Patents

Literature

1074 results about "Petroleum sulfonate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Sodium Petroleum Sulphonate / Sulfonate is obtained from sulfonation of base oil, neutralised by Sodium Hydroxide. The Product mainly works as a Surface Active Agent, Emulsification & Dispersion of Liquid's, Wetting & Dispersion of Liquid – Solid System, Inhibition of Rust & Corrosion, Dispersion & Wetting of Solids.

Composite lithium-base grease and method for making same

The present invention provides composite lithium-based lubricating grease and a preparation method thereof. The composite lithium-based lubricating grease consists of thickener, base oil and additive. The thickener consists of 12-hydroxy stearic acid lithium dibasic acid and / or lithium borate, and the mol ratio is 1 ®U 0.1 to 1 ®U 0.1to 1. The base oil is mineral oil or poly-alpha-olefin synthesis oil. The additive consists of organic amine compound antioxidant, benzotriazole and barium petroleum sulfonate or barium dinonylnaphthalene sulfonate anti-corrosion additive and rust protection agent, dialkyl dithiocarbamate or dibenzyl disulfide and sulfurized olefin cottonseed oil extreme pressure antiwear additive and nanometer copper powder repairing additive. The contents of the thickener and the base oil are respectively 6 percent to 18 percent and 82 percent to 94 percent according to the weight percentage. The lubricating grease has the multi-effect performances of high dripping point, good high-temperature performance and low-temperature performance, chemical invariability, colloid invariability, antiwear extreme pressure performance etc., and especially has the repairing function towards a damaged bearing.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Nano composite high-temperature-resistant extraction aid for thickened oil and super-thickened oil recovery and preparation method thereof

ActiveCN103320110AGood viscosity reductionReduce dosageDrilling compositionSalt resistanceTemperature resistance

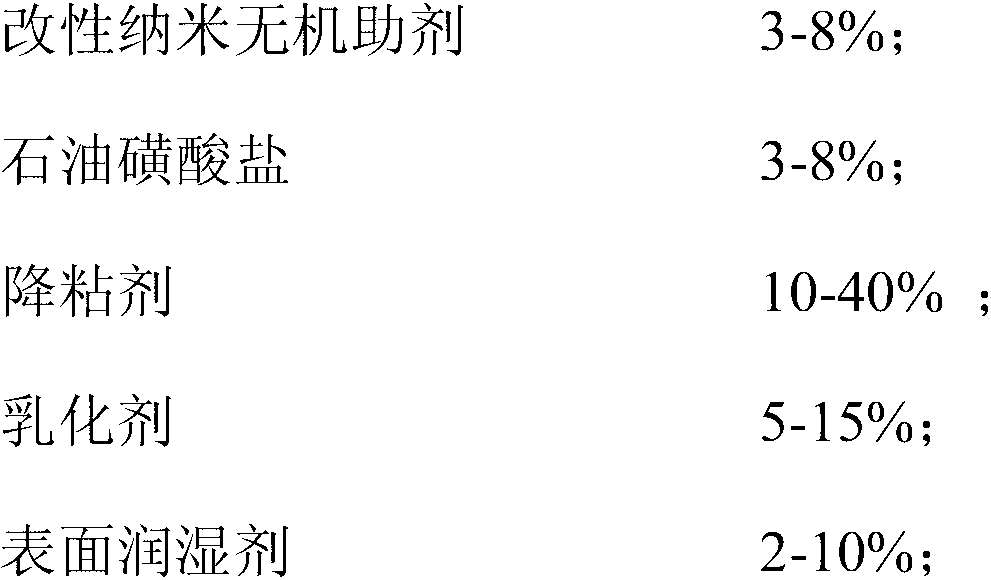

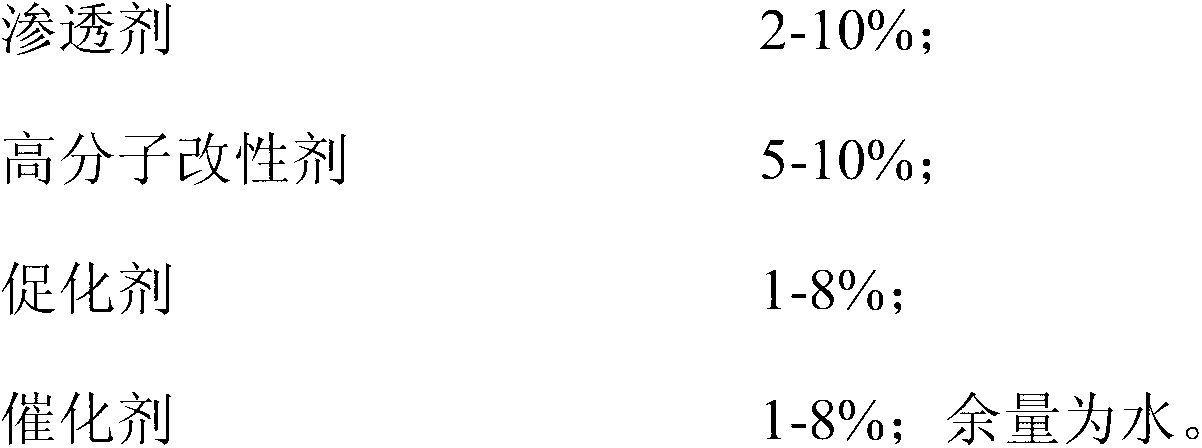

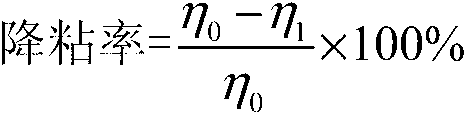

The invention discloses a nano composite high-temperature-resistant extraction aid for thickened oil and super-thickened oil recovery. The nano composite high-temperature-resistant extraction aid is prepared from 3-8 weight percent of modified nano-silica, 3-8 weight percent of petroleum sulfonate, 10-40 weight percent of a viscosity reducer, 5-15 weight percent of an emulsifier, 2-10 weight percent of a surface wetting agent, 2-10 weight percent of a penetrating agent, 5-10 weight percent of a high polymer modifier, 1-8 weight percent of a catalyst and the balance of water. The preparation method comprises the following steps: polymerizing the petroleum sulfonate, viscosity reducer, a promoting agent and the catalyst at the temperature of 60-150 DEG C for 2-6 hours according to a ratio, adding the modified nano inorganic aid, and uniformly mixing; and finally, adding the emulsifier, surface wetting agent, penetrating agent, high polymer modifier and water according to the ratio, and mixing for 1-2 hours. The nano composite high-temperature-resistant extraction aid for thickened oil and super-thickened oil recovery has high high-temperature resistance and excellent emulsification and salt resistance, the production efficiency can be greatly improved, and the recovery rate is reduced.

Owner:GUNGHO CHARGE TIANJIN REFINED PETROLEUM TECH DEV

Metal rust-preventive oil comprising butyl acrylate

ActiveCN103214886AGood gas phase anti-rust effectExcellent contact rust resistanceAnti-corrosive paintsMeth-Composite film

The invention discloses metal rust-preventive oil comprising butyl acrylate. The oil is prepared from the raw materials of: No.120 solvent oil, paraffin, methyl diethanolamine, epoxy octyl stearate, magnesium naphthenate, a silane coupling agent KH560, a silane coupling agent A171, microcrystalline wax, aluminum stearate, magnesium lanolin soap, monoethanolamine, barium petroleum sulfonate, sodium lauryl sulfate, trioctyl trimellitate, benzotriazole, 2-aminoethyl heptadecenyl imidazoline, zinc stearate, an antioxidant BHT, an antioxidant 1010, dipropylene glycol, phytic acid, butyl acrylate, modified nano-grade dolomite powder, a composite film-forming material, and ferrocene. The rust-preventive oil provided by the invention has excellent contact rust resistance and good gas-phase rust resistance. The rust-preventive oil provided by the invention provides good gas-phase rust resistance and contact rust resistance for steel and brass.

Owner:SHANTOU HONGSHENG BOLT IND CO LTD

Composite calcium-sulfonate-based tetrapolyurea lubricating grease and preparation method thereof

ActiveCN102453599AGood extreme pressure and anti-wear propertiesLong lubrication lifeThickenersCorrosionSulfonic acid

The invention discloses a composite calcium-sulfonate-based tetrapolyurea lubricating grease and a preparation method thereof. With the weight of the lubricating grease as a reference, the lubricating grease comprises components of: (1) 10-70% of non-Newtonian fluid calcium sulfonate; (2) 1-10% of higher fatty acid calcium; (3) 1-15% of small-molecule inorganic acid calcium or organic acid calcium; (4) 0.5-30% of tetrapolyurea; and (5) 10-80% of lubricating base oil. According to the lubricating grease, calcium petroleum sulfonate or synthesized calcium sulfonate is adopted as a raw material, and the lubricating oil contains a composite calcium thickening agent and a tetrapolyurea compound. The lubricating grease has excellent extreme pressure wear resistance, ultra-long lubricating life, good adhesion, water resistance, colloid stability, high dropping point, thermal stability, corrosion resistance, and salt spray resistance.

Owner:CHINA PETROLEUM & CHEM CORP +1

Highly effective mixed oil expellant applied to tertiary oil recovery and its preparation method

The invention discloses a third oil extraction high-efficient built oil displacement agent and preparing method in the chemical oil displacement domain, which is characterized by the following: adapting oil sulfonate as main surface activator to build with non-ion surface activator, anion surface activator, organic solvent and natrium chloratum; reducing oil water interface tension without influencing by mineralizing degree; improving the crude oil recovery efficiency by over 20 percent with polymerization.

