Lubricating oil composition and its preparation method

A technology of lubricating oil composition and mixture, which is applied in the field of lubricating oil, can solve problems such as poor stability, achieve the effects of reducing energy consumption, easily obtaining raw materials, and reducing wear and friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0050] According to the lubricating oil composition of the present invention, the preparation method of the hydrophilic fumed silica (d) comprises the following steps:

[0051] After gasifying silicon tetrachloride at high temperature, in the presence of hydrogen and oxygen, or air, perform gas phase hydrolysis at high temperature to obtain fumed silica;

[0052] Purging the fumed silica with nitrogen-containing air until the pH is between 4-6 to obtain the hydrophilic fumed silica (d).

[0053] Specifically, the preparation method of said hydrophilic fumed silica (d) comprises the following steps:

[0054] Silicon tetrachloride is gasified at a flame temperature of 1000-1800°C, and in the presence of hydrogen, oxygen, or air, gas-phase hydrolysis is carried out at a high temperature of about 1800°C to obtain fumed silica; the gas phase produced at this time Silica particles are extremely fine and form an aerosol with gas, which is not easy to capture. Therefore, the obtaine...

Embodiment 1

[0066] 1 weight part of dodecyltrimethoxysilane (manufacturer: Nanjing Quanxi Chemical Co., Ltd., the same below) is added to 1 weight part of hydrophilic fumed silica (manufacturer: Evonik Degussa company, Trademark: AEROSIL300) in the heating container, be warmed up to 80 ℃, fully stir 20min; 50 parts by weight of saturated polyol ester (manufacturer: Croda Chemical Company, brand: Priolube3987), 50 parts by weight of mineral oil 500N (produced Manufacturer: Sinopec Maoming Petrochemical Company, brand: 500N) into a stainless steel blending kettle with a stirrer, keep the temperature of the kettle at 80 ° C, add 1 weight part of stearic acid, stir for 7 minutes until uniform and transparent; then put it into the heating container The mixture of dodecyltrimethoxysilane and hydrophilic fumed silica was added into a stainless steel mixing kettle, stirred for 10 minutes, the heating was stopped, and the temperature of the kettle was lowered to 50° C. with cooling water to obtain ...

Embodiment 2

[0076] The finished lubricating oil composition VI was obtained in the same manner as in Example 1, except that 1 part by weight of the hydrophilic fumed silica in Example 1 was replaced by 0.4 parts by weight.

