Patents

Literature

40results about How to "Good wear reduction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

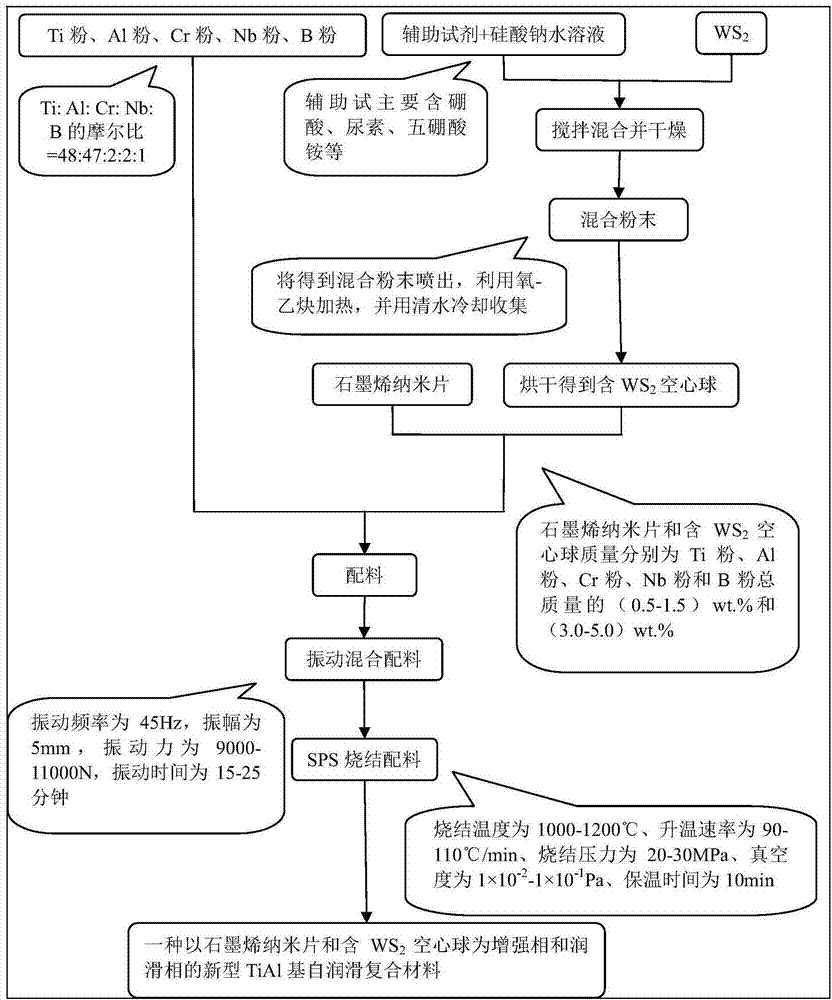

Novel TiAl base self-lubricating composite and preparing method

InactiveCN105861876AImprove mechanical propertiesGood wear reductionGraphene nanoplateletMechanical property

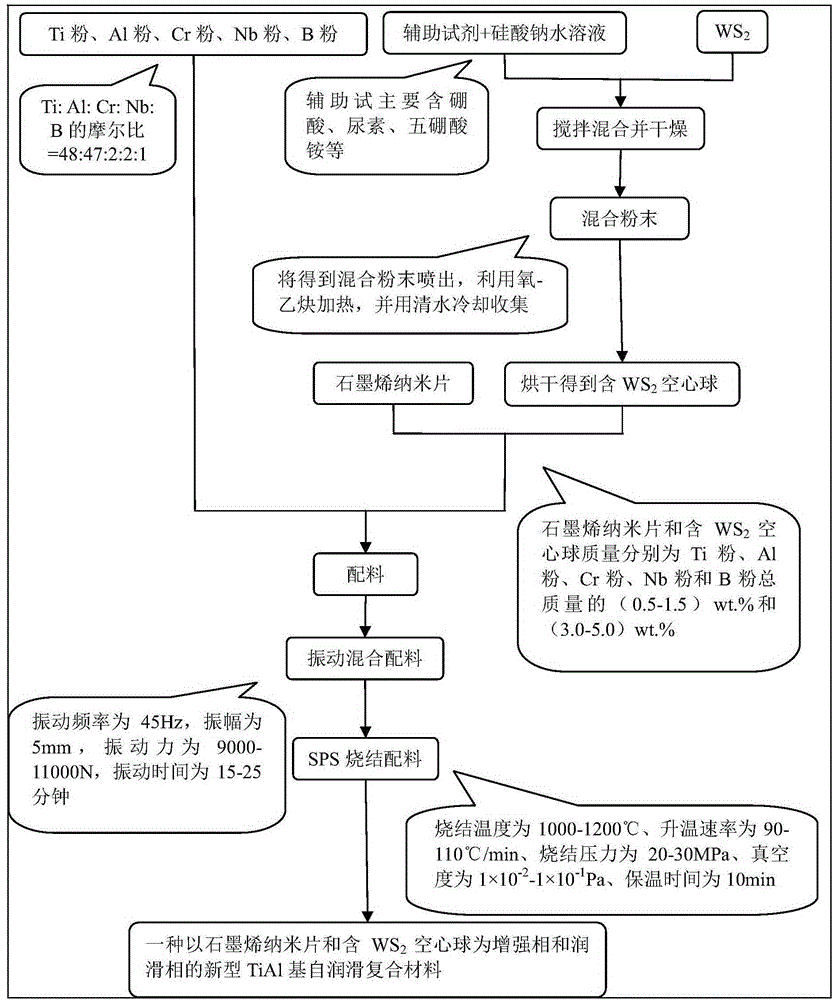

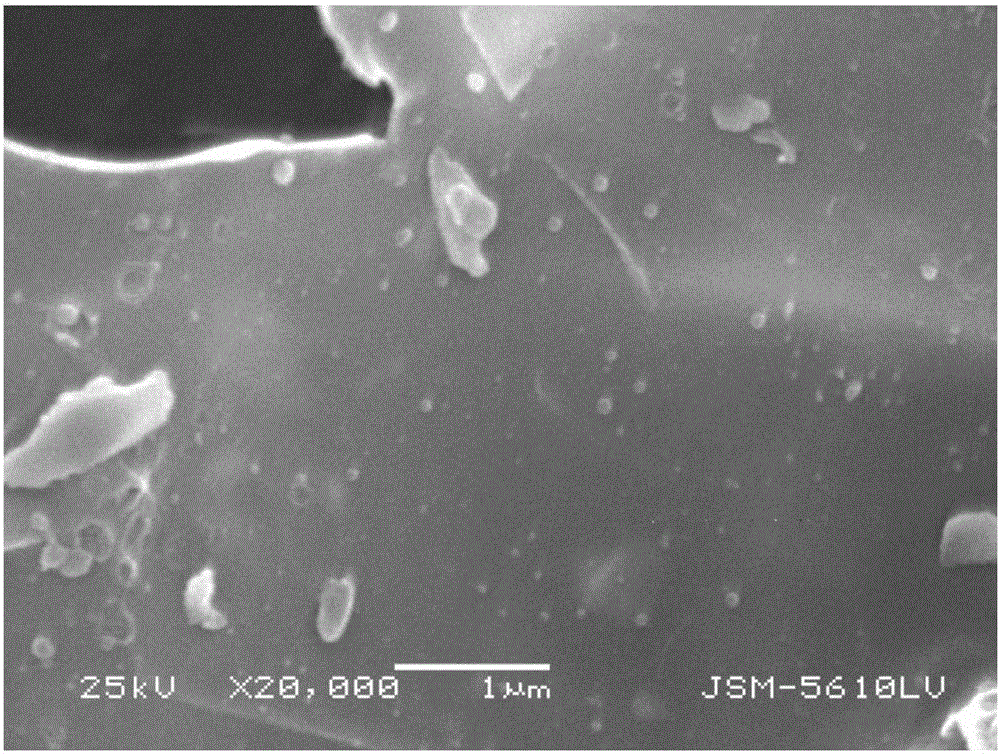

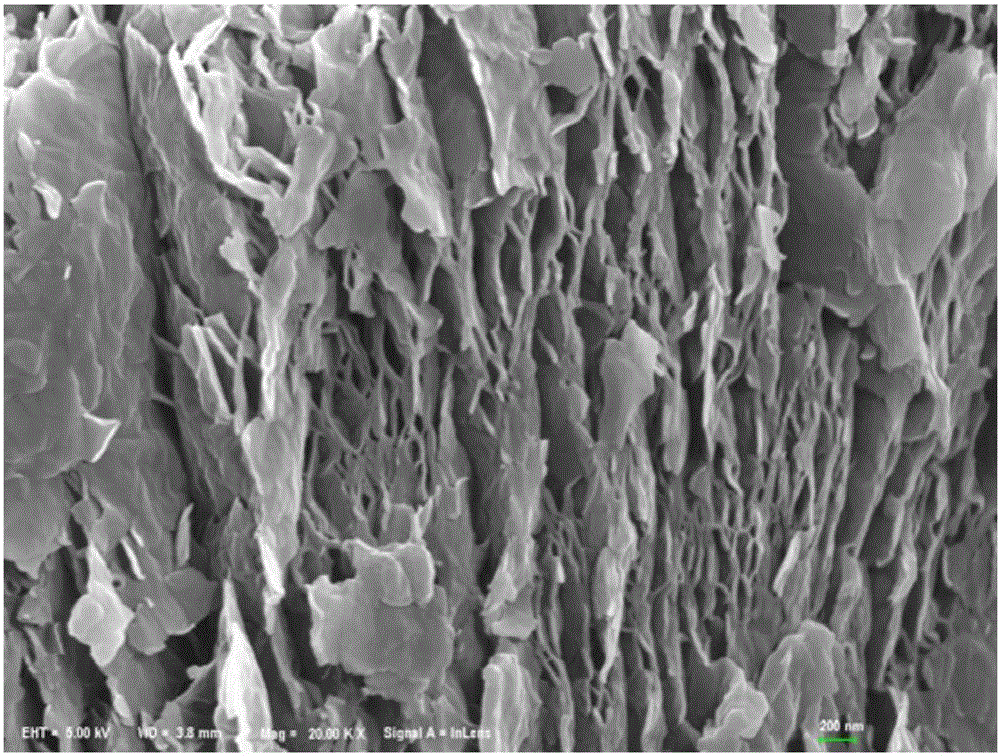

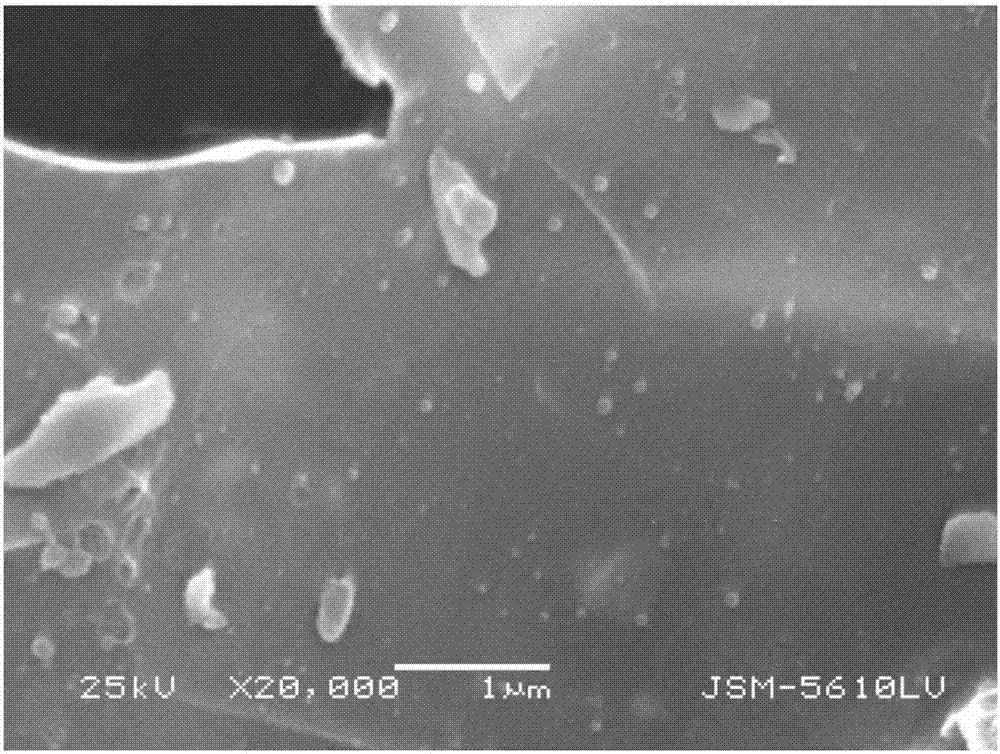

The invention relates to a novel TiAl base self-lubricating composite. The novel TiAl base self-lubricating composite is characterized in that a TiAl base serves as a matrix, and graphene nanosheets and hollow spheres containing WS2 serve as an enhancing phase and a lubricating phase. The graphene nanosheets account for 0.5-1.5 wt.% of the matrix by mass, and hollow spheres containing WS2 account for 3.0-5.0 wt.% of the matrix by mass. A preparing method of the novel TiAl base self-lubricating composite comprises the following steps that elementary substance powder is weighed according to the mole ratio of elements contained in the TiAl base to serve as matrix materials, the graphene nanosheets and the hollow spheres containing WS2 are weighed according to the proportion, the materials are evenly mixed and then subjected to spark plasma sintering, and the novel TiAl base self-lubricating composite is obtained. With the graphene nanosheets and the hollow spheres containing WS2 as the enhancing phase and the lubricating phase, the TiAl base self-lubricating composite is high in compactness, good in mechanical property and high in abrasion relieving and resisting performance.