Owner:中国石化股份胜利油田分公司地质科学研究院

Long-acting emulsion-type antirust fluid

InactiveCN101608310AGood oil solubilityGood water solubilityDiethylene glycol monobutyl etherBarium salt

The invention relates to a long-acting emulsion-type antirust fluid used for metal rust prevention. Every 100 parts of the antirust fluid include the following components according to parts by weight: 3-15 oil soluble surfactant, 1-10 alcohol ether type couplant, 1-10 oily-type rust preventive and the balance base oil, wherein the oil soluble surfactant is any one of petroleum sodium sulfonate with molecular weight ranging from 300 to 800, sodium heavy alkylbenzene sulfonate and sodium sulfanilate, the alcohol ether type couplant is any one of ethyl alcohol, ethyl ether, butyl ether, diethylene glycol monobutyl ether, diethylene glycol propyl ether, butyl glycol ether and ethylene glycol propyl ether, the oily-type rust preventive is any one of barium petroleum sulfonate, dinonyl naphthalenesulfonic acid barium salt and barium soap of petroleum ester oxide, and the base oil is any one of cycloalkyl base oil and paraffin base oil. The long-acting emulsion-type antirust fluid has the advantages of meeting the demands of short-term rust prevention of metal and having lower using cost.

Owner:NANJING KERUN LUBRICANTS

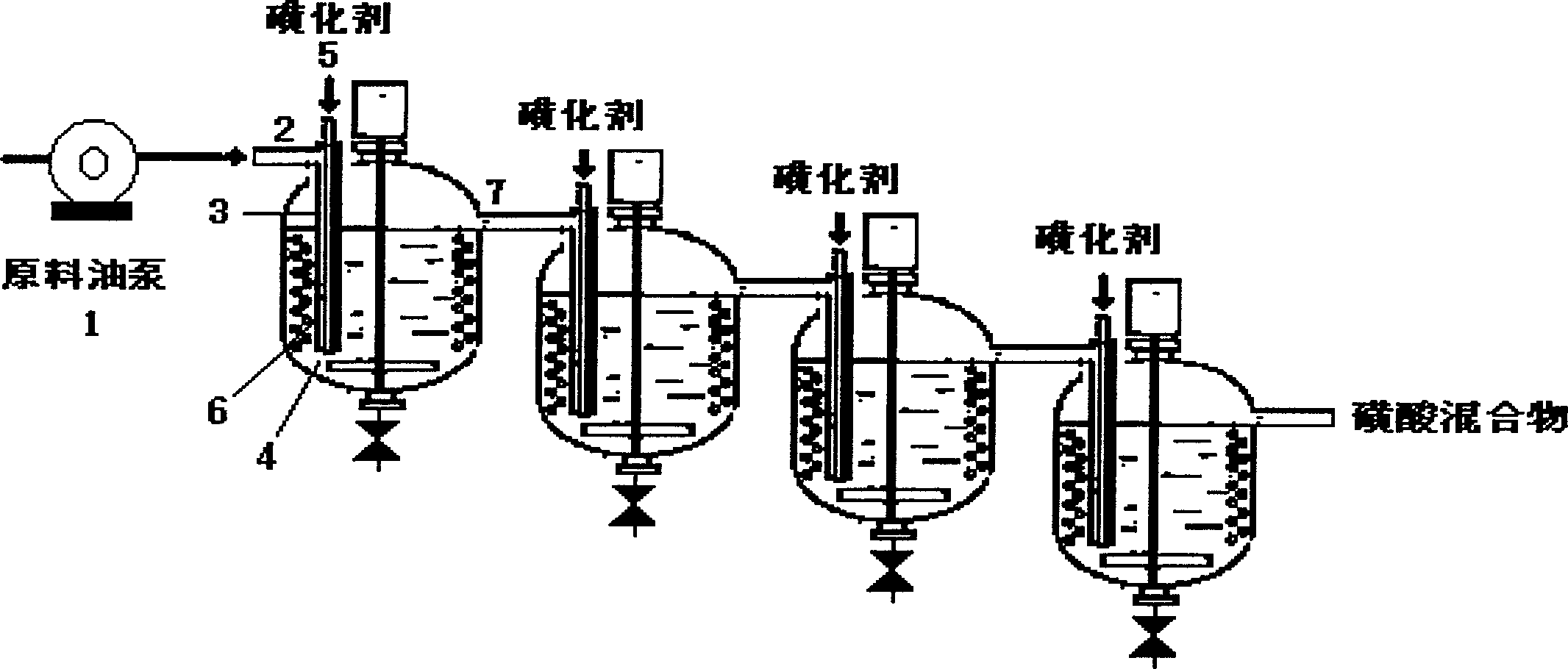

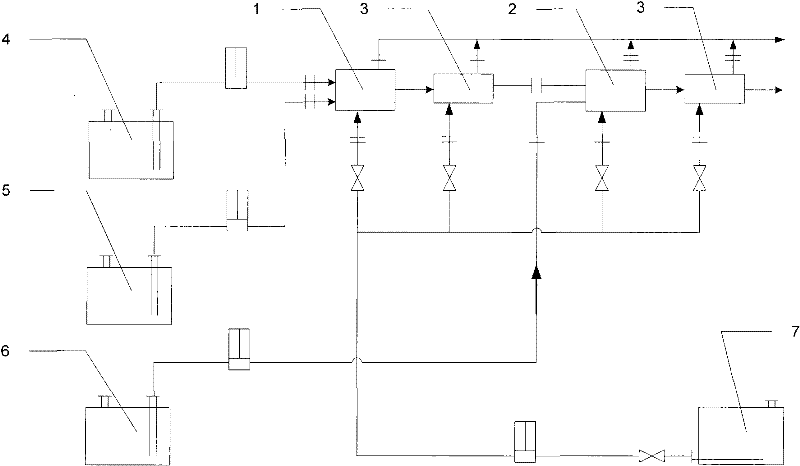

Continuous preparing method for petroleum sulfosalt

A process for continuously preparing petroleum sulfonate with serially connected 2-8 sulfonating reactors includes such steps as feeding the crude oil and sulfonating agent respectively in the first reactor, sulfonating reacting, feeding the resultant mixture in the second reactor, and so on, and neutralizing the sulfonic acid discharged from the last reactor to obtain petroleum sulfonate. Its advantage is high sulfonating rate.

Owner:CHINA PETROLEUM & CHEM CORP +1

Molecular compound surfactant and preparation method thereof

InactiveCN101596428AOvercome viscoelasticityOvercome structureTransportation and packagingMixingSalt resistanceActive component

The invention relates to a molecular compound surfactant and a preparation method thereof. The molecular compound surfactant respectively comprises the following components and weight percent thereof: 20 to 40 of petroleum sulfonate surfactant, 6 to 30 of surfactant, 5 to 10 of high molecular modifier, 1 to 5 of viscosity reducer, 1 to 5 of additive and water added to 100. The preparation method comprises the following steps that: the petroleum sulfonate surfactant, the surfactant, the high molecular modifier, the viscosity reducer, the additive and the water are added into a reactor with a stirring device according to the weight ratio and are stirred at room temperature for 1.5 to 2.5 hours so as to obtain a finished product. The compound surfactant is prepared by utilizing a plurality of associations of structure complementary and good compatibility as well as the mechanism of intermolecular interaction of the surfactant of a plurality of association and active components with complemental structure and well matching, and the system has the properties of high-temperature resistance, salt resistance, high-viscosity resistance, ultra-low interfacial tension and the like, conforms to the requirement of environmental protection and can obviously enhance the recovery ratio of crude oil after being used for the oil displacement of tertiary oil recovery.

Owner:GUNGHO CHARGE TIANJIN REFINED PETROLEUM TECH DEV

High-extreme pressure water-resistant antirust lubricating grease and preparation method thereof

ActiveCN101705143AImprove water stabilityAntioxidantLubricant compositionLithium hydroxideAntioxidant

The invention relates to high-extreme pressure water-resistant antirust lubricating grease and a preparation method thereof. The high-extreme pressure water-resistant antirust lubricating grease is prepared by the reaction of various substances by weight parts as follows: 43.5-77.5 parts of high-viscosity mineral oil, 7-10 parts of fatty acid, 0.7-1.0 part of lithium hydroxide, 0.3-0.5 part of calcium hydroxide, 10-30 parts of high base number calcium petroleum sulfonate, 1-3 parts of transforming agent, 1-3 parts of antirust agent, 1-3 parts of extreme-pressure additive, 0.5-1.0 part of antioxidant, and 1-5 parts of thickening agent. In the invention, the water comprehensive stability and water antirust performance of the lubricating grease are improved, and the water stability of the thickening agent and the extreme-pressure additive is improved.

Owner:辽宁海华科技股份有限公司

Environmental-friendly micro emulsion cutting fluid

InactiveCN102533418AImprove the lubrication effectEasy to cleanLubricant compositionPhosphoric Acid EstersChemical industry

The invention relates to an environmental-friendly micro emulsion cutting fluid, which belongs to the field of chemical industry. The invention aims to provide the environmental-friendly micro emulsion cutting fluid, which not only is capable of protecting the environment but also is capable of performing cooling and lubrication actions in the metal cutting abrasive machining process. The environmental-friendly micro emulsion cutting fluid comprises 10# industrial white oil, sodium petroleum sulfonate, oleic acid, triethanolamine, alkylphenol polyoxyethylene OP-10, alkyl alcohol amido phosphate ester 6503, an antirusting agent monomer, tetradecyl alcohol or stearyl alcohol, benzotriazole, sodium tetraborate, sodium carbonate, triazine compound / benzisothiazolinone bactericide (NEUF652), a defoaming agent MS-455 and water. The environmental-friendly micro emulsion cutting fluid not only has the advantages of good lubricity of an emulsion-type cutting fluid and strong cleaning capacity of synthetic cutting fluid but also is capable of overcoming the defects that the emulsion-type cutting fluid is easy to go bad and stink and has a short service life and the synthetic cutting fluid has poorer lubricating property, and has the characteristics of good lubricity, strong cooling and cleaning capacity, long service life and the like.

