Lubricating grease

A technology of lubricating grease and lauryl hydroxystearin, which is applied in the field of lubricating oil, can solve the problems that the performance of lubricating grease needs to be improved, and achieve excellent thermal performance, dimensional stability, good fluidity, anti-rust function of high-temperature oxidation surface Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

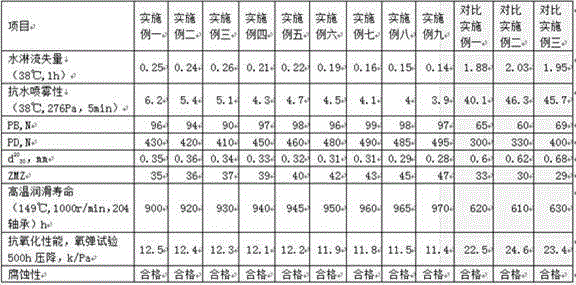

Examples

Embodiment 1

[0070] A. Add 4 parts of lauryl hydroxystearic acid, 5 parts of petroleum calcium sulfonate, 2 parts of rosin, 8 parts of vegetable oil, (NH 4 ) x MoS 2 Add 7 parts, 3 parts of the first solid additive and 1.5 parts of the second solid additive to 88 parts of base oil, ultrasonically disperse, then add 0.05 parts of lithium hydroxide, 2.4 parts of potassium hydroxide and 20 parts of dicarboxylic acid, heat to 60 ℃ for 10 minutes to obtain the first reaction solution;

[0071] Among them, the base oil is a mixture of paraffin, cycloalkyl and polyalphaolefin in a weight ratio of 1:3:4; the viscosity of the base oil at 60°C is 100cSt, the open flash point is 230°C, and the pour point is -40 ℃;

[0072] The total base number of calcium petroleum sulfonate is 300;

[0073] The specific surface area of PTFE is 2m 2 / g;

[0074] The particle size range of the first solid additive is 0.8-5 microns; wherein, the particles of 0.8-1 microns account for 20% of the total weight of...

Embodiment 2

[0078] In order, 7 parts of lauryl hydroxystearic acid, 10 parts of petroleum calcium sulfonate, 2-6 parts of rosin, 15 parts of vegetable oil, (NH 4 ) x MoS 2 Add 13 parts, 7 parts of the first solid additive and 6 parts of the second solid additive into 88-95 parts of base oil, ultrasonically disperse, then add 1.25 parts of lithium hydroxide, 0.8 parts of potassium hydroxide and 10 parts of dicarboxylic acid, heat React at 80°C for 15 minutes to obtain the first reaction liquid;

[0079]Among them, the base oil is a mixture of paraffin, cycloalkyl and polyalphaolefin in a weight ratio of 1:5:2; the viscosity of the base oil at 60°C is 100-300cSt, the open flash point is 250°C, and the pour point is at -10°C;

[0080] The total base number of calcium petroleum sulfonate is 350;

[0081] The specific surface area of PTFE is 6m 2 / g;

[0082] The particle size range of the first solid additive is 0.8-5 microns; wherein, the particles of 0.8-1 microns account for 40% o...

Embodiment 3

[0086] Add 5 parts of lauryl hydroxystearic acid, 7 parts of petroleum calcium sulfonate, 4 parts of rosin, 12 parts of vegetable oil, (NH 4 ) x MoS 2 Add 9 parts, 5 parts of the first solid additive and 4 parts of the second solid additive to 92 parts of base oil, ultrasonically disperse, then add 0.95 parts of lithium hydroxide, 1.4 parts of potassium hydroxide and 15 parts of dicarboxylic acid, heat to 70 ℃ for 12 minutes to obtain the first reaction solution;

[0087] Among them, the base oil is a mixture of paraffin, cycloalkyl and polyalphaolefin in a weight ratio of 1:4:3; the viscosity of the base oil at 60°C is 200cSt, the open flash point is 240°C, and the pour point is -20 ℃;

[0088] The total base number of calcium petroleum sulfonate is 330;

[0089] The specific surface area of PTFE is 4m 2 / g;

[0090] The particle size range of the first solid additive is 0.8-5 microns; wherein, the particles of 0.8-1 microns account for 30% of the total weight of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Open flash point | aaaaa | aaaaa |

| Pour point | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com