Forging press machine operation condition information acquisition and analysis system based on the internet of things technology

An Internet of Things technology, a technology for forging machine tools, applied in general control systems, control/regulation systems, comprehensive factory control, etc., can solve problems such as the inability to automatically generate machine tool operation reports, complex remote server data management, and inconvenience for users to use data. , to achieve the effect of convenient data access, convenient expansion of storage space, and low power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to further understand the content of the present invention, the present invention will be described in detail in conjunction with the accompanying drawings and embodiments.

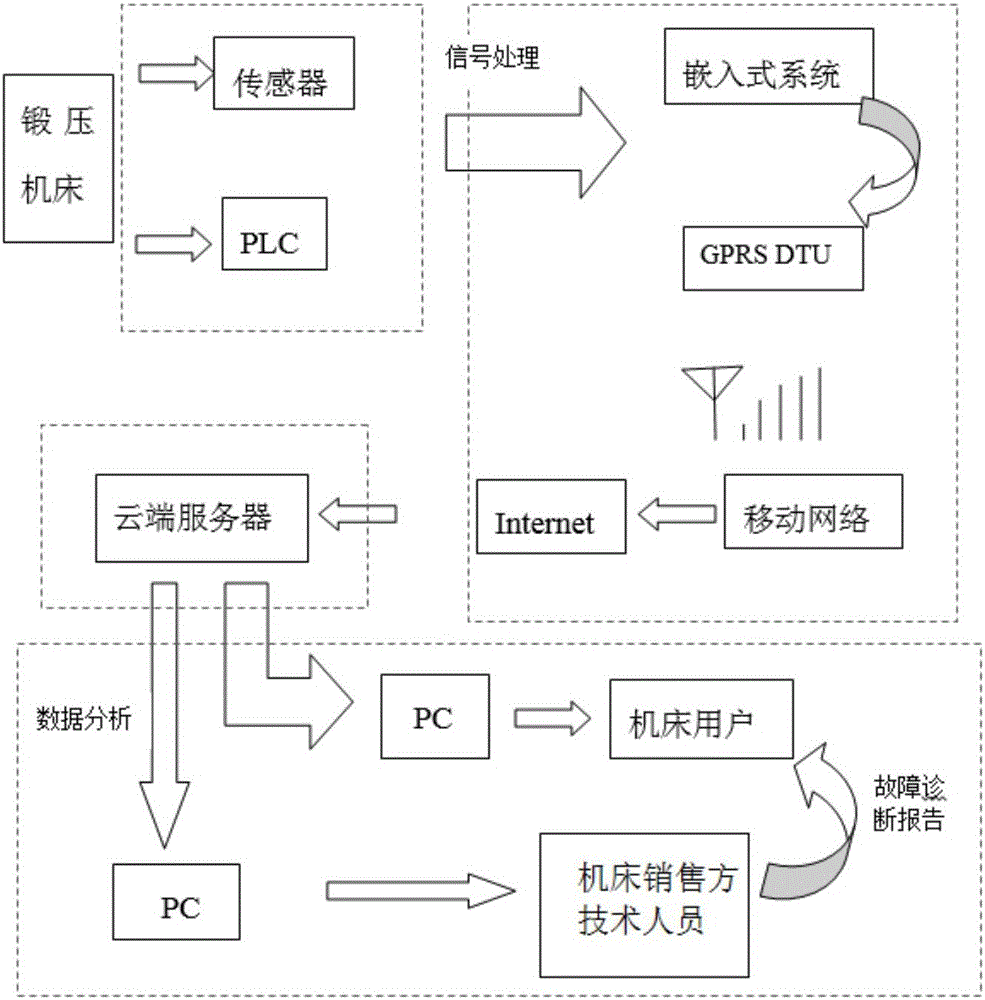

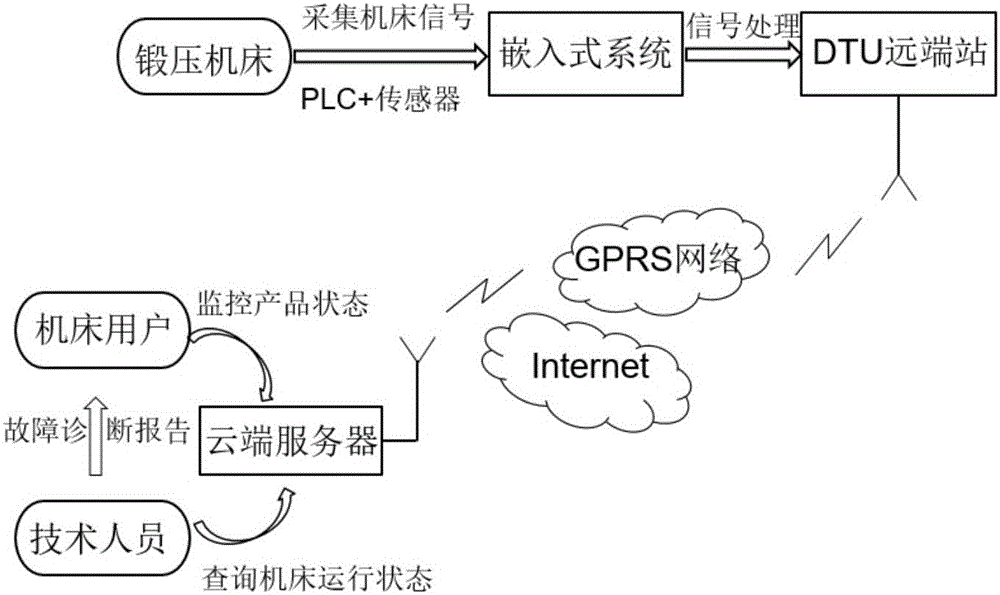

[0026] combined with figure 1 , what the embedded system in the device of the present invention adopted at present is BroadcomBCM2835700MHzARM1176JZFS processor, band FPU and VideoCoreIV dual-core GPU; Server end CPU is single IntelXeonE5-2400, supports dual CPU; Client CPU is IntelCorei3.

[0027] The operating status information of the machine tool is collected by displacement sensors, temperature sensors, current sensors, liquid level sensors and PLC. The sensor mainly collects analog quantities including spindle current, spindle power, temperature, etc., and obtains information such as the power-on state of the machine tool, spindle start and stop, and coolant switch through the collection of machine tool electrical circuits and PLC signal points;

[0028] The working principle and wo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com