Owner:FAW GROUP

Corrosion inhibiting and descaling agent of industrial cooling circulating water system

InactiveCN1754840APlay a role in corrosion inhibitionPlay the effect of anti-scalingTreatment using complexing/solubilising chemicalsChemical industryMercaptobenzothiazole

The present pertains to the field of chemical industry, wherein an antisludging agent for industrial circulating water systems is disclosed, which comprises acroleic acid-acrylate-petroleum sulfonate copolymer, mercaptobenzothiazole, sodium humate, lignin and water. The antisludging agent has good protection action to industrial cooling-water systems.

Owner:SHANGHAI WANSEN WATER TREATMENT CO LTD

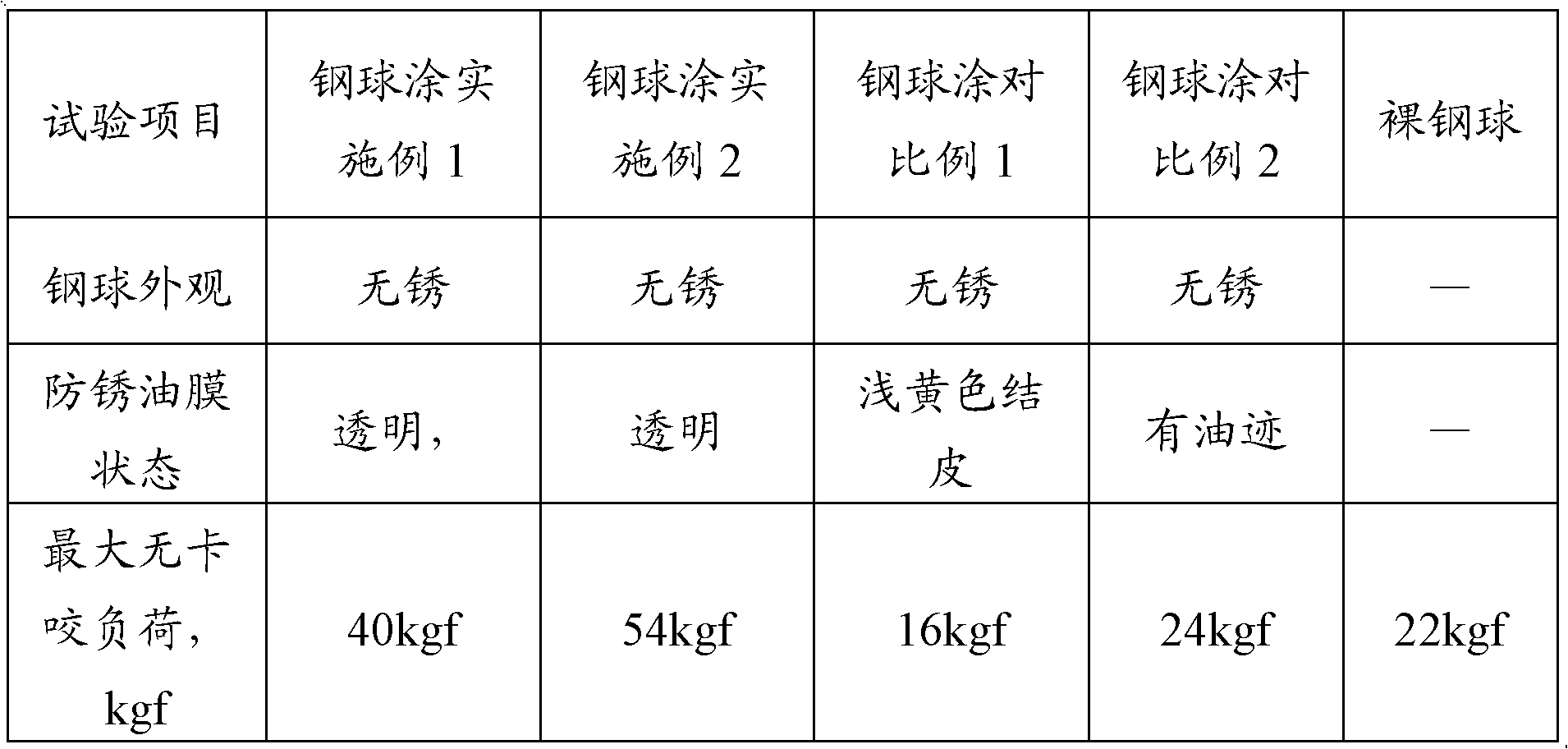

Antirust oil and preparation method thereof

The invention provides antirust oil, which comprises the following components in percentage by weight: 75 to 87.5 percent of base oil, 1 to 3 percent of complex ester, 4 to 10 percent of barium petroleum sulfonate, 2 to 6 percent of barium dinonyl sulfonate, 0.5 to 1.5 percent of dodecylene succinic acid, 0.3 to 0.8 percent of benzotriazole and 3 to 6 percent of di-n-butyl phthalate, wherein the complex ester is obtained by reacting raw materials comprising polyalcohol and dicarboxylic acid. The antirust oil provided by the invention has the advantages of oil-film antirust oil and soft-film antirust oil and long antirust time. A workpiece coated with the antirust oil can be directly put into use without being cleaned or being provided with an additional lubricating additive. The antirust oil can be applied to long-term rusting protection of metal workpieces, such as internal surface rusting protection of engines, gearboxes and pumps.

Owner:KASONG SCI & TECH

Composite calcium sulfonate-based octaurea lubricating grease, and preparation method thereof

ActiveCN102453598AGood extreme pressure and anti-wear propertiesLong lubrication lifeThickenersSulfonateBase oil

The present invention provides a composite calcium sulfonate-based octaurea lubricating grease, and a preparation method thereof. According to the lubricating grease, the lubricating grease comprises the following components by adopting the weight of the lubricating grease as the reference, wherein the components comprise, by weight, 1) 10-70% of non-Newtonian calcium sulfonate, 2) 1-10% of higher fatty acid calcium, 3) 1-15% of small-molecule inorganic calcium or organic calcium, 4) 0.5-30% of octaurea, and 5) 10-80% of lubricating base oil. According to the present invention, the lubricating grease adopts the calcium petroleum sulfonate or the synthetic calcium sulfonate as the raw material, and contains the composite calcium thickener and the octaurea compound; the lubricating grease has properties of excellent extreme pressure antiwear property, ultralong lubricating life, excellent adhesion, water resistance, colloidal stability, high drop point, thermal stability, corrosion resistance, salt mist resistance and the like.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for carrying out profile control on fracture-type oil reservoir

The invention relates to a method for carrying out profile control on a fracture-type oil reservoir, which comprises the following steps of injecting 0.1 to 0.3 percent of zwitterionic polymer solution into an oil layer; suspending and carrying expansion-retarding 0.2 to 1.0 percent of salt-resistance high-intensity water-absorbent resin particles by a zwitterionic gel profile control agent and injecting the obtained product into a fracture of the oil layer; injecting 30 to 50m<3> of acrylamide gel; suspending 0.2 to 0.5 percent of water insoluble solid particles by the zwitterionic gel profile control agent and injecting the obtained product into the fracture; and alternately injecting 1,000m<3> of partially hydrolyzed polyacrylamide solution with a molecular weight of 15 million, degree of hydrolysis of 10 to 20 percent and 1,000m<3> of petroleum sulfonate surfactant solution, wherein the concentration of the hydrolyzed polyacrylamide solution is 0.05 to 0.15 percent and the concentration of the petroleum sulfonate surfactant solution is 0.2 to 0.5. According to the method, profile control and flooding effects of the fracture-type oil reservoir can be improved; water content of a fracture main direction oil well is reduced; and yield of crude oil of a fracture side direction oil well is increased.

