Novel TiAl base self-lubricating composite and preparing method

A composite material and a new type of technology are applied in the field of new TiAl-based self-lubricating composite materials and their preparation to achieve good tribological properties, good anti-wear and anti-wear properties, and improve tribological properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

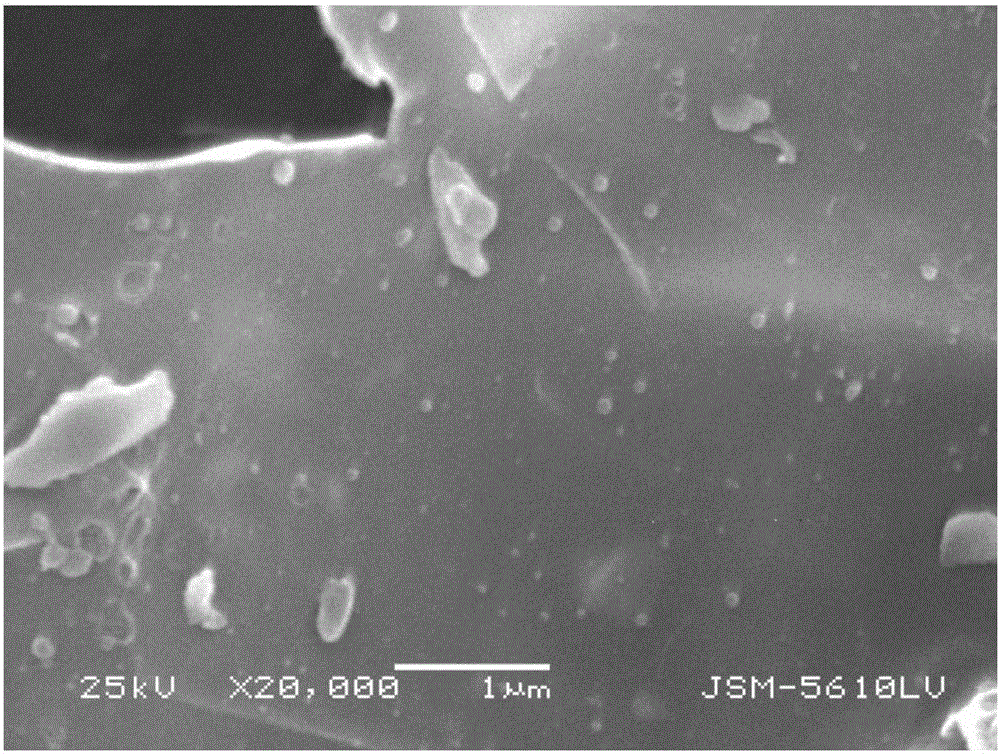

[0034] In the following examples, the WS-containing 2 The hollow sphere powders are composed of lubricating phase WS 2 and glassy phase, composed of WS 2 Prepared from powder and aqueous solution of sodium silicate containing auxiliary reagents. The present invention provides a specific preparation method, but does not limit its preparation method. The WS-containing 2 The hollow sphere powder of is also suitable for the present invention.

[0035] The present invention provides containing WS 2 The preparation method of the hollow spherical powder is: select WS 2The powder is added to the sodium silicate aqueous solution containing auxiliary reagents to form a mixed solution, and the resulting mixed solution is dried and then subjected to high-temperature melting treatment with oxygen-acetylene, and the molten droplet-shaped reactant is collected in water for condensation, and the upper layer of the collected water floats The particulate matter, after drying, is the requir...