Owner:WUHAN UNIV OF TECH

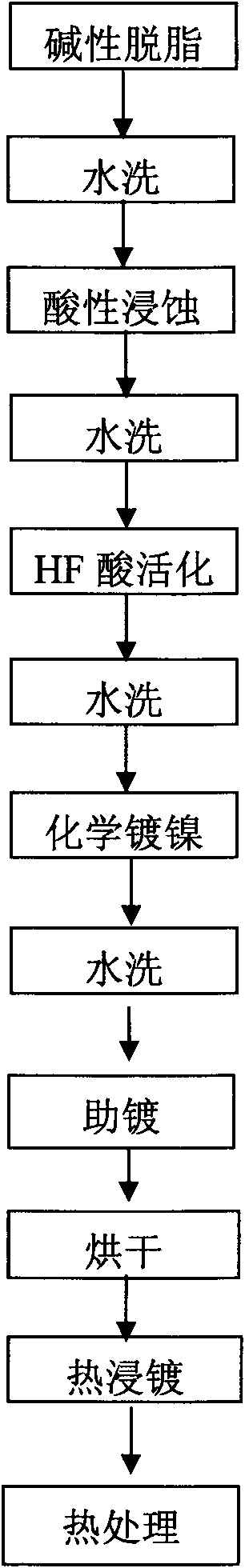

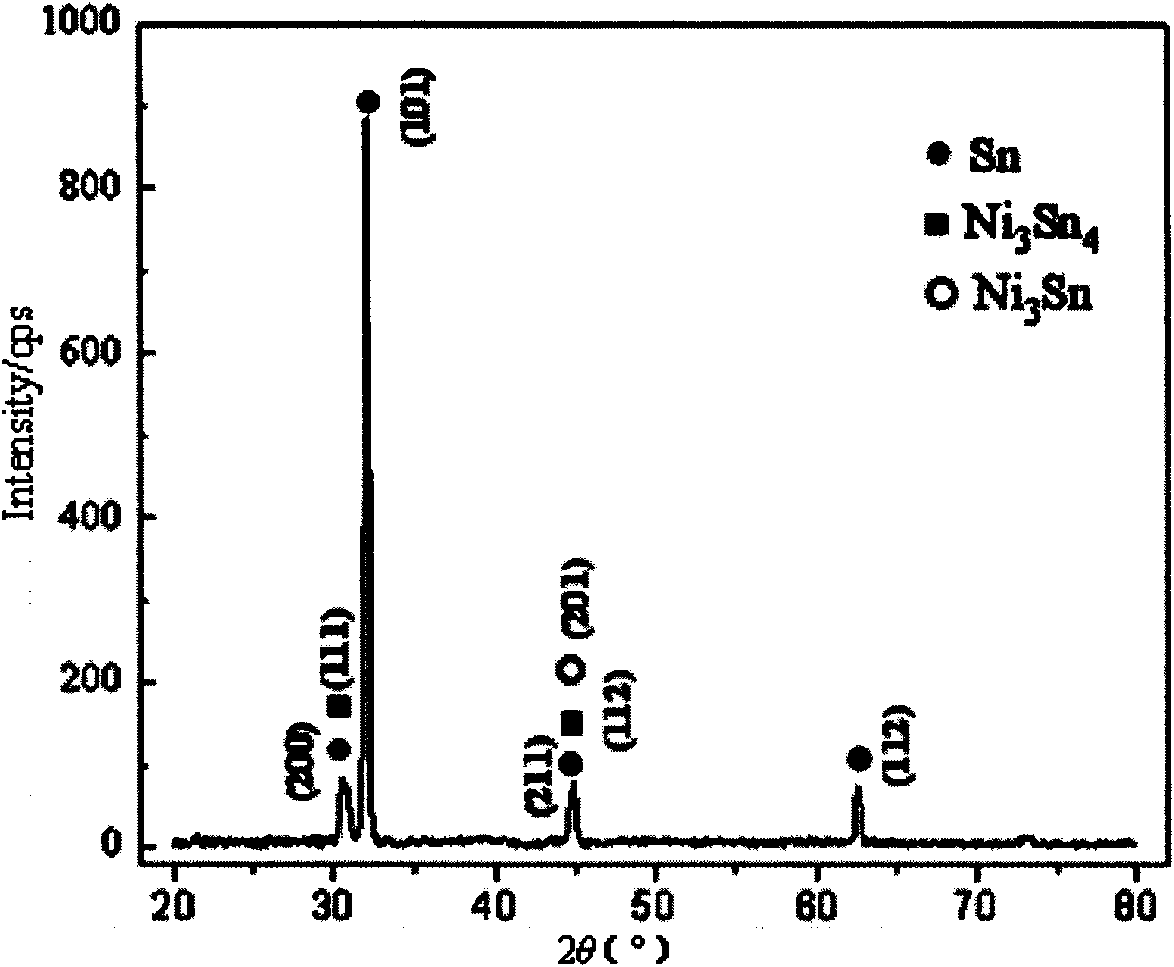

Magnesium or magnesium alloy surface hot-dip tinning or tin base alloy method

InactiveCN101660114AStrong paintabilityExcellent brazeabilityHot-dipping/immersion processesLiquid/solution decomposition chemical coatingChemical treatmentTinning

The invention relates to a magnesium or magnesium alloy surface hot-dip tinning or tin base alloy method, belonging to the magnesium alloy surface treatment field. The method includes that a nickel protective layer is precoated on magnesium or magnesium alloy surface by chemical treatment, so as to prevent oxidation of matrix and reaction with plating assistant agent in plating assistant, hot dipping of low melting point alloy (such as tin, tin base alloy and the like) is carried out after plating assistant, and finally heat treatment is carried out on work piece to improve quality of surfacecoating. The coating obtained by the method is continuous and uniform and has certain abrasive resistance, anti-attrition and decay resistance performances; and meanwhile the tin layer has low resistivity and favorable solder ability. The hot dipping technology is mature and reliable and is convenient for practical production and application.

Owner:JIANGSU UNIV

Biological type micro lubricating oil and preparation method and application thereof

InactiveCN101654636AImprove the lubrication effectImprove extreme pressure performanceAdditivesBase-materialsPhosphatePollution

The invention belongs to the technical field of lubricating oil, in particular to biological type micro lubricating oil which comprises the following raw materials in percentage by weight: 62-70 polyalpha olefin (PAO), 24-30 of composite synthetic ester, 1-2 N-lauroyl alanine, 1-2 composite phosphate and 1-2 dispersant. Compared with the prior art, the invention not only has better lubricating property and extreme pressure property so that few lubricating agents can meet high-end requirement of metal processing, but also can reduce the consumption of the lubricating agent to less than 5 percent of the previous consumption, reduces the harm to the environment and worker, can be degenerated biologically, and lowers the pollution to the environment to be maximum.

Owner:SHANGHAI JINZHAO ENERGY SAVING TECH

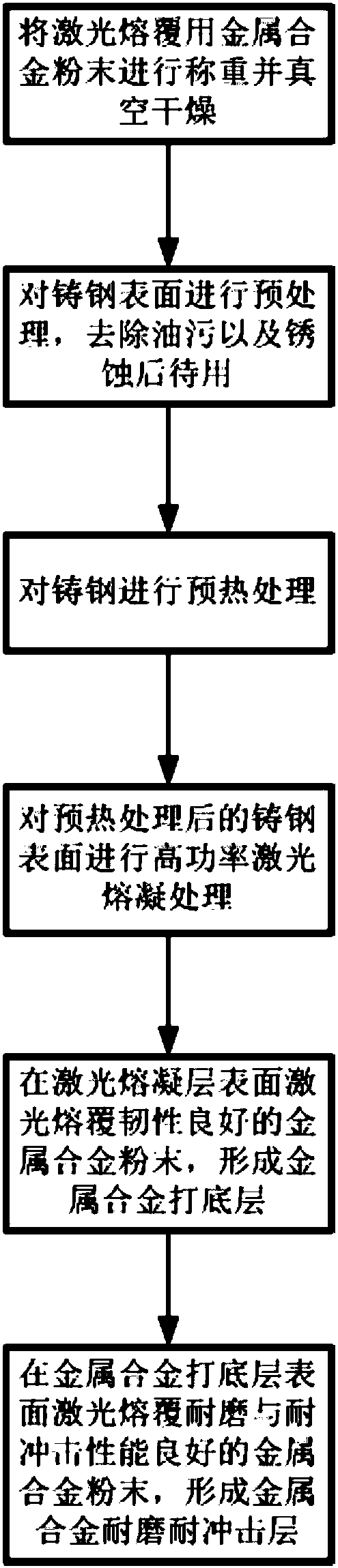

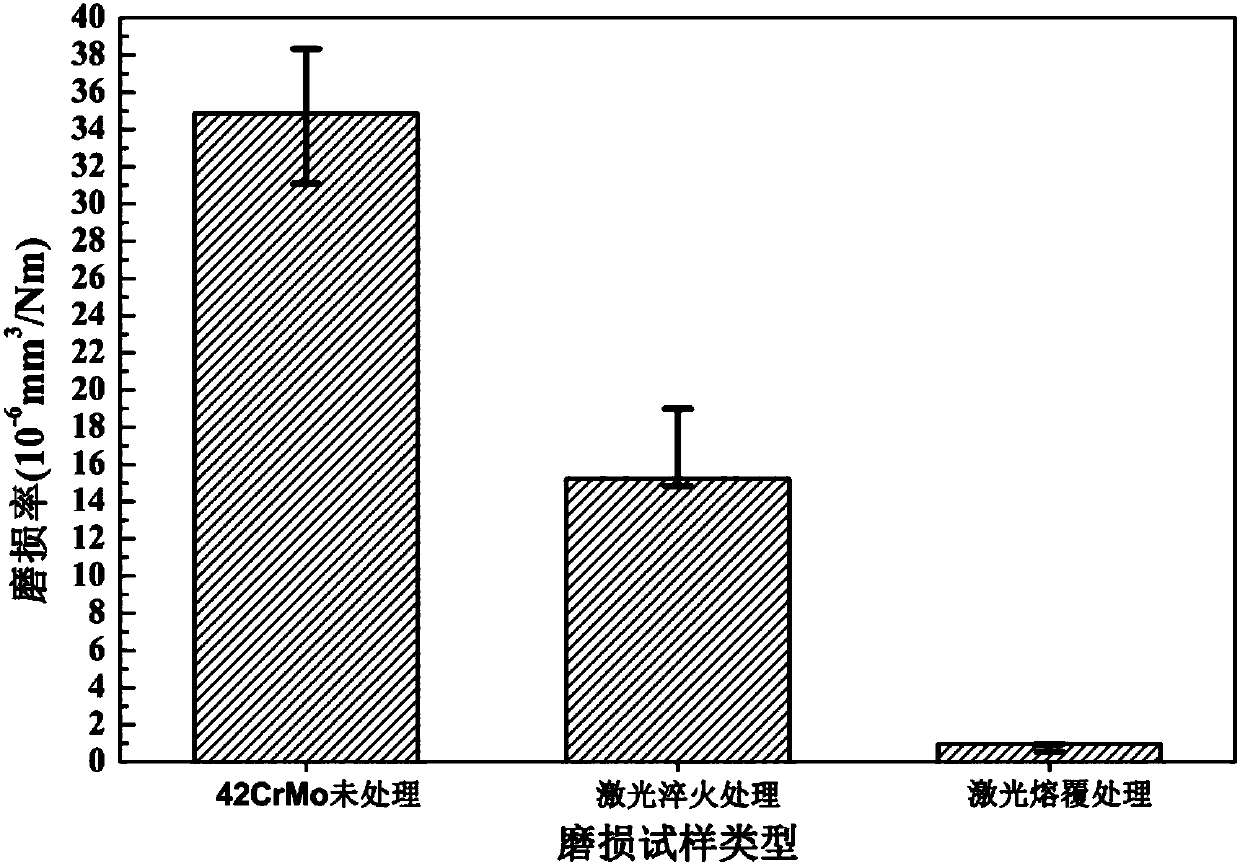

Method for laser cladding of wear-resistant and impact-resistant coating on cast steel surface

ActiveCN107937911AReduce defectsGood metallurgical bondSuperimposed coating processMetal alloyWear resistant

The invention discloses a method for the laser cladding of a wear-resistant and impact-resistant coating on a cast steel surface. The method comprises the following steps: 1, drying metal powder for cladding for 90-120min at temperature of 80-90DEG C; 2, grinding the to-be-processed surface of cast steel with abrasive paper to carry out frosting treatment, and then, using acetone to clean oil stains for a standby purpose; 3, carrying out preheating treatment on the cast steel at 400-500DEG C; 4, carrying out laser cladding treatment on the preheated cast steel surface; 5, after laser claddingtreatment is finished, carrying out coaxial powder feeding and the laser cladding of a metal alloy bottom coating on a formed laser solidified layer; and 6, carrying out coaxial powder feeding and thelaser cladding of a metal alloy wear-resistant and impact-resistant layer again on the formed metal alloy bottom coating.

Owner:CHANGCHUN UNIV OF SCI & TECH

Antiwear additive of lubricating oil

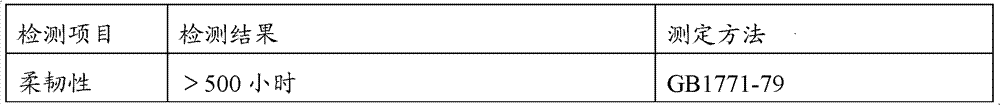

The invention relates to an antiwear additive of lubricating oil, which is characterized by comprising 1%-5% of dispersant, 5%-20% of nanoscale metal powder and the balance of base oil, wherein the nanoscale metal powder comprises copper oxide powder, magnesium powder, chromium powder and boron powder; and the dispersant is polyisobutene-bis-succinimide or polyisobutene-multi-succinimide. A preparation method is simple and practical; in addition, the prepared additive has low cost, can play good abrasion resistant effect on various base oils and has good repairing function but no corrosion effect inside a machine.

