Liquid coating and preparation method thereof

A liquid coating and solution technology, applied in the coating field, can solve the problems of poor oil pressure resistance and lubricating oil medium properties, high temperature resistance, poor wear resistance and self-lubricating comprehensive performance, easy to fall off, etc., to achieve good electrical and thermal conductivity, Good wear reduction and self-lubricating properties, strong resistance to rapid cooling and rapid heating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0044] The present invention also provides a preparation method of liquid paint, comprising:

[0045] Mixing cyclohexanone and ethyl cellulose to obtain a first solution;

[0046] The first solution is mixed with epoxy resin, molybdenum disulfide, graphite and phenolic resin to obtain a liquid paint.

[0047] The mixing of cyclohexanone and ethyl cellulose can be achieved by stirring, and there is no special limitation on the stirring time, it is only necessary to completely dissolve the ethyl cellulose in the cyclohexanone solution to obtain the first solution.

[0048] After obtaining the first solution, mixing the first solution with epoxy resin, molybdenum disulfide, graphite, and phenolic resin can be achieved by stirring, and there is no special limitation on the stirring time, preferably 2 to 5 hours, more preferably 3 to 4 hours.

[0049]In the above technical scheme, the mass ratio of the cyclohexanone, ethyl cellulose, epoxy resin, molybdenum disulfide, graphite an...

Embodiment 1

[0058] At 65°C, add 50kg of cyclohexanone into the stirred tank; slowly add 3kg of ethyl cellulose under stirring to make the ethyl cellulose completely wet; stir for more than 3 hours until the ethyl cellulose is completely dissolved in the In the cyclohexanone solution; in the stirring state, add 15kgE44 epoxy resin, 11kg molybdenum disulfide, 8kg graphite, 16kg bisphenol A type resole phenolic resin in turn; check the addition of materials, and then stir for more than 3 hours; after stirring evenly , unloading packaging. The performance test result of the liquid coating that present embodiment provides is as follows:

