Patents

Literature

30results about How to "Emulsification is cheap" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for preparing ASA paper-making sizing agent emulsion

InactiveCN101333789AReduce dosageEmulsification is cheapWater-repelling agents additionPolyelectrolyteHigh concentration

The invention relates to a process for preparing an emulsion of ASA paper sizing agent, comprising the following steps of: (1) mixing and then dispersing inorganic nano-particles with positive charges and inorganic nano-particles with negative charges to form a water phase; (2) mixing oily ASA with the water phase to form an oil-water mixture; and (3) cutting and emulsifying the mixture by a high-speed mixing device to obtain an ASA emulsion. Wherein, the oil-water mixture ratio is 1: 4 to 1:1, particles with negative charges and ASA are in a ratio of 1:30 to 1:5, and particles with positive charges and particles with negative charges are in a ratio of 1:150 to 1:7.5. The preparation process has advantages of simple emulsification process, having no need of surface active agent and complex polyelectrolyte particles for emulsifying the ASA into stable emulsion, low emulsifying agent consumption, low emulsification cost, and high concentration, good stability and high sizing efficiency of the prepared emulsion.

Owner:QILU UNIV OF TECH

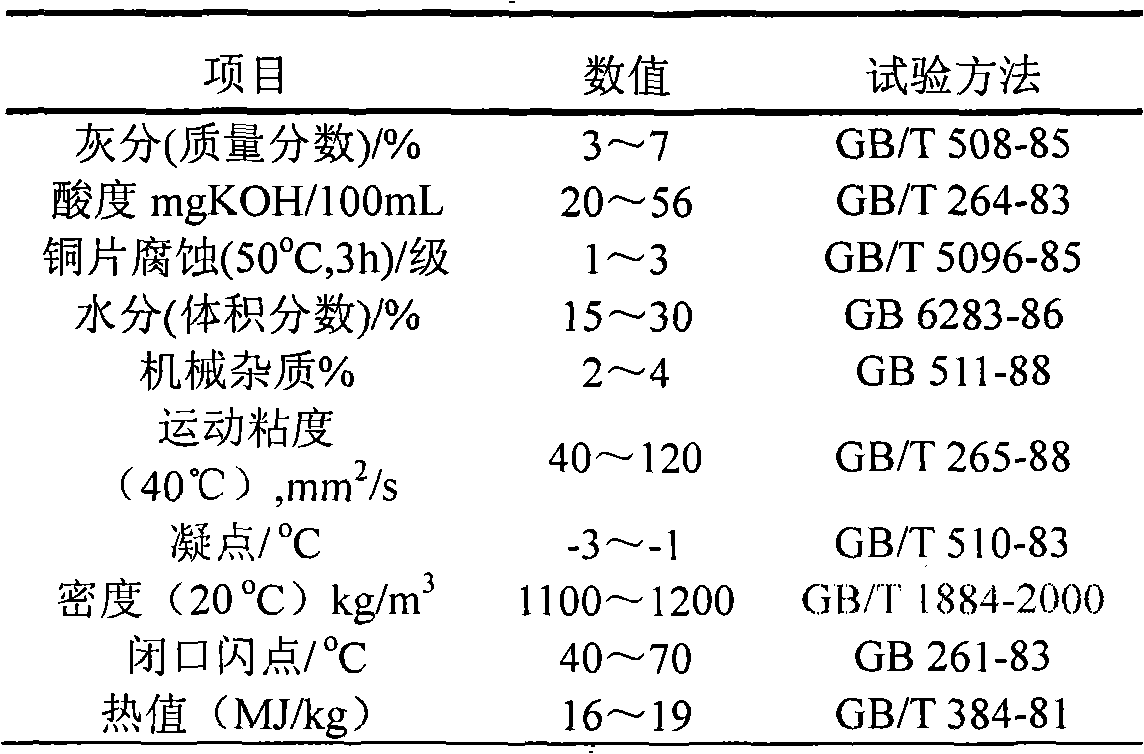

Novel emulsified viscosity reduction agent

InactiveCN102618245AEmulsification is cheapLow viscosityDrilling compositionSalt resistanceOil emulsion

The invention relates to a petroleum production auxiliary, and in particular relates to a novel emulsified viscosity reduction agent. The novel emulsified viscosity reduction agent is characterized by being prepared by mixing the following raw materials in parts by weight: 63 to 65 parts of mahogany petroleum sulfonate, 9 to 15 parts of negative ion surface active agent and 20 to 30 parts of PH value adjusting agent, wherein the PH value adjusting agent is prepared by mixing caustic soda and water according to a weight proportion of 50 to 50. The novel emulsified viscosity reduction agent is suitable for thickened oil with viscosity of lower than 2,400 mPa.s and thickened oil with viscosity of higher than 2,400 mPa.s and has the advantages that the mineral salt resistance is high, the thickened oil can be turned from an emulsified state of oil-packaged water into water-packaged oil emulsion, the emulsified thickened oil is low in viscosity, the emulsion cost is low and the like.

