Durable type wheel belt oil

A durable, tire technology, applied in the field of lubricating oil, can solve problems such as poor lubrication, achieve good lubrication effect, good lubrication, and improve the effect of adhesion lubrication performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

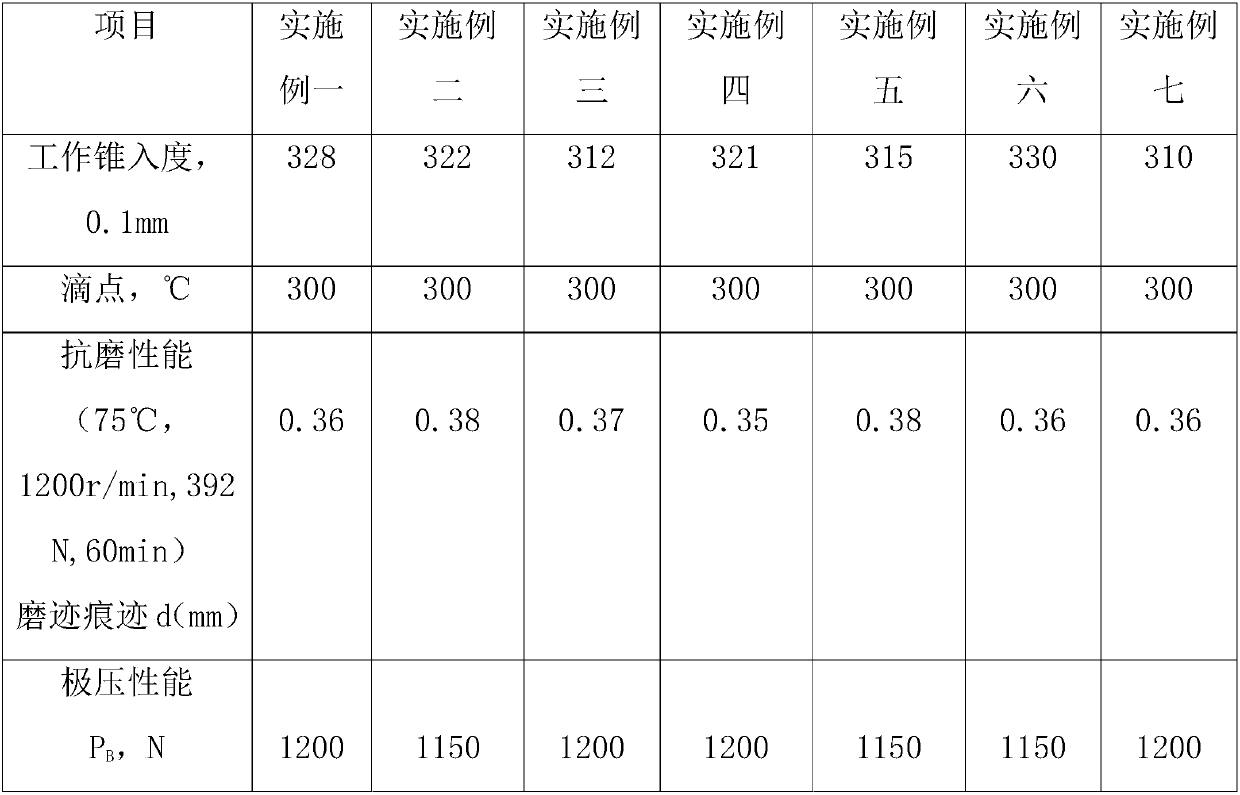

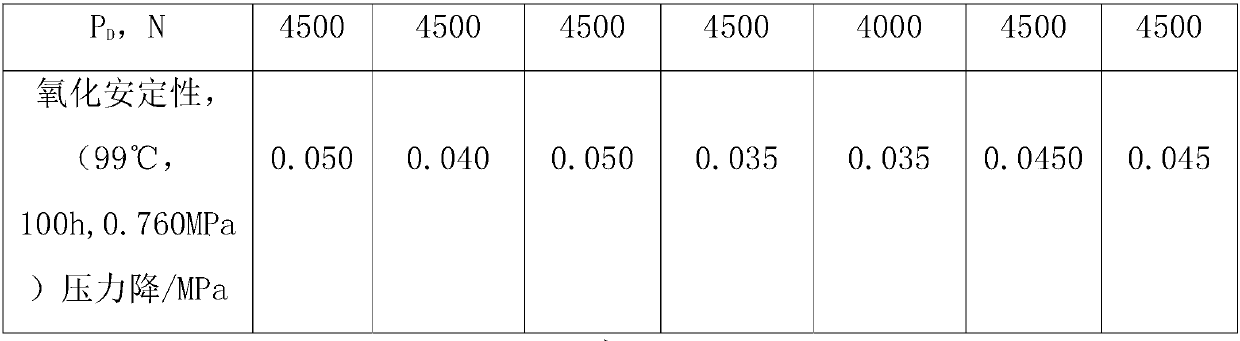

Examples

preparation example Construction

[0024] In this embodiment, the preparation method of the tire oil includes the following steps: adding hydrated magnesium silicate to the phosphoric acid ester at a temperature of 70-80°C, stirring to make it completely mixed, cooling down to 45°C, and then adding graphite powder , copper powder and aluminum powder, stir for 2-3 hours, then add organic molybdenum, after the organic molybdenum is completely dissolved and dispersed evenly, cool down to 30°C, add drawing glue and stir evenly, cool to room temperature to obtain durable tire oil; The preparation method adopted is simple and easy to operate, which can not only ensure the full mixing of each raw material component, but also promote the mutual synergy of each raw material component, better exert the performance advantages, and prepare a durable tire with excellent performance and meet actual needs Oil.

[0025] In this example, all raw material components can be obtained through market purchase.

Embodiment 1

[0028] In the durable tire oil of the present implementation, the raw material of the tire oil comprises the following components by weight percentage: phosphoric acid ester 55%, hydrated magnesium silicate (1250 orders) 12%, graphite powder (800 orders) 16%, Copper powder (500 mesh) 10%, aluminum powder (500 mesh) 4.95%, dialkyl molybdenum dithiophosphate 2%, drawing glue 0.05%;

