Carbon nanotube conductive composite and preparation method thereof

A technology of carbon nanotubes and composites, which is applied in the manufacture of cables/conductors, conductive materials dispersed in non-conductive inorganic materials, circuits, etc., can solve the problem of difficulty in preparing conductive paste with high carbon nanotube content and poor storage stability Good and other problems, to achieve good storage stability, good performance, good dispersion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] 1) Dissolve 1 part of polyvinylpyrrolidone and 0.5 part of pyrazine in 94.5 parts of N-methylpyrrolidone, and then add 4 parts of carbon nanotubes (outer diameter 8nm to 12nm, specific surface area 265m 2 / g) stirring to obtain a predispersion;

[0038] 2) Add the pre-dispersion to a sand mill for rough grinding for 1 hour, and the rough grinding line speed is 7m / s;

[0039] 3) Finely grind for 3 hours after coarse grinding, the fine grinding line speed is 9m / s, and finely grind until the slurry composite fineness is ≤10μm and the viscosity is 1698mPa·s.

[0040] Detect the properties of the prepared slurry composite:

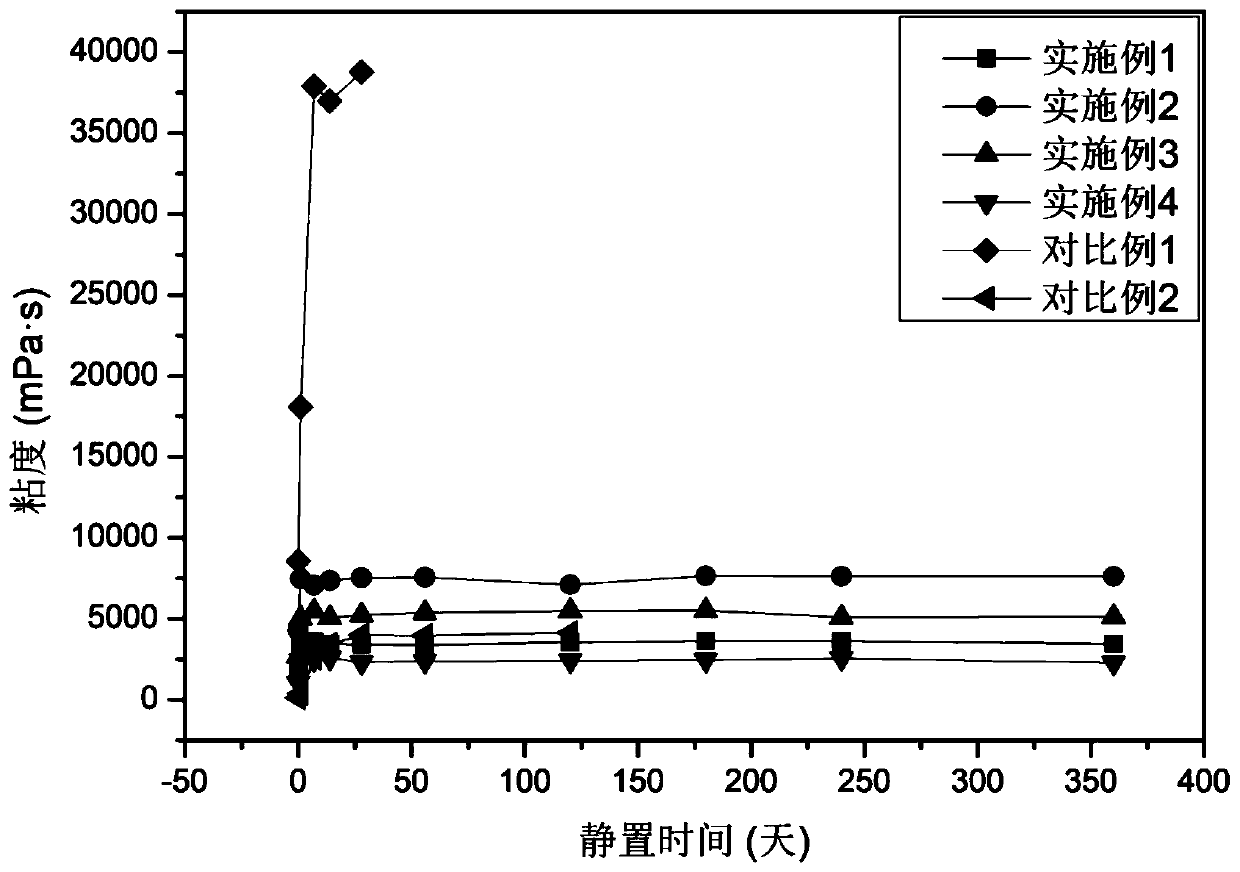

[0041] 1. Observe the appearance and viscosity changes of the prepared slurry composite within 360 days. The test results are shown in Table 1. figure 1 and figure 2 .