Owner:董其宏

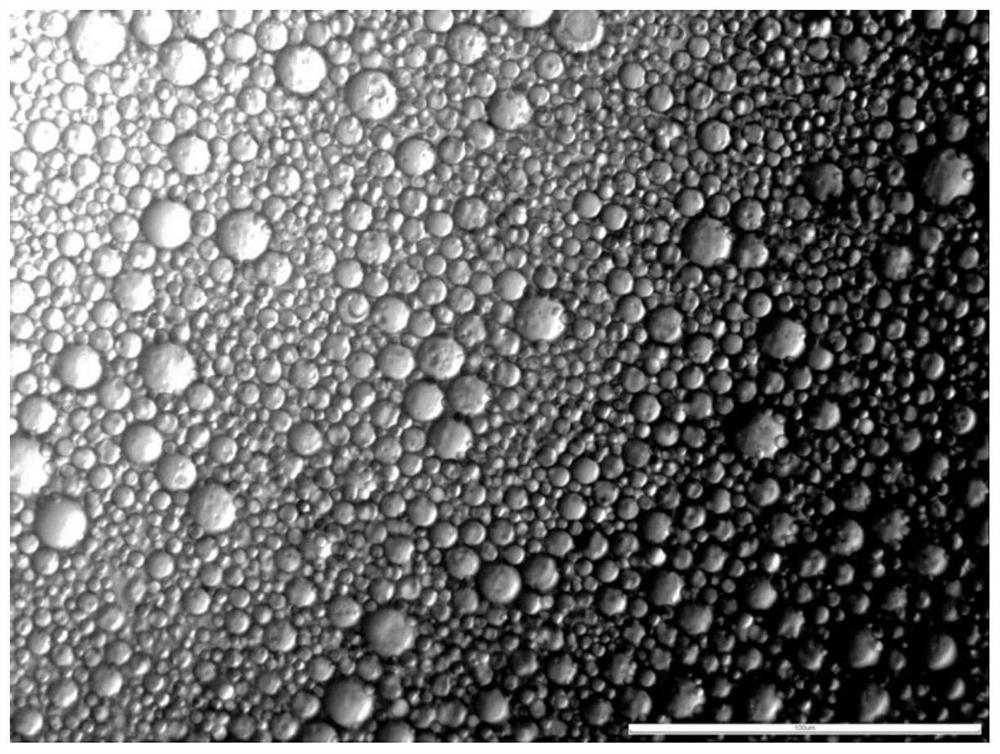

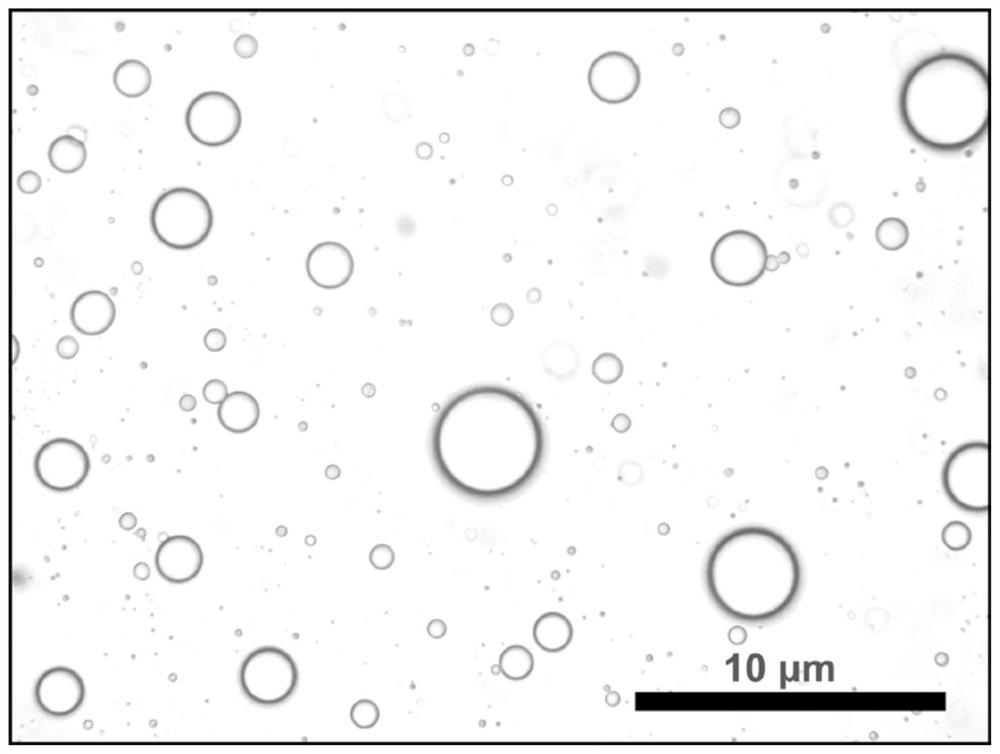

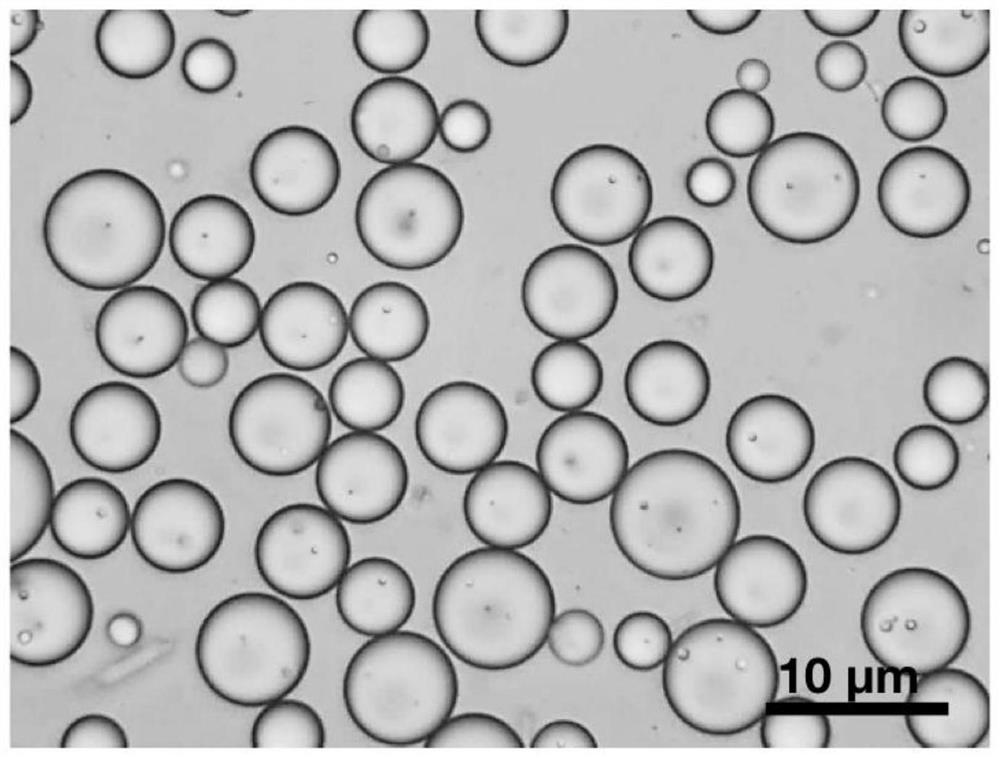

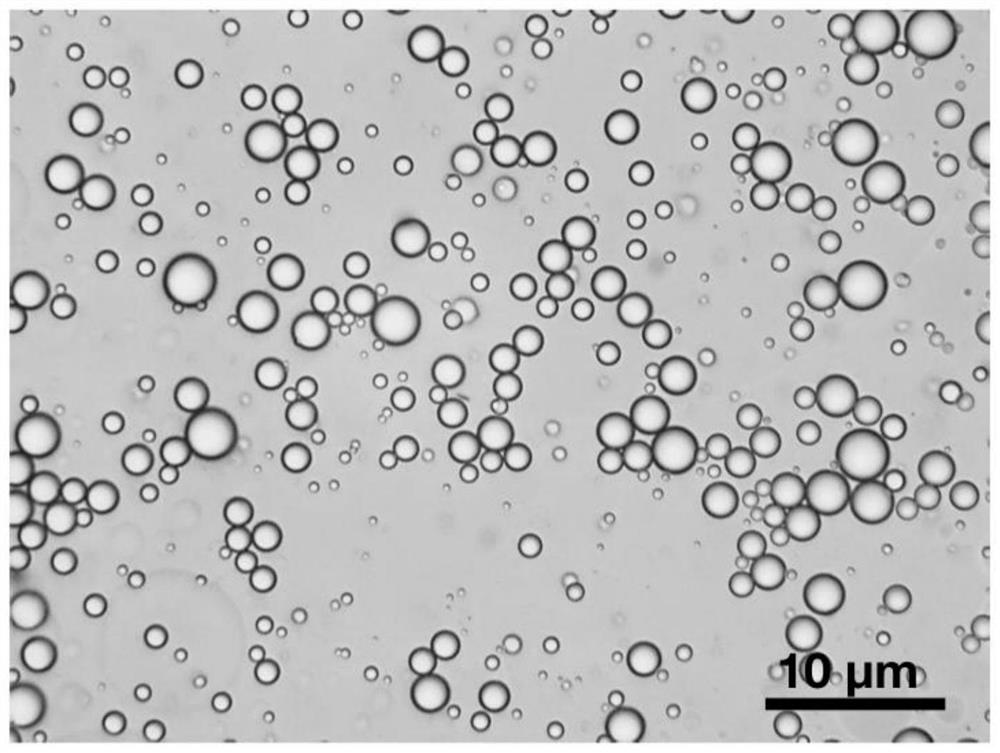

Biodegradable solid particle emulsifier and papermaking sizing agent

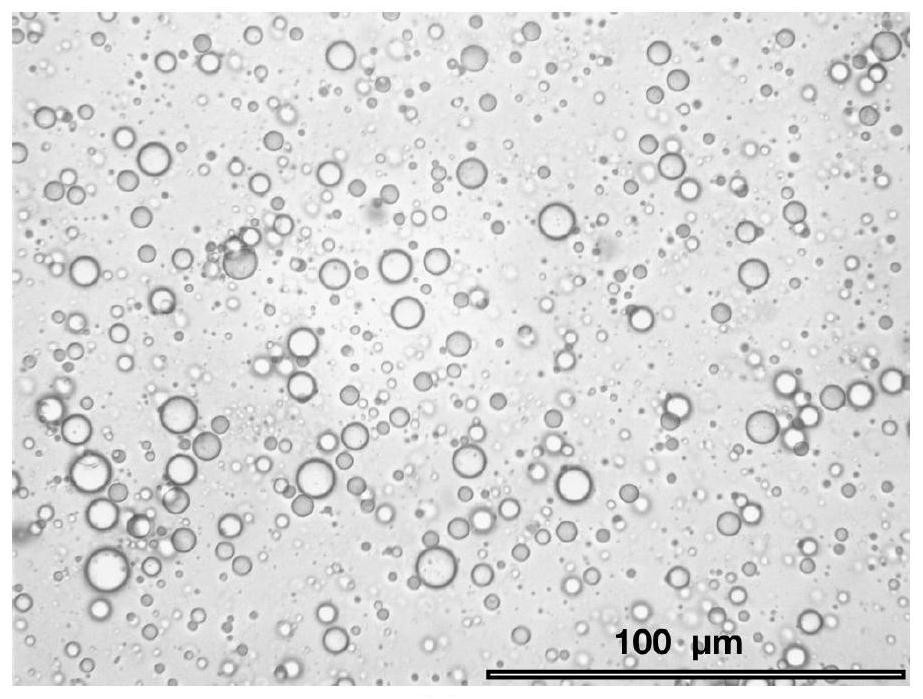

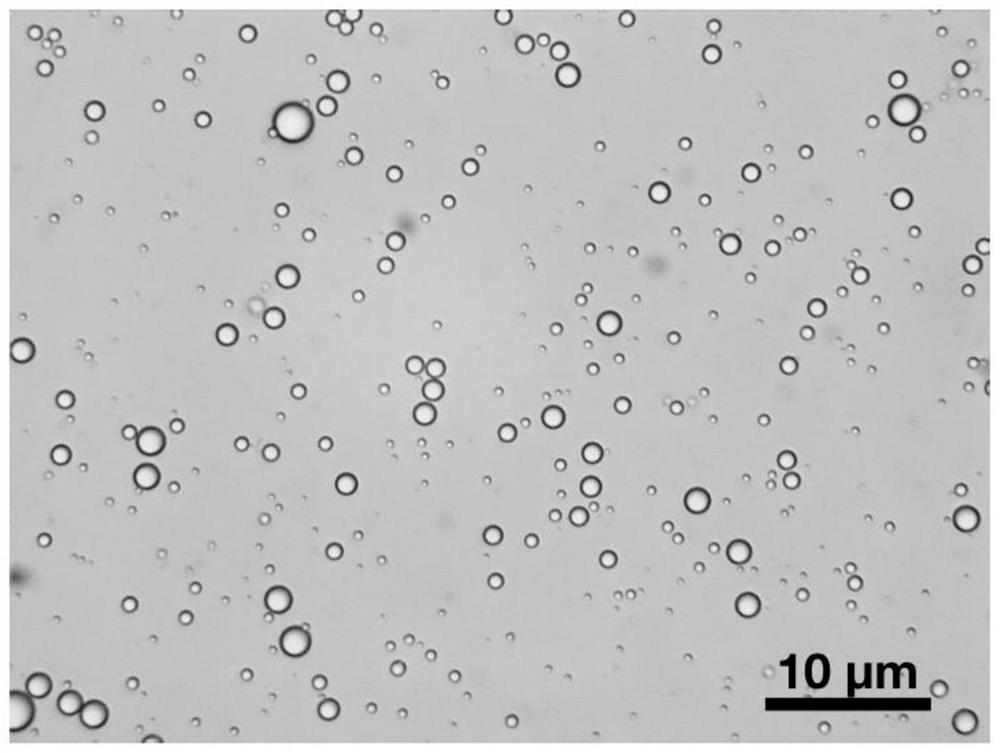

ActiveCN105056830AImprove stabilityImprove sizing effectWater-repelling agents additionTransportation and packagingPolymer scienceGlycolic acid

The invention relates to a biodegradable solid particle emulsifier and a papermaking sizing agent and belongs to the technical field of papermaking sizing agents and related industrial emulsifiers. The biodegradable solid particle emulsifier short for CPs is prepared from cellulose nanocrystals and polylactic-co-glycolic acid. An ASA emulsion prepared from CPs is a Pickering emulsion, has the liquid drop particle size being about 3.4 mu m, has higher stability and cannot gather particles, precipitate or separate out water after being placed for 24 hours; the emulsion can still keep good performance of the papermaking sizing agent after being placed for 3 hours; the preparation process is simple, few emulsifiers are used, the emulsification cost is low, and the emulsifier has biodegradability and has little pollution to the environment.

