Yttrium-rich rare earth high-strength heat-resistant creep-resistant die-casting magnesium alloy

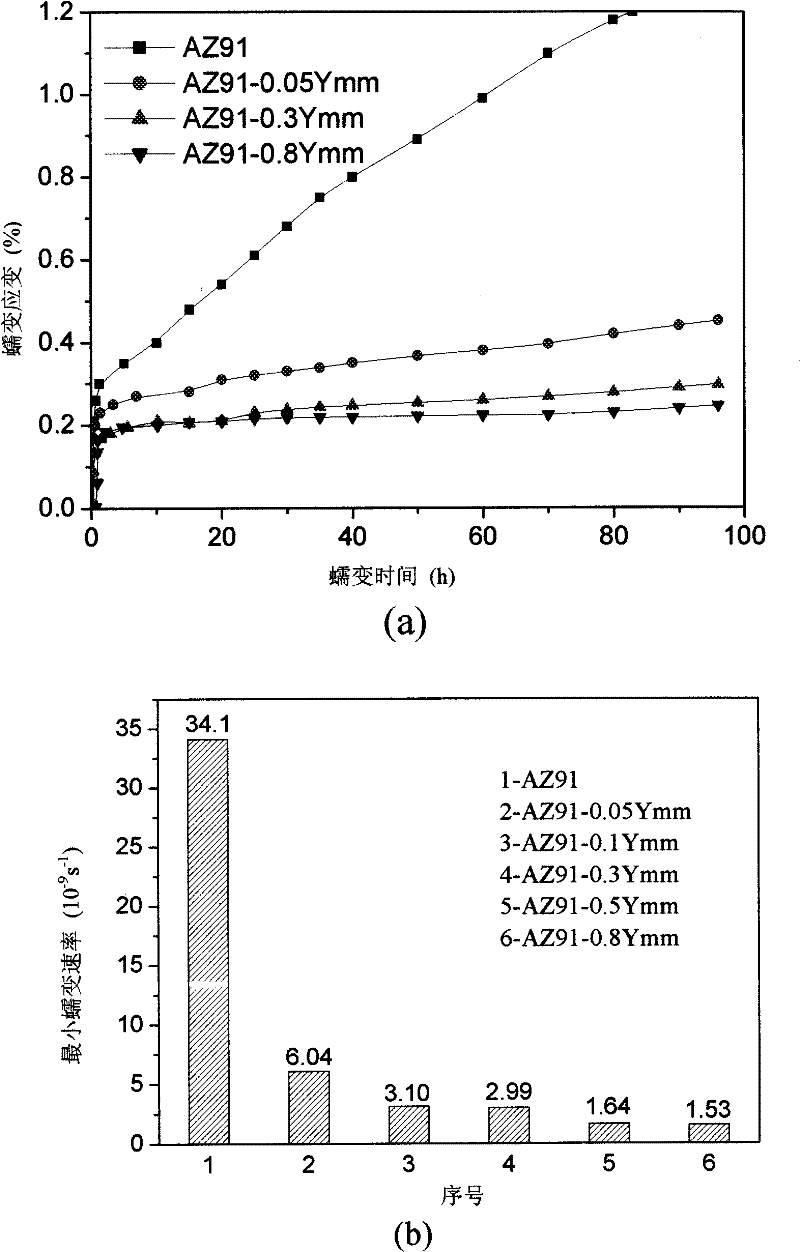

A yttrium-rich rare earth and high-strength technology is applied in the field of yttrium-rich rare earth, high-strength, heat-resistant, creep-resistant die-casting magnesium alloys, which can solve the problems that yttrium-rich rare earth cannot be fully utilized, and achieve the effects of improving creep resistance and reducing harmfulness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0013] Embodiment 1 AZ91+YErHo (Y=0.8%, Er=0.1%, Ho=0.05%) alloy

