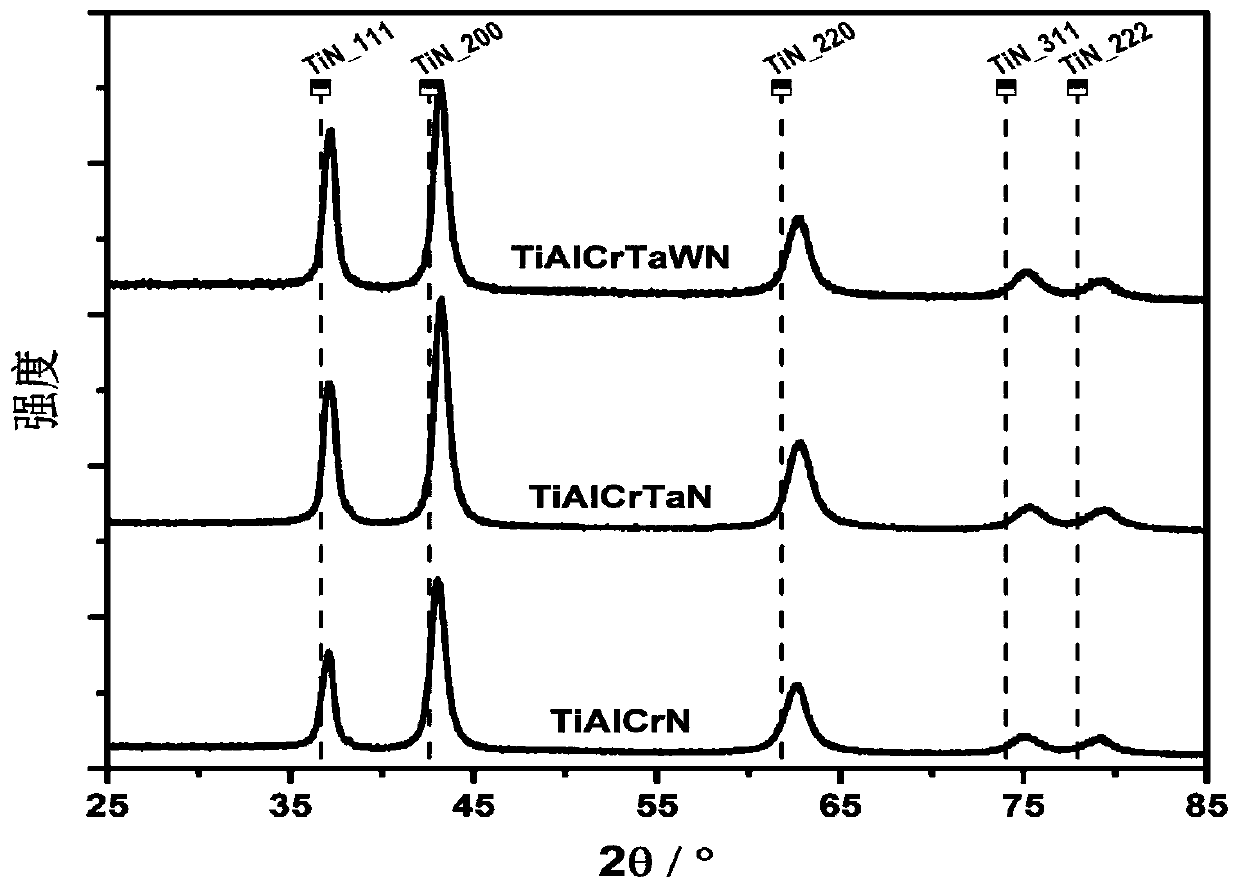

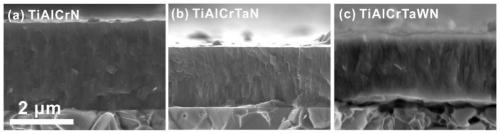

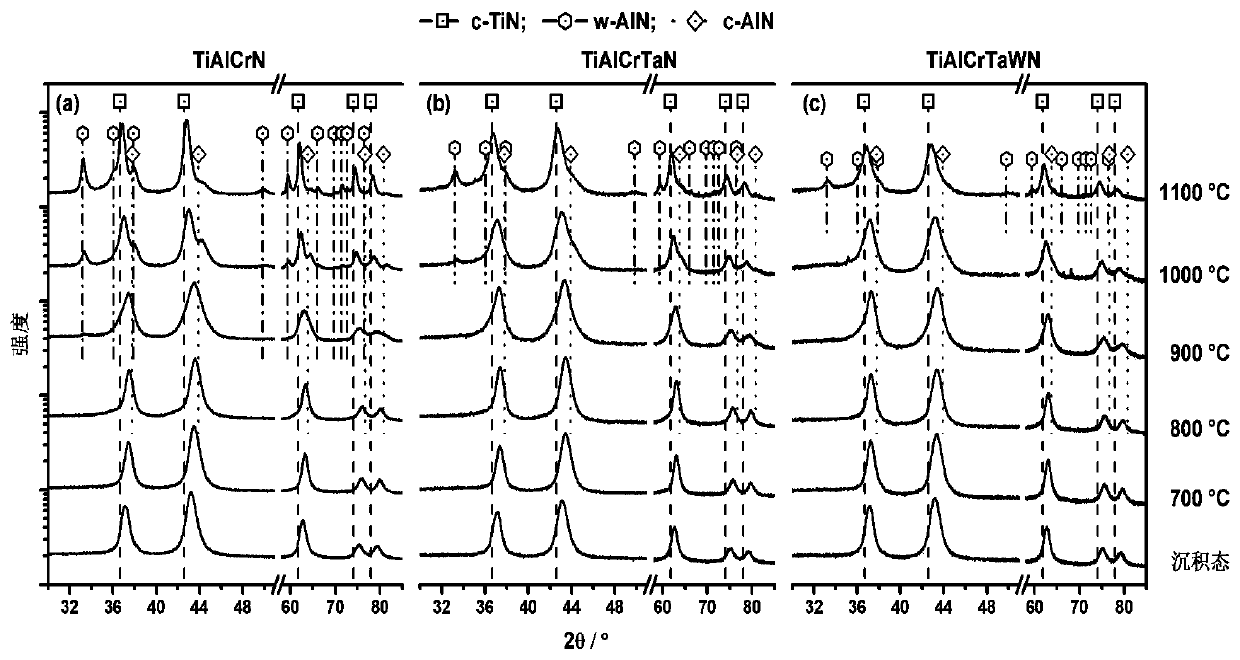

Multicomponent nitride hard coating, preparation method of multicomponent nitride hard coating and application of multicomponent nitride hard coating

ActiveCN110484870AImprove structural stabilityIncrease aggregation energyVacuum evaporation coatingSputtering coatingMechanical stabilityHardness

The invention belongs to the field of surface protective coating materials, and discloses a multicomponent nitride hard coating, a preparation method of the multicomponent nitride hard coating and application of the multicomponent nitride hard coating. The multicomponent nitride hard coating comprises a (TiAlCrTaW) N layer, wherein the (TiAlCrTaW) N layer in a columnar crystal growth structure; and the chemical formula of the (TiAlCrTaW) N layer is (TiaAlbCrcTadWe)N, wherein the summary of a, b, c, d and e is equal to 1, either a or b is greater than or equal to 0.2 but less than or equal to 0.5, and c, d or e is greater than or equal to 0 but less than or equal to 0.2. The multicomponent nitride hard coating has the advantages that the multicomponent nitride hard coating has the properties of excellent high-temperature structure, mechanical stability, inoxidizability and wear resistance; the multicomponent nitride hard coating has a harness number of 30-40 Gpa, and an elasticity modulus of 400-500 Gpa in a deposition state; and the multicomponent nitride hard coating has a harness number of 35-45 GPa and a elasticity modulus of 450-550 GPa under the temperature of 900 DEG C.