Owner:山东熙来淀粉有限公司

Slurry and acoustical panel with reduced bound water

ActiveUS20090011251A1Reduce amountReduce the temperatureLamination ancillary operationsSolid waste managementBound waterSlurry

A composition for a slurry for manufacture of a building panel includes one or more fillers, one or more binders and water. One or more fillers is an expanded perlite at least partially covered with a film-forming, thermoplastic polymer coating Some embodiments use calcined or uncalcined gypsum as a binder or filler. One embodiment is a building panel that includes a solid matrix of calcium sulfate dihydrate crystals bound to expanded perlite.A method of making the panel includes acquiring expanded perlite and coating it with film-forming, thermoplastic polymer coating. After the expanded perlite is prepared, it is combined with water other optional fillers and one or more binders to form a slurry. The slurry is shaped into a panel and allowed to dry.

Owner:UNITED STATES GYPSUM CO

Stable ASA (Alkenyl Succinic Anhydride) papermaking sizing emulsion and preparation method thereof

InactiveCN102493275AReduce dosageIncrease concentrationWater-repelling agents additionActive agentSurface-active agents

The invention relates to the technical field of papermaking sizing agents, in particular to stable ASA (Alkenyl Succinic Anhydride) papermaking sizing emulsion. The stable ASA papermaking sizing emulsion comprises deionized water, ASA, hectorite and urea, wherein the mass ratio of the ASA to the deionized water is 1:(0.8-4); the mass ratio of the hectorite to the ASA is 1:(20-200); and the mass ratio of the urea to the hectorite is 1:(2-100). The preparation method comprises the following steps of: dispersing the hectorite with the deionized water to obtain a hectorite colloid; dissolving the urea in residual deionized water to prepare an aqueous solution of the urea; mixing the hectorite colloid with the aqueous solution of the urea; adjusting the pH value to be 5-8; and then uniformly mixing the mixture with the ASA to obtain the ASA papermaking sizing emulsion. According to the invention, the consumption of an emulsifying agent is little; no traditional surfactant is used; the emulsion has high concentration, favorable stability and high sizing efficiency; the preparation method is simple in process; the emulsification cost is low; and the sizing efficiency of the obtained emulsion can be greatly increased.

Owner:QILU UNIV OF TECH

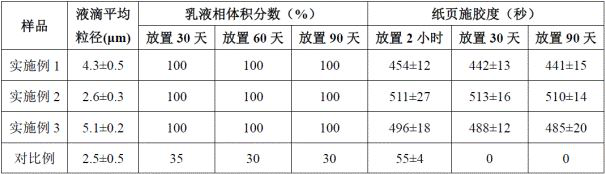

Alkyl ketene dimer sizing agent as well as preparation method and application thereof

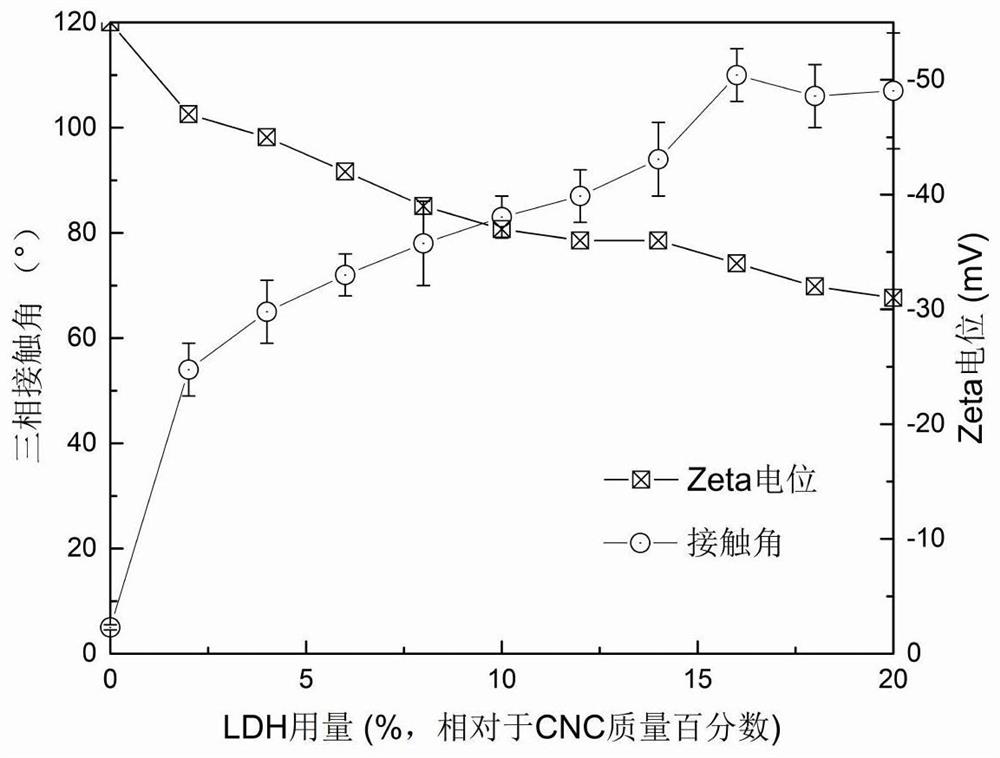

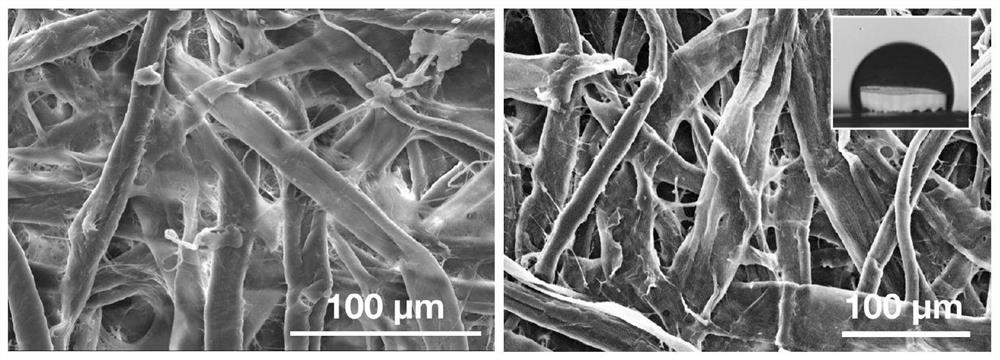

InactiveCN111749046AReduce pollutionBiodegradableCoatings with pigmentsWater-repelling agents additionMagnesium aluminum hydroxidePolymer science

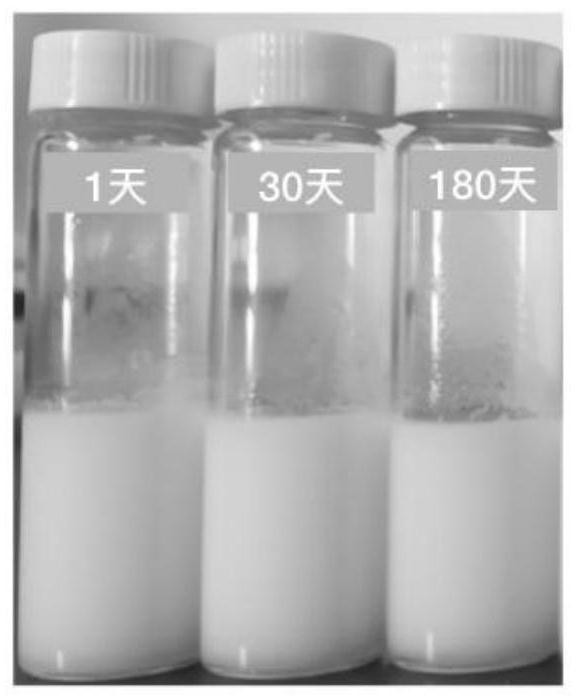

The invention belongs to the technical field of papermaking, and particularly relates to an alkyl ketene dimer sizing agent as well as a preparation method and application thereof. The preparation method comprises the following steps: mixing a cellulose nanocrystalline dispersion liquid, magnesium aluminum hydroxide and an alkyl ketene dimer, and carrying out first emulsification to obtain an emulsion; and adding nano cellulose fibers into the emulsion, and carrying out second emulsification to obtain the alkyl ketene dimer sizing agent. The alkyl ketene dimer sizing agent emulsion prepared bythe invention has excellent surface sizing performance and alkyl ketene dimer hydrolysis resistance, and can still keep good paper surface sizing performance after being placed for 6 months (the emulsion sizing degree can reach 756 seconds after being placed for 180 days); the alkyl ketene dimer sizing agent has ultrahigh stability and cannot be demulsified, flocculated, precipitated or separatedout of a phase within 3-6 months, and the storage period of the alkyl ketene dimer sizing agent is obviously prolonged.

Owner:QILU UNIV OF TECH

Stable alkenyl succinic anhydride sizing emulsion for papermaking and preparation method thereof

InactiveCN102493276AReduce dosageEmulsification is cheapWater-repelling agents additionInorganic compound additionPapermakingAlanine

The invention relates to a sizing agent in the technical field of papermaking, in particular to stable alkenyl succinic anhydride sizing emulsion for papermaking. The stable alkenyl succinic anhydride sizing emulsion for papermaking comprises deionized water, alkenyl succinic anhydride, hectorite and alanine, wherein a mass ratio of the alkenyl succinic anhydride to the water is 1:(1-5); a mass ratio of the hectorite to the alkenyl succinic anhydride is 1:(20-200); and a mass ratio of the alanine to the hectorite is 1:(20-200). A preparation method is characterized by comprising the following steps of: dispersing the hectorite in the deionized water to obtain a hectorite colloid; adding an aqueous solution of alanine into the hectorite colloid; regulating pH, and uniformly mixing with the alkenyl succinic anhydride (ASA) to obtain the stable alkenyl succinic anhydride sizing emulsion for papermaking. The using amount of an emulsifier is small, and the emulsification cost is low; and the prepared emulsion has high concentration, stability and sizing efficiency. An emulsification process is simple, and the sizing efficiency of the obtained emulsion can be greatly improved.

