Molybdenum-doped argyrodite type sulfide electrolyte and preparation method thereof

A technology of sulfide electrolyte and sulfide silver germanium ore, which is applied in the manufacture of electrolyte batteries, non-aqueous electrolyte batteries, circuits, etc., can solve the problems of accelerating the practical application development of high-performance solid-state batteries, poor chemical stability of electrolytes, etc., and achieve accelerated practical application. Effects of development, good electrochemical stability, high ionic conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0032] According to one aspect of the present invention, the present invention proposes an arginine-type sulfide electrolyte and a preparation method thereof. According to an embodiment of the present invention, it includes:

[0033] (1) Prepare the raw materials in an argon-filled glove box, mix them thoroughly to obtain the mixture powder and seal it in a ball mill to avoid contact with air;

[0034] (2) mixing the ball mill tank on the planetary ball mill to obtain preliminary solid electrolyte powder;

[0035] (3) compressing the solid electrolyte powder obtained in step (2) under a pressure of 350 MPa to obtain a solid electrolyte sheet;

[0036] (4) encapsulate the obtained solid electrolyte in a quartz tube, and the vacuum sealing tube pressure is 10 -4 Pa

[0037] (5) The quartz tube of (4) is sintered at a high temperature in a muffle furnace, and after cooling, an arginite-type sulfide electrolyte is obtained.

[0038] Thus, the present invention prepares a kind o...