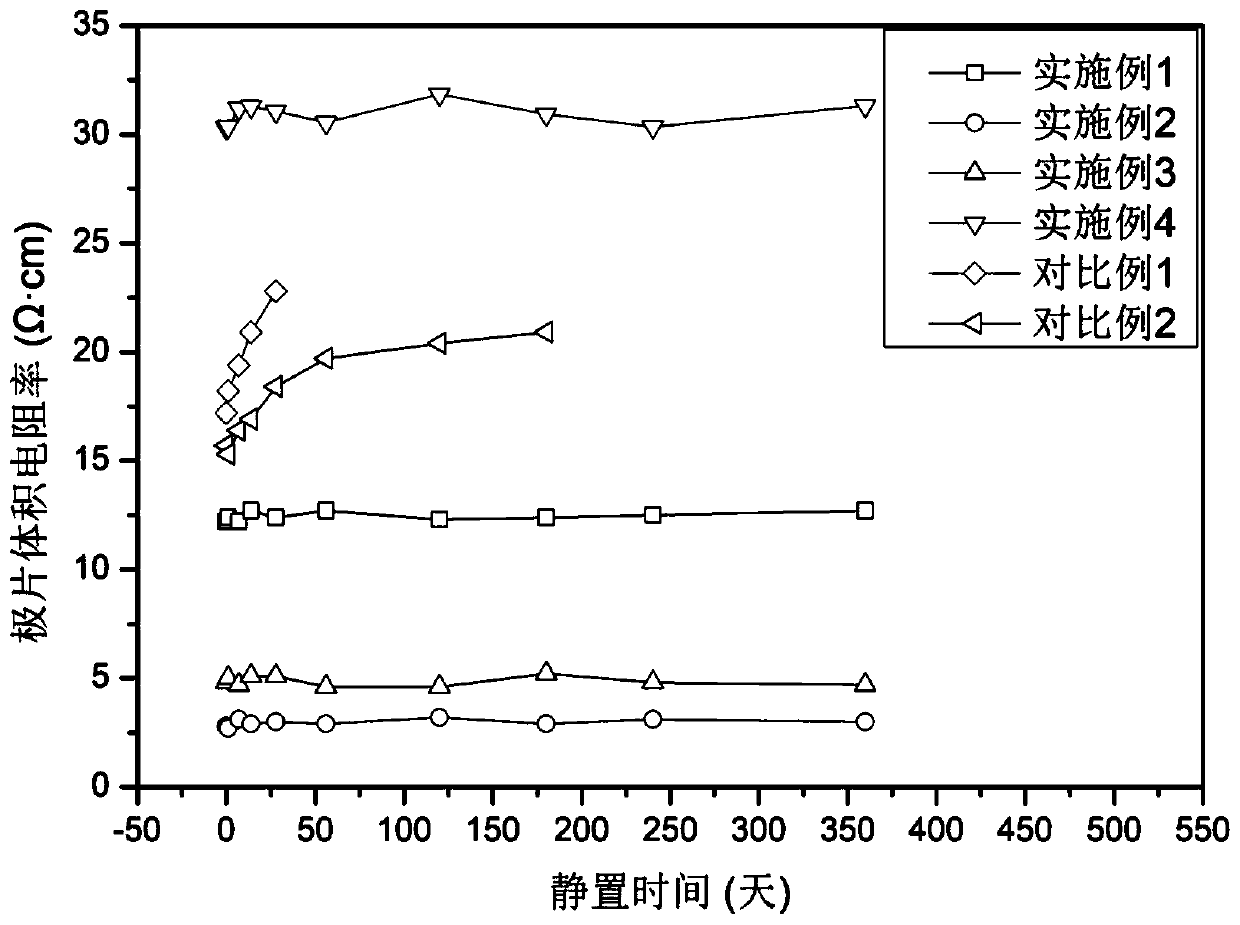

[0042] 2. Volume resistivity of lithium iron phosphate positive electrode sheet containing 1% carbon nanotubes: at the end of sand milling, take the prepared slurry compound and mi...

Embodiment 2

[0044] 1) Dissolve 0.8 parts of polyvinylpyrrolidone and 0.12 parts of pyrazine in 98.08 parts of N-methylpyrrolidone, and then add 1 part of carbon nanotubes (outer diameter 4nm to 6nm, specific surface area 496m 2 / g) stirring to obtain a predispersion;

[0045] 2) Add the pre-dispersion to a sand mill for rough grinding for 1 hour, and the rough grinding line speed is 6m / s;

[0046] 3) Finely grind for 3 hours after coarse grinding, the fine grinding line speed is 9.5m / s, and finely grind until the slurry composite fineness is ≤10μm and the viscosity is 4294mPa·s.

[0047] The performance of the prepared slurry composite is detected with reference to the method in Example 1, and the detection results are shown in Table 1, figure 2 and image 3 .

Embodiment 3

[0049] 1) Dissolve 1 part of polyvinylpyrrolidone in 95.5 parts of N-methylpyrrolidone, and then add 3 parts of carbon nanotubes (outer diameter 6nm ~ 10nm, specific surface area 327m 2 / g) stirring to obtain a predispersion;

[0050] 2) Add the pre-dispersion liquid and 0.5 parts of pyridine into the sand mill for rough grinding for 1.5 hours, and the rough grinding line speed is 6m / s;

[0051] 3) Fine grinding for 3.5 hours after coarse grinding, the fine grinding line speed is 9.5m / s, until the fineness of the slurry composite is ≤10μm and the viscosity is 2672mPa·s.

[0052] The performance of the prepared slurry composite is detected with reference to the method in Example 1, and the detection results are shown in Table 1, figure 2 and image 3 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com