Owner:QILU UNIV OF TECH

Emulsified biomass fuel oil and emulsifying method thereof

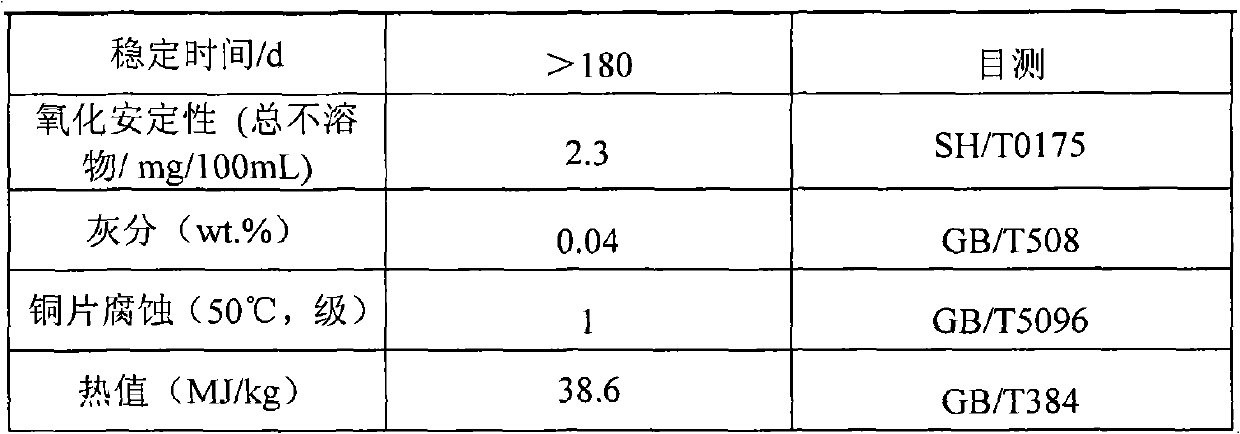

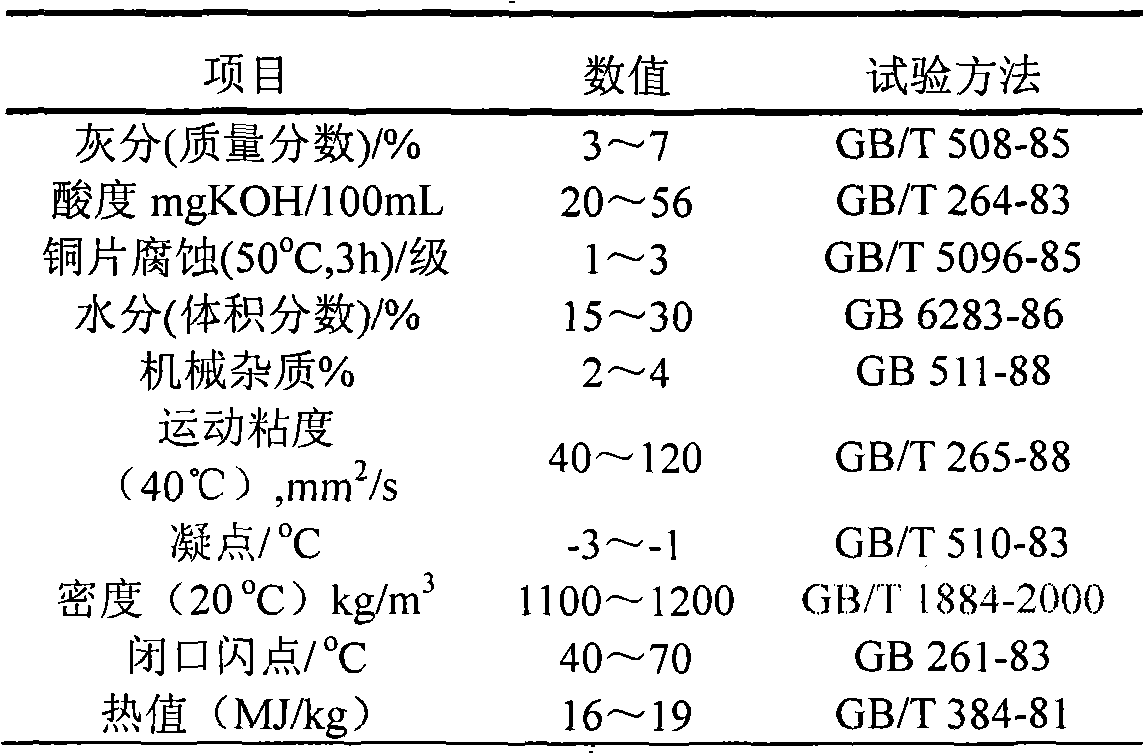

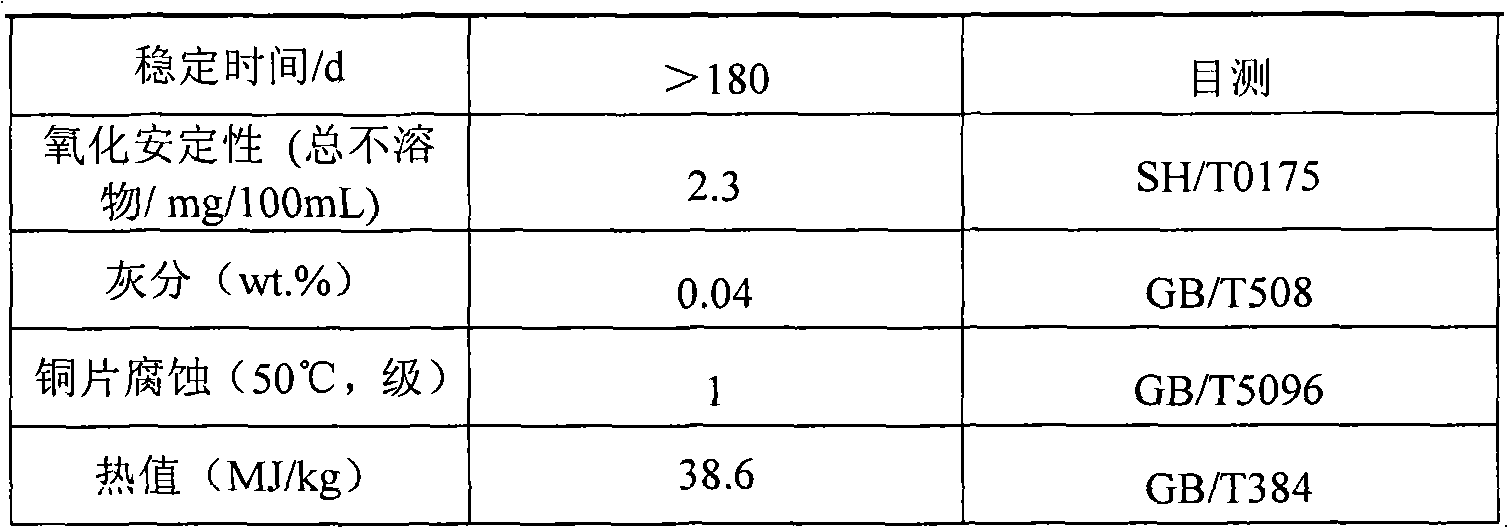

InactiveCN101906331AEmulsification is cheapSimple methodLiquid carbonaceous fuelsFuel additivesChemistryBiomass

The invention discloses emulsified biomass fuel oil, which comprises the following components in percentage by weight: 1 to 15 percent of biomass crude oil, 75 to 95 percent of diesel oil, 0.45 to 9 percent of emulsifying agent, 0.05 to 0.2 percent of co-surfactant, 0.01 to 0.06 percent of oxidation and corrosion inhibitor and 0.01 to 1 percent of isooctyl nitrate. A preparation method for the emulsified oil comprises the following steps of: filtering the biomass crude oil to remove coarse impurities, and removing heavy components from the biomass crude oil by using a centrifugal machine; and then, adding ester emulsifying agent and ether emulsifying agent into the diesel oil and the biomass crude oil respectively, adding the two kinds of mixed solution into a high-shear homogenizing emulsifier, stirring the mixed solution for 20 to 60 minutes with shearing at the temperature of between 30 and 50 DEG C under 1,500 and 3,000rpm, finally adding the co-surfactant, the oxidation and corrosion inhibitor and an inflame improver into the mixed solution, and uniformly emulsifying the mixed solution to obtain the emulsified biomass crude oil. The emulsified biomass crude oil has long stabilization time which can reach over 6 months; the emulsified biomass crude oil has the advantages of high utilization rate of biomass oil, good anti-oxidation stability, low corrosion, low ash content and high combustion heat value; and the preparation method is simple and feasible, and has low environmental pollution.

Owner:HEFEI UNIV OF TECH

Slurry and acoustical panel with reduced bound water

ActiveUS7875358B2Reduce amountReduce the amount of fuelLamination ancillary operationsSolid waste managementBound waterSlurry

A composition for a slurry for manufacture of a building panel includes one or more fillers, one or more binders and water. One or more fillers is an expanded perlite at least partially covered with a film-forming, thermoplastic polymer coating Some embodiments use calcined or uncalcined gypsum as a binder or filler. One embodiment is a building panel that includes a solid matrix of calcium sulfate dihydrate crystals bound to expanded perlite.A method of making the panel includes acquiring expanded perlite and coating it with film-forming, thermoplastic polymer coating. After the expanded perlite is prepared, it is combined with water other optional fillers and one or more binders to form a slurry. The slurry is shaped into a panel and allowed to dry.