Owner:PETROCHINA CO LTD

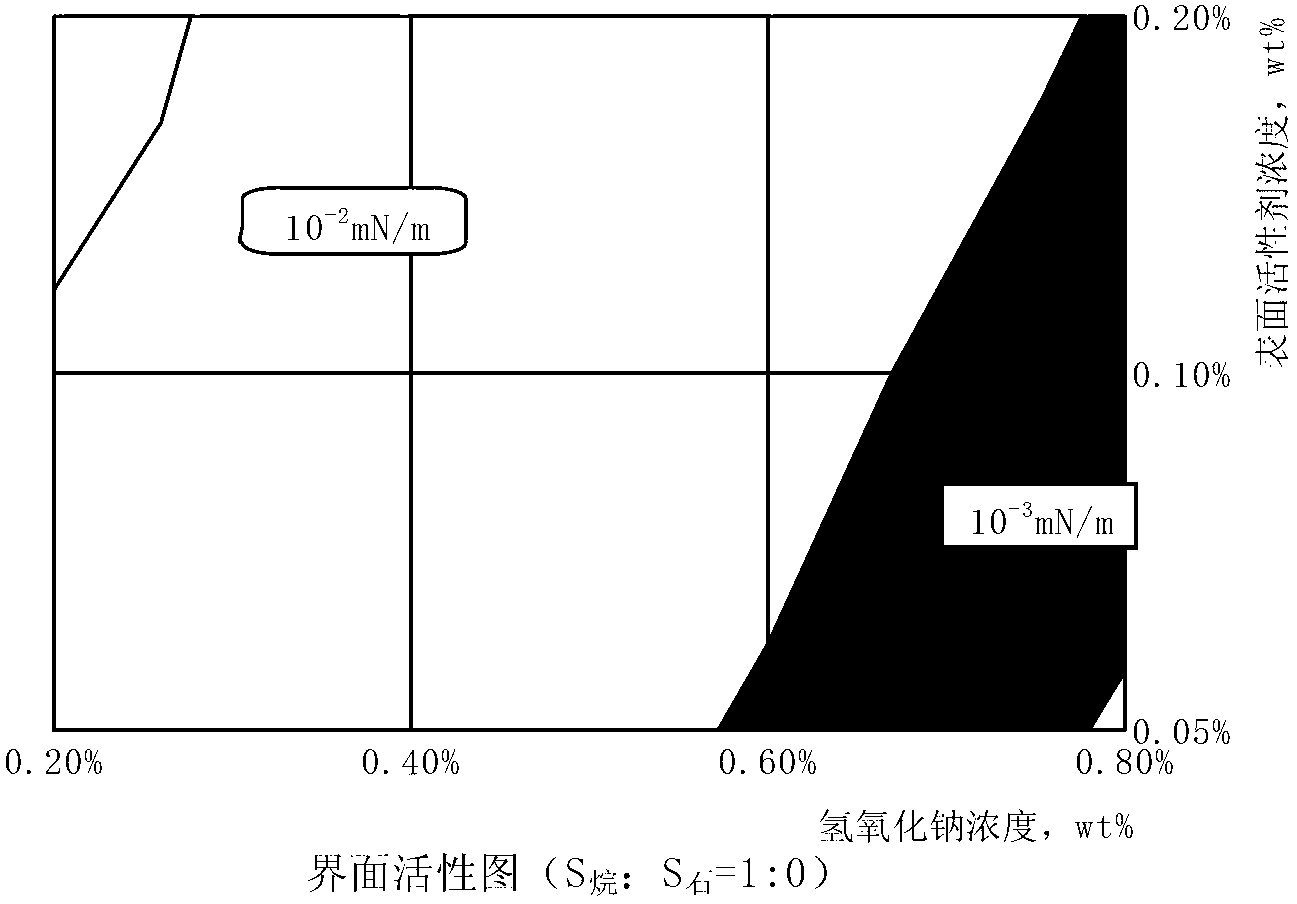

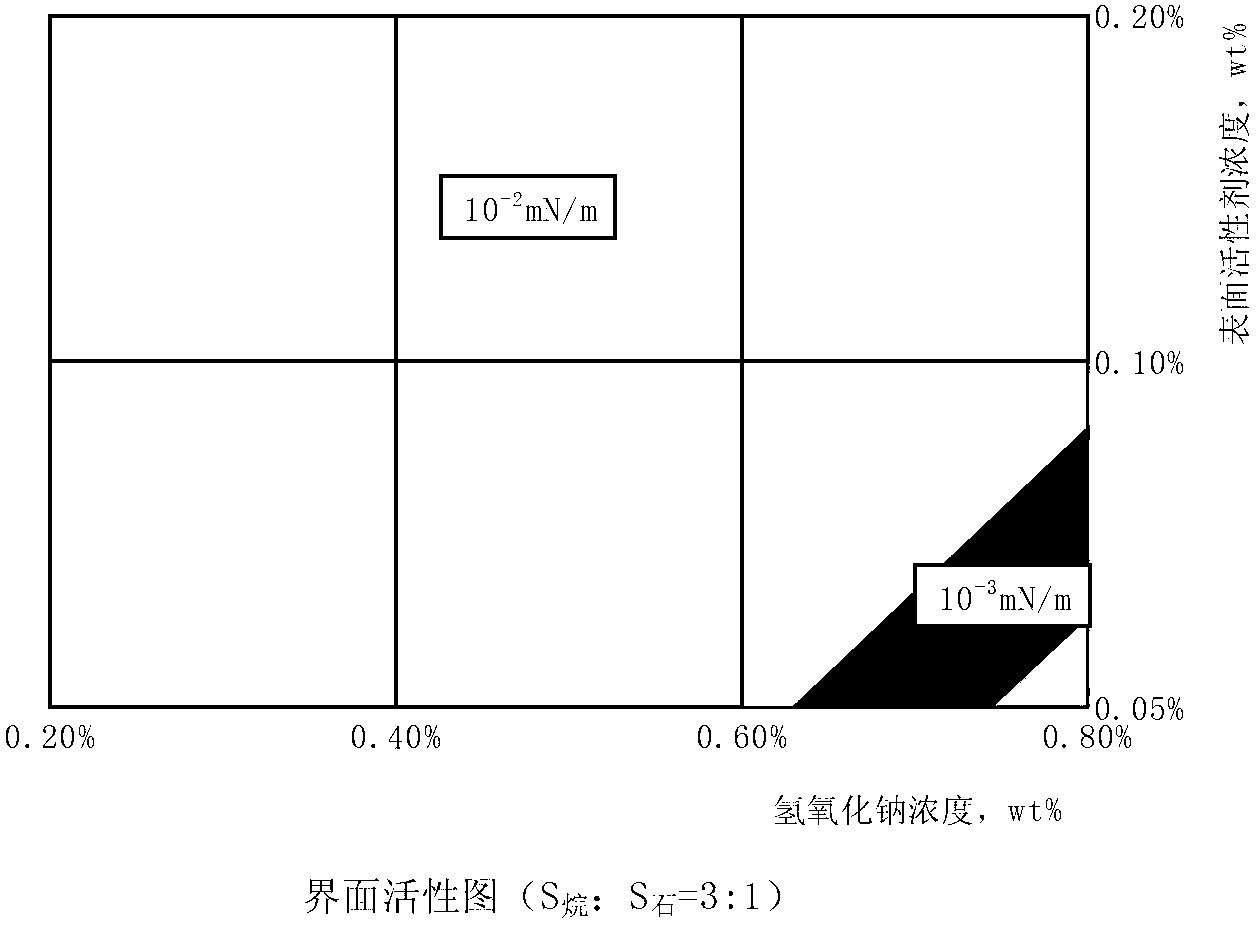

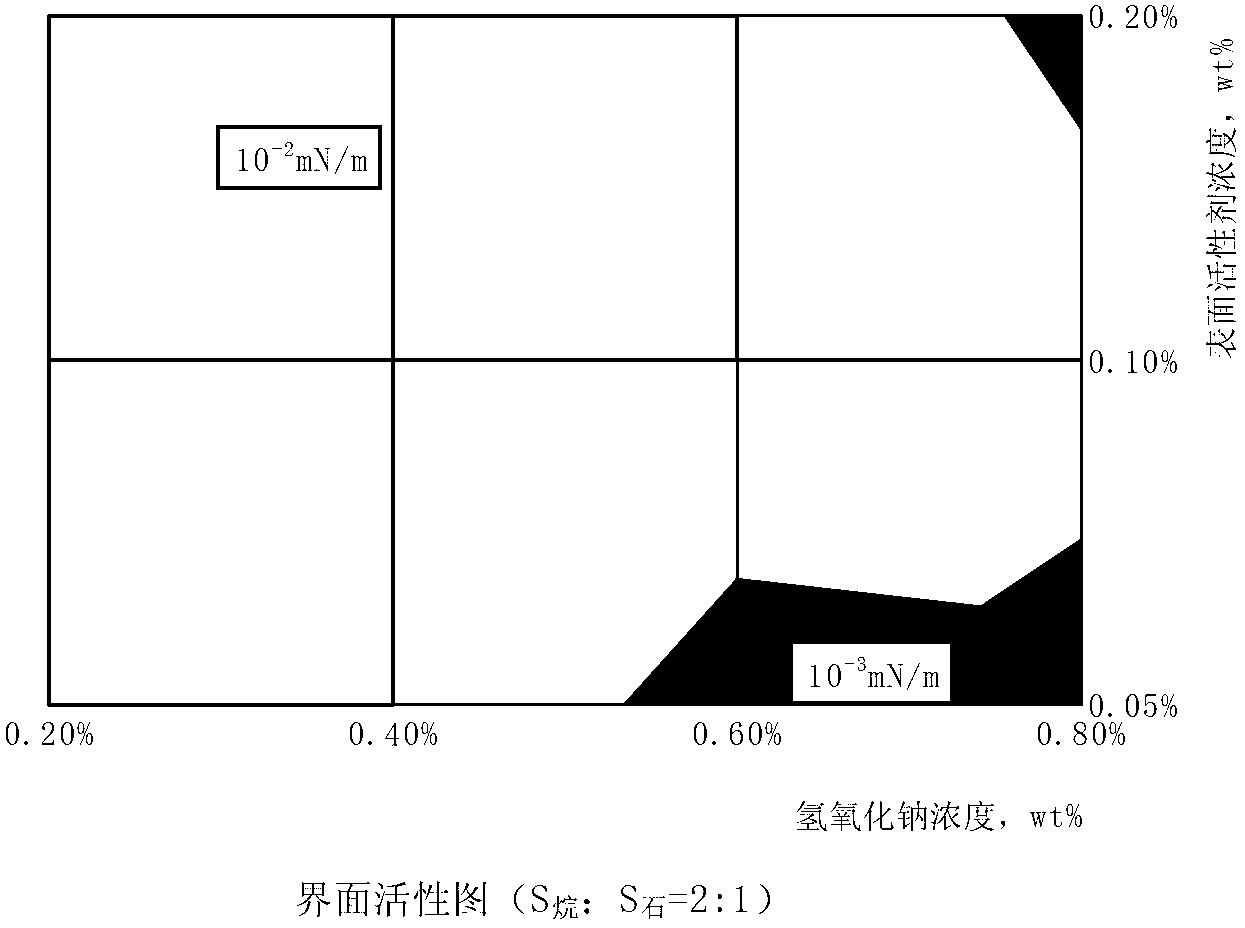

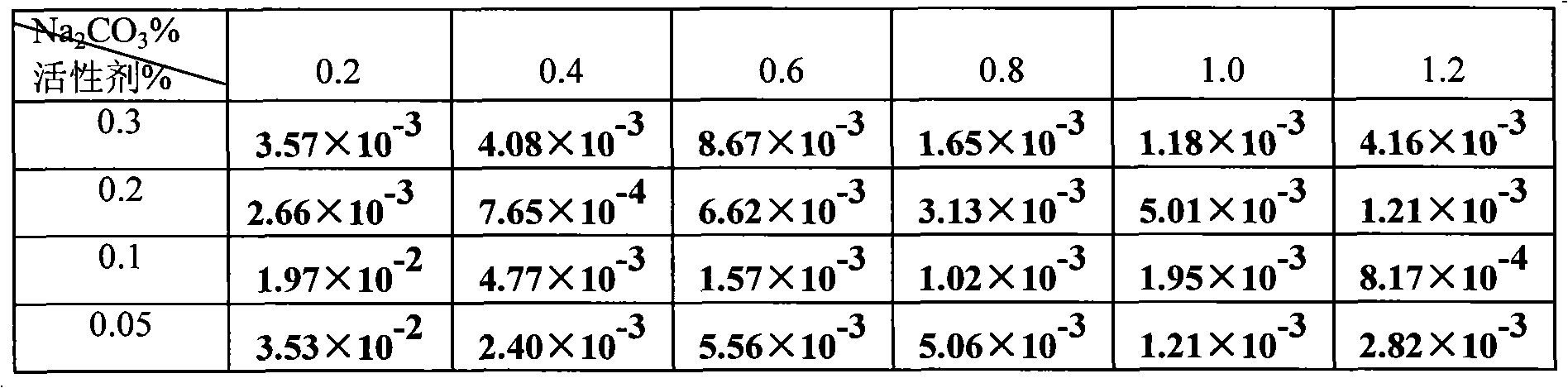

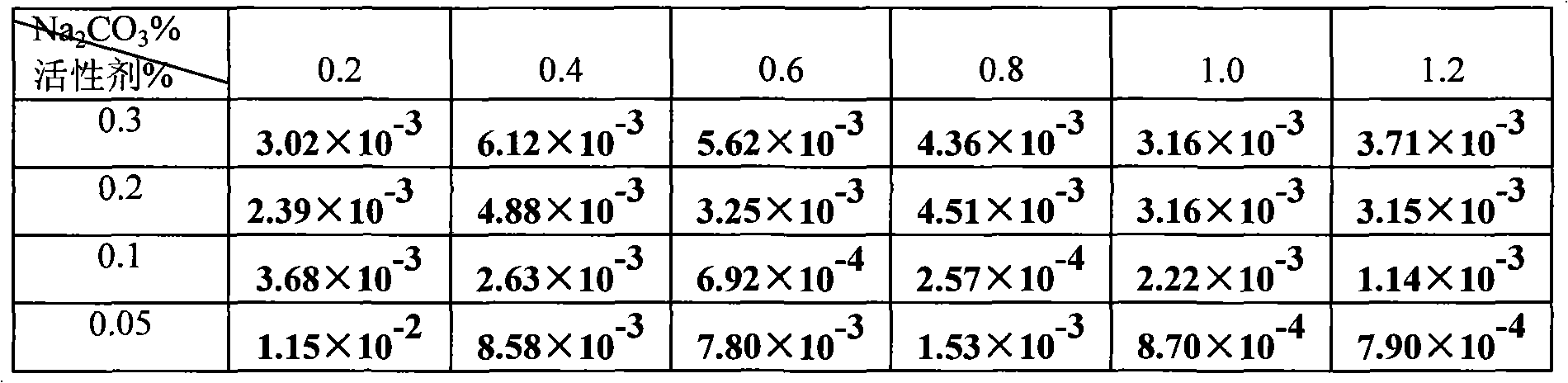

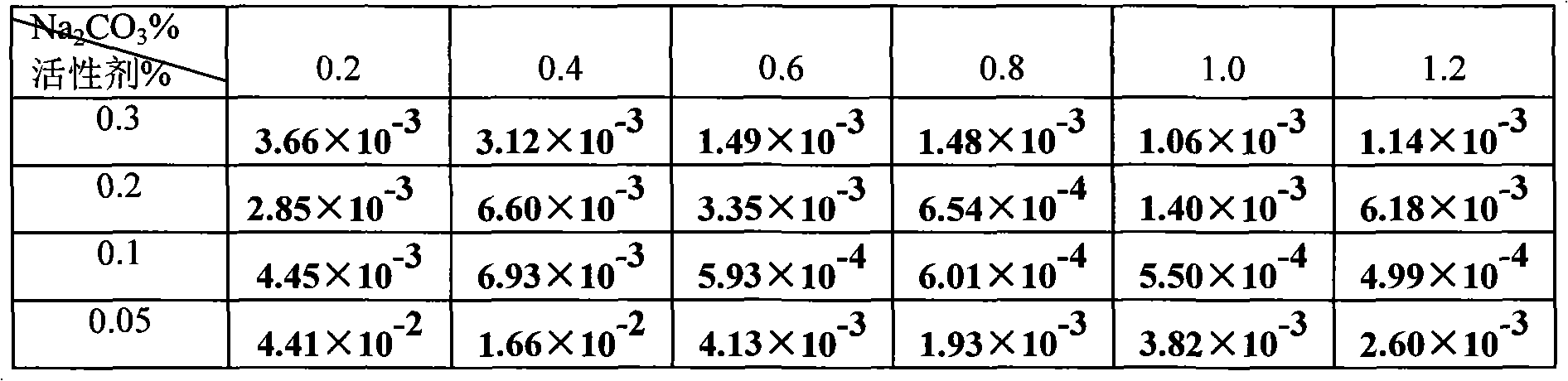

Weak base ternary composite reservoir oil displacement composition with formulated surfactant and application thereof

ActiveCN103224777AImprove handling difficultyEnhanced overall recoveryFluid removalDrilling compositionAdditive ingredientGround system

The invention provides a weak base ternary composite reservoir oil displacement composition with formulated surfactant and application thereof, and the ternary composite reservoir oil displacement composition contains a formulated surfactant, which is formulated by mahogany petroleum sulfonate and HABS according to 3:1 weight ratio; 0.4 wt.% and 0.6 wt.% of sodium carbonate; polymer. The ternary composite reservoir oil displacement composition provided by the invention has synergism between each ingredient, and can the recovery efficiency is increased by more than 20%; simultaneously because the reservoir oil displacement composition of the present invention does not have highly basic sodium hydroxide, and the sodium carbonate concentration in the prior art weak base ternary system is reduced, and the possibility for dissolving rock in stratum is reduced, thereby solving the lifting system problem caused by scaling in the extraction well and reducing treatment difficulty of the ground system.

