Biodegradable machine oil for refrigerating compressor and preparation method thereof

A refrigeration compressor and biodegradation technology, which is applied in the field of compressors, can solve problems such as affecting the working performance of the compressor, insufficient mutual solubility of refrigerating machine oil and refrigerant, and lack of wear-reducing and lubricating properties of refrigerating machine oil.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

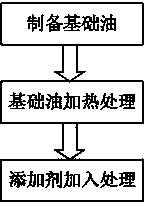

[0021] The specific preparation method is as follows:

[0022] a) Preparation of base oil, the preparation of base oil includes preparation of hydrogenated tea oil and blending. Among them, the process of preparing hydrogenated tea oil is as follows: first, the tea seed oil is washed, rolled, fried, and pressed under the condition of strict control of moisture and temperature to obtain crude oil; then the crude oil is subjected to alkali refining, decolorization, deodorization, Filtration and other refining, then enter the hydrogenation tank for treatment, and then filter to obtain hydrogenated camellia oil. When blending the ratio, blend the diester-type synthetic oil and hydrogenated tea oil at a mass ratio of 5:1.

[0023] b) Heating treatment of base oil. The treatment process is as follows: the base oil with a weight percentage of 91% is sent into the blending kettle with a gear pump, and after evacuation, stirring and heating processes, the temperature is raised to 85°C...

Embodiment 2

[0026] The specific preparation method is as follows:

[0027] a) Preparation of base oil, the preparation of base oil includes preparation of hydrogenated tea oil and blending. Among them, the process of preparing hydrogenated tea oil is as follows: first, the tea seed oil is washed, rolled, fried, and pressed under the condition of strict control of moisture and temperature to obtain crude oil; then the crude oil is subjected to alkali refining, decolorization, deodorization, Filtration and other refining, then enter the hydrogenation tank for treatment, and then filter to obtain hydrogenated camellia oil. When blending the ratio, blend the diester-type synthetic oil and hydrogenated tea oil at a mass ratio of 5:1.

[0028] b) Heating treatment of base oil. The treatment process is as follows: the base oil with a weight percentage of 95% is sent into the blending kettle with a gear pump, and after evacuation, stirring and heating processes, the temperature is raised to 90°C...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com