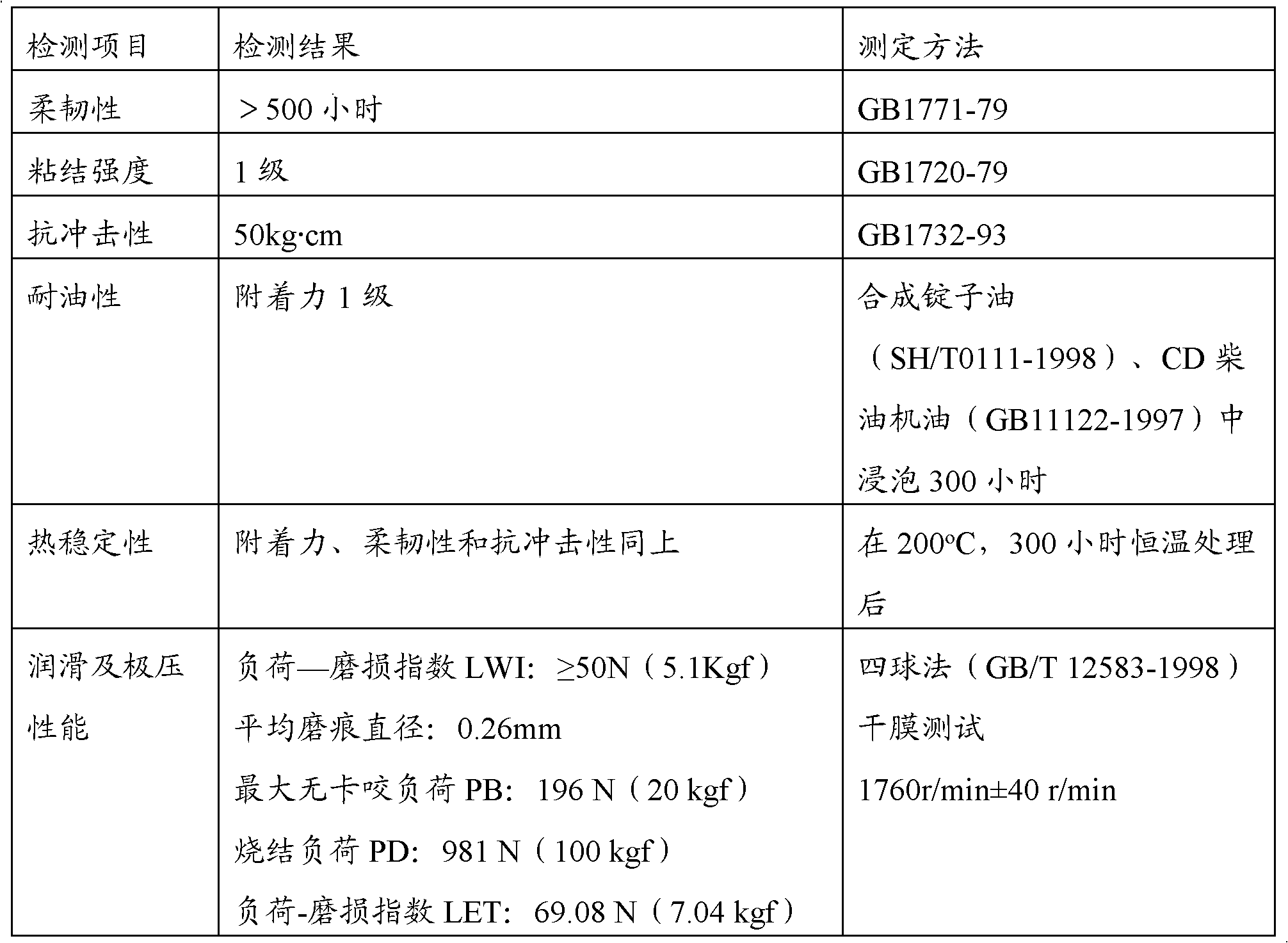

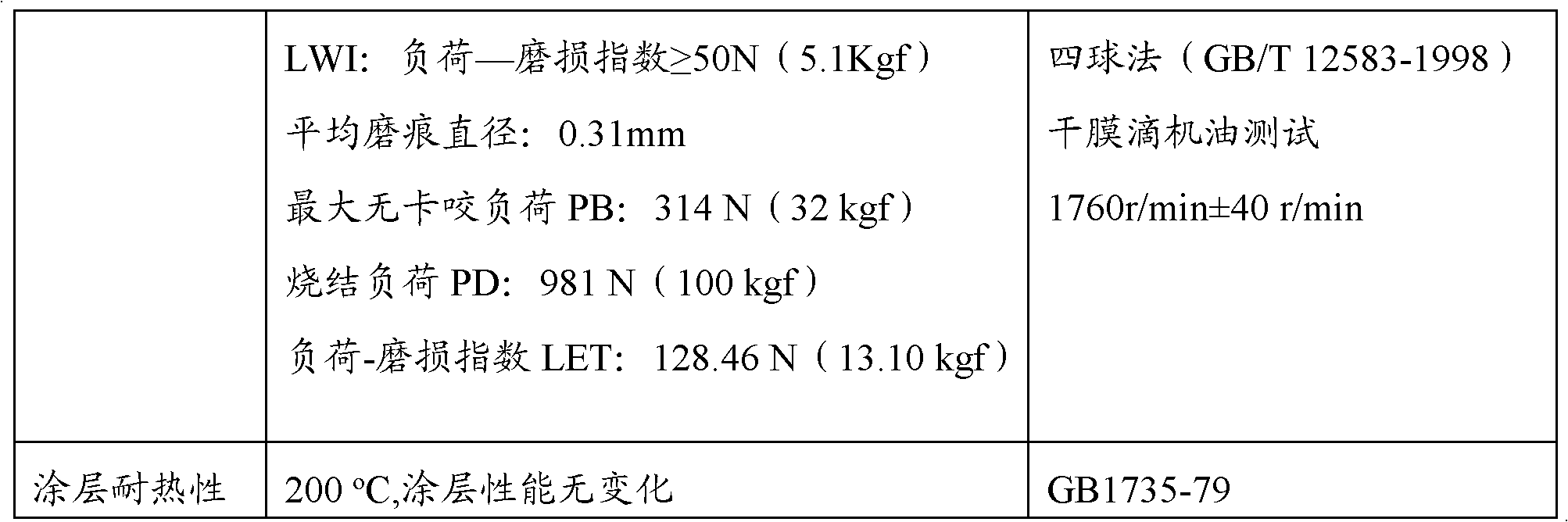

[0059] The performance test result of the liquid coating that table 1 embodiment 1 provides

[0060]

[0061]

Embodiment 2

[0063] PSHTd-26H cast iron pistons are provided, and the pistons are treated according to degreasing, chrome plating, cleaning, dehydrogenation and phosphating procedures well known to those skilled in the art, and the liquid coating provided in Example 1 is coated on the surface of the treated pistons;

[0064] Oil immersion treatment of pistons coated with liquid paint.

[0065] The thickness of the coating on the surface of the piston measured by the thickness gauge is 18 μm.

[0066] The surface of the above-mentioned piston is inspected by wiping method, specifically: after wiping the surface of the test piston with 500±5 grams of pine wood back and forth for 30 times, the total film thickness is measured to be 15 μm. After rubbing the test surface of the piston with 500±5 grams of Q235A steel block back and forth for 30 times, the total film thickness was measured to be 11 μm. The test result of wiping method shows that the liquid coating prepared in this embodiment has...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com