Graphene lubricating oil and preparation method thereof

A graphene and lubricating oil technology, applied in the petroleum industry, lubricating compositions, additives, etc., can solve the problems of poor graphene dispersion and wear resistance stability, and achieve improved friction reduction and anti-wear performance, excellent lubrication and Protective performance, strong adsorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Take 0.0025g of 1-octyl-3-methylimidazolium hexafluorophosphate and 0.01g of graphene and add it to 100g of turbine oil, place it in an ultrasonic breaker after magnetic stirring, and ultrasonicate at 600W for 60min to obtain graphene lubricating oil. Under the action of ultrasound, the degree of graphene powder agglomeration can be reduced, and the anti-wear performance can be greatly improved.

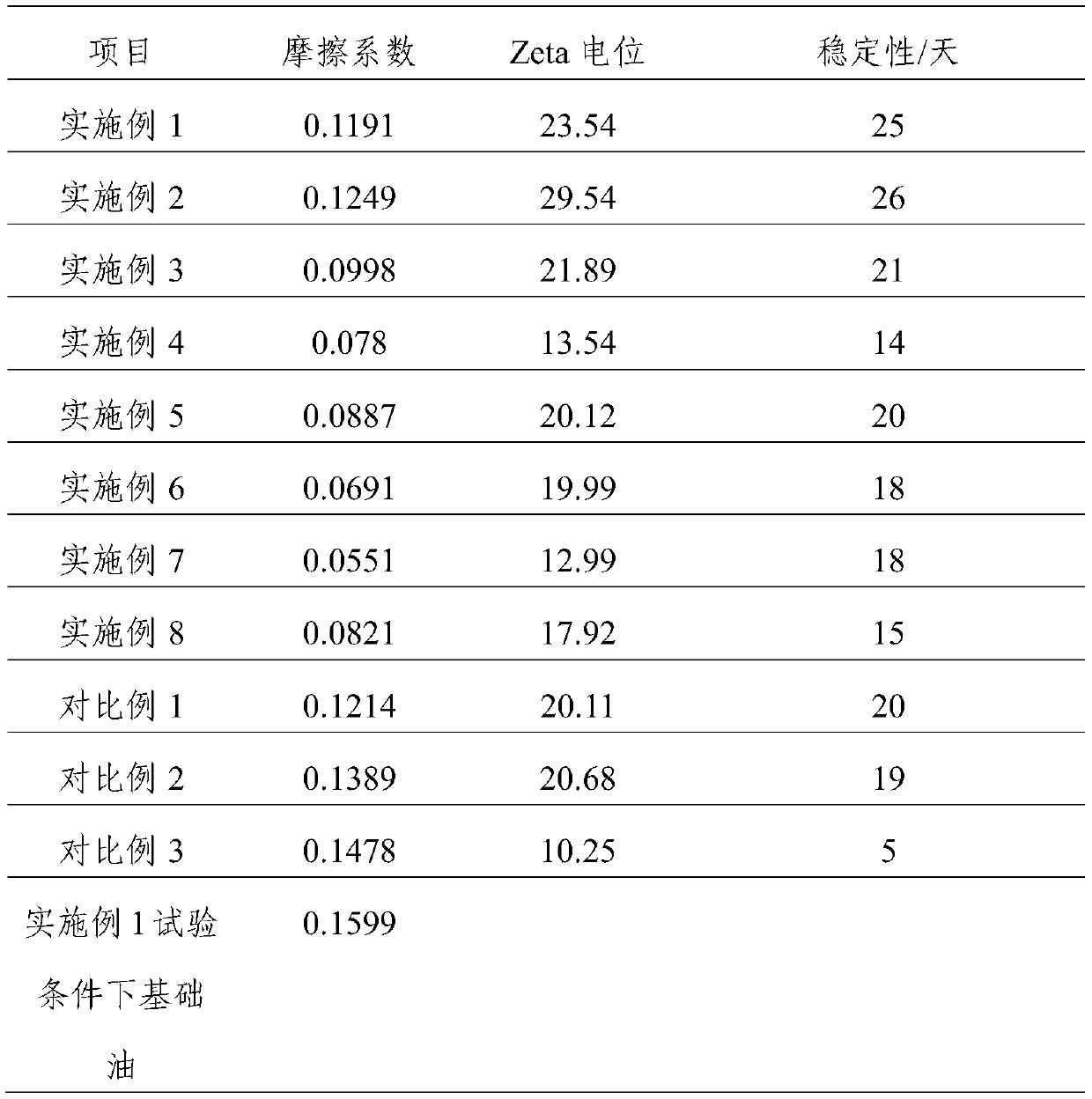

[0021] A multi-functional friction and wear testing machine was used to test the graphene lubricating oil with silicon nitride ceramic ball and bearing steel as the friction pair. The results show that the friction coefficient of the lubricating oil is 0.1191 at a speed of 1500 rpm and a load of 40N, which is 19.42% lower than that of the base oil, and the Zeta potential is 23.54, and there is still no settlement after 25 days of storage, indicating that it has Good dispersion stability.

Embodiment 2

[0023] Take 0.1g of 1-octyl-3-methylimidazolium hexafluorophosphate and 0.075g of graphene and add it to 100g of turbine oil, place it in an ultrasonic breaker after magnetic stirring, and ultrasonicate at 800W for 40min to obtain graphene lubricating oil.

[0024] A multi-functional friction and wear testing machine was used to test the graphene lubricating oil with silicon nitride ceramic ball and bearing steel as the friction pair. The results show that at a speed of 1500 rpm and a load of 80N, the friction coefficient of the graphene lubricating oil is 0.1249, which is 15.49% lower than that of the base oil, and the Zeta potential is 29.54, and there is still no sedimentation after 26 days of storage. It shows good dispersion stability.

Embodiment 3

[0026] Take 0.0001g of 1-hexyl-3-methylimidazolium tetrafluoroborate and 0.01g of graphene and add it to 100g of turbine oil, place it in an ultrasonic breaker after magnetic stirring, and ultrasonicate for 90min at 700W to obtain graphene lubricating oil.

[0027] A multi-functional friction and wear testing machine was used to test the graphene lubricating oil with silicon nitride ceramic ball and bearing steel as the friction pair. The results show that at a speed of 500 rpm and a load of 80N, the friction coefficient of the graphene lubricating oil is 0.0998, which is 31.45% lower than that of the base oil, and the Zeta potential is 21.89, and there is still no sedimentation after 21 days of storage. It shows good dispersion stability.

PUM

| Property | Measurement | Unit |

|---|---|---|

| friction coefficient | aaaaa | aaaaa |

| friction coefficient | aaaaa | aaaaa |

| friction coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com