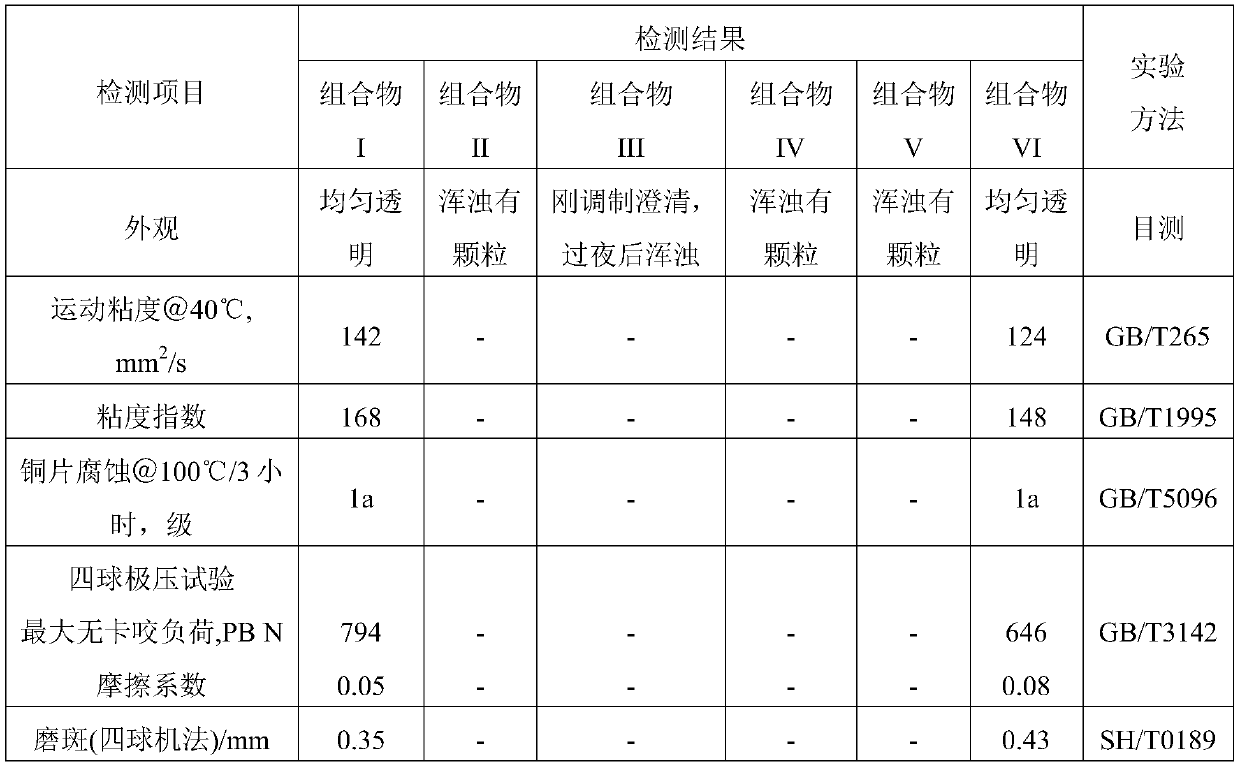

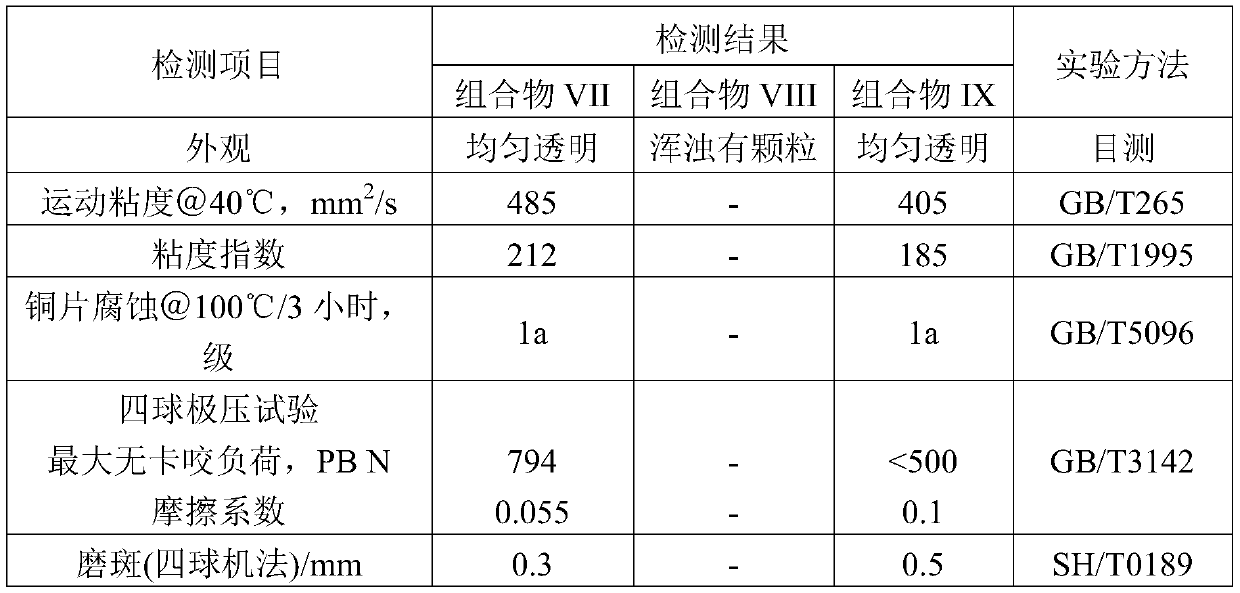

[0077] Table 1 lists the performance test data of the above lubricating oil compositions I, II, III, IV, V and VI.

[0078] The performance test data of table 1 lubricating oil composition I, II, III, IV, V and VI

[0079]

[0080] In Example 1 of the present invention, fatty acids and alkylsilanes, that is, dodecyltrimethoxysilane, have significant dispersion-promoting and dissolution-promoting effects after they are coordinated together, and the hydrophilic fumed silica can be uniformly and stably dissolved to In lubricating oils, a clear liquid is formed.

[0081] However, only alkylsilanes were added to the lubricating oil composition of Comparative Example 1, and other types of silanes were used instead of alkylsilanes in the lubricating oil composition III o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com