Owner:PETROCHINA CO LTD +1

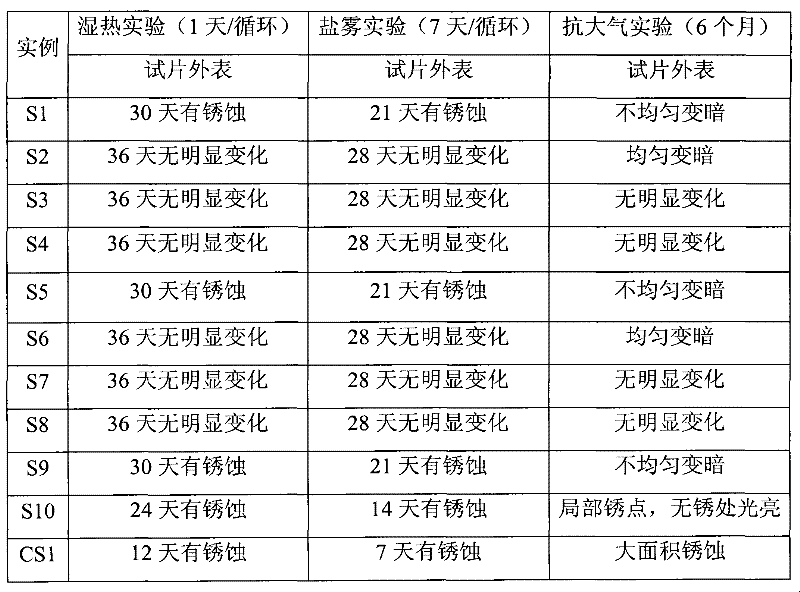

Rust preventive oil and preparation method thereof

The invention provides a rust preventive oil. The rust preventive oil comprises a composite antirust agent and base oil. The composite antirust agent is a mixture of a rare earth-beta-dione complex and at least one of barium petroleum sulfonate, sodium petroleum sulfonate, calcium petroleum sulfonate, barium dinonylnaphthalene sulfonate, barium heavy alkyl benzene sulfonate, non-barium heavy alkyl benzene sulfonates, a lanolin magnesium soap, a lanolin aluminum soap, aluminium stearate, a oxidized petroleum ester barium soap and zinc naphthenate. The invention also provides a preparation method of the rust preventive oil. The preparation method comprises putting the base oil into a reaction vessel, adding the composite antirust agent into the base oil, stirring the mixture with heating to dehydrating the mixture, and then filtering to obtain the rust preventive oil. The rust preventive oil prepared by the invention can keep a rust-preventing effect for a long time in three environments of a temperature and humidity experiment, a salt spray experiment and an atmospheric corrosion resistance experiment, and thus can satisfy needs.