Owner:UNITED STATES GYPSUM CO

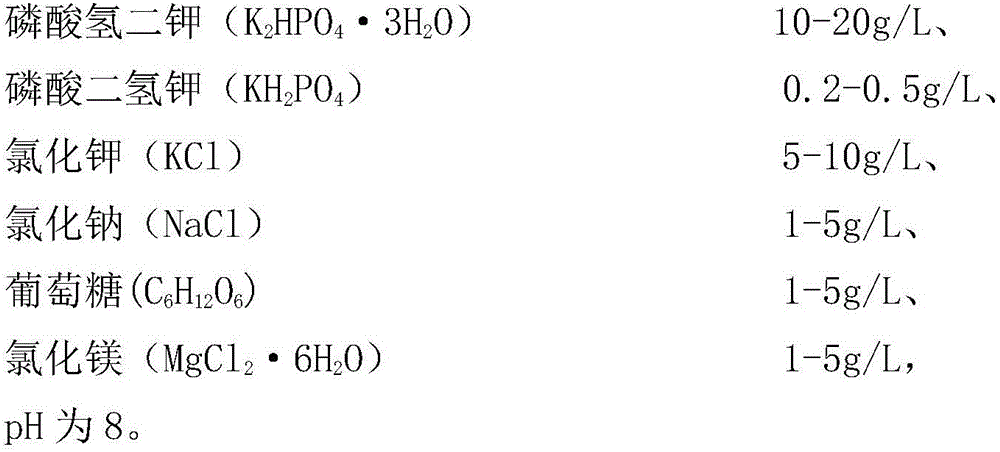

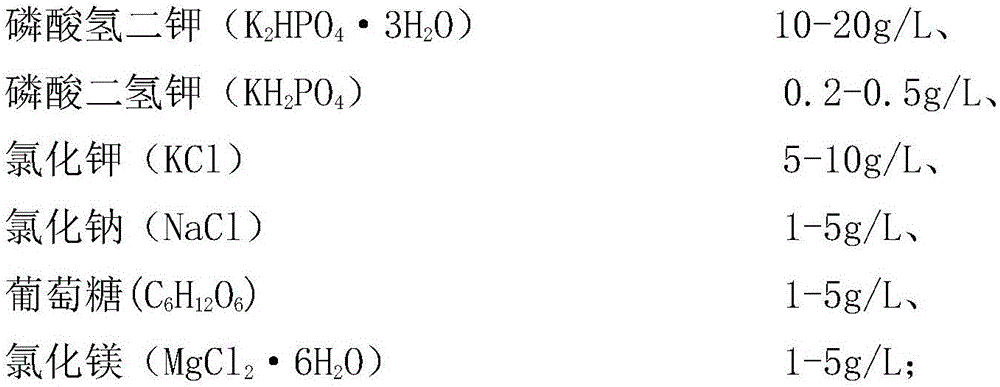

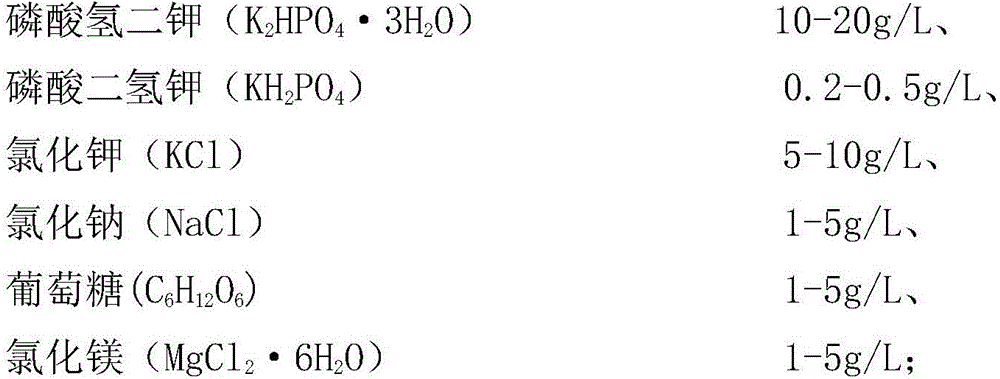

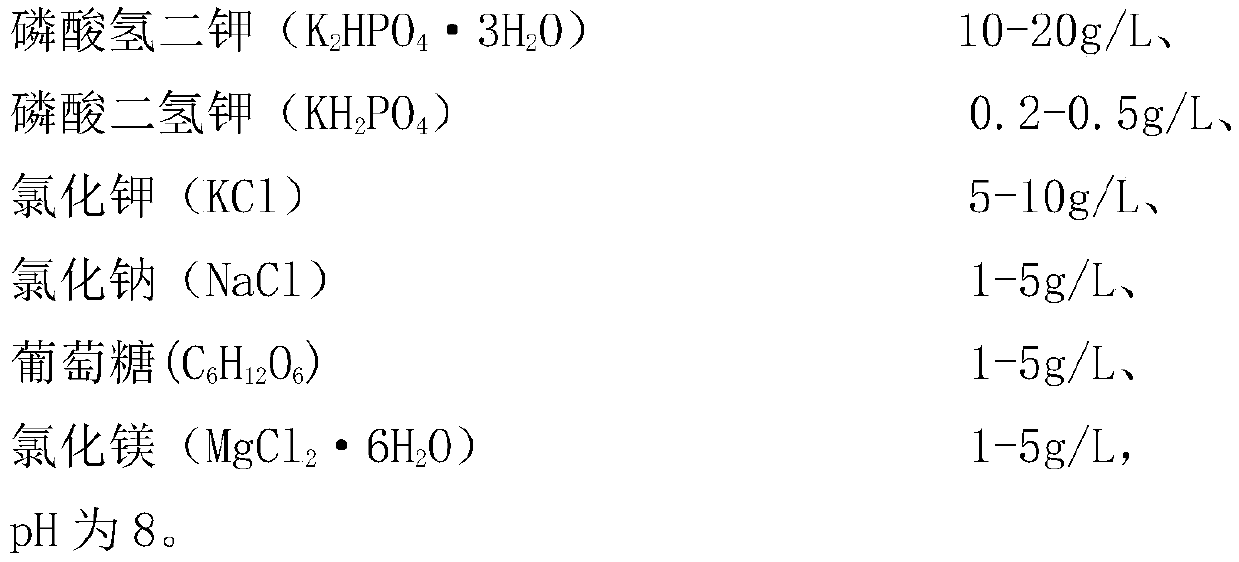

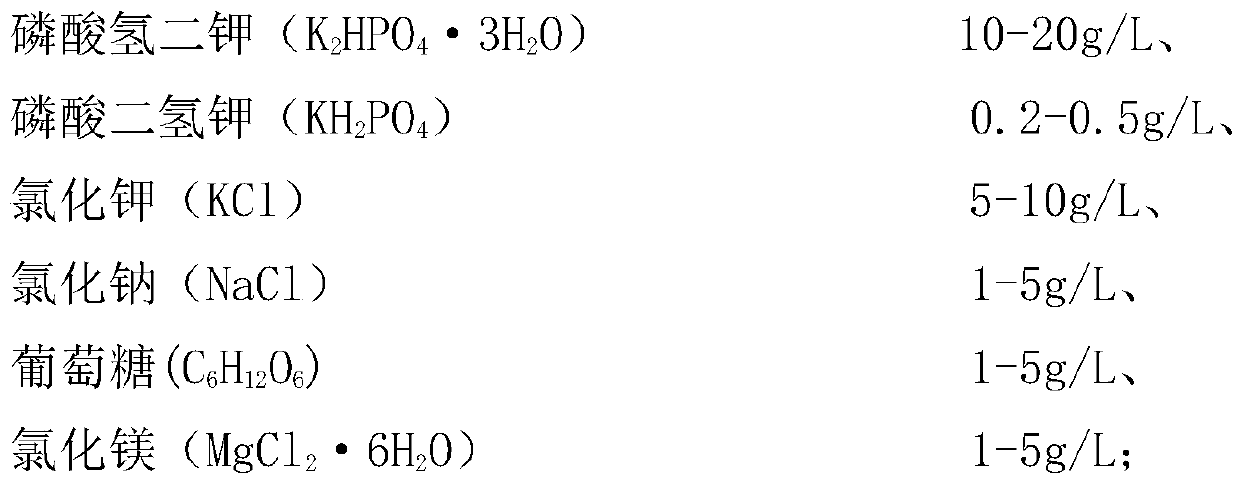

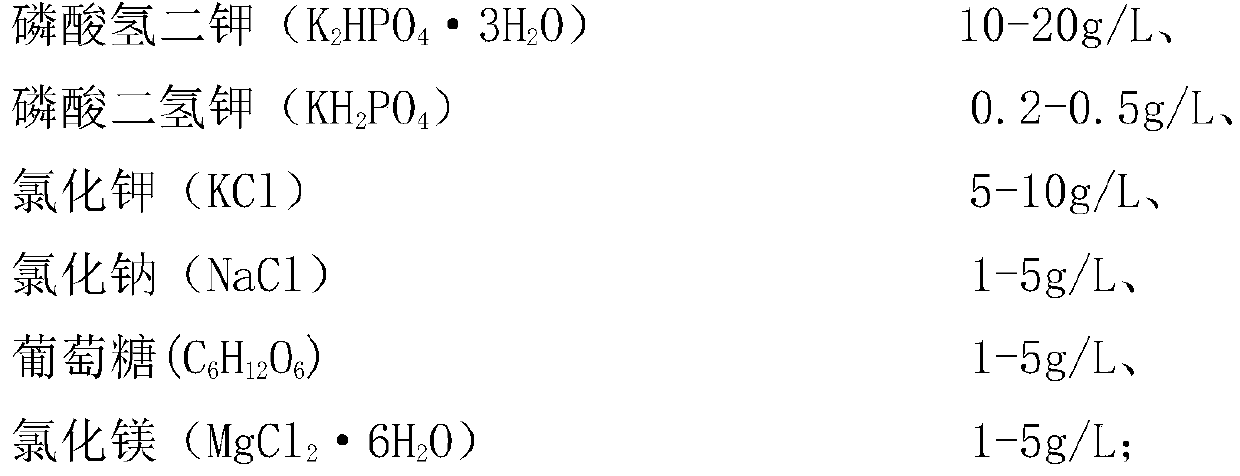

Foot-and-mouth disease vaccine diluent as well as preparation method and application thereof

ActiveCN106109414AAccurately obtain actual efficacy dataPrecision inoculationInorganic non-active ingredientsEmulsion deliveryMedicineDiluent

The invention discloses foot-and-mouth disease vaccine diluent as well as a preparation method and application thereof. When the foot-and-mouth disease vaccine diluent is used for diluting a foot-and-mouth disease vaccine, precise inoculation can be realized, and the defect that the actual potency data can not be accurately obtained in an existing testing process can be overcome, so that potency testing precision and accuracy are improved. Besides, by virtue of the foot-and-mouth disease vaccine diluent disclosed by the invention, the vaccine can be concentrated for more times, storage and transportation cost is reduced, large-scale inoculation in a farm, an immune station and the like is facilitated, volume of an emulsification tank can also be reduced in a subsequent emulsifying process, and stirring and temperature are more uniform during emulsifying, so that emulsifying effect can be improved, and meanwhile emulsification cost is saved.