Owner:TIANJIN GONGBO SCI TECH DEV

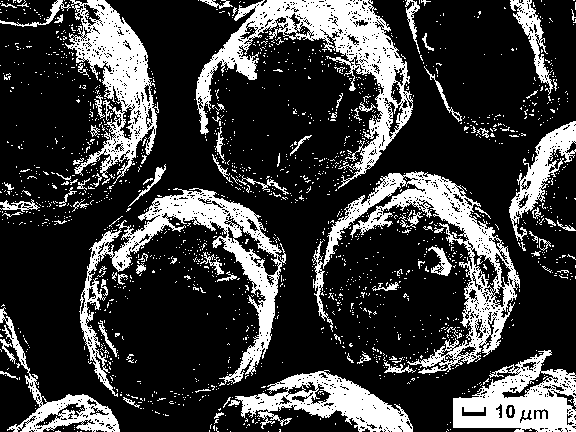

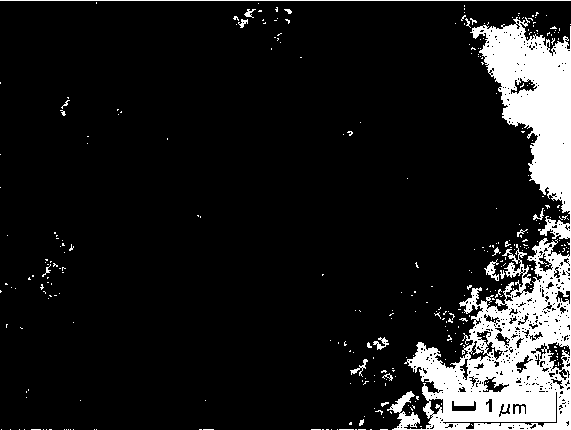

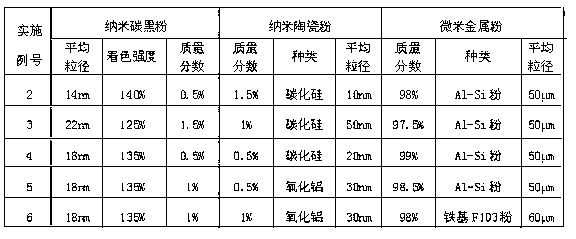

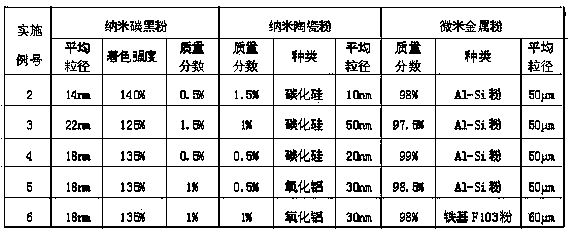

Diphase nanometer strengthened metal matrix micro-nanometer power and preparation method thereof with both antifriction and wear-resistant effects

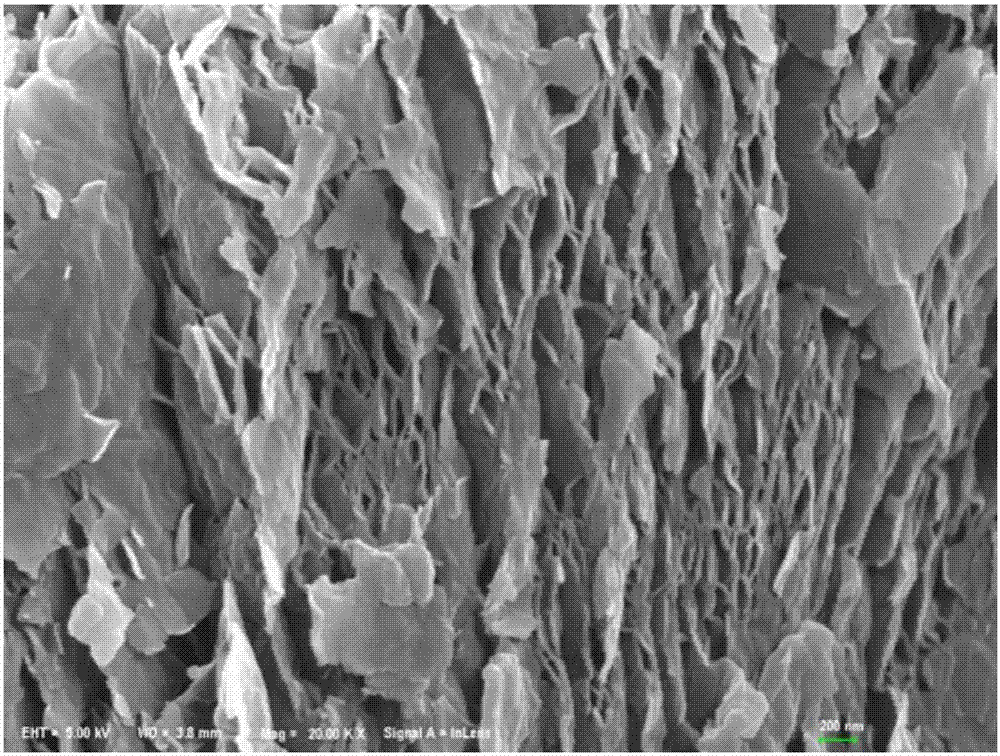

InactiveCN102990063AImprove wear resistanceGood wear reductionCoatingsCarbon blackMechanical properties of carbon nanotubes

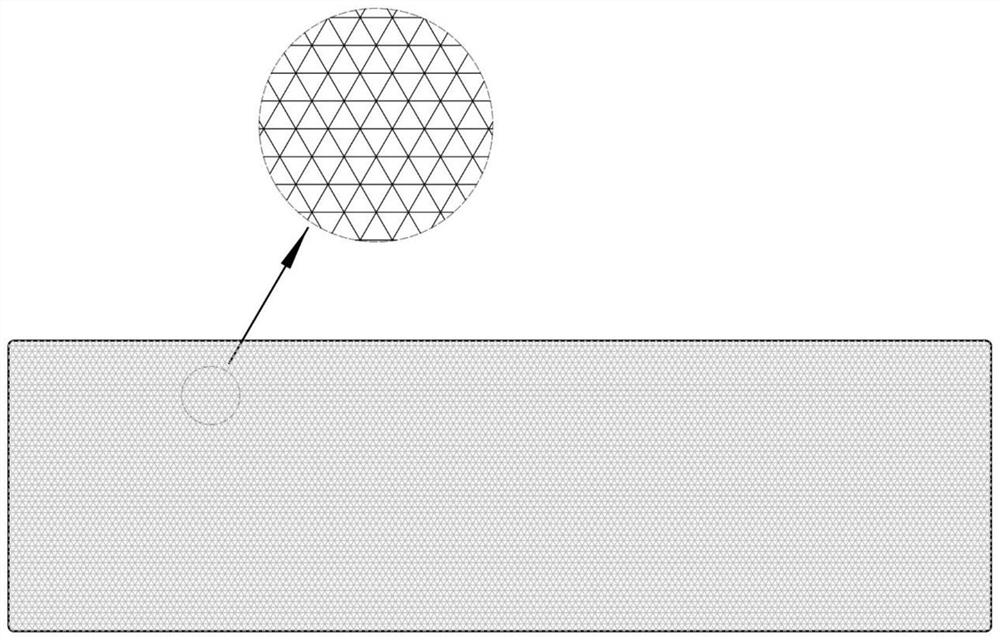

Diphase nanometer strengthened metal matrix micro-nanometer power and a preparation method thereof with both antifriction and wear-resistant effects are characterized in that, the diphase nanometer strengthened metal matrix micro-nanometer power is composed of compositions of, by weight percentage, nanophase carbon black power of 0.5-1.5%, nanophase ceramics power of 0.5-1.5% and micron metal powder of 97-99%, wherein the sum of the weight percentage of the compositions is 100%; micro-nanometer power in a core shell structure and with the micron metal powder as a core and with the nanophase carbon black power and the nanophase ceramics power as a shell is formed, and the preparation method of the micro-nanometer power mainly includes preparation of single-phase nanophase carbon black suspension liquid and single-phase nanophase ceramics suspension liquid, preparation of carbon black and ceramics diphase suspension liquid, pre-spheroidization of the micron metal powder, drying of the carbon black and ceramics diphase suspension liquid, and drying of ball-milling composite and micro-nanometer slurry after ball-milling compositing of the micron metal powder after preprocessing. A laser wear-resistant modified layer prepared by the preparation method is small in friction coefficient, low in volume abrasion rate, narrow in heat affected zone, tiny and compact in organization, and basically without carbide mingled, has a better mechanical property compared with reproducing of micrometer power, and simultaneously, the micro-nanometer power has good absorptivity for lasers.

Owner:JIANGSU UNIV

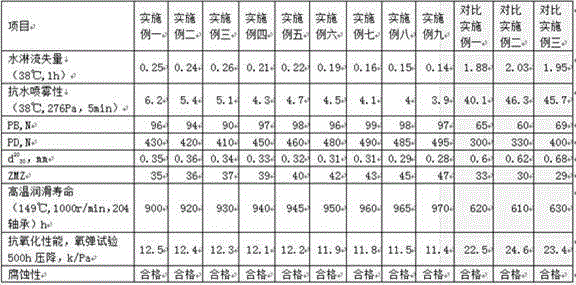

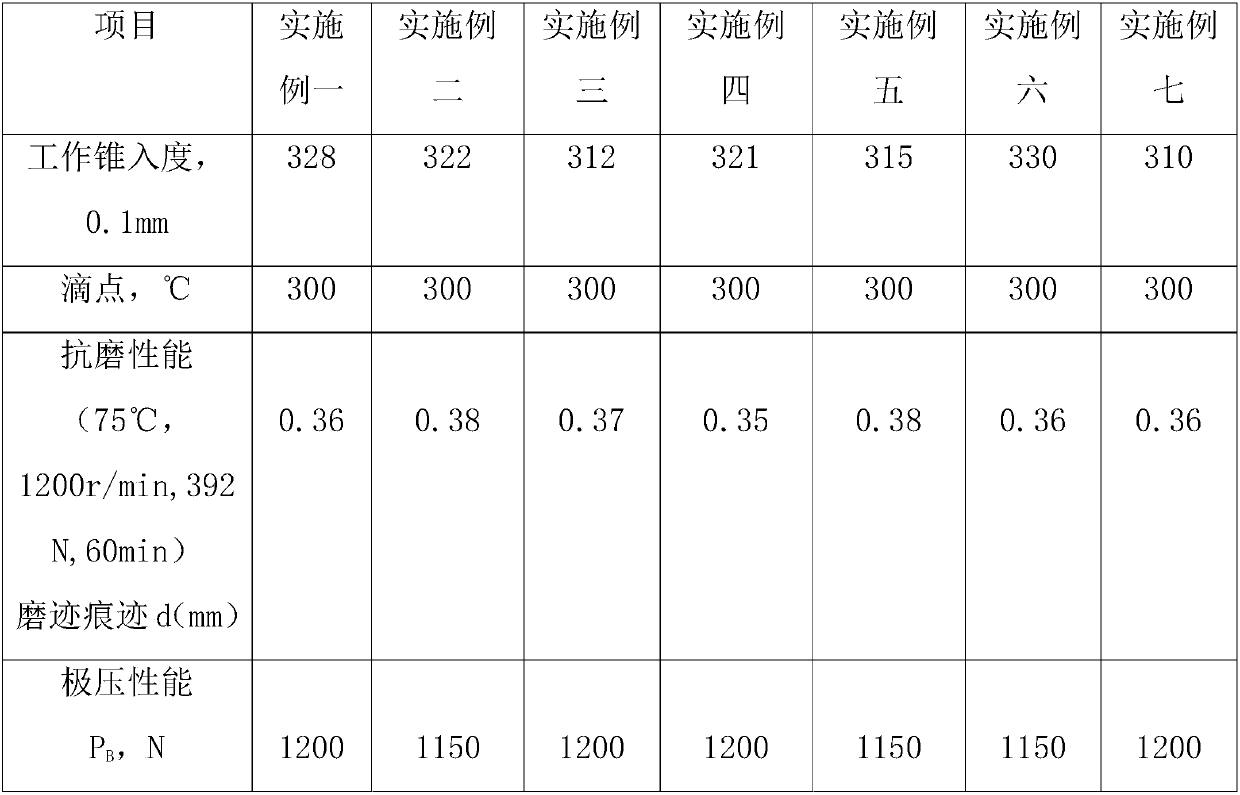

Lubricating grease

The present invention relates to a lubricating grease, which comprises base oil, 12-hydroxystearic acid, lithium hydroxide, potassium hydroxide, petroleum calcium sulfonate, rosin, vegetable oil, (NH4)xMoS2, a first solid additive, a second solid additive, a first composite modifier comprising trioctylmethylammonium bromide, glycerol and polytetrafluoroethylene, a second composite modifier comprising diphenylamine, 2,6-di-tert-butyl and benzotriazole, and a third composite modifier comprising sulfurized cottonseed oil T404, bis(2-mercapto-4-n-propylamino-1,3,5-triazine)thioether and bis(2-mercapto-4-cyclopentylamino-1, 3,5-triazine)thioether. The lubricating grease of the present invention has advantages of good sealing performance, strong corrosion resistance, excellent anti-wear performance, and excellent anti-extreme pressure performance.