Owner:BYD CO LTD

High-efficiency phosphino-carboxylic acid dirt dispersion agent

InactiveCN1837101APrevent precipitationGood corrosion inhibitionScale removal and water softeningTricarboxylic acidCarboxylic acid

The invention provides a PBTC anti-scaling disperser, which comprises 2-phosphonobutane-1,2,4-tricarboxylic acid, acroleic acid-acrylate-petroleum sulfonate copolymer, zinc chloride, benzotrizaole and water, which can be operated under high pH, and can be used for forming a layer of thin and compact anti-corrosive film on the surface of metals, thus effectively inhibiting metallic corrosion.

Owner:SHANGHAI WANSEN WATER TREATMENT CO LTD

Water soluble anti-rust agent

InactiveCN101712817AShort film forming timeImprove quick-drying performanceAnti-corrosive paintsHazardous substanceSebacic acid

The invention relates to a water soluble anti-rust agent on the surface of ferrous metal, which comprises the following components: 2 to 10 weight percent of barium petroleum sulfonate and / or barium dinonyl decyl sulfonate, 1 to 6 weight percent of sodium molybdate and / or amine molybdate, 0 to 10 weight percent of sebacic acid, 2 to 10 weight percent of polyacrylic ester, 3 to 20 weight percent of triethanolamine oleic soap and / or 2 to 6 weight percent of polyoxyethylenesorbitan monooleate, 0 to 15 weight percent of sodium alkylsulfonate, 0 to 8 weight percent of glycerin and the balance of water or machine oil. Compared with the conventional water soluble anti-rust agent, the water soluble anti-rust agent of the invention has the advantages of short film forming time, firm film forming adsorption and good anti-rust effect; the actual anti-rust period can reach 3 to 6 months; the formed film is thin and only 3 to 5 microns; common workpieces do not need film removal and can be directly assembled and coated; the film removal is convenient, and the film is only soaked and rinsed in mild water over 50DEG C and then can be removed quickly; and the anti-rust agent has no component containing toxic and harmful substances, does not contain phosphorus, has the advantages of good environmental protection and no pollution to the environment, and is the environment-friendly water soluble anti-rust agent.

Owner:无锡市弘育化工有限公司

In-situ emulsification and viscosity increase system with controllable viscosity, and application thereof in water-flooding oil reservoir

ActiveCN110173244ANot affected by the salinity of mineralized waterEasy injectionFluid removalDrilling compositionSuspending AgentsPetroleum

The invention discloses an in-situ emulsification and viscosity increase system with controllable viscosity. The system comprises ingredients by weight, including 0.3%-1.5% of emulsifier, 0.05%-0.5% of superfine colloidal particles, 0.01%-0.1% of suspending agent and the balance being mineralized water, wherein the emulsifier is one of or a combination of mahogany petroleum sulfonate, petroleum carboxylate, sodium dodecyl sulfate, sodium dodecyl benzene sulfonate, alkyl polyglycoside, aliphatic alcohol ether carboxylate, aliphatic alcohol ether sulfonate, hydroxyl sulphobetaine and alkanolamide; the superfine colloidal particles are made of one of superfine silicon dioxide, superfine montmorillonoid, superfine ferric oxide, superfine ferroferric oxide, superfine aluminum oxide and superfine titanium dioxide; and the suspending agent is one of partially hydrolyzed polyacrylamide, amylose, carboxymethyl chitosan, hydroxymethyl cellulose, xanthan gum and align. The in-situ emulsificationand viscosity increase system is applicable to a water-flooding oil reservoir with the viscosity of lower than 50 mPa.s, is not influenced by temperatures and a degree of mineralization of the oil reservoir, has a very broad coverage scope and outstanding economic benefits and can effectively promote efficient development of water-flooding oil reservoirs.

Owner:SOUTHWEST PETROLEUM UNIV +1

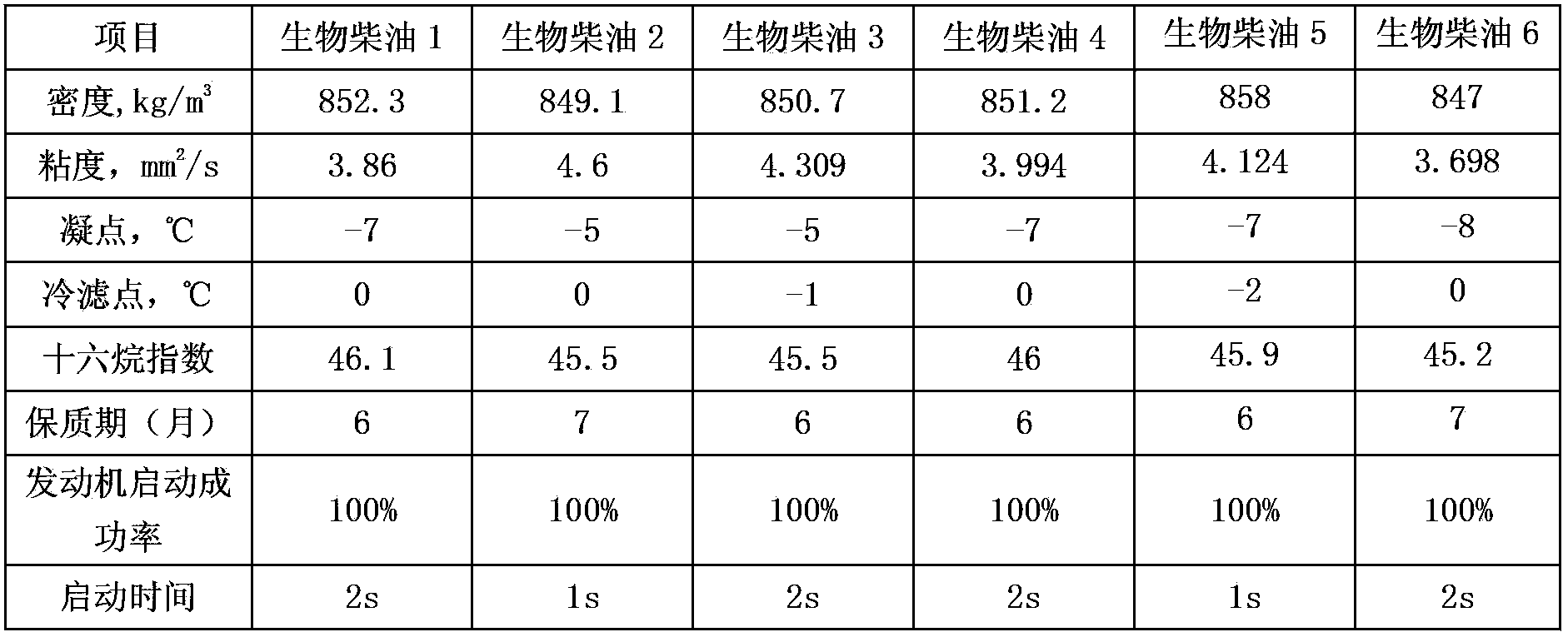

Biodiesel and preparation method thereof

InactiveCN103509611APowerfulHigh calorific valueBiofuelsLiquid carbonaceous fuelsIsobutanolAntioxidant

The invention discloses a biodiesel and a preparation method thereof. The biodiesel comprises a methanol-based fuel, an additive, and common fossil diesel. The additive is prepared from a pH value buffering pair composed of sodium petroleum sulfonate and barium petroleum sulfonate, isobutanol, tricresyl phosphate, dimethyl carbonate, an organic solvent, isooctyl nitrate, co-emulsifying dispersing agent and an antioxidant according to a certain process method. The biodiesel prepared with the method provided by the invention has the advantages of high cetane number, high flash point, low corrosion, low emission, and low cost. The biodiesel can be used for replacing common diesel in the fields such as boilers, vehicles and vessels. The biodiesel has substantial energy-saving and emission-reducing effects.

Owner:东莞恒量新能源科技有限公司 +1

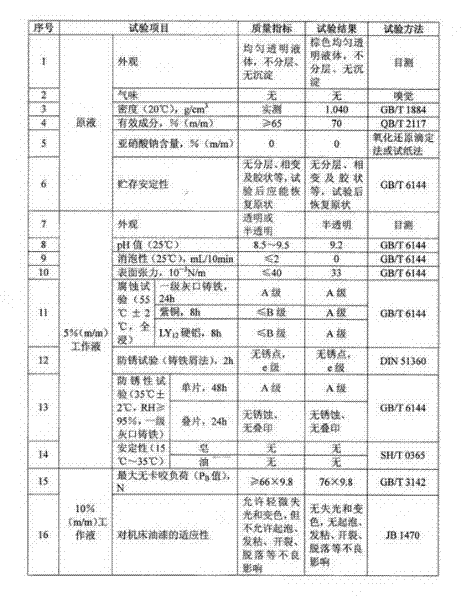

Formula and preparation technology of machine tool working solution

InactiveCN103242946ALong effective timeImprove efficiencyLubricant compositionSodium phosphatesAlkylphenol

The invention discloses a formula and a preparation technology of a machine tool working solution. The formula of the machine tool working solution is characterized by comprising the following materials: 10-20 parts of dodecenylsuccinic acid, 5-10 parts of petroleum sodium sulfonate, 5-7 parts of alkylphenol ethoxylates, 2-6 parts of edible calcium benzoate, 5-7 parts of polyethylene glycol, 2-7 parts of sodium phosphate, 5-10 parts of barium petroleum sulfonate, 5-8 parts of tricthanolamine, 5-8 parts of sodium dodecyl sulfate, 2-4 parts of ethylenediamine tetraacetic acid, 1-3 parts of rosin, 1-2 parts of defoaming agent and the balance of deionized water. According to the preparation technology of the machine tool working solution, the machine tool working solution is prepared from the materials through three steps. The technical problem to be solved by the invention is to provide the formula and the preparation technology of the machine tool working solution; and the cutting solution provided by the invention does not contain sodium nitride, machine oil or heavy metals, is harmless to hands and does not cause the falling of paint.