[0029] in:

[0030] The phosphate is a low-corrosion phosphate, and the drawing glue is an ethylene-propylene copolymer;

[0031] The Cu content in the copper powder is ≥98.1%, and the Al content in the aluminum powder is ≥99.6%.

[0032] In the present embodiment, the preparation method of described wheel belt oil comprises the steps:

[0033]Add hydrated magnesium silicate to the low-corrosion phosphate ester at 70°C, stir to make it completely mixed, then cool down to 45°C, then add graphite powder, copper powder and aluminum powder, stir for 2.5 hours, and then add dialkyl Oxymolybdenum dithi...

Embodiment 2

[0036] In the durable tire oil of the present implementation, the raw materials of the tire oil include the following components by weight percentage: phosphate ester 58%, hydrated magnesium silicate (1250 orders) 10%, graphite powder (1250 orders) 17%, Copper powder (300 mesh) 9%, aluminum powder (300 mesh) 4%, dialkylmolybdenum dithiophosphate 1.94%, drawing glue 0.06%;

[0037] in:

[0038] The phosphate is a low-corrosion phosphate, and the drawing glue is an ethylene-propylene copolymer;

[0039] The Cu content in the copper powder is ≥98.1%, and the Al content in the aluminum powder is ≥99.6%.

[0040] In the present embodiment, the preparation method of described wheel belt oil comprises the steps:

[0041] Add hydrated magnesium silicate to the low-corrosion phosphate at 80°C, stir to make it completely mixed, then cool down to 45°C, then add graphite powder, copper powder and aluminum powder, stir for 3 hours, and then add dialkyl di Oxymolybdenum thiophosphate, af...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com