Owner:HANGZHOU DADI OCEAN ENVIRONMENT PROTECTION

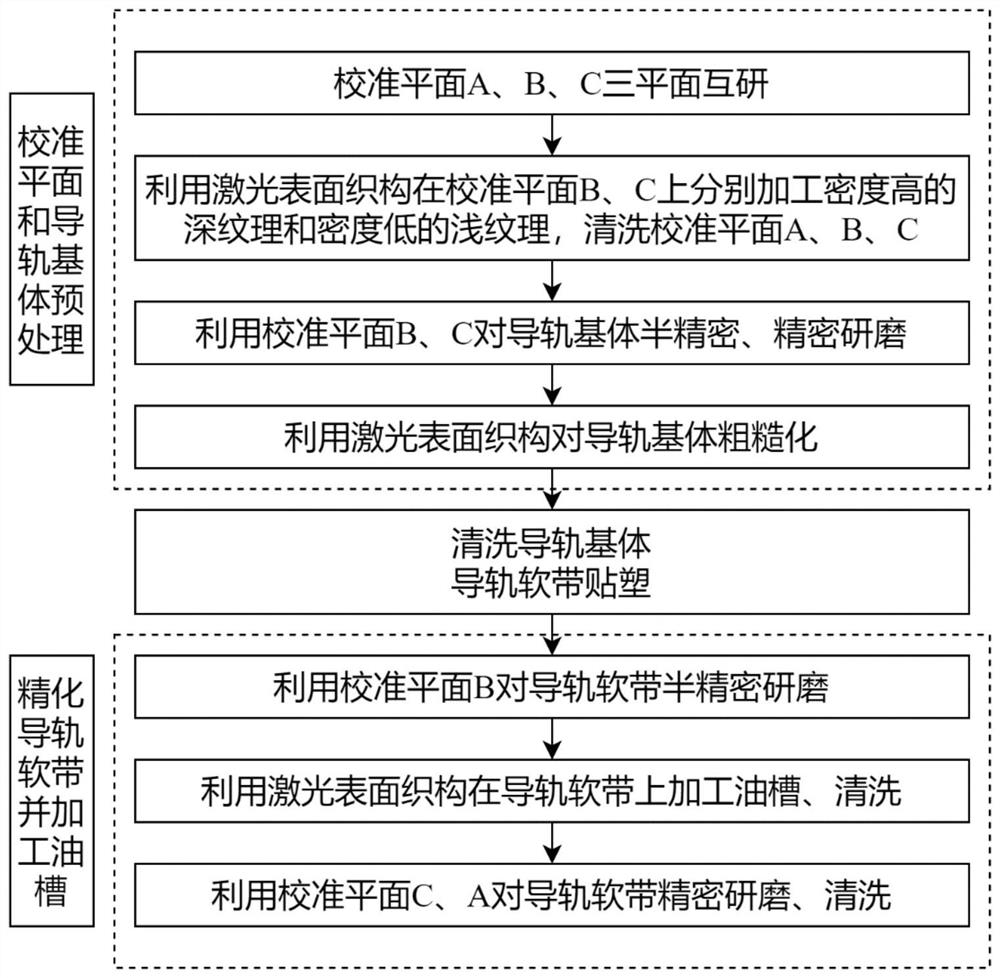

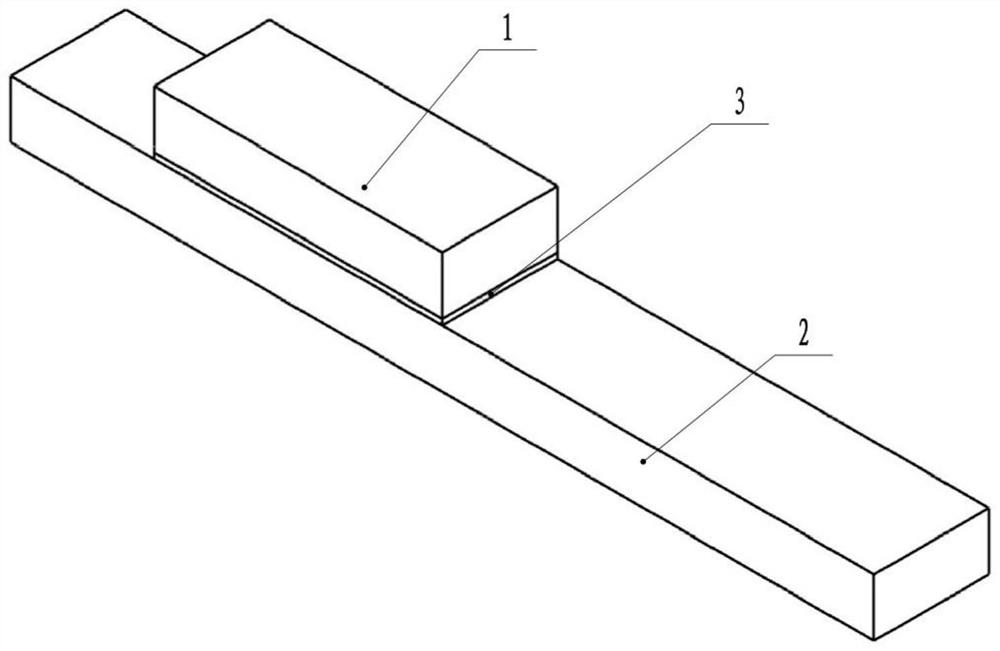

Sliding guide rail plastic-pasting process method

The invention belongs to the technical field of precision machining and testing, and relates to a sliding guide rail plastic-pasting process method, which comprises the following steps of: machining a high-flatness calibration plane by utilizing a three-plane mutual grinding method to grind and refine a guide rail base body, roughening the guide rail base body by utilizing a laser surface texture, and after the guide rail base body is subjected to plastic pasting, matching the laser surface texture with the calibration plane for grinding to refine a guide rail soft belt and machine an oil groove. The method can replace manual scraping to machine the guide rail base body and the guide rail soft belt, so that the machining efficiency is higher, the labor intensity is lower, and the precision consistency is better; the sliding guide rail can be subjected to high-precision plastic pasting machining without more scraping experience, so that the processing cost is lower; and complex oil grooves with different shapes and depths can be designed, so that flowing of lubricating oil and antifriction of the sliding guide rail are facilitated, the using performance of a sliding pair is improved, the service life of the sliding pair is prolonged, and the good market application prospect and popularization value are achieved.

Owner:DALIAN UNIV OF TECH

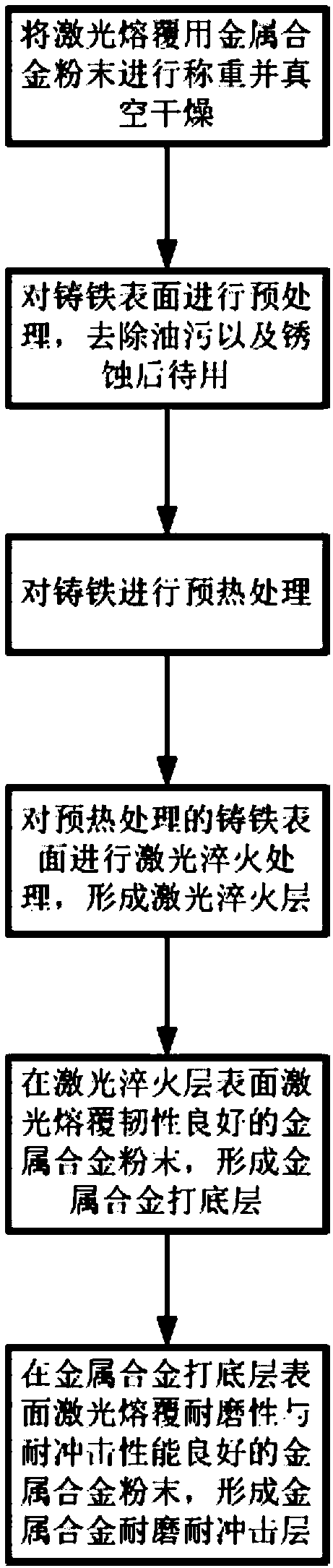

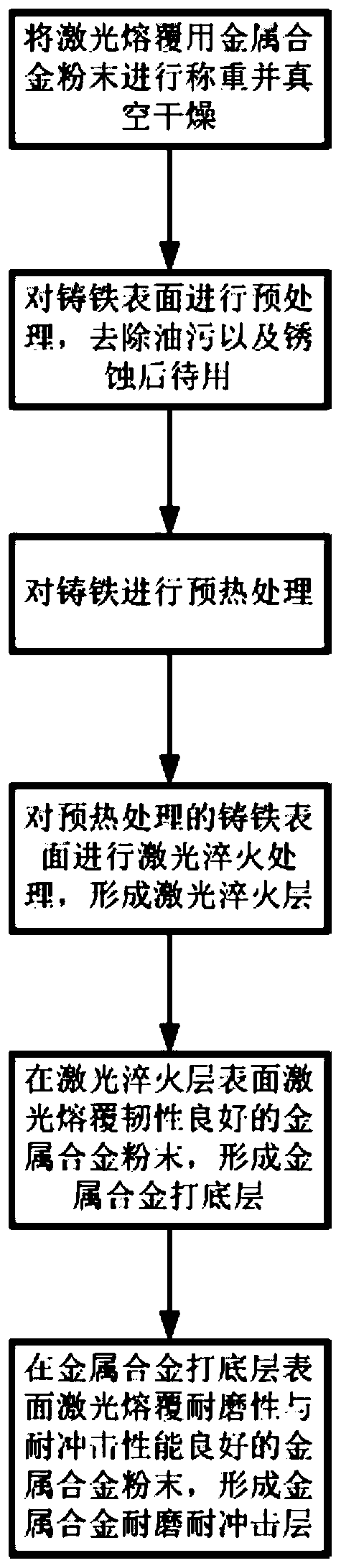

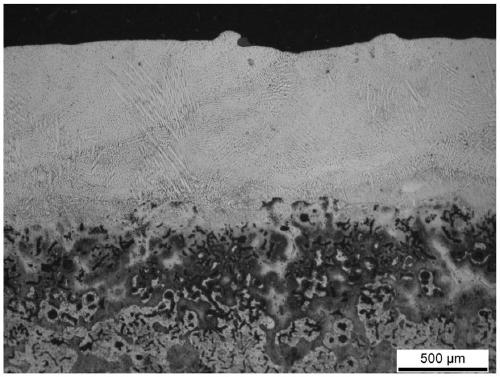

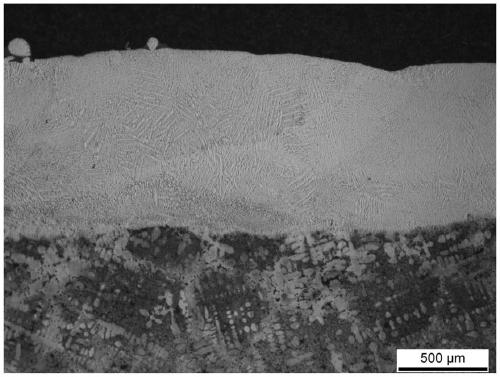

Method for carrying out laser cladding to form wear-resistant and impact-resistant coating layer on cast iron surface

ActiveCN108130532AReduce carbon contentReduce porosityMetallic material coating processesCast ironWear resistant

The invention discloses a method for carrying out laser cladding to form a wear-resistant and impact-resistant coating layer on a cast iron surface. The method comprises the following steps of (1) drying metal powder for cladding at a drying temperature of 80-90 DEG C for 90-120 min; (2) polishing the machined cast iron surface by virtue of abrasive paper and carrying out roughening treatment, andthen removing oil stain by virtue of acetone for the future use; (3) coating the machined cast iron surface with a blackening coating material for laser quenching, and then carrying out laser quenching treatment; (4) after the laser quenching treatment is concluded, carrying out coaxial powder feeding and laser cladding to form a metal alloy prime coating layer on the formed laser quenching layer; and (5) carrying out coaxial powder feeding and laser cladding again to form the metal alloy wear-resistant and impact-resistant layer on the formed metal alloy prime coating layer.

Owner:CHANGCHUN UNIV OF SCI & TECH

High temperature resistance rubber material for vehicles

InactiveCN105400013APracticalImprove high temperature resistanceArtifical filament manufactureRubber materialColemanite

The invention discloses a high temperature resistance rubber material for vehicles, which is prepared through raw materials with parts by weight: polyacrylonitrile 24-27, graphite 12-13, coal ash microspheres 3-4, lauryl sodium sulfate 0.7-1, liquid acrylonitrile butadiene rubber 42-55, methacrylic acids 0.6-1, nitrile rubbers 52-60, butadiene styrene rubber 20-25, colemanite 17-20, benzoyl peroxide 0.4-0.6, vulcanizing agent N,N'-m-phenylenedimaleimide (PDM) 2-3, liquid paraffin 2-3, an anti-aging agent D1-2, double fourteen carbon alcohol esters 1-2, clays 13-15, pyrophyllite in powder 7-8 and magnesium stearate 1-2. The high temperature resistance rubber material for the vehicles is excellent in high temperature resistance, cheap in raw materials, low in production cost and strong in practicality, has excellent application prospect when being used for the vehicles, and is simple in preparation method and easy for industrialization.