Owner:CHANGSHA HAODI ELECTROMECHANICAL TECH

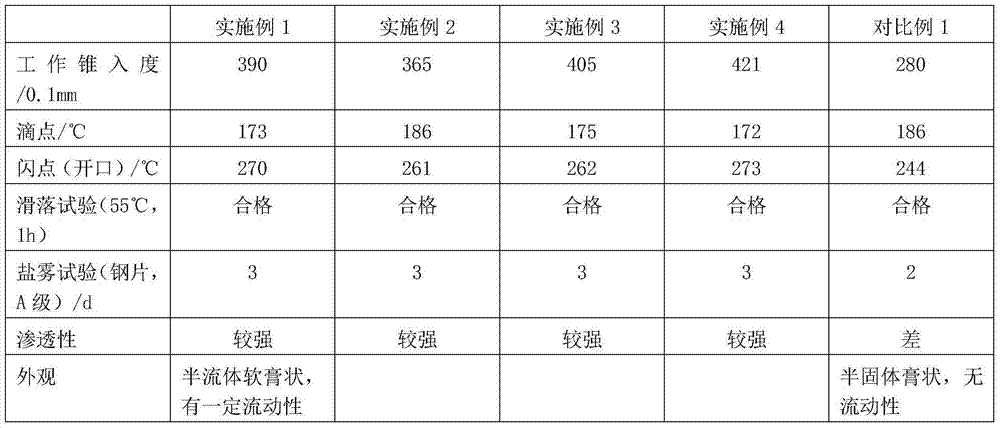

Lubricating grease composition for elevator wire ropes and preparation method thereof

ActiveCN103484218AImprove adhesionImprove permeabilityLubricant compositionMicrocrystalline waxOleic Acid Triglyceride

Owner:WUJIANG JUNDA ELEVATOR PARTS

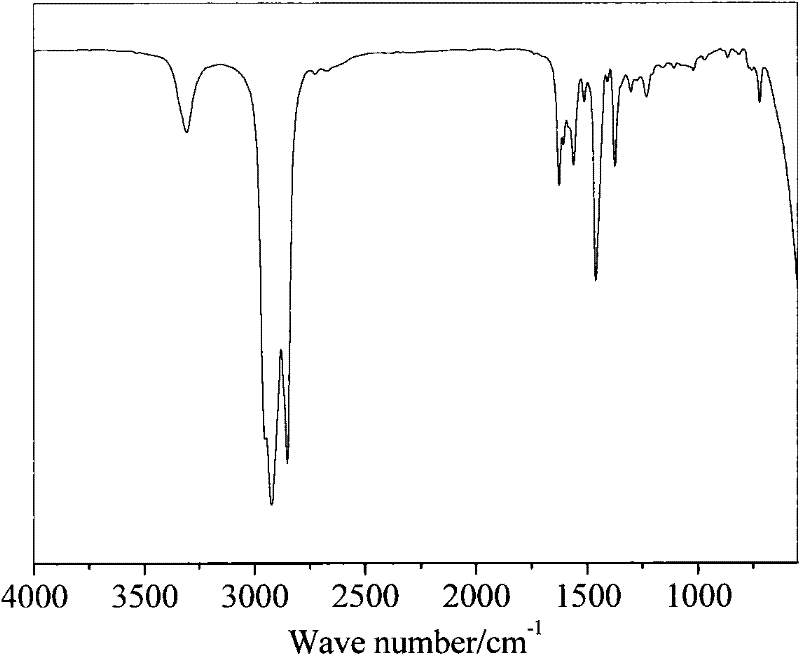

A method for synthesizing petroleum sulfonate in a microreactor

ActiveCN102295586AReduce dosageReduce interfacial tensionChemical industrySulfonic acids salts preparationReaction temperatureSolvent

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Method for preparing petroleum sulfonate surfactant by falling film sulfonation

The invention discloses a method for preparing petroleum sulfonate surfactant, which belongs to the petrochemical field and is mainly used for preparing the petroleum sulfonate surfactant. In the method, crude oil distillate with 350 to 500 DEG C in temperature is served as a raw material, solvent naphtha with 60 to120 DEG C in temperature, aryl chloride or chloralkane are served as diluent, and gas-phase sulfur trioxide are served as sulfonating agent; a falling film reactor is adopted; and reaction temperature and aging temperature are controlled, so that the target product is obtaind. When the method is used for producing petroleum sulfonate, the range of applicable raw materials is wide and the sulfonating raw materials can be heavy petroleum distillate; in the reaction process, the fluidity of the reaction materials is high, the operation is stable and the reactor and the pipeline thereof are not blocked; the reaction effect is good, the conversion rate of aromatic reaction is high, the monosulfonate selectivity is high and the product quality is good and stable; and the production efficiency of the petroleum sulfonate is high and the production cost is low.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Petroleum sulfonate composition, preparation method and application thereof

InactiveCN101955450AImprove adaptabilityWide molecular weight rangeSulfonic acids salts preparationFluid removalAlkali freeFurfural

The invention relates to a petroleum sulfonate composition, a preparation method and application thereof. The preparation method comprises the following steps of: mixing two or more than two of vacuum second-line, vacuum third-line or vacuum fourth-line inverted dewaxed oil or vacuum second-line, vacuum third-line or vacuum fourth-line distillate oil or vacuum second-line, vacuum third-line or vacuum fourth-line furfural extract oil serving as raw materials of which aromatic hydrocarbon content is more than 26 percent and which comprise the components in weight by percentage: 5 to 95 percent of fractions with average molecular weight of 252 to 312, 5 to 95 percent of fractions with average molecular weight of 313 to 395 and 0 to 50 percent of fractions with average molecular weight of 396 to 490; sulfonating by using SO3 at the temperature of between 50 and 80 DEG C; and neutralizing by using 15 to 40 percent alkali liquor until the pH value is between 7 and 10 to obtain a sulfonate composition. The petroleum sulfonate composition can improve the displacement efficiency by over 20 percent under weak alkali and alkali-free composite systems and weaken or eliminate scale formation caused by alkali, and has the advantages of low concentration of used polymers and low cost of combination flooding.

Owner:PETROCHINA CO LTD

Copper wire drawing lubricating fluid and preparation method thereof

InactiveCN103614221AImprove cooling effectExtended service lifeAdditivesManufacturing technologyPhosphate

The invention discloses a copper wire drawing lubricating fluid and a preparation method thereof. The lubricating fluid and the preparation method are characterized in that: the lubricating fluid is prepared from following raw materials by weight: 15-25 parts of palm oil, 2-3 parts of sodium petroleum sulfonate, 30-35 parts of polyethylene glycol, 1-2 parts of sulfurized calcium alkyl phenolate, 1-2 parts of a sodium naphthenate, 2-3 parts of a water soluble phosphate ester, 1-2 parts of sodium benzoate, 2-3 parts of triethanolamine oleate, 0.2-0.4 part of diamond nanoparticles, 10-14 parts of an antiwear agent and 1000 parts of water; nano aluminium nitride powder is added into the antiwear agent, thus promoting heat dissipation, enhancing cooling effects, enhancing film-forming property and prolonging the service lifetime; the service cycle of the lubricating fluid is long; and copper wires after wire drawing processes have significant characteristics of shining surfaces, capability of being stored for a long time, difficult surface oxidation, simple manufacturing technology, low technical requirements, and the like.

Owner:全威(铜陵)铜业科技有限公司

Novel emulsified viscosity reduction agent

InactiveCN102618245AEmulsification is cheapLow viscosityDrilling compositionSalt resistanceOil emulsion

The invention relates to a petroleum production auxiliary, and in particular relates to a novel emulsified viscosity reduction agent. The novel emulsified viscosity reduction agent is characterized by being prepared by mixing the following raw materials in parts by weight: 63 to 65 parts of mahogany petroleum sulfonate, 9 to 15 parts of negative ion surface active agent and 20 to 30 parts of PH value adjusting agent, wherein the PH value adjusting agent is prepared by mixing caustic soda and water according to a weight proportion of 50 to 50. The novel emulsified viscosity reduction agent is suitable for thickened oil with viscosity of lower than 2,400 mPa.s and thickened oil with viscosity of higher than 2,400 mPa.s and has the advantages that the mineral salt resistance is high, the thickened oil can be turned from an emulsified state of oil-packaged water into water-packaged oil emulsion, the emulsified thickened oil is low in viscosity, the emulsion cost is low and the like.

Owner:董其宏

Preparation method of raw material sand for quartz crucible

The invention discloses a preparation method of raw material sand for a quartz crucible. The method comprises the following steps: adopting cocoamine acetate, sodium petroleum sulfonate and pine oil to perform targeted mica flotation, iron flotation and feldspar flotation against feldspar, mica, iron oxides and the like in quartz sand so as to remove the mica, the feldspar, and iron impurities in ore, then performing acid treatment by applying hydrofluoric acid to further remove the mica, the feldspar and the iron impurities in the ore, and finally using a 20000 Gauss magnetic field to perform separation so as to remove iron and other magnetic foreign and miscellaneous matters; introducing oxygen and nitrogen for calcination under high-temperature conditions, performing high-temperature purification with hydrogen chloride gas and performing further refining to improve the purity of the quartz sand and further improve the viscosity of the quartz crucible. The raw material sand for the quartz crucible, prepared according to the invention, can be comparable to high-purity quartz sand of U.S. UNIMIN Company in the aspects of purity and viscosity, the price is just 1 / 2 of the high-purity quartz sand, and the localization of the high-purity quartz sand is further realized.