Embodiment 1

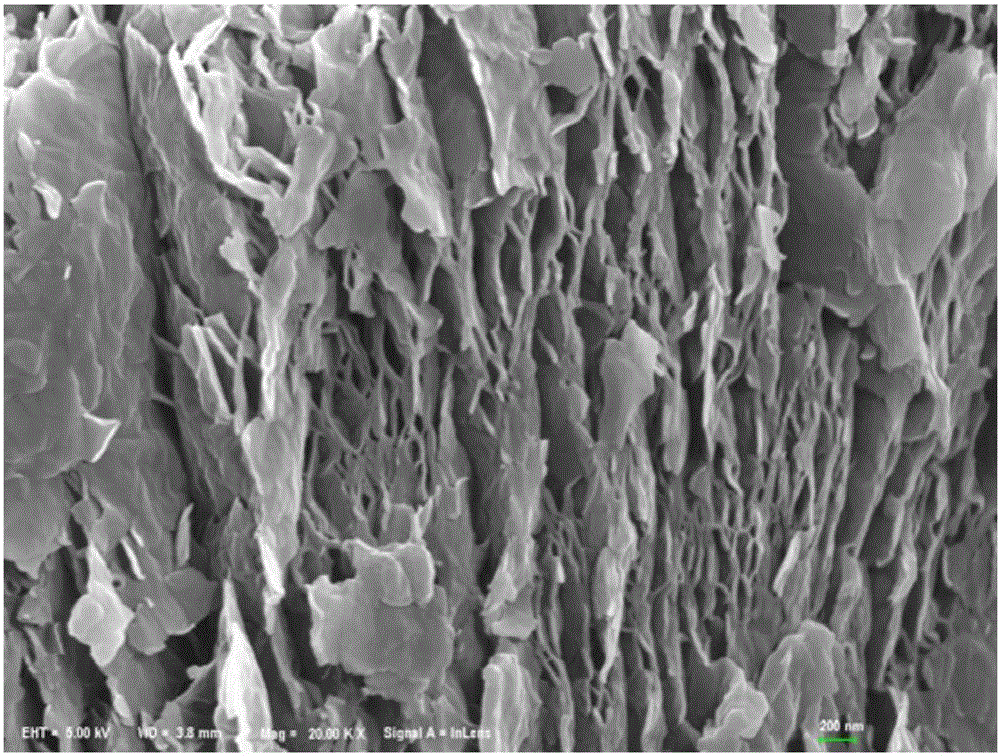

[0038] A new type of TiAl-based self-lubricating composite material, with TiAl alloy doped with trace elements as the matrix, graphene nanosheets and WS-containing 2 The hollow spheres are the reinforcing phase and the lubricating phase. Among them, graphene nanosheets are 0.5wt.% of the mass of the matrix, containing WS 2 The quality of the hollow sphere is 3.0wt.% of the mass of the matrix; the WS-containing 2 The hollow sphere powder consists of a lubricating phase WS 2 Composed of and glass phase; the thickness of the graphene nanosheet is 20nm-2μm, and the particle size is 5-200μm; the matrix is composed of Ti, Al, Cr, Nb, B in a molar ratio of 48:47:2: 2:1 composition.

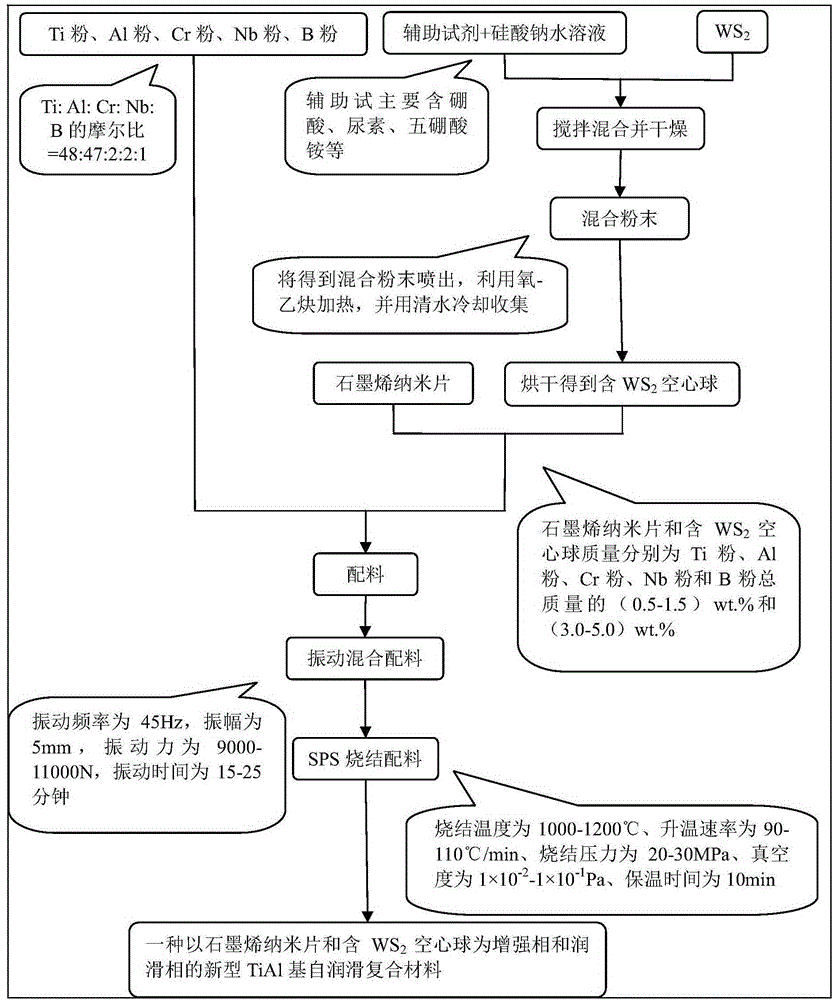

[0039] Such as figure 1 Shown, a kind of preparation method of novel TiAl base self-lubricating composite material, it comprises the steps:

[0040] 1) According to the molar ratio of Ti:Al:Cr:Nb:B=48:47:2:2:1, weigh and select 10.70g Ti powder, 5.90g Al powder, 0.48g Cr powder, 0.86g Nb powder an...

Embodiment 2

[0047] A new type of TiAl-based self-lubricating composite material, with TiAl alloy doped with trace elements as the matrix, graphene nanosheets and WS-containing 2 The hollow spheres are the reinforcing phase and the lubricating phase. Among them, graphene nanosheets are 1wt.% of the mass of the matrix, containing WS 2 The quality of the hollow sphere is 4.0wt.% of the mass of the matrix; the WS-containing 2 The hollow sphere powder consists of a lubricating phase WS 2 and glass phase; the thickness of the graphene nanosheets is 20nm-2μm, and the particle size is 5-200μm; the TiAl matrix is composed of Ti, Al, Cr, Nb, and B in a molar ratio of 48:47:2 :2:1 composition.

[0048] A kind of preparation method of novel TiAl-based self-lubricating composite material, it comprises the steps:

[0049] 1) According to the molar ratio of Ti:Al:Cr:Nb:B=48:47:2:2:1, weigh and select 10.70g Ti powder, 5.90g Al powder, 0.48g Cr powder, 0.86g Nb powder and 0.05 g B powder is used a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com