Owner:安徽创奇乐智能游乐设备有限公司

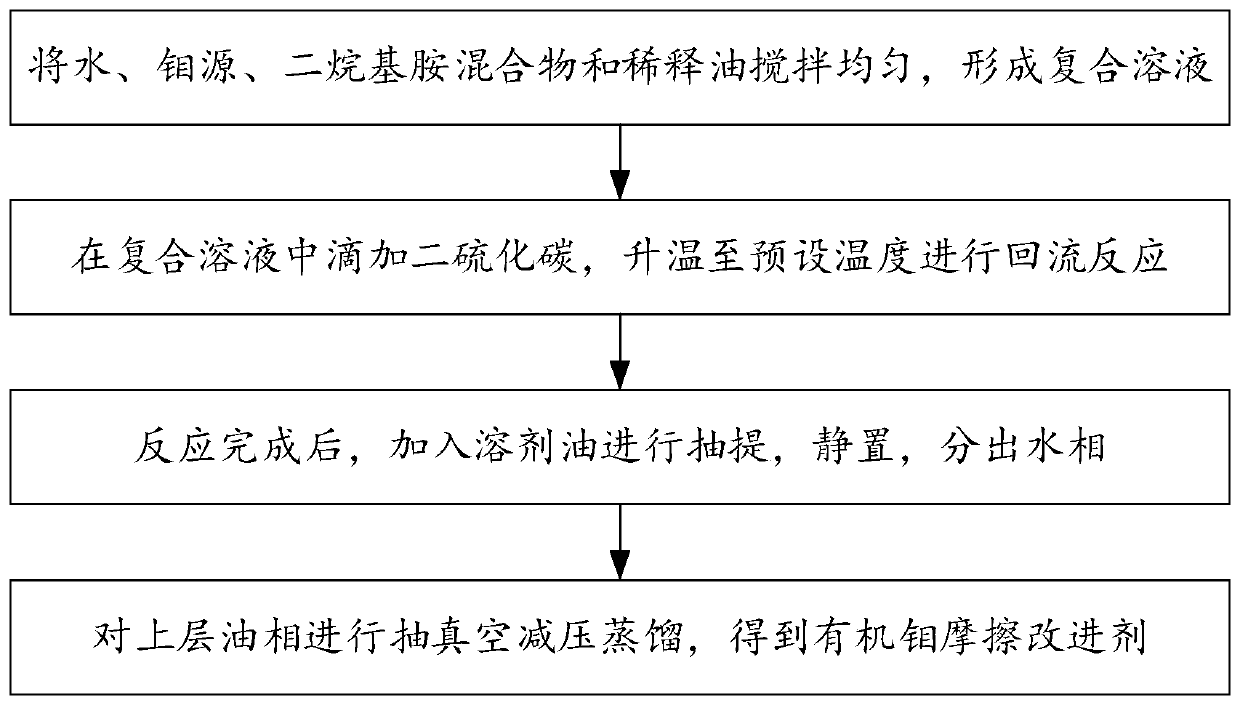

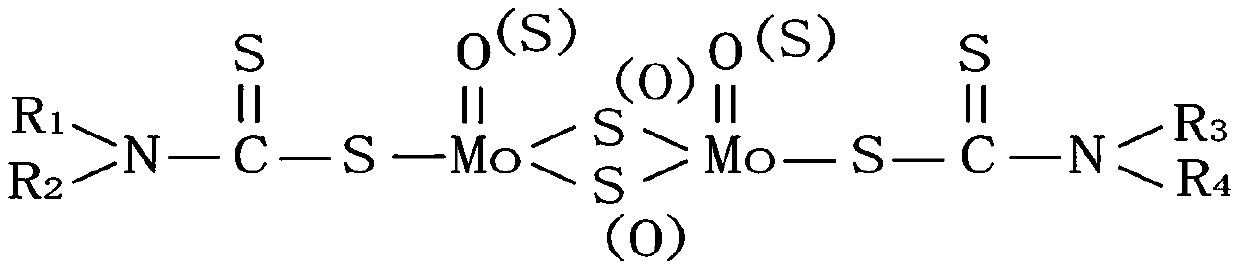

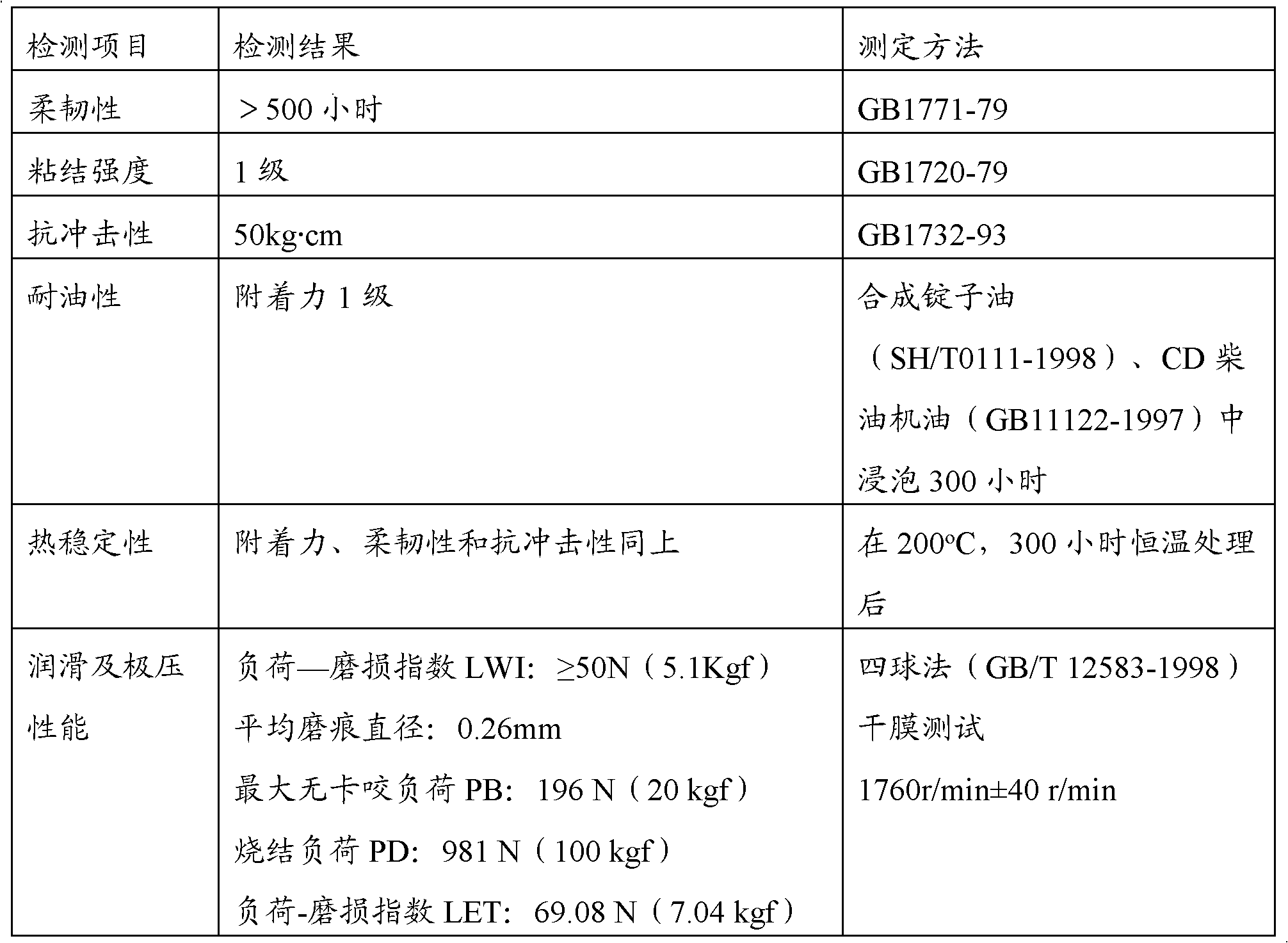

Preparation method of oil-soluble organic molybdenum friction modifier

The invention discloses a preparation method of an oil-soluble organic molybdenum friction modifier, wherein the preparation method comprises the steps: uniformly stirring water, a molybdenum source,a dialkylamine mixture and diluent oil to form a composite solution; dropwise adding carbon disulfide into the composite solution, heating to a preset temperature, and carrying out a reflux reaction;after the reaction is finished, adding solvent oil for extraction, standing, and separating out a water phase; and carrying out vacuum-pumping reduced pressure distillation on the upper-layer oil phase to obtain the organic molybdenum friction modifier. According to the preparation method, inorganic and organic reagents such as sodium hydrosulfide, hydrochloric acid, sulfuric acid, methyl alcoholand methylbenzene are not used, equipment under pressure is not needed, the production cost is low, and the production process is safe; the preparation method disclosed by the invention does not needcomplicated processes such as water washing and filtering, adopts solvent oil to extract the product after synthesis is finished, is simple in process and strong in operability and repeatability, andis suitable for large-scale industrial production; meanwhile, the separated water phase and the solvent oil recovered by reduced pressure distillation can be recycled, and basically no three wastes are generated.

Owner:XINXIANG RICHFUL LUBE ADDITIVE CO LTD

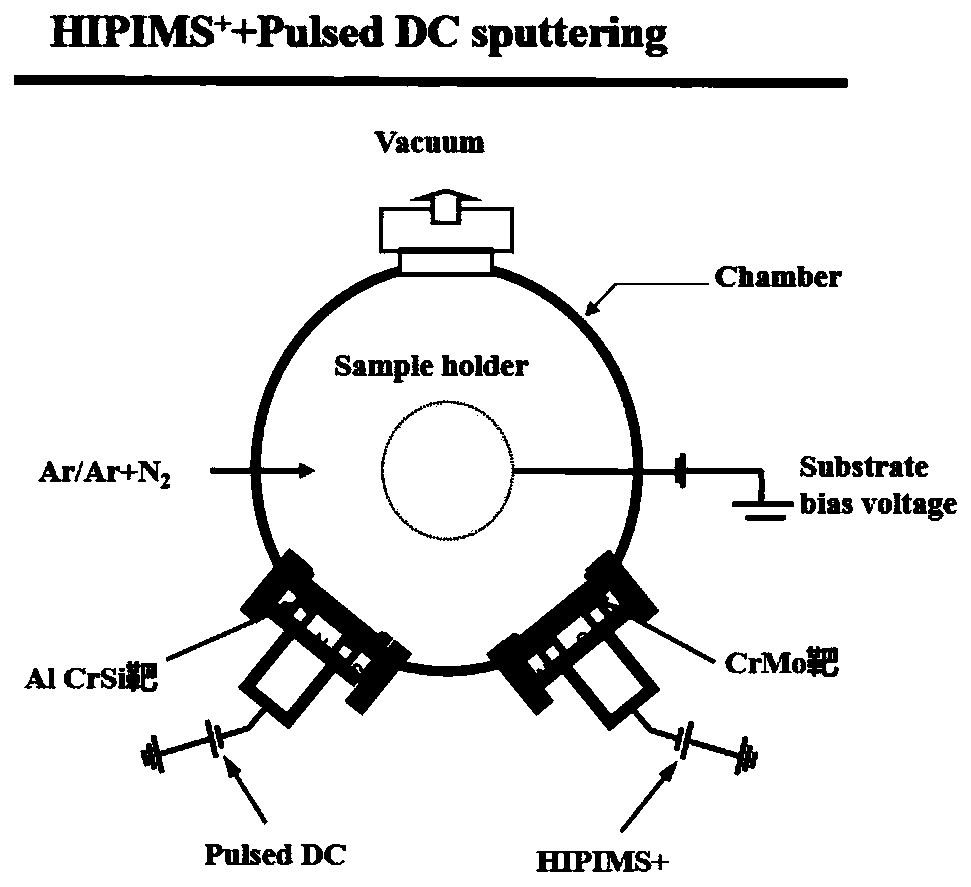

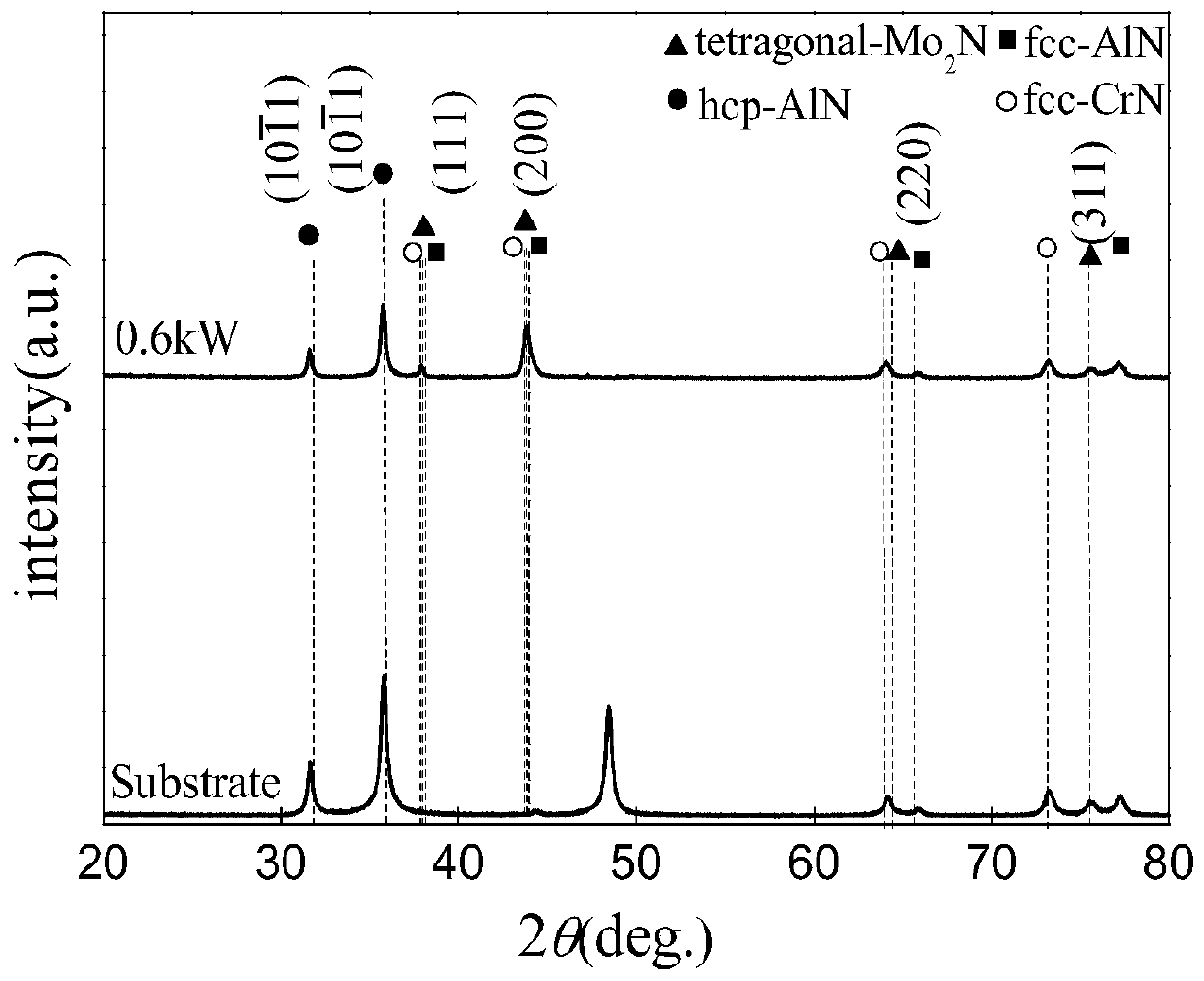

Mo-doped AlCrSiN/Mo self-lubricating film and preparation method thereof

InactiveCN110607499AIncreased resistance to dislocation movementImprove performanceVacuum evaporation coatingSputtering coatingMo elementHardness

The invention discloses a Mo-doped AlCrSiN / Mo self-lubricating film and a preparation method of the Mo-doped AlCrSiN / Mo self-lubricating film, and belongs to the technical field of films and preparation of the films. The AlCrSiN / Mo self-lubricating film is formed by doping Mo elements into a AlCrSiN film, the doping amount of the Mo elements is 0.3-6.3at.%, and the film is prepared on a substrateby adopting a high-power pulse magnetron sputtering technology and a pulse direct current magnetic control coating technology. The prepared AlCrSiN / Mo self-lubricating film is high in hardness, good in toughness, excellent in wear reduction property and capable of remarkably reducing friction between a cutter and chip, and has good chemical stability and easy-to-shear lubricating property.