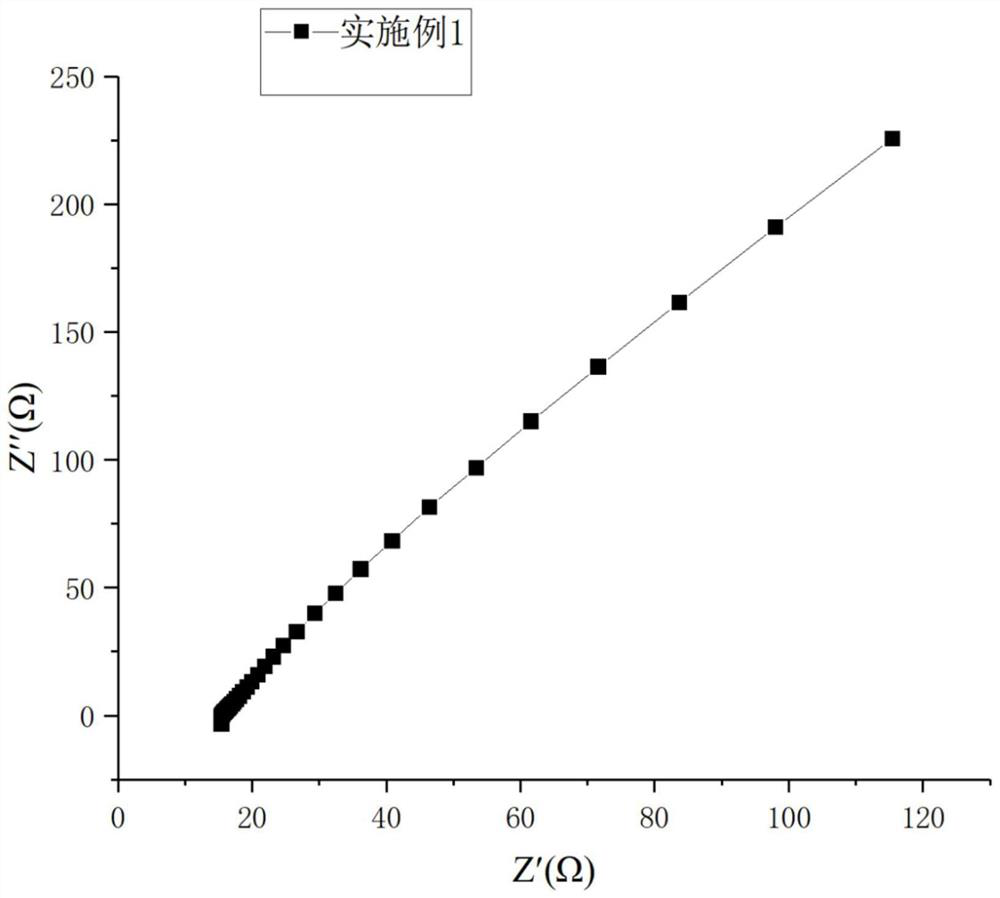

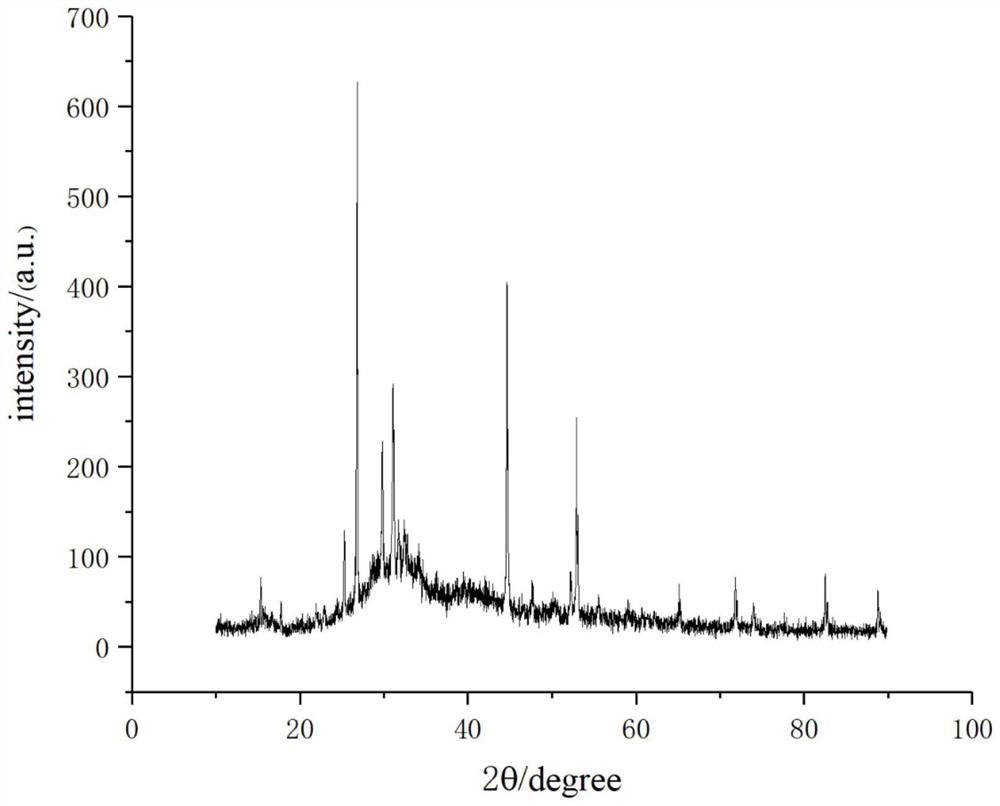

Embodiment 1

[0052] The preparation steps of a modified argentite-type sulfide electrolyte are as follows:

[0053] (1) Put Li in an argon-filled glove box 2 S. Mo 2 S 3 , LiCl, P 2 S 5 According to the molar ratio of 2.575: 0.0375: 1: 0.4625 for pre-mixing, avoid contact with air.

[0054] (2) Fix the sealed ball mill jar on the planetary ball mill for ball milling, the rotational speed is 550rpm, and the time is 16h.

[0055] (3) Press the preliminary solid electrolyte powder obtained in step (2) into tablets in a glove box with a pressure of 350 MPa and a thickness of 500 μm.

[0056] (4) Put the initial solid electrolyte sheet obtained in step (3) in a quartz tube or a glass tube, and seal it in a vacuum with a vacuum pressure of 1×10 -4 Pa.

[0057] (5) Place the sealed quartz tube or glass tube in step (4) in a muffle furnace for sintering, the time is 10h, the temperature is 600°C, and the temperature rise and fall rates are both 0.5°C / min -1 .

[0058] (6) get the composit...

Embodiment 2

[0061] The preparation steps of a modified argentite-type sulfide electrolyte are as follows:

[0062] (1) Put Li in an argon-filled glove box 2 S. Mo 2 S 3 , LiCl, P 2 S 5 The pre-mixing was carried out at a molar ratio of 2.55:0.025:1:0.475 to avoid contact with air.

[0063] (2) Fix the sealed ball mill jar on the planetary ball mill for ball milling, the rotational speed is 550rpm, and the time is 16h.

[0064] (3) Pressing the preliminary solid electrolyte powder obtained in step (2) into a glove box with a pressure of 350 Mpa and a thickness of 500 μm.

[0065] (4) Put the initial solid electrolyte sheet obtained in step (3) in a quartz tube or a glass tube, and seal it in a vacuum with a vacuum pressure of 1×10 -4 Pa.

[0066] (5) Place the sealed quartz tube or glass tube in step (4) in a muffle furnace for sintering, the time is 12h, the temperature is 550°C, and the temperature rise and fall rates are both 0.5°C / min -1 .

[0067] (6) get the composition as L...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com