Composite micro-nanometer zirconia-based high temperature abradable sealed coating material and preparation method thereof

A technology of nano-zirconia and sealing coating, which is applied in the coating, powder coating, etc., can solve the problems of low spraying deposition efficiency, easy block falling off, etc., and achieve good sprayability, suitable holes and density, and deposition Significant effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Take 7.0 kg of nano-scale yttrium oxide partially stabilized zirconia Y-PSZ with a particle size of 20-60 nm, the content of nano-zirconia accounts for 93-95 mol%, the content of nano-yttrium oxide accounts for 5-7 mol%, and the particle size is 0.5-5 μm Grade yttria partially stabilized zirconia Y-PSZ1.8kg, the content of micron zirconia accounts for 93~95mol%, and the content of nanometer yttrium oxide accounts for 5~7mol%. 0.5kg of nano-alumina powder with a particle size of 15-30nm, which is high-temperature stable α-Al 2 o 3 , 0.2 kg of hexagonal boron nitride powder with a particle size of 0.5 to 2 μm, and 0.5 kg of polyphenylene with a particle size of 20 to 38 μm, and mix them uniformly. Take 0.4 kg of dextrin, add it to the raw material powder and mix thoroughly, then add 8.0 kg of distilled water, and stir to form a uniformly dispersed and suspended slurry for use.

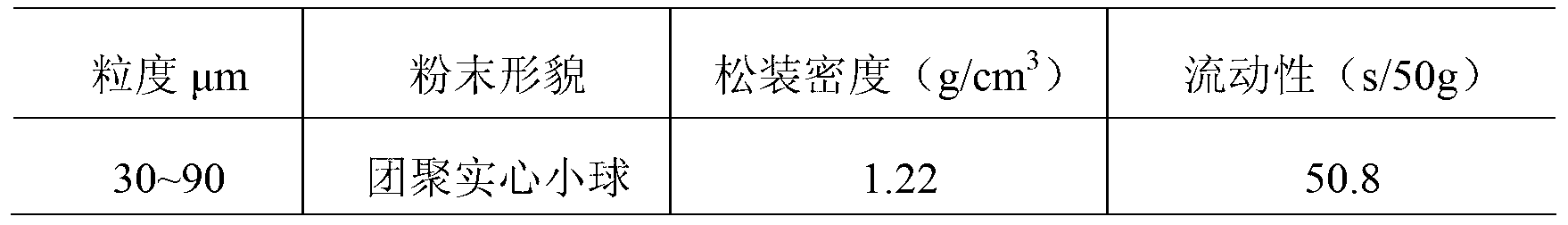

[0027] Use a centrifugal atomizing nozzle to atomize the slurry into fine droplets and spray...

Embodiment 2

[0033] Take 6.2 kg of nano-scale yttrium oxide partially stabilized zirconia Y-PSZ with a particle size of 20-60 nm, the content of nano-zirconia accounts for 93-95 mol%, the content of nano-yttrium oxide accounts for 5-7 mol%, and the particle size is 0.5-5 μm Grade yttrium oxide partially stabilized zirconia Y-PSZ1.9kg, the content of micron zirconia accounts for 93-95mol%, and the content of nano-yttria accounts for 5-7mol%. Mix 1.0kg of alumina powder with a particle size of 15-30nm, 0.3kg of hexagonal boron nitride powder with a particle size of 0.5-2um, and 0.6kg of polyphenylene with a particle size of 20-38um. Take 0.3 kg of dextrin, add it to the raw material powder and mix thoroughly, then add 7.5 kg of distilled water, and stir to form a uniformly dispersed and suspended slurry for use.

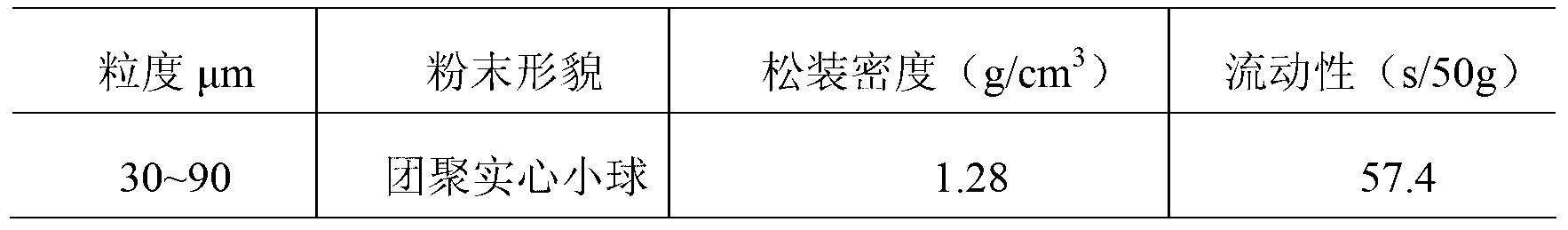

[0034]Use a centrifugal atomizing nozzle to atomize the slurry into fine droplets and spray them into the spray granulation tower. The gas pressure is controlled at 0.8MPa, and the...

Embodiment 3

[0040] Take 6.8 kg of nano-scale yttrium oxide partially stabilized zirconia Y-PSZ with a particle size of 20-60 nm, the content of nano-zirconia accounts for 93-95 mol%, the content of nano-yttrium oxide accounts for 5-7 mol%, and the particle size is 0.5-5 μm Grade yttria partially stabilized zirconia Y-PSZ1.5kg, the content of micron zirconia accounts for 93-95mol%, and the content of nano-yttria accounts for 5-7mol%. Mix 0.8 kg of alumina powder with a particle size of 15-30 nm, 0.1 kg of hexagonal boron nitride powder with a particle size of 0.5-2 um, and 0.8 kg of polyphenylene with a particle size of 20-38 um. Take 0.4 kg of dextrin, add it to the raw material powder and mix thoroughly, then add 8.0 kg of distilled water, and stir to form a uniformly dispersed and suspended slurry for use.

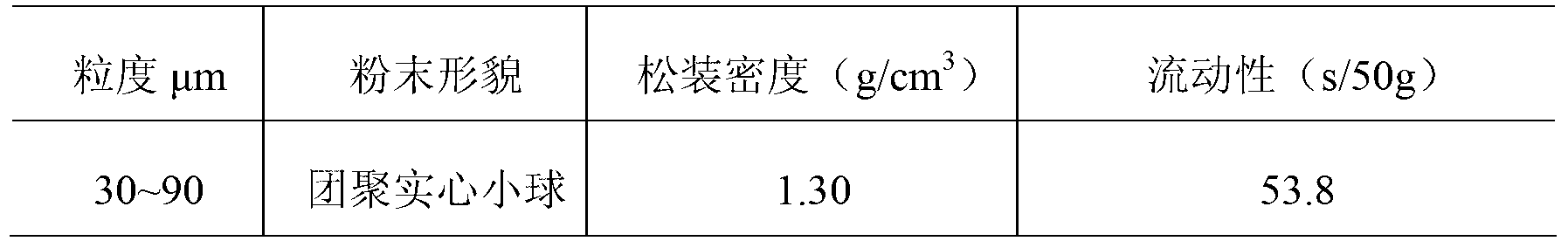

[0041] Use a centrifugal atomizing nozzle to atomize the slurry into fine droplets and spray them into the spray granulation tower. The gas pressure is controlled at 0.8MPa, and the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com