Owner:TIANJIN UNIV OF TECH & EDUCATION TEACHER DEV CENT OF CHINA VOCATIONAL TRAINING & GUIDANCE

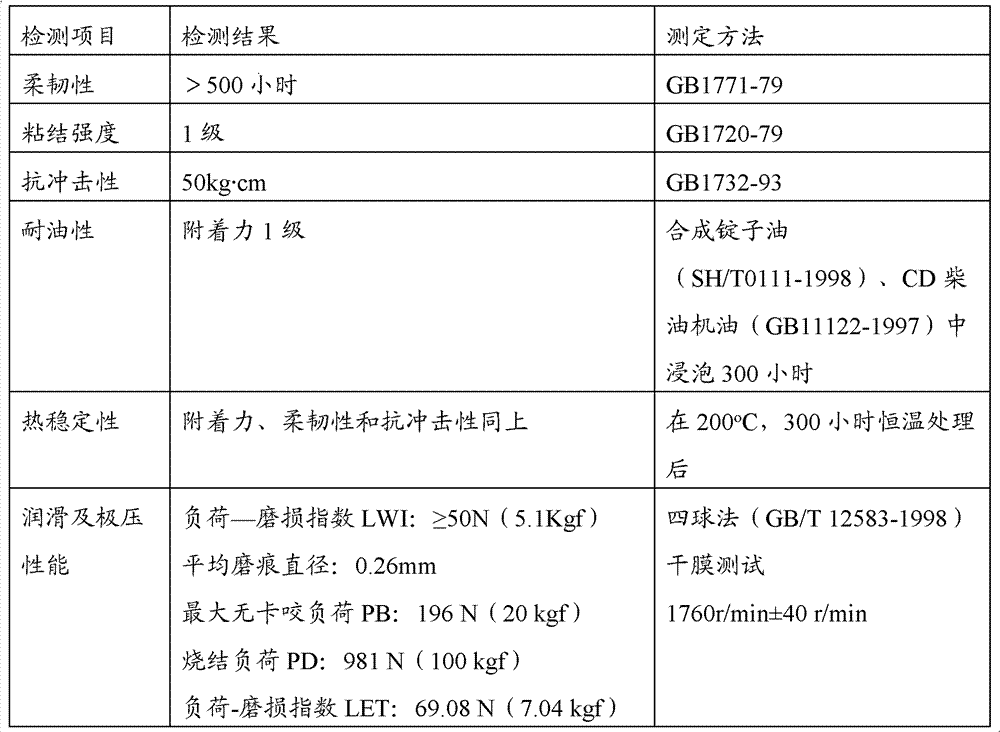

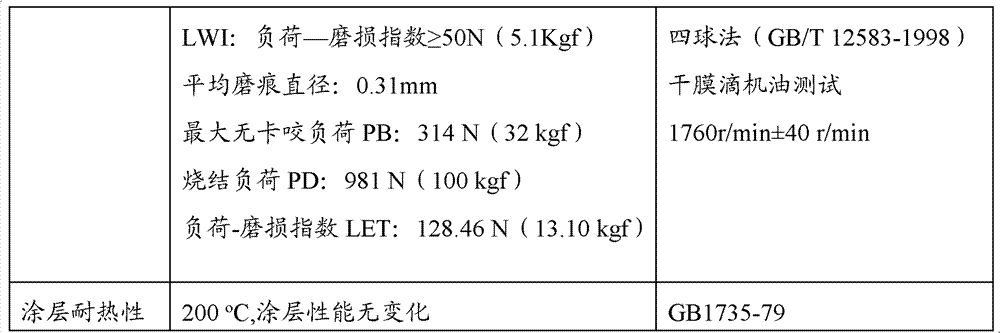

Liquid coating and preparation method thereof

ActiveCN102002302AImprove conductivityImprove thermal conductivityEpoxy resin coatingsEpoxyCyclohexanone

The embodiment of the invention discloses a liquid coating and a preparation method thereof, wherein the liquid coating comprises the following ingredients: 40 wt% - 60 wt% of cyclohexanone, 2 wt% - 10 wt% of ethyl cellulose, 10 wt% - 30 wt% of epoxy resin, 5 wt% - 20 wt% of phenolic resin, 5 wt% - 15 wt% of molybdenium disulfide, and 1 wt% - 10 wt% of graphite. The experimental result shows thatthe liquid coating of the invention has the functions of thermostability, wear resistance and self lubrication, and has excellent comprehensive performance and low cost, and is applicable to the components, such as a piston.

Owner:ANQING CSSC DIESEL ENGINE

Graphene lubricating oil and preparation method thereof

The embodiments of the invention disclose graphene lubricating oil. The graphene lubricating oil is formed by mixing an ionic liquid, graphene and base oil, wherein a mass ratio of the ionic liquid tothe base oil is 0.0001%-1%; and a mass ratio of the graphene to the base oil is 0.001%-1%. According to the lubricating oil provided by the embodiments of the invention, after the graphene and the ionic liquid are added, the graphene is uniformly and firmly adhered to the surface of a metal to form a film having excellent lubrication and protective properties, and the graphene has very strong adsorption effects on the ionic liquid, so that the antifriction and anti-wear performance of the lubricating oil can be significantly improved, and the bearing capacity of lubricating oil can be improved.

Owner:SHENYANG JIANZHU UNIVERSITY

Cooling lubricating oil

InactiveCN103725375AGood wear reductionExcellent self-healing performanceLubricant compositionOctanoic AcidsMachine parts

The invention discloses cooling lubricating oil which comprises the following components by mass: 1-3 parts of phenylalanine, 3-4 parts of m-anisaldehyde, 1.2-1.8 parts of trilinolein, 2-4 parts of trimethyl octane, 1-3 parts of trimethyl decane, 3-6 parts of molybdenum disulfide, 2-5 parts of polytetrafluoroethylene, 20-25 parts of cobalt naphthenate, 35-45 parts of lead isocaprylate, 1.6-1.8 parts of an alpha-olefin copolymer pour point depressant, 1-3 parts of a nonionic surfactant, 1.5-2.5 parts of a clearing agent, 2-2.5 parts of a dispersing agent, 0.5-1.2 parts of an anti-wear reagent at extreme pressure, 0.6-0.8 part of an antirust agent, 0.3-0.6 part of an antioxidant, 0.1-0.15 part of a pour point depressant, 20-80PPM of an antifoaming agent, 5-9 parts of a tackifier, 0.6-0.8 part of an oxidation and corrosion inhibitor, 3-5 parts of a viscosity index improver, 0.1-0.2 part of a demulsifying agent, 0.1-1 part of nano-graphite, 10-15 parts of nano ZrO2. According to the cooling lubricating oil, friction on machinery can be effectively reduced, the machinery and machined parts are protected, mechanical impurities, carbon residue, ash content and sulphated ash are removed, the effect of cooling the machinery is extremely obvious, and the cooling lubricating oil is convenient to use and low in manufacturing cost.

Owner:ZHANGJIAGANG LINDA ADMIXTURE FACTORY

Rubber material high in toughness and not prone to breakage

InactiveCN105462003AHigh tensile strengthImprove toughnessElectroconductive/antistatic filament manufactureSodium lactateRubber material

The invention discloses a rubber material high in toughness and not prone to breakage. The rubber material is prepared from raw materials in parts by weight as follows: 10-14 parts of talcum powder, 1-2 parts of an accelerant CZ, 2-3 parts of melamine polyphosphate, 10-13 parts of polybutadiene, 24-27 parts of polyacrylonitrile, 12-13 parts of graphite, 3-4 parts of fly-ash microspheres, 0.7-1 part of lauryl sodium sulfate, 42-55 parts of liquid nitrile rubber, 0.6-1 part of methylacrylic acid, 52-60 parts of nitrile rubber, 20-25 parts of butadiene styrene rubber, 8-10 parts of porcelain clay, 0.2-0.3 parts of citric acid, 1-2 parts of cardamom oil, 6-8 parts of barium metaborate, 6-7 parts of gelatin, 4-5 parts of polytetrafluoroethylene and 0.2-0.3 parts of sodium lactate. The prepared rubber material has the excellent flame retardance, is uninflammable, good in tensile strength, good in toughness, not prone to breakage and excellent in physical and mechanical performance, and has the long service life in a severe environment.

Owner:安徽创奇乐智能游乐设备有限公司

Nano copper lubricated micro-emulsification cutting solution

InactiveCN106675720ALow costImprove scratch resistanceLubricant compositionAmmonium dodecyl sulfateFatty acid

The invention discloses a nano copper lubricated micro-emulsification cutting solution prepared from the following raw materials: refined mineral oil, ammonium lauryl sulfate, coconut monoethanol amide, polyoxyethylene fatty acid, undecanedioic acid, triglyceride sulfide, diethanolamine, petroleum sodium sulfonate, sodium chloride, propanetriol, cetanol, a defoaming agent, copper sulfate pentahydrate, polystyrene sulfonic acid, ammonium persulfate, an appropriate amount of aniline, an appropriate amount of ethylenediamine tetraacetic acid, an appropriate amount of sodium hypophosphite, an appropriate amount of methanol, and an appropriate amount of deionized water. The prepared micro-emulsification cutting solution according to the invention does not contain substances harmful to the environment and human health, has excellent processability, strong universality, excellent antirust performance, corrosion resistance and wear resistance, and a long service life, and has a high price / performance ratio and is worthy of promotion compared with like products.

Owner:TIANCHANG RUNDA METAL ANTIRUST AUX

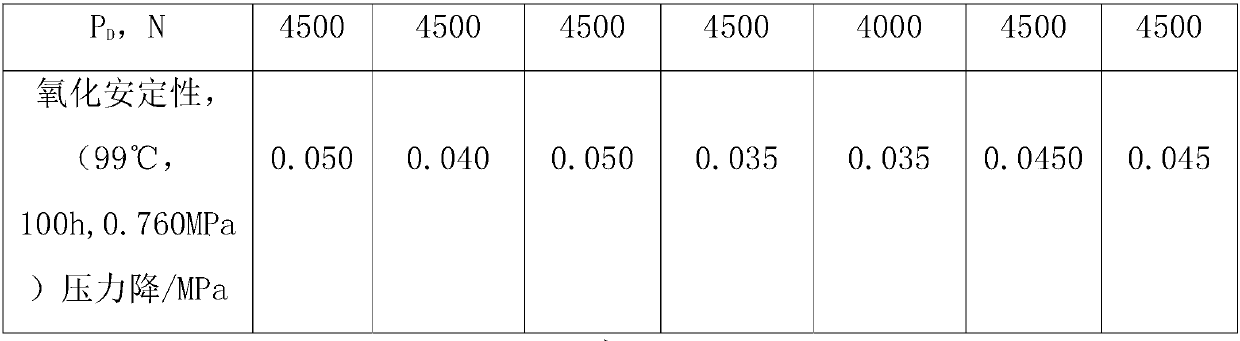

Biodegradable machine oil for refrigerating compressor and preparation method thereof

InactiveCN103468373AMeet high performance requirementsEasy to manufactureBase-materialsRefrigeration compressorAntioxidant

The invention provides biodegradable machine oil for a refrigerating compressor and a preparation method thereof. The biodegradable machine oil contains the ingredients in percentage by weight: 91-95% of base oil, 1-2% of antioxidant, 0.5-1% of antifoamer, 0.5-1% of anti-emulsifier, 2-3% of metal passivator and 1-2% of rust preventer. The preparation method of the biodegradable machine oil comprises the steps of (a) preparing the base oil; (b) carrying out heating treatment on the base oil; (c) carrying out additive adding treatment. According to the biodegradable machine oil for the refrigerating compressor and the preparation method thereof, provided by the invention, the biodegradable machine oil is reasonable in proportion and simple and convenient in preparation, has relatively high natural degradability, can be excellently dissolved with a refrigerant of the compressor and has relatively good oxidation, rusting, wearing and hydrolysis resistance, so that the requirements of the refrigerating compressor for high performance are met.

Owner:CHANGSHU MIAOQUAN COMPRESSOR ACCESSORIES

Lubrication oil antiwear additive

The invention relates to a lubrication oil antiwear additive, which is characterized by consisting of base oil, dispersant, nanoscale metal powder, pour point depressant and viscosity index improver, wherein the nanoscale metal powder comprises copper oxide powder, magnesium powder, manganese powder and chromium powder. The dispersant is a polyisobutylene-bis-succinimide; the pour point depressant is polymethacrylate; and the viscosity index improver is ethylene propylene copolymer (OCP). The invention has the advantages that the manufacturing method is simple and practical, and the manufactured additive has low cost and good oil solubility, can have good antiwear effect on various kinds of lubrication oil, has good antifriction and repair functions and has no corrosion to the inside of the machine.

