Mine mining fracture evolution and distribution monitoring device and method

A fissure evolution and monitoring device technology, applied in the field of mine pressure and safety, can solve the problems of not being able to reflect the time and space evolution of coal and rock mass mining fissures in time, and unable to meet the actual needs of mines, so as to reduce the detection workload, The effect of high degree of automation and simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] An embodiment of the present invention is described below in conjunction with accompanying drawing:

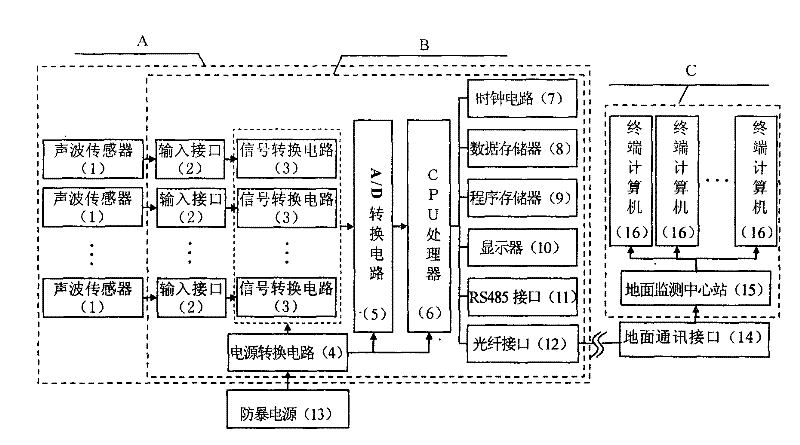

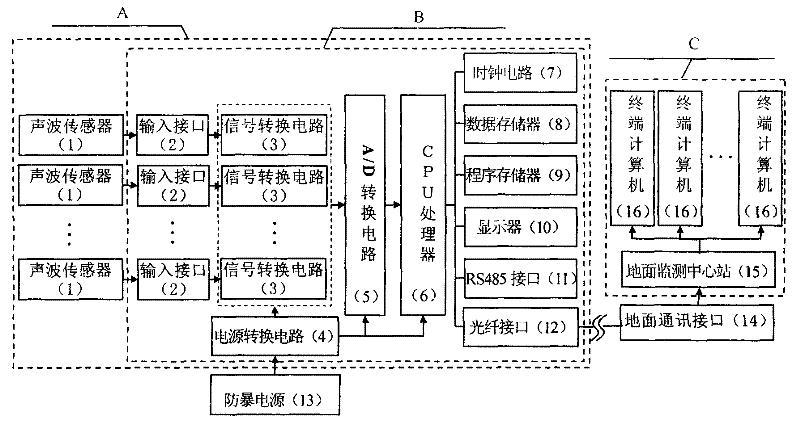

[0023] figure 1As shown, the mining fracture evolution and distribution monitoring device of the present invention is mainly composed of four parts: an explosion-proof acoustic wave monitor A, an explosion-proof power supply 13, a ground communication interface 14, and a ground monitoring and analysis center C. Explosion-proof sound wave monitor A is mainly composed of sound wave sensor 1, input interface 2, signal conversion circuit 3, power conversion circuit 4, A / D conversion circuit 5, CPU processor 6, clock circuit 7, data memory 8, program memory 9, display 10. Composed of RS485 interface 11 and optical fiber interface 12. Wherein the acoustic wave sensor 1 is an acoustic emission sensor or a micro-vibration sensor; there are at least four acoustic wave sensors; the A / D conversion module of the A / D conversion circuit 5 selects the ADS7852 chip; the CPU processor ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com