Preparation method of composite solid electrolyte

A solid electrolyte and preparation process technology, which is applied in the field of composite solid electrolyte preparation to achieve uniform deposition, low electronic conductivity, and ease of volume effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

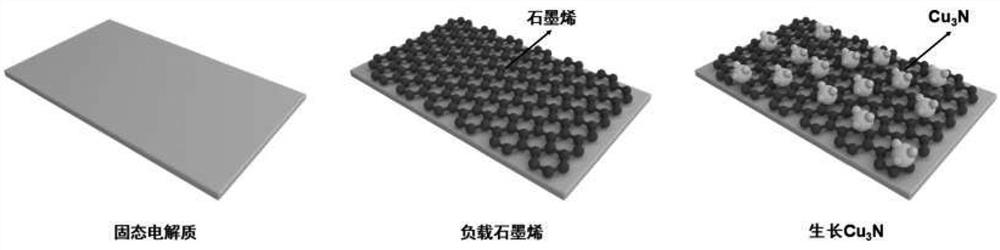

[0027] refer to figure 1 As shown, the present invention discloses a method for preparing a composite solid-state electrolyte that inhibits the growth of lithium dendrites. The steps are as follows:

[0028] (1) The surface treatment of the electrolyte is carried out by a laser cleaning method, and the solid electrolyte is cleaned by a high-energy nanosecond laser.

[0029] (2) Put the solid electrolyte into the quartz tube of the plasma-enhanced chemical vapor deposition device, and evacuate the quartz tube to 4Pa.

[0030] (3) Turn on the heating, heat from room temperature to 750°C, the heating rate is 2°C / min, and the temperature is kept for 4h.

[0031] (4) A mixture of nitrogen, hydrogen and methane (flow ratio 2:1:1) was introduced, and the pressure and temperature in the tube were 50pa. The hydrogen flow was 10 mL / min.

[0032] (5) Turn on the radio frequency plasma source and slowly adjust the high power to 300W. Growth time was controlled within 30 minutes.

[0...

Embodiment 2

[0042] A preparation method of a composite solid electrolyte of the present embodiment, the steps are as follows:

[0043] (1) The surface of the electrolyte is treated by a laser cleaning method, and the solid electrolyte is cleaned by a high-energy nanosecond laser.

[0044] (2) Put the solid electrolyte into the quartz tube of the plasma-enhanced chemical vapor deposition device, and evacuate the quartz tube to 5Pa.

[0045] (3) Turn on the heating, heat from room temperature to 800°C, the heating rate is 3°C / min, and the temperature is kept for 5h.

[0046] (4) A mixture of nitrogen, hydrogen and methane (flow ratio 2:1:1) was introduced, and the pressure and temperature in the tube were 50pa. The hydrogen flow was 15 mL / min.

[0047] (5) Turn on the radio frequency plasma source and slowly adjust the high power to 200W. Growth time was controlled within 60 minutes.

[0048] (6) Turn off the radio frequency plasma, stop feeding hydrogen and methane, keep feeding nitrog...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com