Owner:GUANGDONG UNIV OF TECH

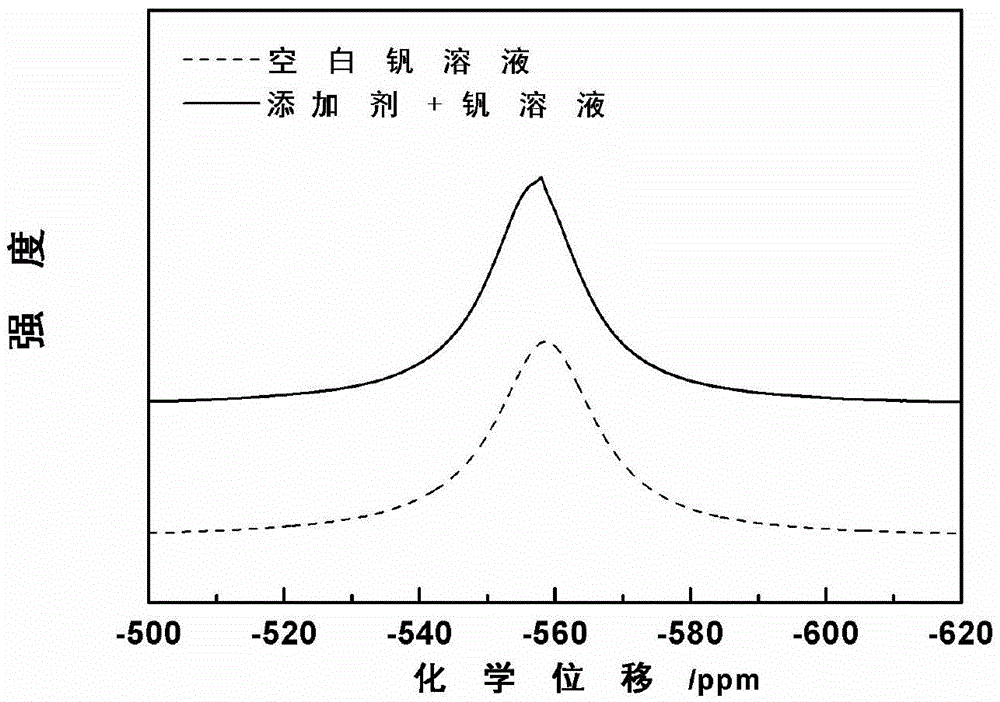

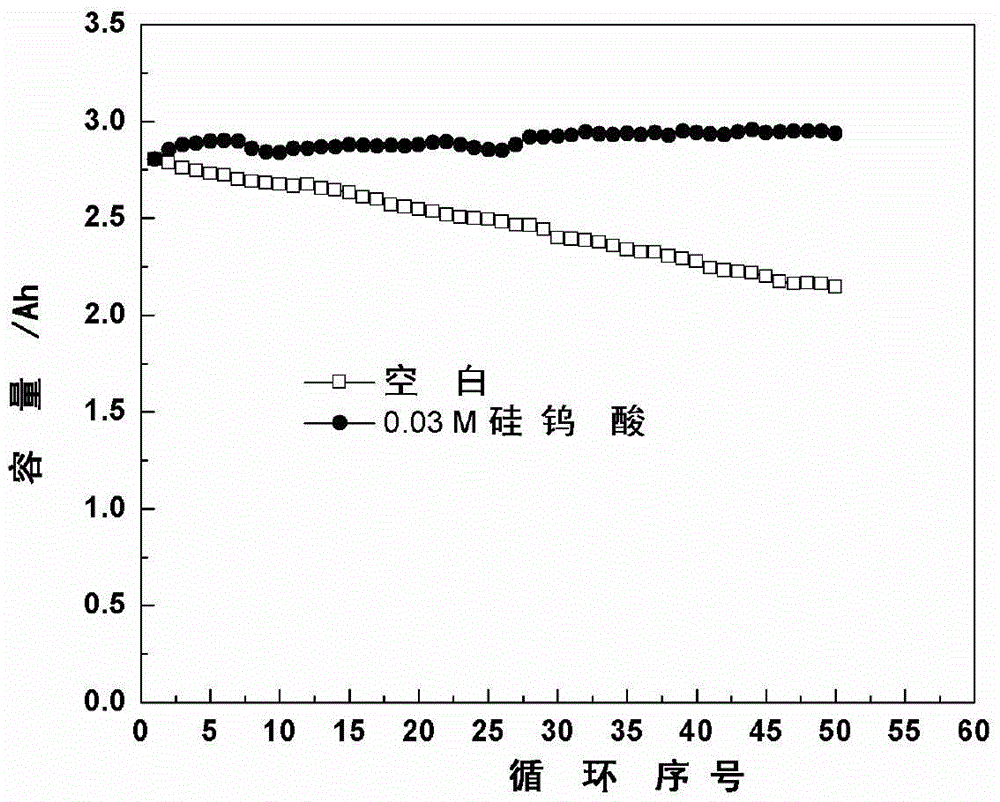

Silicon-containing heteropolyacid positive electrode electrolyte for all-vanadium redox flow battery

ActiveCN106505234AImprove high temperature thermal stabilityImprove coordination environmentIndirect fuel cellsOrganic electrolytesRedoxSilicotungstic acid

The invention relates to a positive electrode electrolyte with a silicon-containing heteropolyacid additive for an all-vanadium redox flow battery. The silicon-containing heteropolyacid additive is one or two kinds of silicotungstic acid, silicomolybdic acid, silicon niobic acid or silicon tantalic acid; and the concentration of the silicon-containing heteropolyacid as the additive is 0.01-0.5mol / L. By taking the silicon-containing heteropolyacid as the positive electrode electrolyte additive, the problem of capacity fading in the operation of the battery at a high temperature can be effectively suppressed, and the stable operation of the battery can be realized; and in addition, the positive electrode electrolyte is simple in preparation process, energy-saving and environment-friendly, low in cost, and capable of realizing stable operation of the electrolyte in the battery.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

SiC fiber and fabric and preparation method thereof

InactiveCN101660225BUniform vertical and horizontal performanceHigh strengthInorganic material artificial filamentsVegetal fibresIn planePolymer science

The invention relates to an SiC fiber or fabric and a preparation method thereof and belongs to the technical field of composite materials. By taking natural vegetable fiber or the fabric thereof as the template, the SiC fiber or fabric is obtained through impregnation in silica sol and high-temperature calcination. The preparation method includes the following steps: impregnating silica sol in natural vegetable fiber or fabric thereof carbonized or pretreated by organic expanding agent by adopting a vacuum or vacuum pressure way or the vacuum or vacuum pressure way simultaneously combined with a concentration gradient diffusion way to achieve 75-166 percent of weight