Positive plate and application thereof

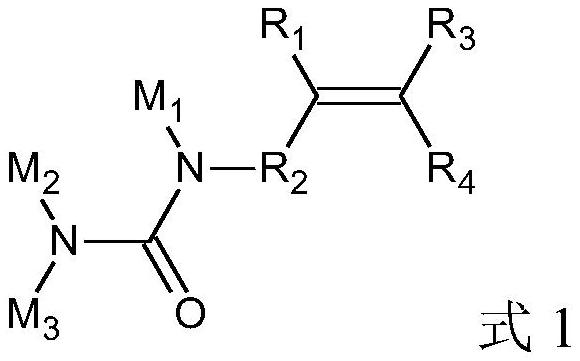

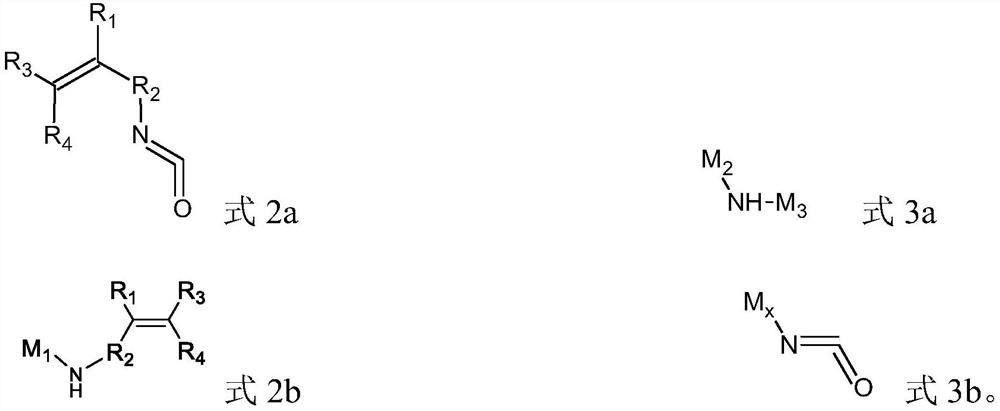

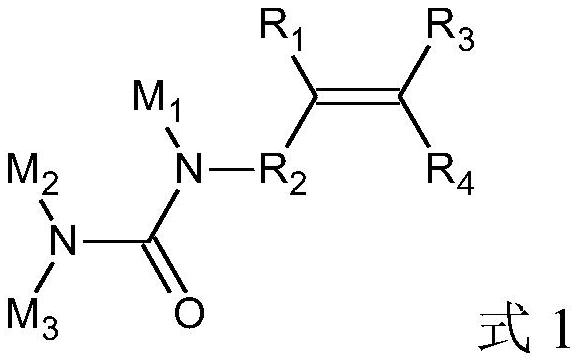

A technology of positive electrode and positive electrode activity, applied in positive electrode and its application field, can solve the problems of positive electrode side reaction, battery cycle performance deterioration, etc., achieve stability, excellent electrochemical stability, and take into account the effect of service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0072] The preparation method of the polymer of the present invention has no other particularity with the preparation method of the polymer in the art, for example, the solvent system comprising the monomer and the initiator is heated to a certain temperature under the protection of an inert gas to initiate the polymerization reaction, and can be Real-time monitoring of the degree of polymerization of the reaction system to judge the progress of the reaction, which is beneficial to obtain a polymer that meets the target molecular weight.

[0073] Specifically, the amount of the initiator added is 0.01-0.5% of the total mass of the polymer monomers. The initiator can be an initiator commonly used in this field, including but not limited to azobisisobutyronitrile AIBN, azobisisoheptanonitrile ABVN, dimethyl azobisisobutyrate, benzoyl peroxide BPO, benzoyl peroxide At least one of tert-butyl formate TBPB, ethyl 4-(N,N-dimethylamino)benzoate, and methyl o-benzoylbenzoate.

[0074...

Embodiment 1-3

[0100] The preparation method of the lithium ion battery of the present embodiment comprises the following steps:

[0101] 1) Preparation of positive electrode sheet

[0102] The positive electrode sheet of this embodiment includes a positive electrode current collector and a positive electrode active layer disposed on both functional surfaces of the positive electrode current collector, wherein the polymer is distributed inside the positive electrode active layer.

[0103] The preparation method of positive plate comprises the following steps:

[0104] a. Mix and disperse positive electrode active material, polymer, binder (PVDF), conductive agent (conductive carbon black) in NMP to prepare positive electrode slurry;

[0105] b. Coating the positive electrode slurry on the two functional surfaces of the aluminum foil, drying at 100° C. for 24 hours, rolling, and cutting to obtain the positive electrode sheet.

[0106] 2) Preparation of negative electrode sheet

[0107] The...

Embodiment 4-6

[0115] The preparation method of the lithium ion battery of the present embodiment comprises the following steps:

[0116] 1) Preparation of positive electrode sheet

[0117] The positive electrode sheet of this embodiment includes a positive electrode current collector and a positive electrode active layer arranged on both functional surfaces of the positive electrode current collector, wherein the positive electrode active layer includes a first active layer and a second active layer (polymer layer), and the second active layer Keep away from current collectors.

[0118] The preparation method of the positive electrode sheet of the present embodiment comprises the following steps:

[0119] a. Mix and disperse the positive electrode active material, binder (PVDF), and conductive agent (conductive carbon black) in NMP to prepare the first active layer slurry;

[0120] b. Coating the first active layer slurry on the two functional surfaces of the aluminum foil and drying at 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Gram capacity | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Single sided density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com