Owner:JINYUBAOLING BIO PHARMA CO LTD

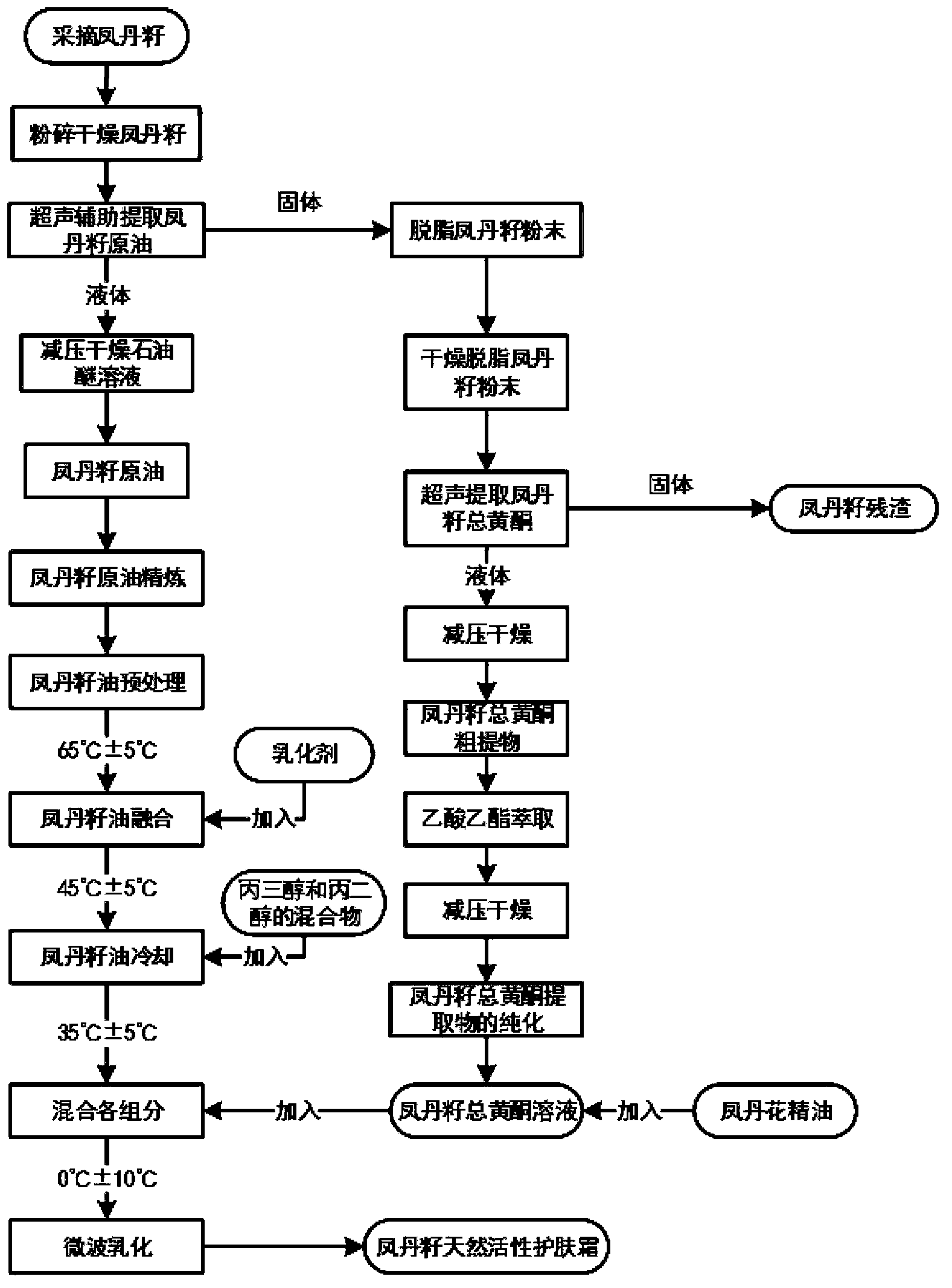

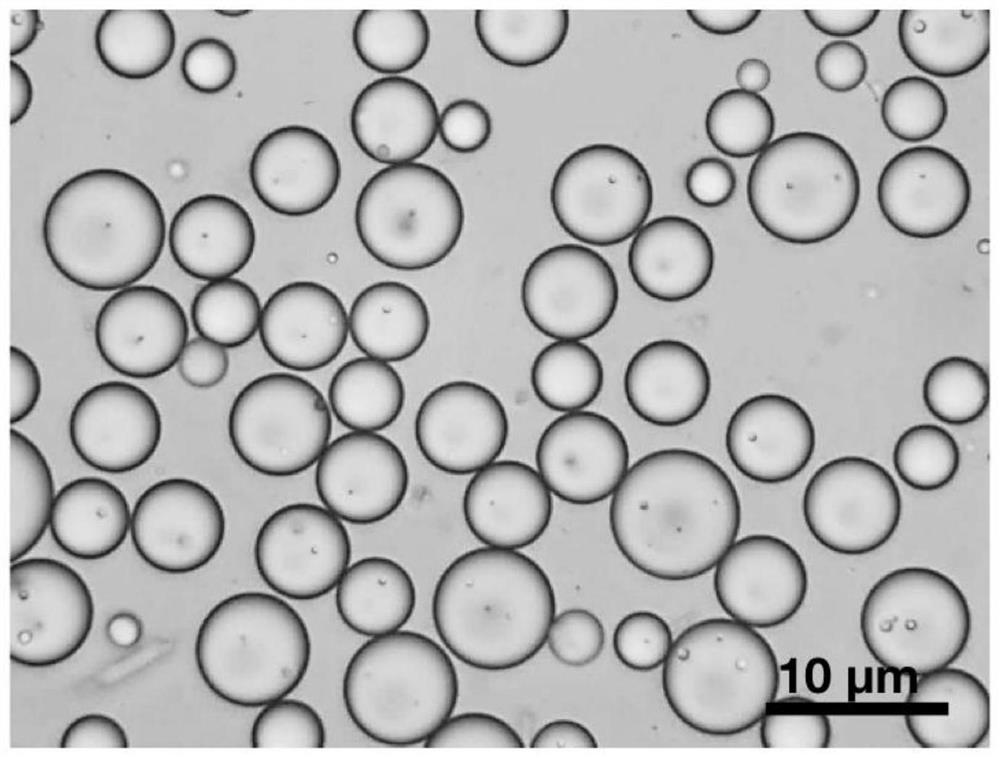

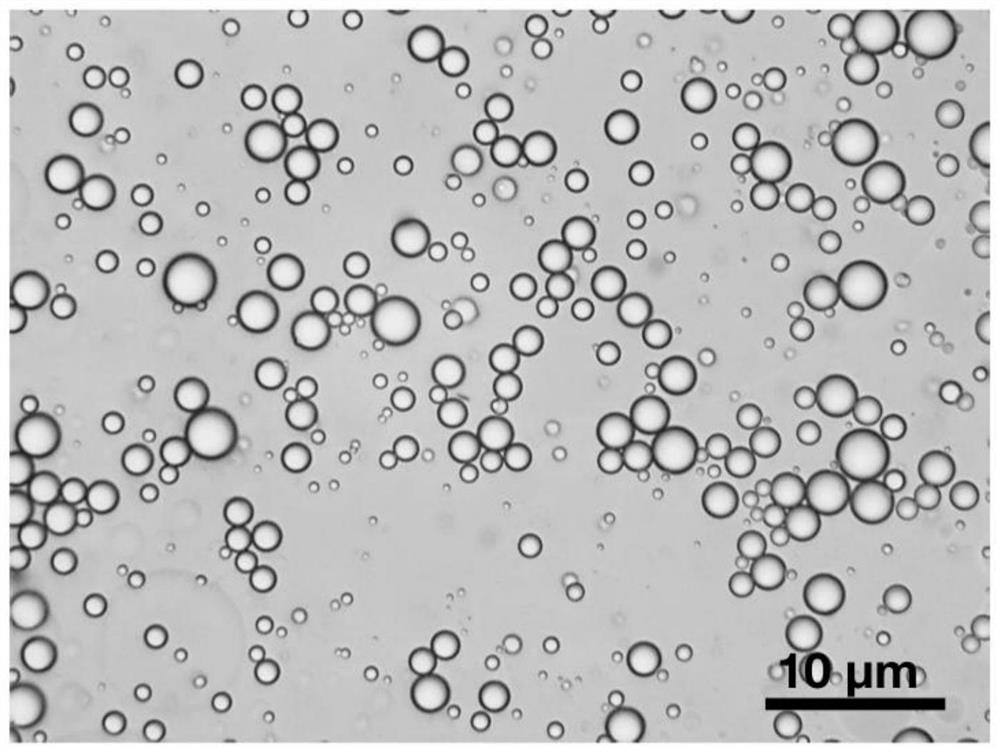

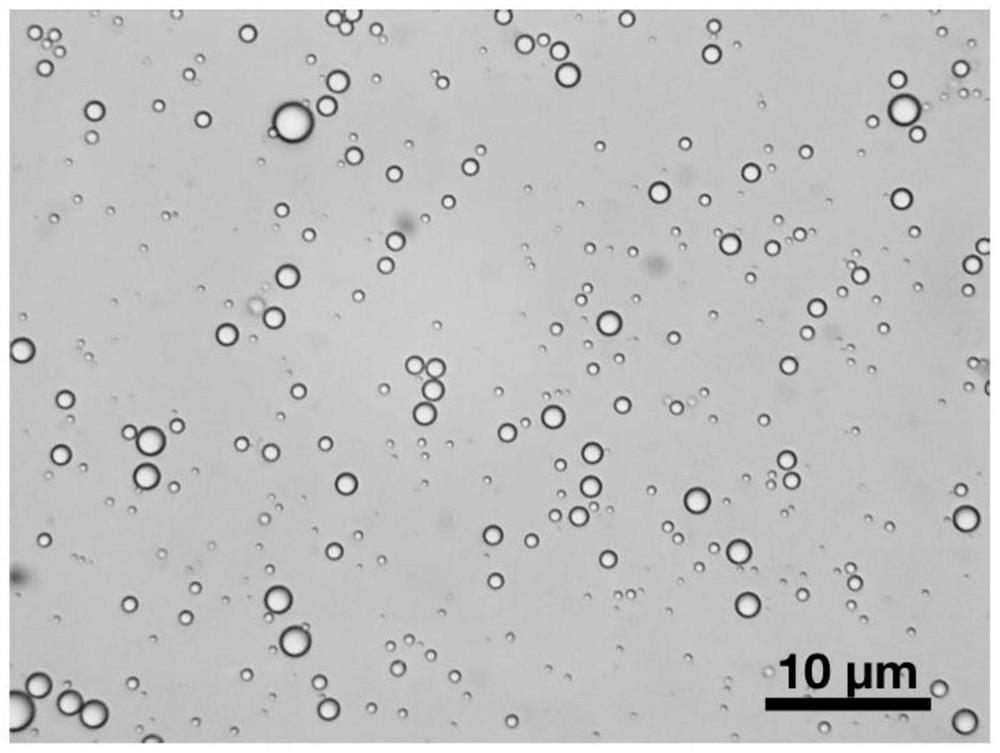

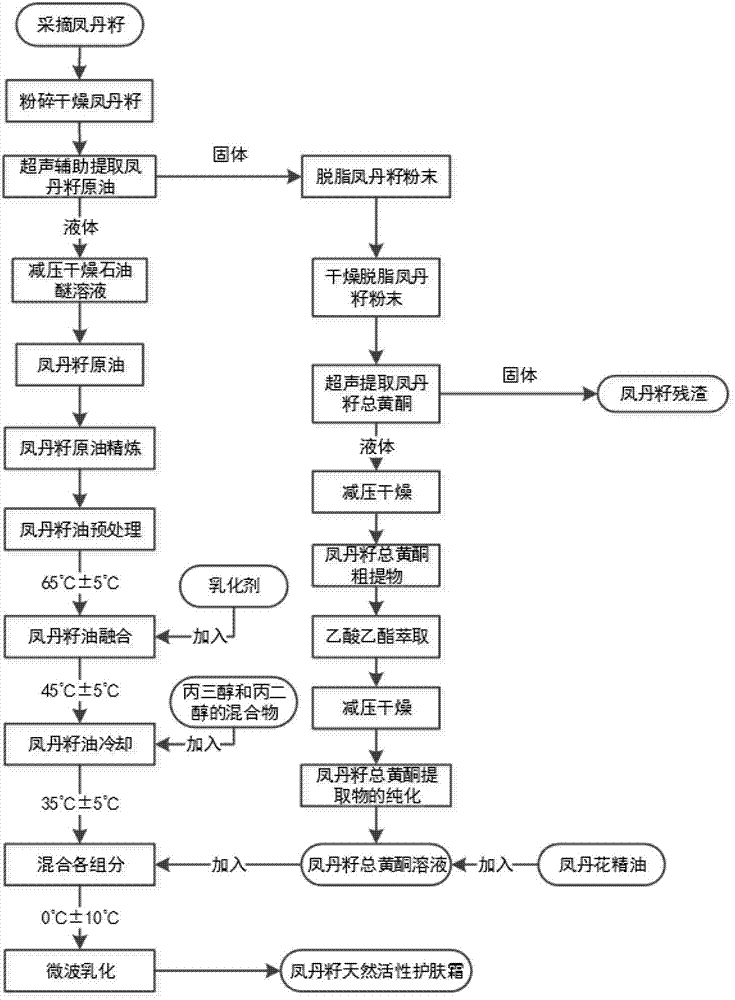

Paeonia ostii seed natural activity skin cream and preparation method thereof

InactiveCN103432028ASignificant antioxidantSignificant antibacterialCosmetic preparationsToilet preparationsGlycerolSolvent

The invention discloses a paeonia ostii seed natural activity skin cream which comprises the following component substances: paeonia ostii seed oil, paeonia ostii seed general flavone extract, an emulsifier and a solvent, wherein the melting point of the emulsifier is 30-65 DEG C, and the emulsifier is solid at normal temperature; the solvent is a mixture of glycerol and propylene glycol. The invention also discloses a method for preparing the paeonia ostii seed natural activity skin cream. The method comprises the following steps of: fully mixing the emulsifier and the paeonia ostii seed oil at the temperature of 65+ / -5 DEG C, reducing the temperature, adding the solvent and the paeonia ostii seed general flavone extract, mixing and continuously reducing the temperature to be 0+ / -10 DEG C, performing microwave emulsification on the mixture, and obtaining the product. The paeonia ostii seed natural activity skin cream has the sunscreen, skin care, skin whitening, health care and inflammation diminishing effects; the method for preparing the paeonia ostii seed natural activity skin cream is simple, low in emulsification cost and easy for industrial production.

Owner:佰氏健康(广州)大健康科技有限公司

Fluorescent alkenyl succinic anhydride (ASA) sizing agent for papermaking and preparation method of fluorescent ASA sizing agent for papermaking

InactiveCN103790072AFluorescentHigh sizing efficiencyWater-repelling agents additionPolyelectrolyteElectrolysis

The invention relates to a fluorescent alkenyl succinic anhydride (ASA) sizing agent for papermaking and a preparation method of the fluorescent ASA sizing agent for papermaking, belonging to the technical field of sizing agent for papermaking. According to the fluorescent ASA sizing agent for papermaking, firstly, a carbon quantum dot is added