gain rate, and then under protective gas, calcining the obtained material at the temperature of 1400-1600 DEG C for 1.5-4h, and converting the obtained material into complete SiC fiber or fabric. The SiC fiber or fabric not only completely maintains the structure of natural vegetable fiber, but also is characterized by high strength, high-temperature thermostability and resistance to acid and alkali corrosion of SiC material. Meanwhile, the SiC fiber or fabric is also characterized by vertical and horizontal performance uniformity of fabrics and very suitably used as the enhanced phase of in-plane equidirectional composite material of high performance.

Owner:国际竹藤网络中心

Preparation method of automobile bearing material

InactiveCN105755314AHigh temperature strengthImprove high temperature thermal stabilityChemical compositionTitanium

Owner:SUZHOU RISING AUTO PARTS

Method for promoting high temperature heat stability of thermoplastic polymer or compound thereof by utilizing inorganic and alkyl metallic phosphites

ActiveCN109181294AImprove high temperature thermal stabilityProtection from temperature effectsDecompositionHeat stability

The invention discloses a method for promoting high temperature heat stability of a thermoplastic polymer or compound thereof by utilizing inorganic and alkyl metallic phosphites. The compound of inorganic metallic phosphite and alkyl metallic phosphite is added into the raw materials; the addition of the compound is 0.1-2%, on the basis of the total weight of the thermoplastic polymer or compoundthereof; the weight ratio of inorganic metallic phosphite to alkyl metallic phosphite is at 1:(1-10); the structural formula of alkyl metallic phosphite is shown by formula (I) or (II); R is selectedfrom straight chain fat alkyl with 1-6 aryl groups or carbons and Me is selected from zinc, calcium or magnesium. According to the method disclosed by the invention, under the combined action of hightemperature and shearing force, the thermoplastic polymer or compound thereof is capable of avoiding the problems of cross-linking, decomposition, degradation, discoloration, and the like, and can maintain various properties of the materials.

