Online verification method for thermal monitoring instrument of power plant

A technology for thermal instruments and monitoring instruments, applied in testing/calibration devices, instruments, measuring devices, etc., which can solve the problems of calibration, poor timeliness and flexibility of calibration, and difficulty in judging the specific source of data deviation, etc., to reduce additional Effects of tolerances, guaranteed timeliness and flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention is not limited to the following examples in connection with the accompanying drawings.

[0021] Embodiment.

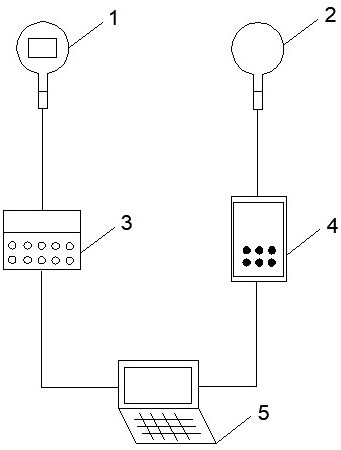

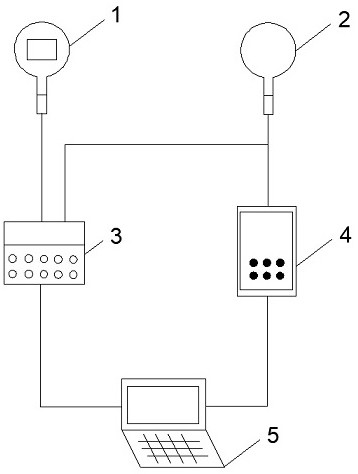

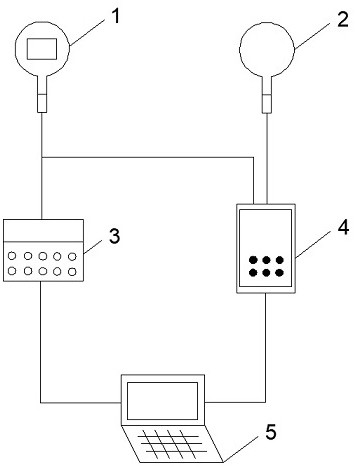

[0022] See Figure 1 to 3 In the present embodiment, a power plant thermal monitoring meter is online calibration method, including standardizer 1. Online thermal instrument 2, data acquisition system 3, thermal monitoring system 4, and verification analysis system 5, steps are as follows:

[0023] The first step is based on the category and mounting position of the verified online thermal instrument 2, and the corresponding file library is established in the verification analysis system 5. For example, the hot engine meter 2 is a pumping force, and the position is located at a steam of steam. On the pipeline, the file library is named "a pumping force" while entering the performance parameters of the instrument. The specific test scheme and power plant values should be communicated before the test, and the test begins to the test end time per...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com