Thrust bearing friction torque measurement method and measurement apparatus

A friction torque and thrust bearing technology, which is used in mechanical bearing testing, measuring devices, torque measurement and other directions to achieve the effect of strong versatility, reducing additional errors and improving measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

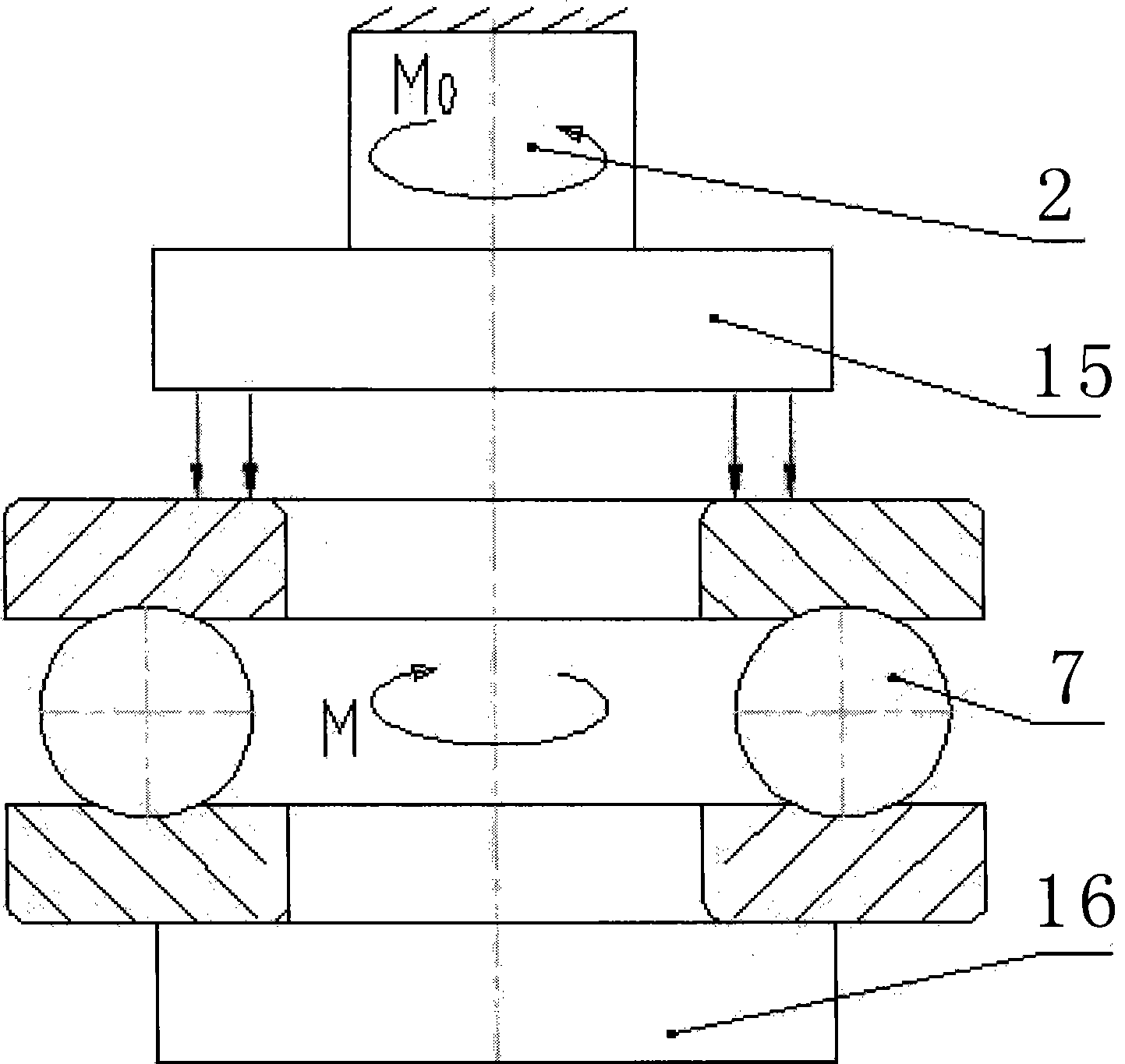

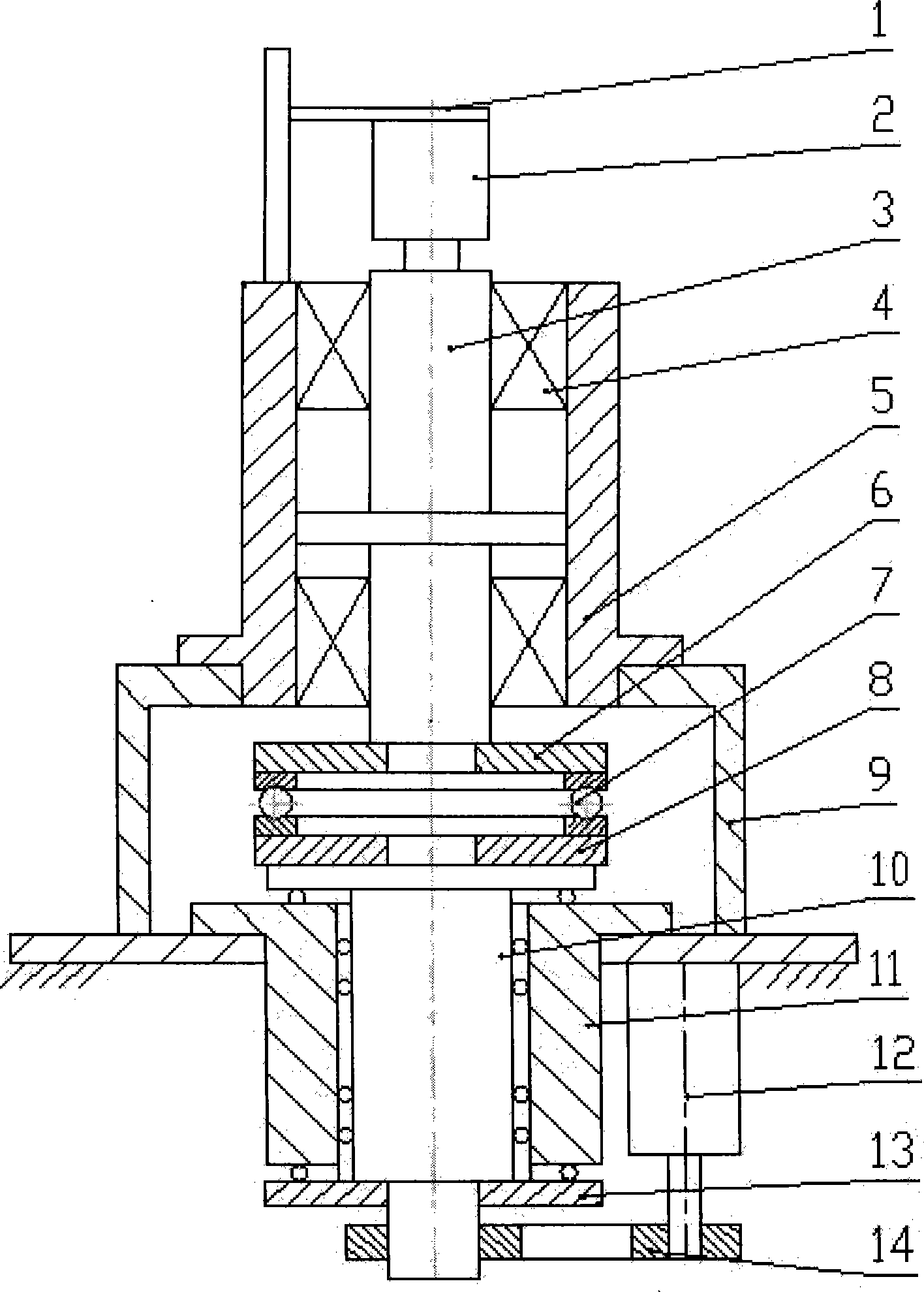

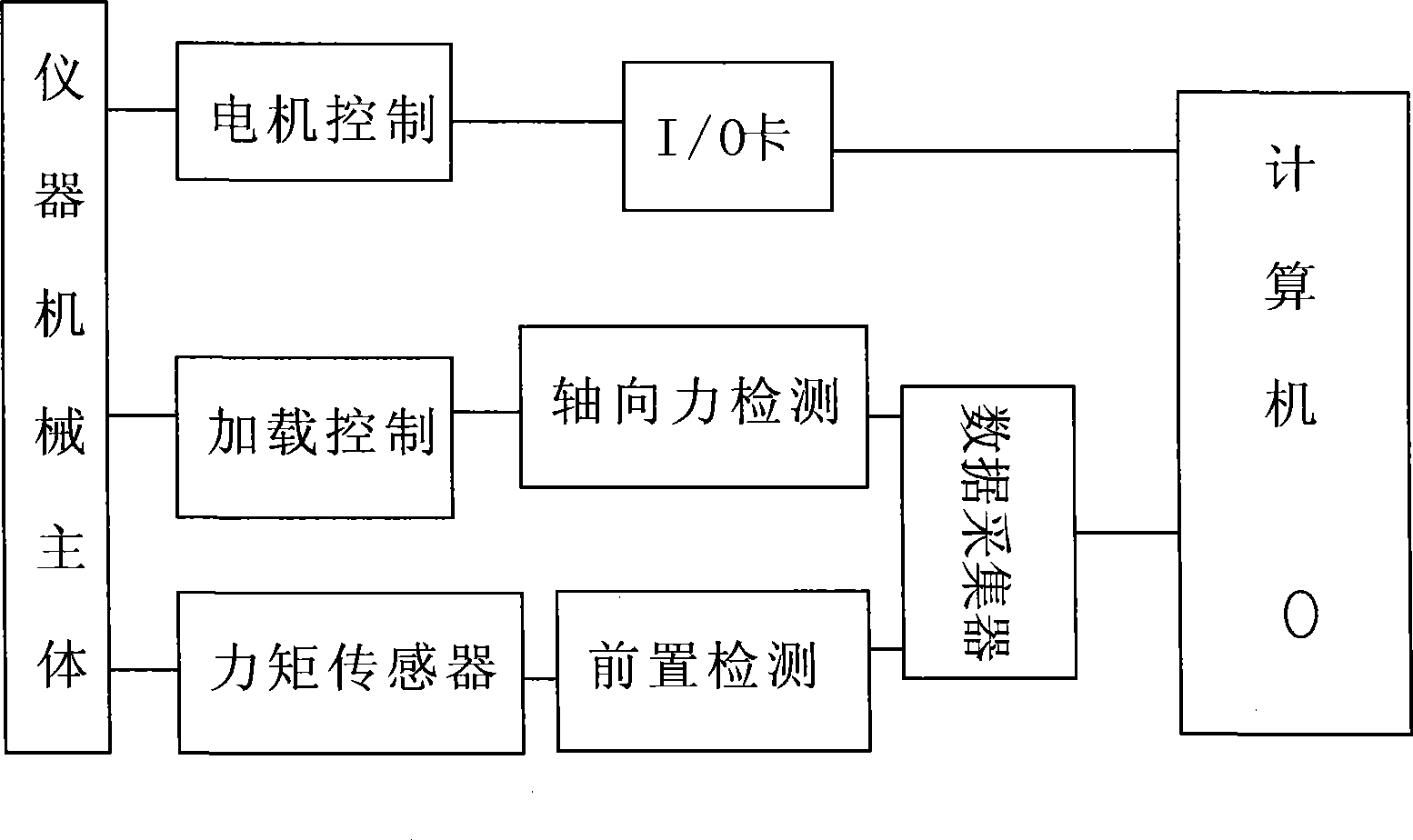

[0022] combine figure 1 , the measuring method of the thrust bearing friction moment of the present invention is to measure the friction moment of the thrust bearing according to the moment balance method, the thrust bearing (7) to be measured is placed between the loading device (15) and the driving device (16), and the loading device (15) Connected with a torque sensor (2), first set the measuring speed in the computer, send a loading command to the loading device (15) to apply an axial load to the upper end of the thrust bearing (7) to be tested, the size of the axial load is determined by the loading The device (15) is adjusted, and then the driving device (16) is given a rotation command to drive the lower end of the thrust bearing (7) to rotate; because there is a frictional moment M inside the thrust bearing (7), when the lower end of the thrust bearing (7) rotates, its upper end There will also be a tendency to rotate, and the friction torque M will be transmitted to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com