[0014] Yttrium-rich rare earth high-strength heat-resistant and creep-resistant die-casting magnesium alloy, the composition and mass percentage are: aluminum: 9%, Zn: 0.9%, manganese: 0.2%, Y: 0.8%, Er: 0.1%, Ho: 0.05%, Impurity elements Fe≤0.02%, Cu≤0.002%, Si≤0.01%, Ni≤0.001%, and the balance is magnesium. The raw materials used are: AZ91 magnesium alloy, magnesium-20% yttrium-rich master alloy, of which yttrium-rich is from rich The yttrium-rich rare earth after extracting Eu, Dy, Tb, and Lu high-valent elements from the yttrium-rich rare earth, the composition and mass percentage of the yttrium-rich rare earth are that Y is 20%-90%, Er is 5%-20%, and Ho is 1 %~10%.

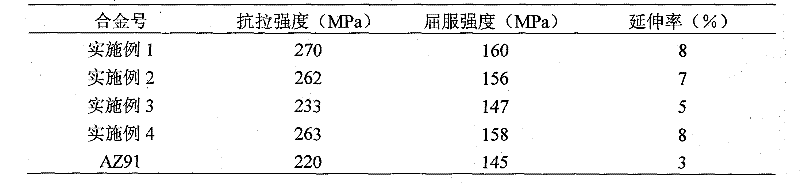

[0015] The properties of the alloy are shown in Table 1.

[0016] Weigh the raw materials according to the ratio, Preheat the base alloy to 200°C, put it into a crucible preheated to 300°C, and pass SF 6 :CO 2 SF with a volume ratio of 1:...

Embodiment 2

[0017] Example 2 AZ91+YErHo (Y=1.5%, Er=0.15%, Ho=0.1%) alloy

[0018] Yttrium-rich rare earth high-strength heat-resistant and creep-resistant die-casting magnesium alloy, the composition and mass percentage are: aluminum: 9%, Zn: 0.9%, manganese: 0.2%, Y: 1.5%, Er: 0.15%, Ho: 0.1%, Impurity elements Fe≤0.02%, Cu≤0.002%, Si≤0.01%, Ni≤0.001%, and the balance is magnesium. The raw materials used are: AZ91 magnesium alloy, magnesium-20% yttrium-rich master alloy, of which yttrium-rich is from rich The yttrium-rich rare earth after extracting Eu, Dy, Tb, and Lu high-valent elements from the yttrium-rich rare earth, the composition and mass percentage of the yttrium-rich rare earth are that Y is 20%-90%, Er is 5%-20%, and Ho is 1 %~10%.

[0019] The properties of the alloy are shown in Table 1.

[0020] Weigh the raw materials according to the ratio, Preheat the base alloy to 200°C, put it into a crucible preheated to 300°C, and pass SF 6 :CO 2 SF with a volume ratio of 1:100...

Embodiment 3

[0021] Example 3 AZ91+YErHo (Y=0.1%, Er=0.03%, Ho=0.01%) alloy

[0022] Yttrium-rich rare earth high-strength heat-resistant and creep-resistant die-casting magnesium alloy, the composition and mass percentage are: aluminum: 9%, Zn: 0.9%, manganese: 0.2%, Y: 0.1%, Er: 0.03%, Ho: 0.01%, Impurity elements Fe≤0.02%, Cu≤0.002%, Si≤0.01%, Ni≤0.001%, and the balance is magnesium. The raw materials used are: AZ91 magnesium alloy, magnesium-20% yttrium-rich master alloy, of which yttrium-rich is from rich The yttrium-rich rare earth after extracting Eu, Dy, Tb, and Lu high-valent elements from the yttrium-rich rare earth, the composition and mass percentage of the yttrium-rich rare earth are that Y is 20%-90%, Er is 5%-20%, and Ho is 1 %~10%.

[0023] The properties of the alloy are shown in Table 1.

[0024] Weigh the raw materials according to the ratio, Preheat the base alloy to 200°C, put it into a crucible preheated to 300°C, and pass SF 6 :CO 2 SF with a volume ratio of 1:1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com