into the ASA sizing agent, so that ASA sizing emulsion which can be used as the fluorescent sizing agent for papermaking and effectively improves the water resistance of paper is successfully prepared; a new emulsion stabilizer is provided for the ASA sizing agent, and the stable emulsifying agent enables the sizing agent to have fluorescence property and high sizing efficiency; furthermore, the emulsion stabilizer serving as the carbon quantum dot has the advantages of being few in dosage, non-toxic, low in cost, etc. The fluorescent ASA sizing agent for papermaking adopts a simple preparation technology, and a surface active agent, a polymer polyelectrolyte and a dye type fluorescent agent do not need to be added into the fluorescent ASA sizing agent.

Owner:QILU UNIV OF TECH

Fluorescent alkenyl butanedioic anhydride sizing emulsion and preparation method thereof

InactiveCN103774499AGood emulsifying effectImprove stabilityWater-repelling agents additionPolyelectrolytePolymer science

The invention relates to a fluorescent alkenyl butanedioic anhydride sizing emulsion and a preparation method thereof, and belongs to the technical field of emulsification of papermaking sizing agents. According to the invention, the alkenyl butanedioic anhydride sizing emulsion which can serve as a fluorescent papermaking sizing agent and can be used for effectively improving the water resistance of paper is successfully prepared by jointly adding carbon quantum dots and bentonite into an alkenyl butanedioic anhydride sizing agent for the first time. A novel emulsion stabilizer is provided for the alkenyl butanedioic anhydride sizing agent. The emulsion stabilizer ensures that the sizing agent have the fluorescent performance. In addition, carbon quantum dots and bentonite as the emulsifier have the advantages of less use level, no toxicity, low cost and the like. The fluorescent alkenyl butanedioic anhydride sizing emulsion provided by the invention is simple in preparation process, and no surfactants, macromolecular polyelectrolytes and dyeing type fluorescent agents need to be added.

Owner:QILU UNIV OF TECH

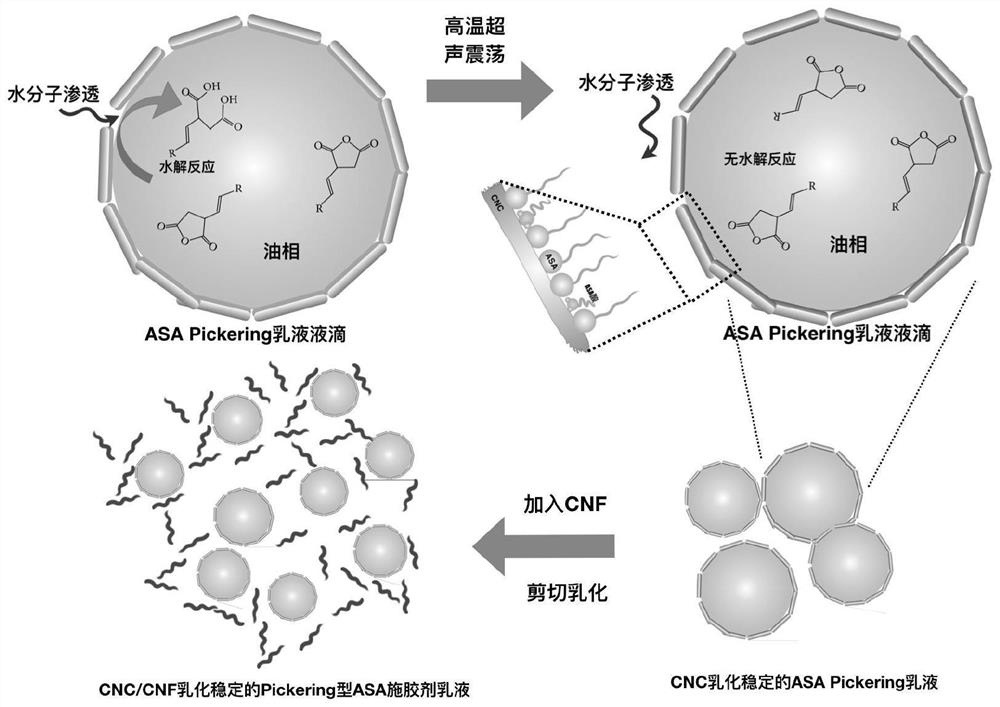

Alkenyl succinic anhydride sizing agent as well as preparation method and application thereof

