Mo-doped AlCrSiN/Mo self-lubricating film and preparation method thereof

A self-lubricating, doped technology, applied in metal material coating process, vacuum evaporation plating, coating and other directions, can solve the problems of high cutting temperature, reduced friction, cutting hot cutting temperature, high friction coefficient, and achieve high temperature Thermal stability, good bond strength, effect of reducing friction coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] In this example, the HiPIMS / Pulse DC composite magnetron sputtering system is used to make single crystal tungsten steel sheet (20mm×10mm×1.0mm), SUS304 stainless steel sheet (40mm×40mm×2.0mm) and cemented carbide substrate (35mm×35mm ×4.5mm) deposited AlCrSiN / Mo composite thin film. The film preparation process is as follows:

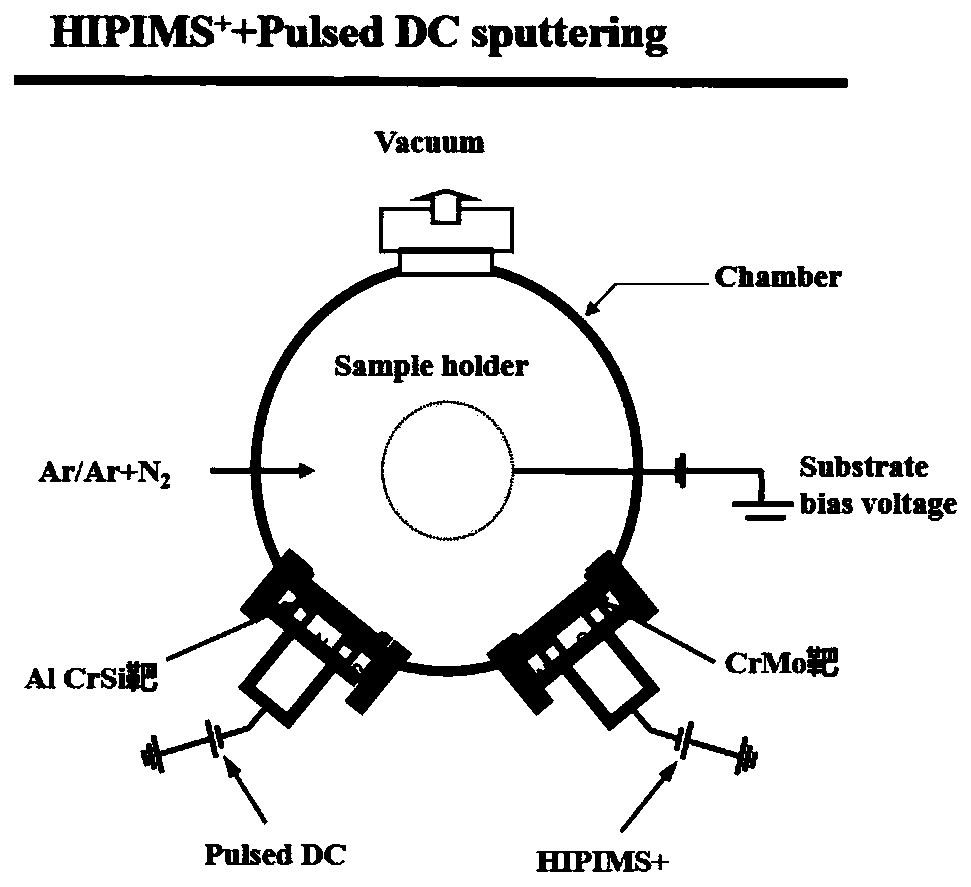

[0039] (1) All substrates were cleaned with ultrasonic cleaner in acetone and alcohol solution for 30 minutes respectively, and then cleaned with high-purity N 2 Blow dry, and then place it on the rotating rack facing the target in the vacuum chamber. figure 1It is the target material distribution map of high power pulsed and pulsed DC magnetron sputtering. It can be seen from the figure that the AlCrSi target is loaded on the pulsed DC power supply, and the CrMo target is loaded on the HiPIMS (HighPower Impulse Magnetron Sputtering) high-power pulse power supply.

[0040] The rotational speed of the rotating frame is selected as 2.5r / min, an...

Embodiment 2

[0056] In this example, the HiPIMS / Pulse DC composite magnetron sputtering system was used to make single crystal Si sheets (40mm×40mm×0.67mm), SUS304 stainless steel sheets (40mm×40mm×2.0mm) and cemented carbide substrates (35mm×35mm× 4.5mm) AlCrSiN / Mo composite thin film was deposited on it. The film preparation process is as follows:

[0057] (1) All substrates were cleaned with ultrasonic cleaner in acetone and alcohol solution for 30 minutes respectively, and then cleaned with high-purity N 2 Blow dry, and then place it on the rotating rack facing the target in the vacuum chamber. The CrMo target is loaded on a pulsed DC power supply, and the AlCrSi target is loaded on a HiPIMS (High Power Impulse Magnetron Sputtering) high-power pulse power supply.

[0058] The rotational speed of the rotating frame is selected as 2.5r / min, and the base distances of the targets are 80mm (AlCrSi target) and 280mm (CrMo target) respectively. The working gas and reaction gas in the coati...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com