Owner:ADVANCED QUARTZ MATERIAL (HANGZHOU) CO LTD

Gas-phase anti-corrosion paint

InactiveCN101245218ADry fastHigh hardnessAnti-corrosive paintsPolyester coatingsBenzoic acidOctanoic Acids

The invention relates to a gas phase antirust coating, the components of the combination account according to parts by weight, and the scope is as follows: 8 to 25 parts of acrylate modified alkyd resin, 5 to 20 parts of 2402 phenolic resin, 0 to 15 parts of petroleum sulfonate barium, 0 to 25 parts of oxidized malthenes magnesium soap, 0 to 5 parts of dodecatylene base succinic acid imidazoline, 0 to 6 parts of sebacic acid morpholine, 0 to 6 parts of octanoic acid two cyclohexylamines, 0 to 6 parts of octanoic acid tributyl amine, 0 to 6 parts of capric acid tributyl amine, 0 to 15 parts of benzoic acid monoethanolamine, 0.1 to 1.0 part of drier, 0 to 5 parts of thixotropic agent, 1 to 5 parts of dibutyl phthalate, 0 to 5 parts of black paste, and the rest of xylene / 200 model solvent (1:1). The gas phase antirust coating of the invention has the advantages of fast table-drying speed, long antirust time, high rigidity, high brightness, good temperature resistance, etc., and can satisfy the requirements of the automatic pipeline production and long time open storage antirust need of oil steel pipes and other large pipes or profiles.

Owner:DALIAN YATAI SCI & TECH NEW MATERIAL

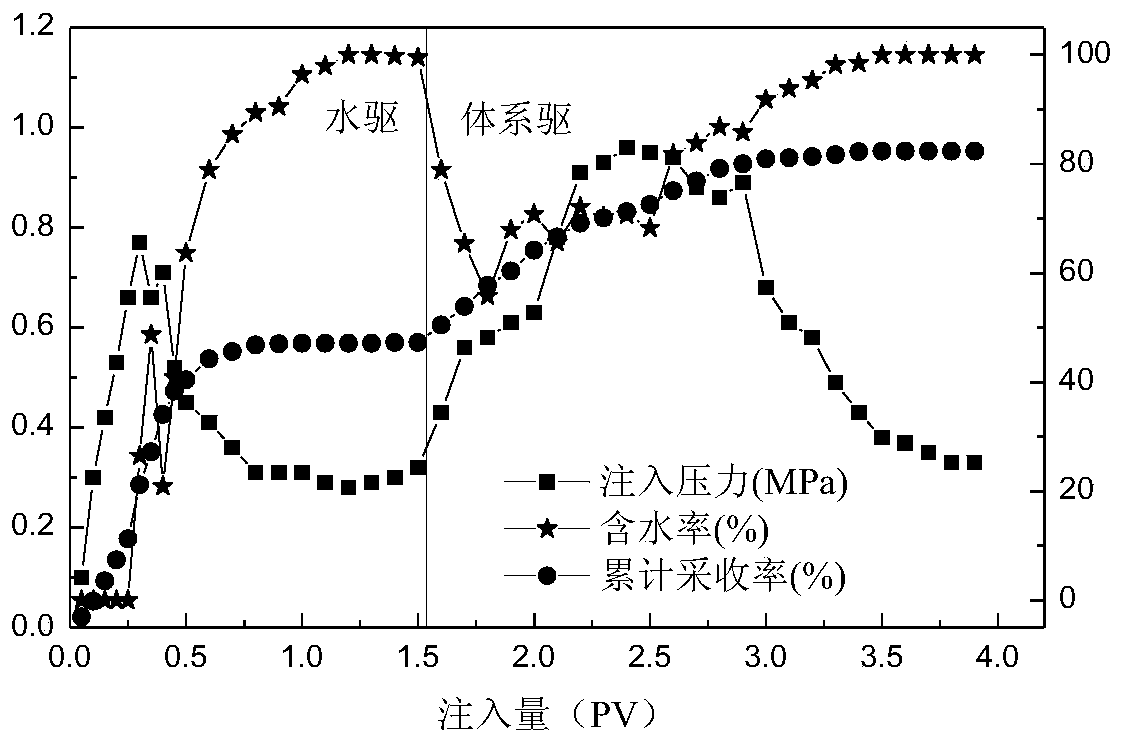

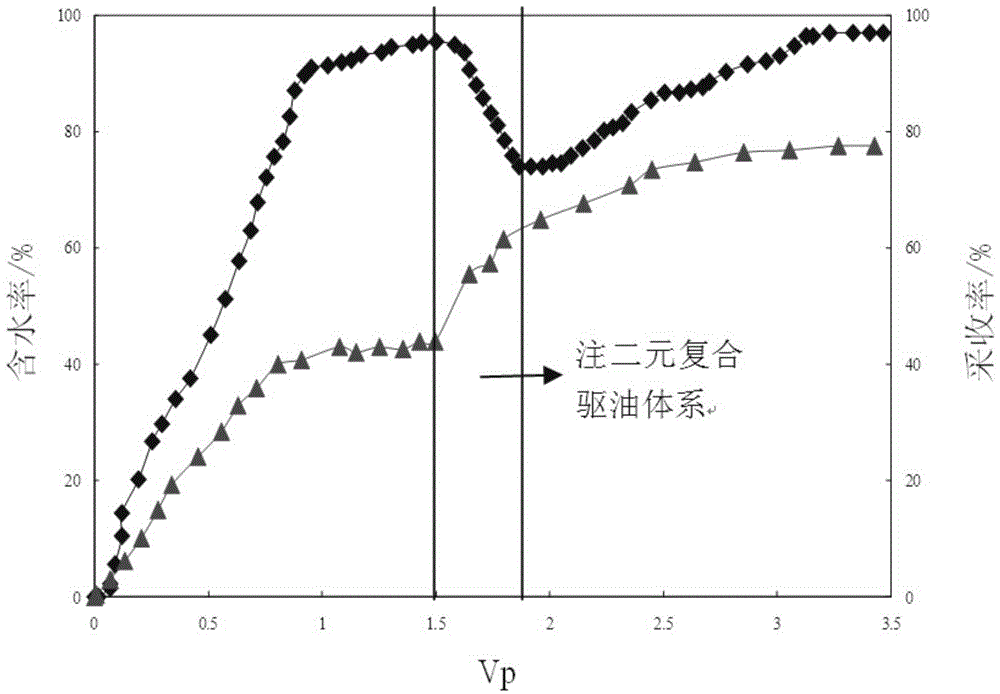

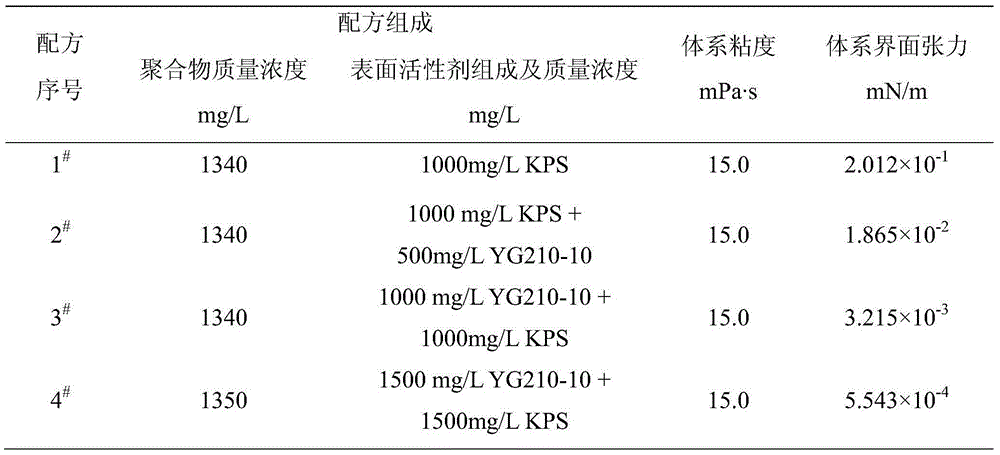

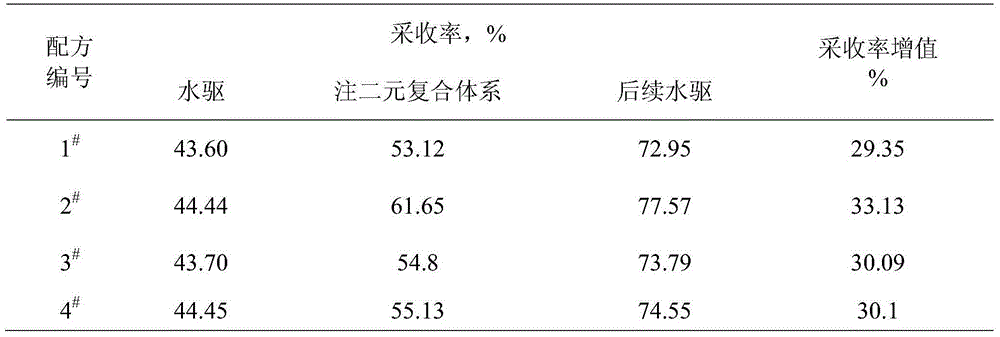

Binary composite oil dispelling system and optimization method thereof

The invention discloses a binary composite oil dispelling system and an optimization method thereof. The oil dispelling system is prepared by compounding polymer and a surfactant; the polymer is partly-hydrolyzed polyacrylamide, the surfactant is one or two of anionic surfactant (petroleum sulfonate) and anionic-non-ionic surfactant, and the oil dispelling system is applied to chemical oil dispelling of heterogeneous oil reservoir. By adjusting the interface tension of the binary composite system of polymer and surfactant, the oil yield of middle / high permeability oil reservoir can be prominently increased, the provided optimization method is especially suitable for efficient chemical oil dispelling of middle / high permeability heterogeneous oil reservoir, the reagent cost is effectively reduced, and the risk of chemical oil dispelling is avoided.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com