Owner:TIANJIN SHENGTONG JIAHE TRADE

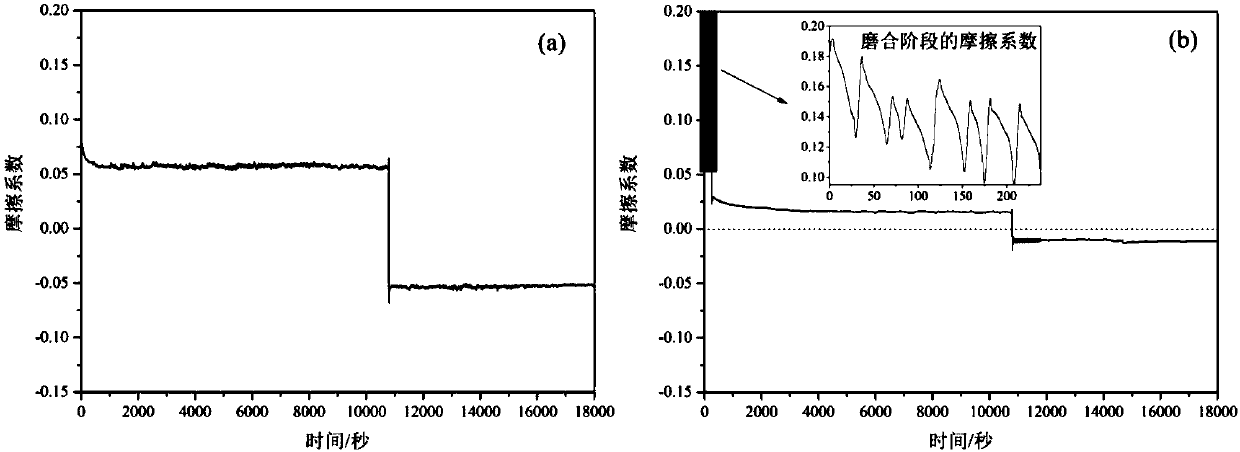

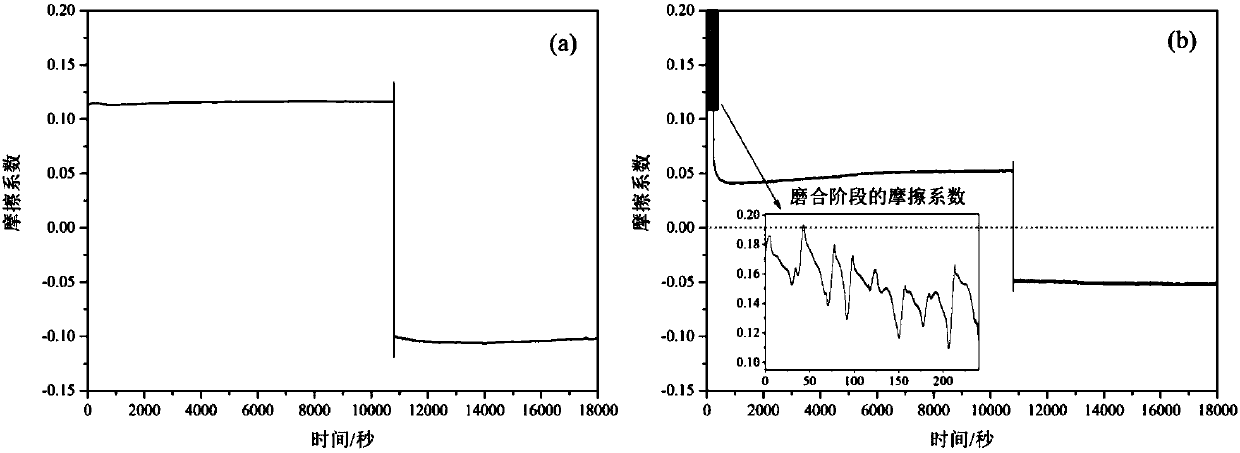

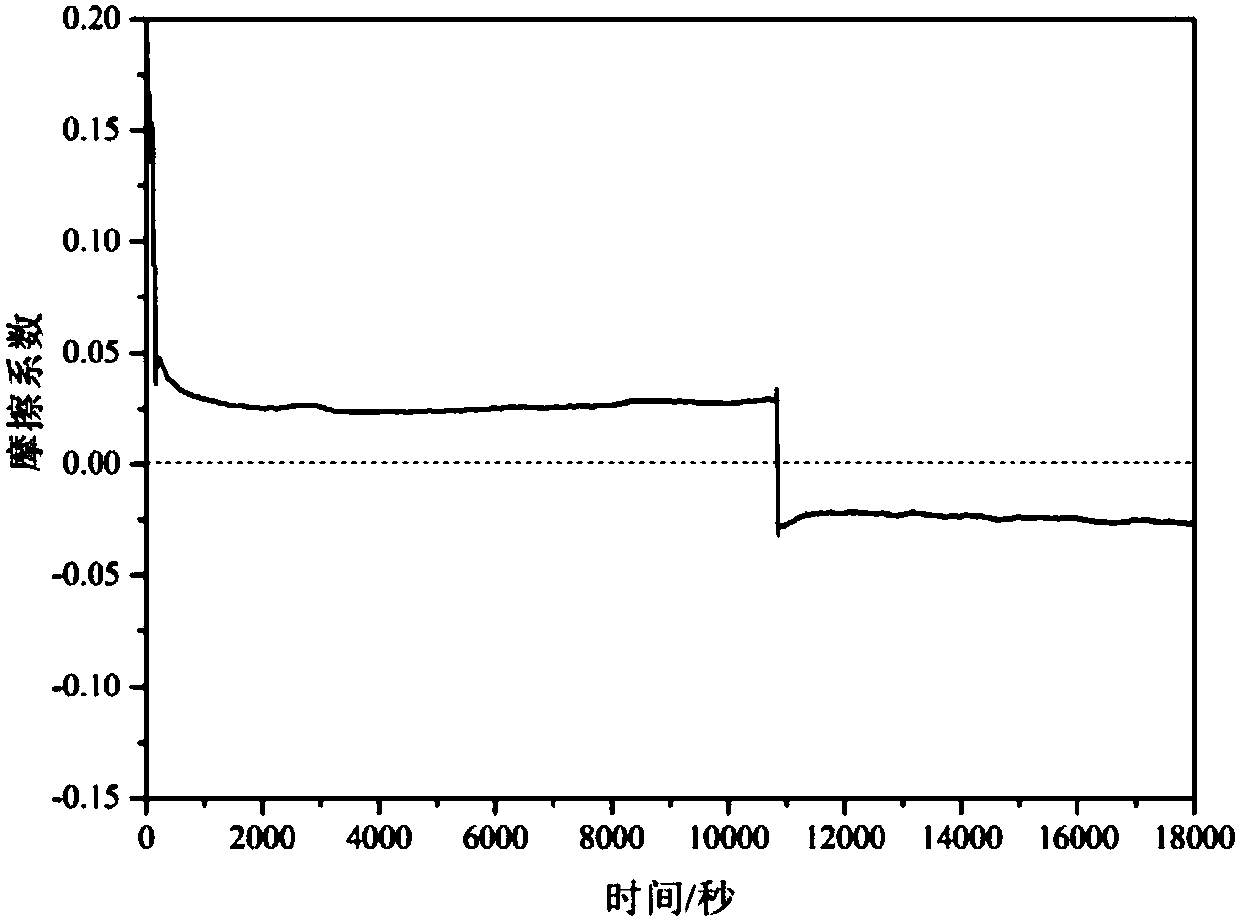

Running-in method for reducing friction coefficient between metal friction pairs

ActiveCN107842706AReduce coefficient of frictionShort run-in timeUsing mechanical meansAdditivesMetalMaterials science

The invention relates to a running-in method for reducing the friction coefficient between metal friction pairs. The method adopts an acetylacetone or acetylacetone alcoholic solution as a running-inagent, the two stages of pre-running-in and running-in are included, and the total running-in time is 60-480 seconds. The method is easy to implement and high in practicability, and can greatly reducethe friction coefficient between the metal friction pairs without a special device.

Owner:QILU UNIV OF TECH

Durable type wheel belt oil

PendingCN107858193AImprove the lubrication effectExtended service lifeLubricant compositionTO-18Brick

The invention provides a durable type wheel belt oil. The durable type wheel belt oil is prepared from the following raw materials and components in percentage by weight: 53% to 60% of phosphate ester, 5% to 12% of hydrated magnesium silicate, 11% to 18% of graphite powder, 5% to 10% of copper powder, 3% to 5% of aluminum powder, 1% to 2% of organic molybdenum, and 0.03% to 0.06% of drawing glue,wherein the sum of the raw materials and components is 100%. The durable wheel belt oil has the advantages that the problem of poor lubricating effect of wheel belt of rotary kiln under adverse environment is effectively solved; the service lives of the wheel belt and related parts are prolonged, the wheel belt and the related parts are well lubricated, the abnormal rolling and displacement due todirect friction / abrasion between the wheel belt and a gasket plate can be avoided, the chattering of the kiln body due to biting or slippery between the contact surfaces can be eliminated, the chattering, torsion and deformation of the rotary kiln and the falling of refractory bricks can be effectively prevented, and the service life of the rotary kiln is prolonged.

Owner:科特龙流体科技(扬州)有限公司

Rubber material for seal ring

InactiveCN105400010AImprove anti-corrosion performanceImprove oxidation resistanceRubber materialMicrosphere

The invention discloses a rubber material for a seal ring. The rubber material is prepared from, by weight parts, magnesium powder, 12-14 parts of micro-encapsulation red phosphorus, 2-3 parts of vulcanizing agent BIPB, 24-27 parts of polyacrylonitrile, 12-13 parts of graphite, 3-4 parts of coal ash microsphere, 0.7-1 part of sodium dodecyl sulfate, 42-55 parts of liquid acrylonitrile butadiene rubber, 0.6-1 part of methacrylic acid, 52-60 parts of acrylonitrile butadiene rubber, 20-25 parts of styrene-butadiene rubber, 3-4 parts of polyethylene wax, 0.2-0.3 part of sodium diacetate, 4-5 parts of polyethylene glycol, 13-15 parts of butadiene styrene rubber, 4-6 parts of manganese powder, 11-13 parts of chalk and 3-4 parts of molybdenum disulfide. The rubber material has very good elasticity, high temperature resistance and aging resistance, has good sealing performance, can serve as various sealing elements, and is good in practicality.

Owner:安徽创奇乐智能游乐设备有限公司

A method of laser cladding wear-resistant and impact-resistant coating on cast iron surface

ActiveCN108130532BGood metallurgical bondReduce carbon contentMetallic material coating processesLaser quenchingMetal alloy

The invention discloses a wear-resistant and impact-resistant coating method for laser cladding on the surface of cast iron. The surface is sanded with sandpaper for textured treatment, and then cleaned with acetone for oil stains; (3) The surface of the machined cast iron is coated with blackening paint for laser quenching, and then laser quenched; (4) To be laser quenched After the end, the coaxial powder feeding laser cladding metal alloy layer is performed on the formed laser quenching layer; (5) the coaxial powder feeding laser cladding metal alloy is again wear-resistant on the formed metal alloy layer. Impact resistant layer.

Owner:CHANGCHUN UNIV OF SCI & TECH

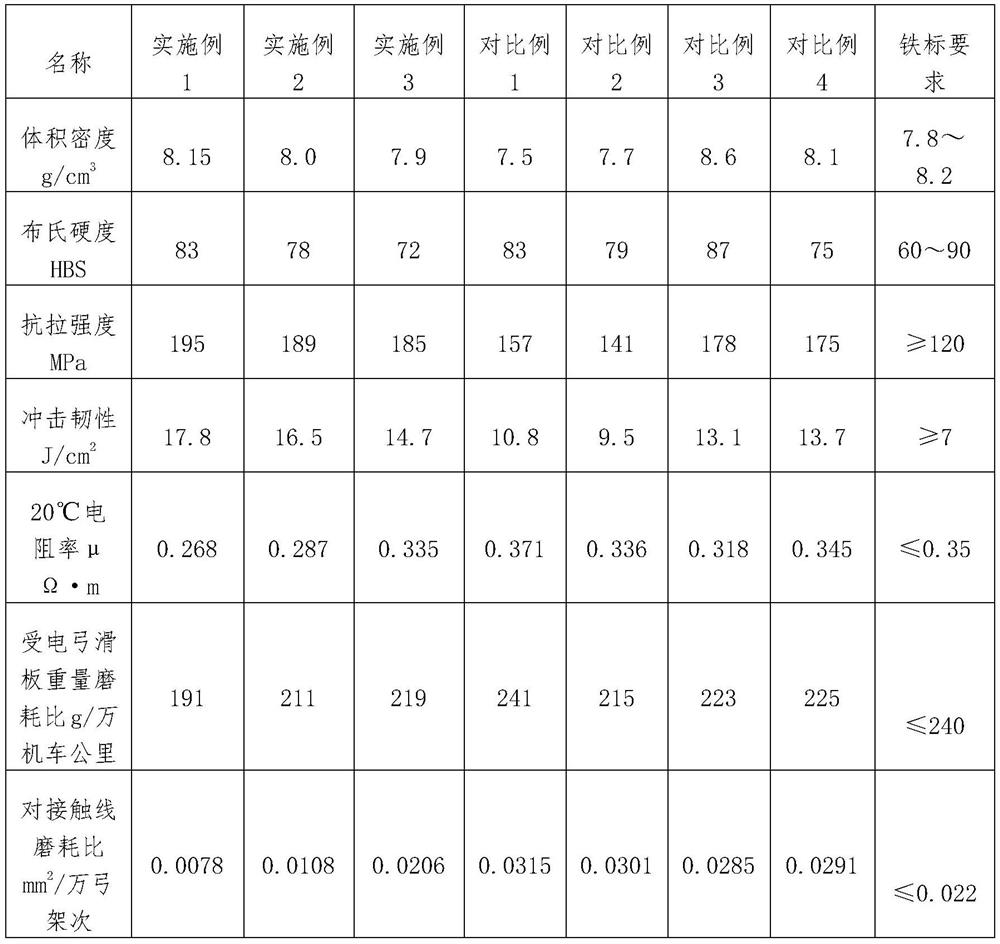

A copper-based powder metallurgy pantograph sliding plate material for monorail vehicles and its preparation method

ActiveCN112063880BImprove high temperature resistanceImprove wear resistanceCeramicwarePower current collectorsSlide plateMonorail

The invention relates to the technical field of sliding friction current collecting materials, in particular to a copper-based powder metallurgy pantograph sliding plate material for monorail vehicles. The components contained in the material and their mass percentages in the material are: 69-75% copper powder, 5-7% graphite, 4-6% tin powder, 4-9% nickel powder, 1-9% chromium powder 3%, molybdenum disulfide 1-3%, conductive ceramics 5-10%. The invention achieves better test results with a simpler process. The invention is characterized by short production cycle, simple process method and wide application prospect.

