Method for laser cladding of wear-resistant and impact-resistant coating on cast steel surface

A technology of laser cladding and impact-resistant layer, applied in the direction of coating, metal material coating process, superimposed layer plating, etc., can solve problems such as the quality decline of cladding layer, reduce defects, improve wear resistance and reduce wear Effect with impact resistance, good bonding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] In this embodiment, cast steel ZG 42CrMo is used as the matrix, and the base layer material is nickel-based alloy powder. The chemical composition (mass percentage of each element) is: C:0.02%, Si:0.1%, Mn:0.4%, Cr:15.5%, Co: 2.0%, Mo: 15.5%, W: 3.8%, Nb: 0.31%, Fe: 0.7%, Ni: balance; the wear-resistant and impact-resistant layer material is iron-based alloy powder, chemical composition (mass percentage of each element) For: C: 0.30%, Si: 3.5%, Cr: 10.5%, B: 2.0%, Fe: 10.0%, Ni: balance;

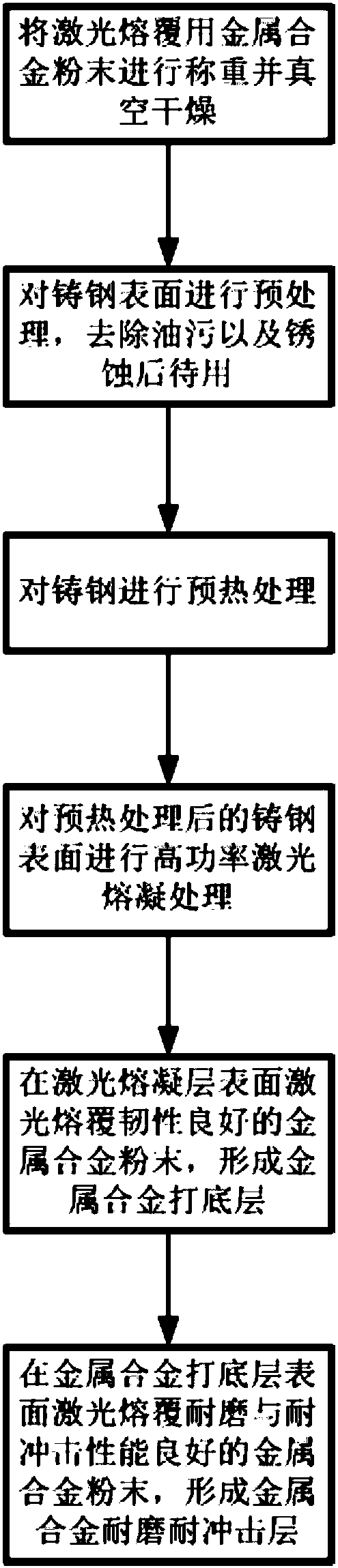

[0052] The specific implementation steps are as follows:

[0053] (1) After weighing the nickel-based alloy powder and the iron-based alloy powder, dry them in a vacuum oven at 80°C for 90 minutes;

[0054] (2) Grinding the ZG 42CrMo surface to be treated with sandpaper for roughening treatment, and then cleaning the oil stain with acetone for later use;

[0055] (3) Preheat ZG 42CrMo at 400°C for 1 hour;

[0056] (4) Perform laser melting treatment on the preheated ZG 42CrMo, wher...

Embodiment 2

[0060] In this embodiment, cast steel ZG 40Cr is used as the substrate, and the base layer material is nickel-based alloy powder. The chemical composition (mass percentage of each element) is: C:0.025%, Si:0.12%, Mn:0.43%, Cr:16%, Co: 2.4%, Mo: 16%, W: 4.2%, Nb: 0.34%, Fe: 0.75%, Ni: balance; the wear-resistant and impact-resistant layer material is nickel-based alloy powder, chemical composition (mass percentage of each element) For: C: 0.32%, Si: 3.9%, Cr: 11, B: 2.3%, Fe: 10.5%, Ni: balance; the specific implementation steps are as follows:

[0061] (1) After weighing the nickel-based alloy powder and the iron-based alloy powder, dry them in a vacuum oven at 85°C for 100 minutes;

[0062] (2) Grinding the surface of ZG 40Cr to be treated with sandpaper for roughening treatment, and then cleaning the oil stain with acetone for later use;

[0063] (3) Preheat ZG 40Cr at 450°C for 1 hour;

[0064] (4) Perform laser melting treatment on the preheated ZG 35SiMn, wherein the la...

Embodiment 3

[0068] In this embodiment, cast steel ZG 35SiMn is used as the substrate, and the base layer material is nickel-based alloy powder. The chemical composition (mass percentage of each element) is: C:0.03%, Si:0.14%, Mn:0.46%, Cr:16.5%, Co: 2.8%, Mo: 16.5%, W: 4.6%, Nb: 0.37%, Fe: 0.8%, Ni: balance; the wear-resistant and impact-resistant layer material is nickel-based alloy powder, chemical composition (mass percentage of each element) For: C: 0.34%, Si: 4.3%, Cr: 11.5%, B: 2.6%, Fe: 11.0%, Ni: balance; concrete implementation steps are as follows:

[0069] (1) Dry the nickel-based alloy powder and the iron-based alloy powder in a vacuum oven at 90°C for 120 minutes after weighing;

[0070] (2) Grinding the surface of ZG 35SiMn to be treated with sandpaper for roughening treatment, and then cleaning the oil stain with acetone for later use;

[0071] (3) Preheat ZG 35SiMn at 500°C for 1 hour;

[0072] (4) Perform laser melting treatment on the preheated ZG 35SiMn, wherein the l...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com