Lithium ion battery diaphragm prepared from inorganic-organic composite material

A technology for lithium ion batteries and composite materials, applied in the field of ion batteries, can solve the problems of poor thermal stability and poor wettability of electrolyte, and achieve the effects of high thermal stability, process saving and good electrochemical stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

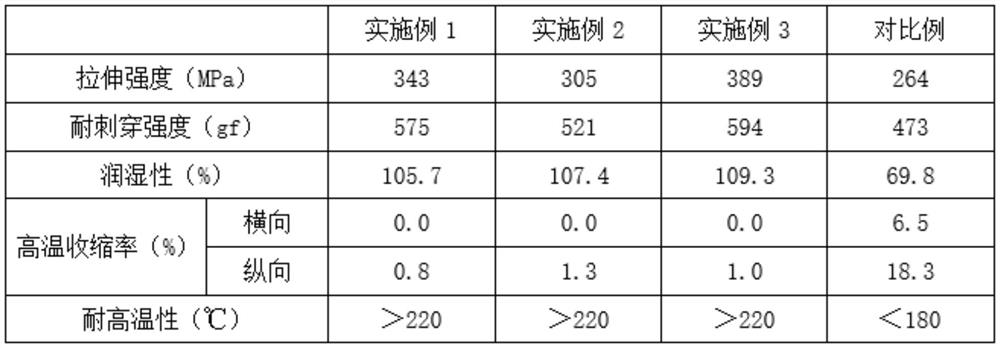

Examples

Embodiment 1

[0035] A lithium ion battery diaphragm prepared using an inorganic organic composite material includes a three-layer polyolefin-based porous film that is superimposed in sequentially, adjacent two-layer polyolefin-based porous membrane is bonded through inorganic organic composite. fixed;

[0036] Among them, inorganic organic composite compounds are calculated according to weight, including the following ingredients:

[0037] 40 parts of the polyolefin emulsion, 8 bonding agents, 5 parts of nanoscale modified composite fibers, 0.3 dispersants, 0.3 plasticizers.

[0038] The polyolefin emulsion is a polyvilted fluoride emulsion.

[0039] In the polyfial fluoride emulsion, the solid content of polyvinylidene ethylene is 60%.

[0040] The adhesive is a polyacrylate waterborne binder.

[0041] The dispersing agent is ammonium polyacrylate.

[0042] The plasticizer is a di (2-ethyl) ester of phthalate.

[0043] The nanometer-based modified composite fiber is nanometer-stage tantalum o...

Embodiment 2

[0059] A lithium ion battery diaphragm prepared using an inorganic organic composite material including a polyolefin-based porous film sequentially superimposed, adjacent two-layer polyolefin-based porous membrane bonded through inorganic organic composite. fixed;

[0060] Among them, inorganic organic composite compounds are calculated according to weight, including the following ingredients:

[0061] 30 parts of polyolefin emulsion, 5 bonding agents, 3 nano-modified composite fibers, 0.2 dispersants, and 0.1 parts of plasticizer.

[0062] The polyolefin emulsion is a polytetrafluoroethylene emulsion.

[0063] In the polytetrafluoroethylene emulsion, the solid content of polyvinylidene ethylene is 60%.

[0064] The adhesive is a polyacrylate waterborne binder.

[0065] The dispersing agent is ammonium polyacrylate.

[0066] The plasticizer is a di (2-ethyl) ester of phthalate.

[0067] The nanometer-based modified composite fiber is nanometer-stage tantalum oxide / carbon-modifie...

Embodiment 3

[0083] A lithium ion battery diaphragm prepared using an inorganic organic composite, the lithium ion battery diaphragm comprising four layers of polyolefin-based porous membranes, adjacent two-layer polyolefin-based porous membrane, bonded through inorganic organic composite fixed;

[0084] Among them, inorganic organic composite compounds are calculated according to weight, including the following ingredients:

[0085] 50 parts of polyolefin emulsion, 10 adhesives, 8 nano-modified composite fibers, 0.5 dispersants, 0.5 plasticizers.

[0086] The polyolefin emulsion is a polyvilted fluoride emulsion.

[0087] In the polyfial fluoride emulsion, the solid content of polyvinylidene ethylene is 60%.

[0088] The adhesive is a polyacrylate waterborne binder.

[0089] The dispersing agent is ammonium polyacrylate.

[0090] The plasticizer is a di (2-ethyl) ester of phthalate.

[0091] The nanometer-based modified composite fiber is nanometer-stage tantalum oxide / carbon-modified compo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com