Owner:贵州新安航空机械有限责任公司

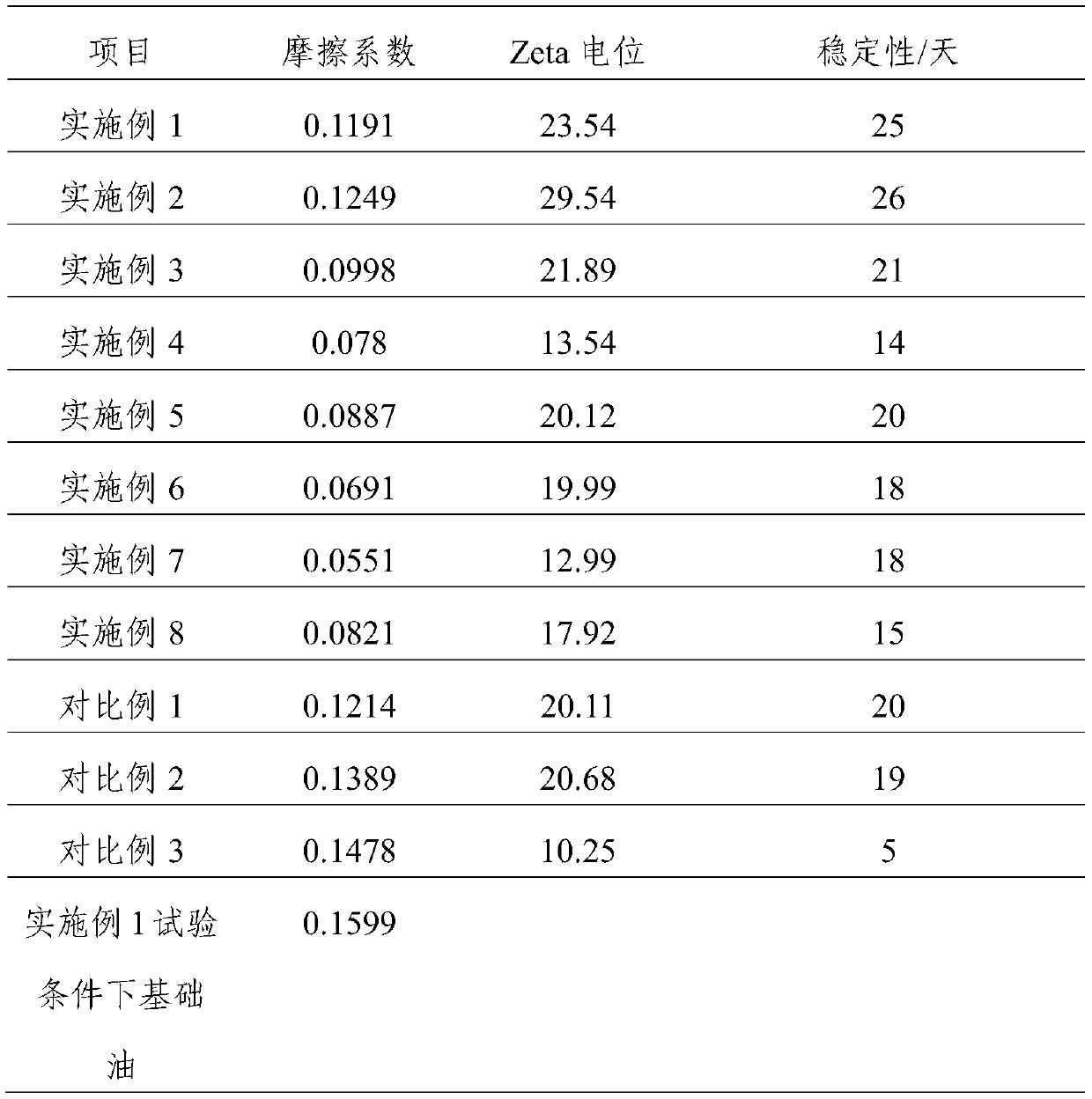

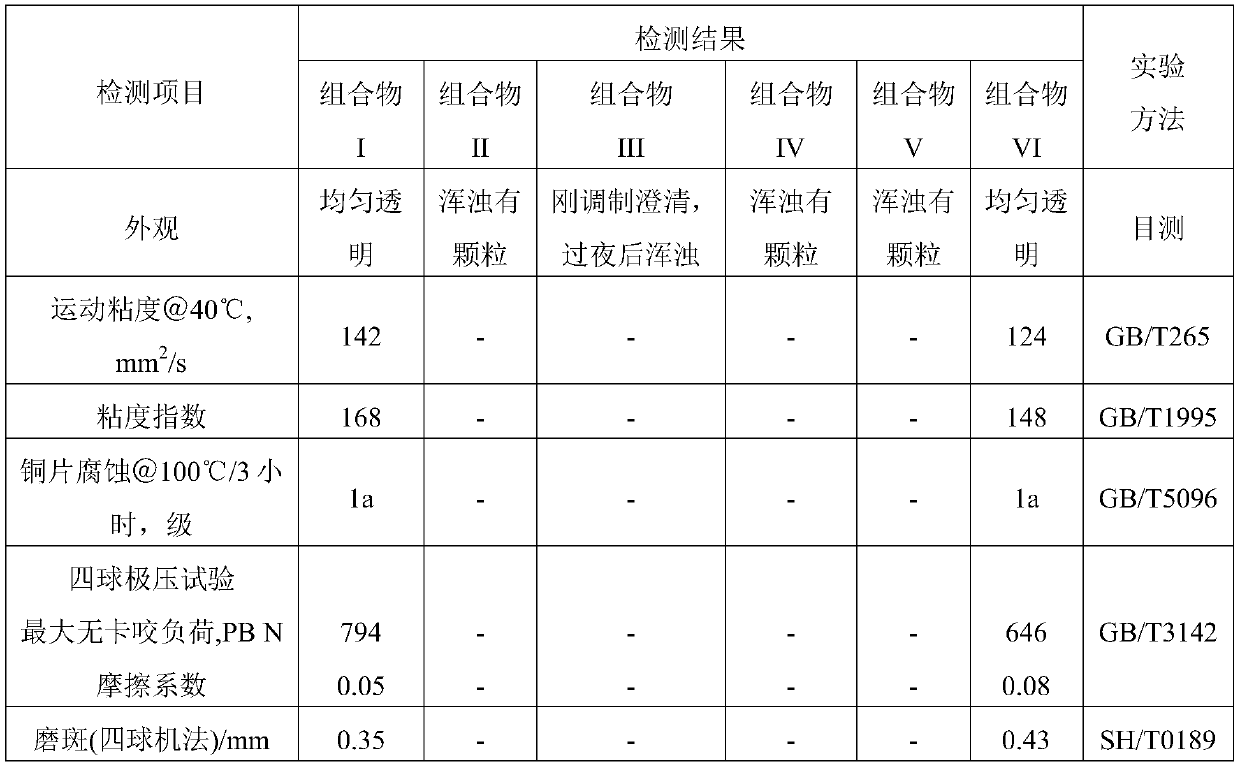

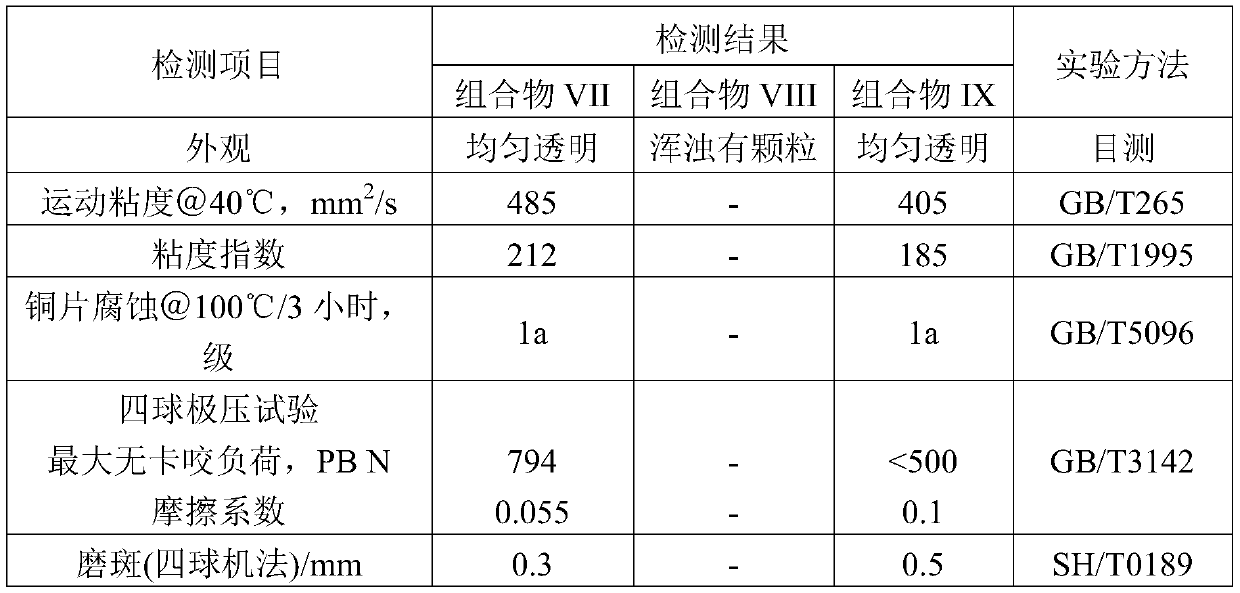

Lubricating oil composition and its preparation method

The invention provides a lubricating oil composition and a preparation method thereof. The lubricating oil composition is prepared from the following components: (a) base oil, (b) fatty acid, (c) alkylsilane and (d) hydrophilic fumed silica, wherein, counted on the basis that the total mass of the base oil (a) is 100 percent, the addition amount of the fatty acid (b) is 0.1 to 3 percent by mass, and is preferably 0.3 to 2 percent by mass; the addition amount of the alkylsilane (c) is 0.1 to 1 percent by mass, and is preferably 0.5 to 1 percent by mass; the addition amount of the hydrophilic fumed silica (d) is 0.3 to 6 percent by mass, and is preferably 0.5 to 3 percent by mass. The lubricating oil composition provided by the invention has excellent wear-reduction, anti-abrasion, extreme-pressure, anti-oxidation, viscosity-temperature and corrosion-prevention performance, is excellent in overall performance, and can be applicable to the lubrication of a device under various loads; the abrasion and the friction of the device can be greatly lightened; the energy consumption is reduced; the service life is prolonged. The preparation method of the lubricating oil composition, which is provided by the invention, is simple, and is suitable for industrialized production; raw materials are easily obtained.

Owner:SHANGHAI HITECRUN SPECIAL LUBRICATE SCI & TECH

A kind of tial-based self-lubricating composite material and preparation method thereof

InactiveCN105861876BImprove mechanical propertiesGood wear reductionGraphene nanoplateletMechanical property

The invention relates to a novel TiAl base self-lubricating composite. The novel TiAl base self-lubricating composite is characterized in that a TiAl base serves as a matrix, and graphene nanosheets and hollow spheres containing WS2 serve as an enhancing phase and a lubricating phase. The graphene nanosheets account for 0.5-1.5 wt.% of the matrix by mass, and hollow spheres containing WS2 account for 3.0-5.0 wt.% of the matrix by mass. A preparing method of the novel TiAl base self-lubricating composite comprises the following steps that elementary substance powder is weighed according to the mole ratio of elements contained in the TiAl base to serve as matrix materials, the graphene nanosheets and the hollow spheres containing WS2 are weighed according to the proportion, the materials are evenly mixed and then subjected to spark plasma sintering, and the novel TiAl base self-lubricating composite is obtained. With the graphene nanosheets and the hollow spheres containing WS2 as the enhancing phase and the lubricating phase, the TiAl base self-lubricating composite is high in compactness, good in mechanical property and high in abrasion relieving and resisting performance.

Owner:WUHAN UNIV OF TECH

Liquid coating and preparation method thereof

ActiveCN102002302BImprove conductivityImprove thermal conductivityEpoxy resin coatingsEpoxyCyclohexanone

The embodiment of the invention discloses a liquid coating and a preparation method thereof, wherein the liquid coating comprises the following ingredients: 40 wt% - 60 wt% of cyclohexanone, 2 wt% - 10 wt% of ethyl cellulose, 10 wt% - 30 wt% of epoxy resin, 5 wt% - 20 wt% of phenolic resin, 5 wt% - 15 wt% of molybdenium disulfide, and 1 wt% - 10 wt% of graphite. The experimental result shows that the liquid coating of the invention has the functions of thermostability, wear resistance and self lubrication, and has excellent comprehensive performance and low cost, and is applicable to the components, such as a piston.

Owner:ANQING CSSC DIESEL ENGINE

High-performance stable rubber material

The invention discloses a high-performance stable rubber material. The high-performance stable rubber material is prepared from, by weight, 3-4 parts of polyoxyethylene, 1-2 parts of anti-aging agent DNP, 5-6 parts of polyethylene glycol, 24-27 parts of polyacrylonitrile, 12-13 parts of graphite, 3-4 parts of flyash microspheres, 0.7-1 part of sodium dodecyl sulfate, 42-55 parts of liquid acrylonitrile butadiene rubber, 0.6-1 part of methacrylic acid, 52-60 parts of butadiene-acrylonitrile rubber, 20-25 parts of styrene-butadiene rubber, 9-12 parts of dihydrate desulfuration gypsum, 5-6 parts of alumina, 1-2 parts of cresyl diphenyl phosphate, 2-3 parts of PE wax, 1-2 parts of sulfonated oil, 2-3 parts of nanometer iron oxide, 0.1-0.2 part of sodium citrate and 13-15 parts of silicon carbide. According to the high-performance stable rubber material, the permanent compression set is good, the performance in all aspects is excellent and stable, the preparation method is simple, and the high-performance stable rubber material can be produced in a large scale and has good use value.

Owner:安徽创奇乐智能游乐设备有限公司

Automobile lubricating oil

InactiveCN106811270AGood wear reductionExcellent self-healing performanceAdditivesWear resistantGraphite

The invention relates to automobile lubricating oil, which is prepared from the following ingredients of basic oil, molybdenum disulfide, lead isocaprylate, 2 to 5 parts of internal combustion engine compounding agents, anti-rust agents, nanometer graphite, nanometer zirconium oxide and the like. The automobile lubricating oil has the characteristics of good dispersing performance, good stability and good anti-friction and wear-resistant performance. The additive of zirconium oxide is enriched on the metal surface defect position, so that a layer of self-restoring lubricating film is built on the surface of a friction pair; the characteristics of good wear reduction performance and good self restoration performance are realized; the graphite is added, so that the mechanical friction is effectively reduced, machinery and processing components are protected; mechanical impurities, residue carbon, ash and sulphated ash cannot remain; the effect on a mechanical automobile is very obvious; the use is convenient; the manufacturing cost is low.

Owner:TIANCHANG EARTHQUAKE OFFICE

Diphase nanometer strengthened metal matrix micro-nanometer power and preparation method thereof with both antifriction and wear-resistant effects

A dual-phase nano-reinforced metal-based micro-nano powder with both anti-wear and anti-wear effects and its preparation method is characterized in that it consists of 0.5-1.5% nano-carbon black powder, 0.5-1.5% nano-ceramic powder Composed of 97~99% micron metal powder, the sum of various components is 100%; and form a core-shell structure micro-nano powder with micron metal powder as the core, nano-carbon black powder and nano-ceramic powder as the shell; the The preparation process of micro-nano powder mainly includes the preparation of single-phase nano-carbon black suspension and single-phase nano-ceramic suspension, the preparation of carbon black and ceramic dual-phase nano-suspension, the spheroidization pretreatment of micron metal powder, carbon black and Ball-milling composite of ceramic dual-phase nano-suspension and micron metal powder after pretreatment and drying of micro-nano powder slurry after ball-milling composite. The laser wear-resistant modified layer prepared by the present invention has a small friction coefficient and a low volume wear rate, and has a narrow heat-affected zone, fine and dense structure, basically no carbide inclusions, and has better mechanical properties than micron powder remanufacturing; At the same time, the micro-nano powder has a good absorption rate for laser light.

Owner:JIANGSU UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com