Solid electrolyte and preparation method thereof, and lithium ion battery

A solid-state electrolyte, lithium-ion battery technology, applied in the field of lithium-ion batteries, can solve the problem that the conductivity of non-thin-film lithium-ion batteries cannot be well met, and achieves the ability to reduce inter-granular resistance and high ionic conductivity. , the effect of low electronic conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

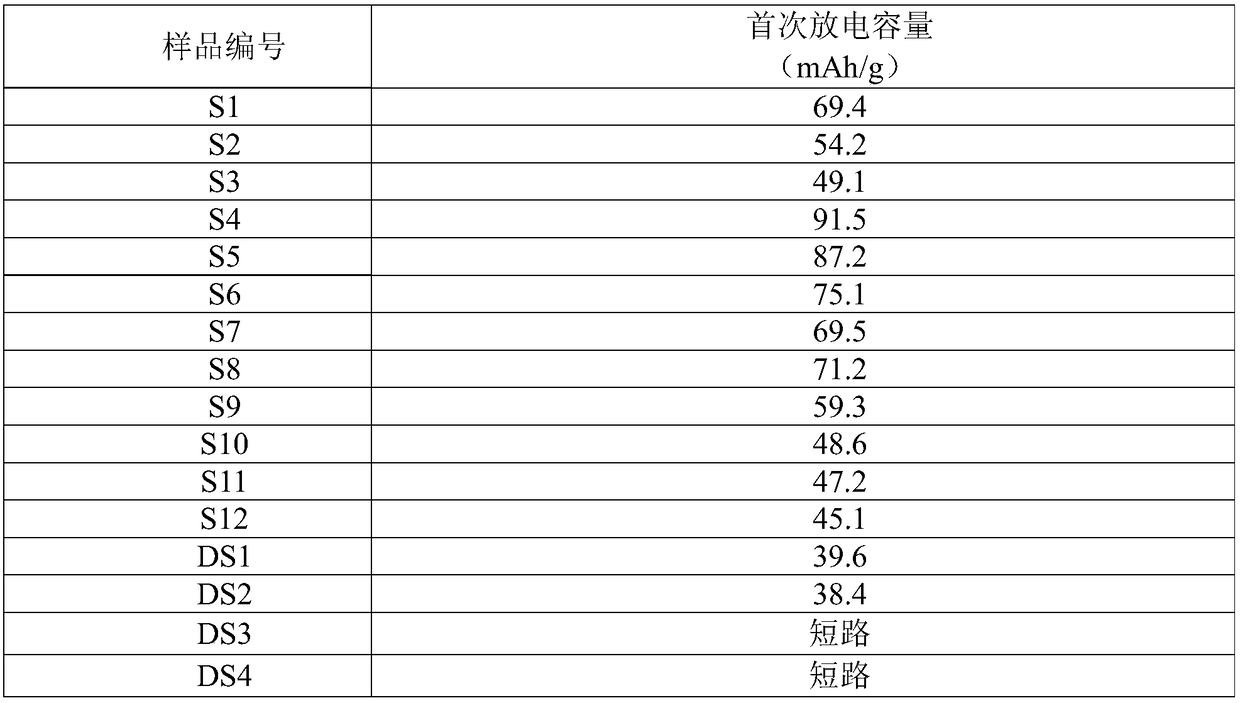

Examples

preparation example Construction

[0051] The preparation method of the lithium-ion battery of the present invention can be various conventional preparation methods of the lithium-ion battery in the field, for example, a solid electrolyte, a positive electrode and a negative electrode can be assembled together to form a lithium-ion battery by a conventional method. In a specific embodiment of the present invention, the method for preparing a lithium ion battery may include: under the protection of an argon atmosphere, the solid electrolyte prepared above is polished to smooth on 800# sandpaper, and then ultrasonically treated in ethanol 10-30 minutes, and drying at 70-80° C. to obtain a solid electrolyte sheet with a clean surface. 1000g of positive electrode active material LiNi 0.5 mn 1.5 o 4 , 50-60g binder SBR, 30-40g acetylene black were added to 1500-1600g solvent anhydrous heptane, and then stirred in a vacuum mixer to form a stable and uniform positive electrode slurry. The positive electrode slurry ...

Embodiment 1

[0058] This example is used to illustrate the solid electrolyte of the present invention and its preparation method.

[0059] (1) 0.53g Li 2 CO 3 Powder, 8.70g TiO 2 powder and 11.19g La 2 o 3 The powder is ball milled in a planetary ball mill at a speed of 350 rpm for 12 hours to mix evenly, then the obtained mixture is put into an alumina crucible, and then placed in a muffle furnace for the first calcination at 1100°C for 6 hours, and then cooled to obtain the chemical formula: Li 0.12 La 0.63 TiO 3 The core material powder has an average particle size of 5 μm;

[0060] (2) Mix 0.07g LiOH, 0.63g Y(NO 3 ) 3 ·6H 2 O, 0.27g NH 4 h 2 PO 4 Disperse 0.03g tetraethyl orthosilicate in deionized water to form an aqueous solution, then add 20g of the core material prepared in step (1) to the aqueous solution and mix evenly, then adjust the pH value of the mixed solution to 11 with 2mol / L ammonia water, to A gel-like uniform coating shell is formed on the surface of the ...

Embodiment 2

[0063] This example is used to illustrate the solid electrolyte of the present invention and its preparation method.

[0064] Prepare solid state electrolyte A2 and lithium ion battery according to the method for embodiment 1, difference is, adopt 0.80gLi 2 CO 3 Powder, 8.78g TiO 2 powder and 10.93g La 2 o 3 To obtain the structural formula as Li 0.18 La 0.61 TiO 3 The core material powder, the average particle diameter of the core material powder is 5 μm, then add 20g of the Li prepared above to the aqueous solution 0.18 La 0.61 TiO 3 The core material powder is observed with an electron microscope and the thickness of the shell material is 25nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com