Owner:ZHEJIANG UNIV

Lithium ion battery diaphragm prepared from inorganic-organic composite material

PendingCN112531292AGood electrochemical stabilityImprove high temperature thermal stabilityMaterial nanotechnologySecondary cellsPorous membranePolyolefin

The invention relates to a lithium ion battery diaphragm prepared from an inorganic-organic composite material. The lithium ion battery diaphragm comprises at least two layers of polyolefin-based porous membranes which are stacked in sequence, and two adjacent layers of polyolefin-based porous membranes are bonded and fixed through an inorganic-organic composite material liquid; wherein the inorganic-organic composite material liquid is prepared from the following components in parts by weight: 30 to 50 parts of polyolefin emulsion, 5 to 10 parts of adhesive, 3 to 8 parts of nanoscale modifiedcomposite fiber, 0.2 to 0.5 part of dispersing agent and 0.1 to 0.5 part of plasticizer. The prepared lithium ion battery diaphragm is relatively stable in performance, is particularly applied to a lithium ion battery for an electric vehicle, and can tolerate relatively high temperature in the working process of the electric vehicle, and the diaphragm shrinkage rate is remarkably reduced comparedwith that of an existing polyolefin-based diaphragm, so that the overall service life of the battery is remarkably prolonged, and the safety is greatly improved; and the use convenience, the safety and the stability of the electric product are also improved.

Owner:宁波启新精合新能源研究院有限公司

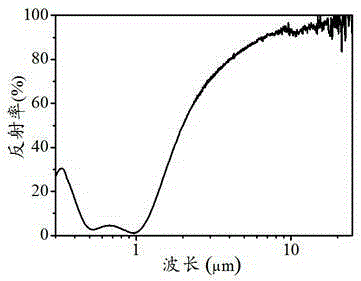

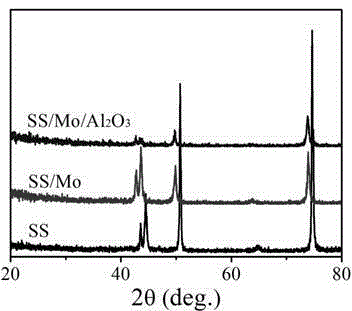

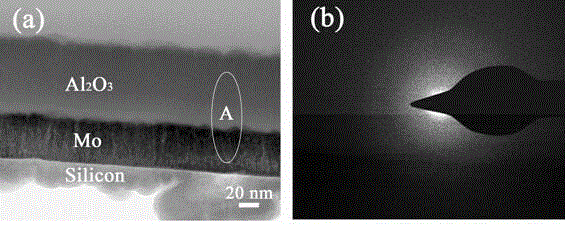

High-temperature-resistant solar energy selective absorbing coating with surface textured metal Mo being absorbing layer and preparation method thereof

InactiveCN105387641AImprove high temperature thermal stabilityAvoid using effectsSolar heat devicesCoatingsVisible infraredInfrared reflectance

The invention discloses a high-temperature-resistant solar energy selective absorbing coating with surface textured metal Mo being an absorbing layer and belongs to the technical field of solar energy utilization. According to the coating, the absorbing layer and an antireflection layer are sequentially formed on a stainless steel substrate, wherein the absorbing layer is composed of a surface textured metal Mo film, the thickness is 40 nm-100 nm, and the roughness value is 0.5 nm-3 nm; the antireflection layer is composed of a ceramic Al2O3 or SiO2 film, and the thickness is 50 nm-150 nm. The solar energy selective absorbing coating has a visible-infrared spectrum high absorbing rate, a low infrared spectrum emission rate and good high-temperature thermal stability; the coating is simple in structure, stable in preparation technology, convenient to operate, low in production cost and short in production period; meanwhile, with the surface textured metal Mo coating being the absorbing layer, using and doping of an infrared reflection layer are effectively avoided, and the application range of low-heat emission metal on the solar energy absorbing coating is widened.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com