InactiveCN111749047ANo pollution in the processReduce manufacturing costWater-repelling agents additionNon-macromolecular organic additionPolymer scienceEmulsion

The invention belongs to the technical field of papermaking, and particularly relates to an alkenyl succinic anhydride sizing agent as well as a preparation method and application thereof. The preparation method comprises the following steps: mixing alkenyl succinic anhydride and a cellulose nanocrystalline dispersion liquid, and carrying out first emulsification to obtain ASA-1 emulsion; and carrying out ultrasonic treatment on the ASA-1 emulsion, mixing the obtained emulsion with nano cellulose fibers, and carrying out second emulsification to obtain the alkenyl succinic anhydride sizing agent. Results of the embodiment show that the ASA sizing agent emulsion does not generate particle aggregation and precipitation after being placed for 30 days, does not have any phase body precipitation and demulsification phenomenon, and is good in stability; the paper sheet sizing degree of the sized paper is 224-332 seconds, and the sizing performance of the ASA sizing agent emulsion is good; after the ASA sizing agent emulsion is placed for 72 hours, the sizing degree of sized paper is 210-325 seconds, and the hydrolysis resistance of the emulsion is good.

Owner:QILU UNIV OF TECH

Method for preparing ASA paper-making sizing agent emulsion

InactiveCN101333789BReduce dosageEmulsification is cheapWater-repelling agents additionPolyelectrolyteHigh concentration

The present invention relates to a process for preparing an emulsion of ASA paper sizing agent, comprising the following steps of: (1) mixing and then dispersing inorganic nano-particles with positive charges and inorganic nano-particles with negative charges to form a water phase; (2) mixing oily ASA with the water phase to form an oil-water mixture; and (3) cutting and emulsifying the mixture by a high-speed mixing device to obtain an ASA emulsion. Wherein, the oil-water mixture ratio is 1: 4 to 1:1, particles with negative charges and ASA are in a ratio of 1:30 to 1:5, and particles with positive charges and particles with negative charges are in a ratio of 1:150 to 1:7.5. The preparation process has advantages of simple emulsification process, having no need of surface active agent and complex polyelectrolyte particles for emulsifying the ASA into stable emulsion, low emulsifying agent consumption, low emulsification cost, and high concentration, good stability and high sizing efficiency of the prepared emulsion.

Owner:QILU UNIV OF TECH

Alkenyl succinic anhydride sizing agent emulsion and preparation method thereof

InactiveCN102493277AAchieve recyclingSolve pollutionWater-repelling agents additionPaper/cardboardPolymer scienceEmulsion

Owner:QILU UNIV OF TECH

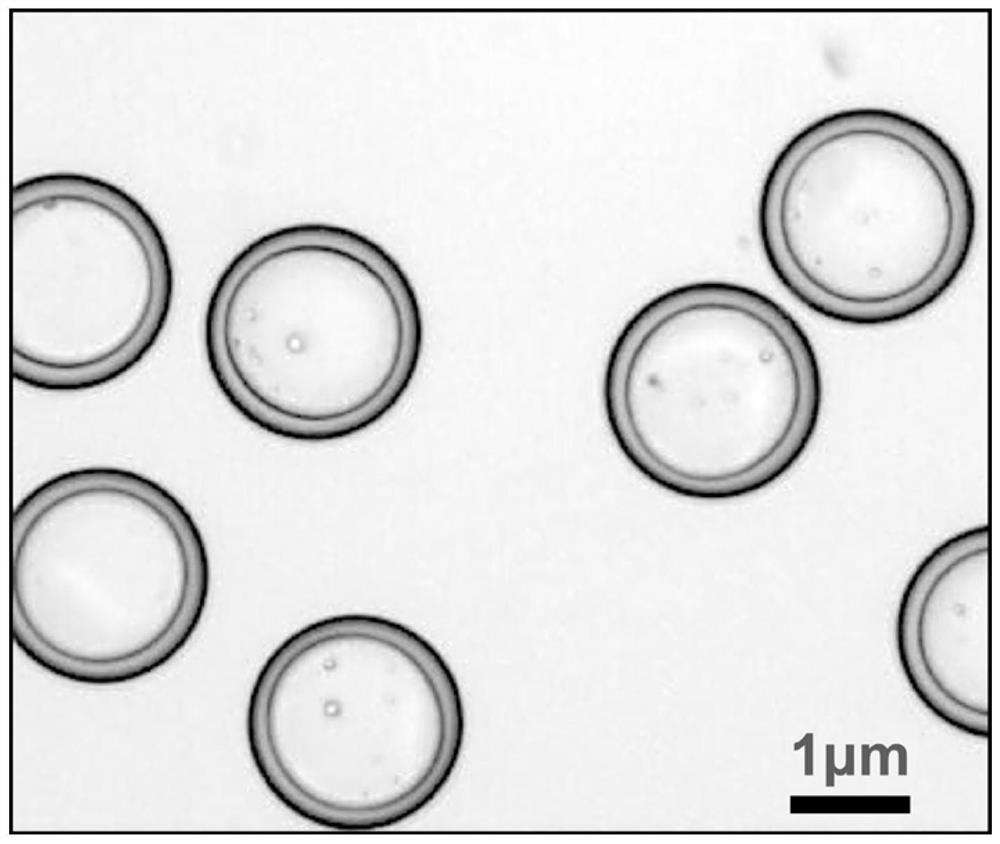

Hydrolysis-resistant alkenyl succinic anhydride sizing agent as well as preparation method and application thereof

ActiveCN112813729AImprove stabilityImprove water resistanceWater-repelling agents additionCellulose pulp after-treatment modificationUltrasonic emulsificationHydrolysis

The invention provides a preparation method of a hydrolysis-resistant alkenyl succinic anhydride sizing agent. The preparation method comprises the following steps: mixing a CNC aqueous dispersion with acetone, ammonia monohydrate and hexadecyl trimethyl siloxane, and carrying out ultrasonic dispersion to obtain a mixed solution I; adding perfluorooctyltriethoxysilane into the mixed solution I, and carrying out ultrasonic dispersion to obtain a mixed solution II; drying the mixed solution II to obtain CNC-R powder; mixing CNC-R powder with perfluorohexane, carrying out ultrasonic dispersion, adding alkenyl succinic anhydride, mixing the components, and carrying out ultrasonic emulsification to obtain ASA-A emulsion; and mixing the ASA-A emulsion with a sodium dodecyl sulfate aqueous solution, and carrying out ultrasonic emulsification to obtain the hydrolysis-resistant alkenyl succinic anhydride sizing agent. The surface sizing performance of the ASA emulsion prepared by the method is remarkably improved, and meanwhile, the hydrolysis resistance of ASA can be greatly improved; in addition, the ASA sizing agent emulsion disclosed by the invention is simple in preparation process, low in emulsifying cost and good in sizing effect, and the dosage of an emulsifying agent is small.

Owner:山东济清科技服务有限公司

Alkenyl succinic anhydride sizing agent as well as preparation method and application thereof

ActiveCN111749045AImprove sizing effectHigh flocculation stabilityWater-repelling agents additionFiberPolymer science

The invention belongs to the technical field of papermaking and especially relates to an alkenyl succinic anhydride sizing agent. In the invention, ethyl lauroyl arginate, cellulose nanocrystals and nanocellulose fibers are used as raw materials, wherein the obtained alkenyl succinic anhydride sizing agent emulsion is a Pickering type emulsion and has ultrahigh flocculation stability, hydrolysis resistance stability and paper pulp internal sizing performance. The surface and in-pulp sizing performance of the alkenyl succinic anhydride sizing agent emulsion is remarkably improved; meanwhile, the hydrolysis resistance of the alkenyl succinic anhydride sizing agent can be greatly improved, and good paper sizing performance can still be kept after the alkenyl succinic anhydride sizing agent emulsion is placed for 48-72 hours; and the alkenyl succinic anhydride sizing agent emulsion does not generate particle aggregation, precipitation or phase separation within 180 days, and has good stability.

Owner:山东济清科技服务有限公司

A kind of fluorescent alkenyl succinic anhydride sizing emulsion and preparation method thereof

InactiveCN103774499BGood emulsifying effectImprove stabilityWater-repelling agents additionPolyelectrolytePolymer science

The invention relates to a fluorescent alkenyl succinic anhydride sizing emulsion and a preparation method thereof, belonging to the technical field of papermaking sizing agent emulsification. In the present invention, carbon quantum dots and bentonite are added to the alkenyl succinic anhydride sizing agent for the first time, and the alkenyl succinic anhydride sizing emulsion that can be used as a fluorescent papermaking sizing agent and effectively improve the water resistance of paper is successfully prepared. A new emulsification stabilizer is provided for alkenyl succinic anhydride sizing agent, and the stable emulsifier can make the sizing agent have fluorescent properties; in addition, carbon quantum dots and bentonite as emulsifiers have low consumption, non-toxic , Low cost and other advantages. The preparation process of the present invention is simple and does not need to add any surfactant, polymer polyelectrolyte and dye type fluorescent agent.

Owner:QILU UNIV OF TECH

Stable alkenyl succinic anhydride sizing emulsion for papermaking and preparation method thereof

InactiveCN102493276BHigh sizing efficiencyEmulsification process is simpleWater-repelling agents additionInorganic compound additionPolymer sciencePapermaking

The invention relates to a sizing agent in the technical field of papermaking, in particular to stable alkenyl succinic anhydride sizing emulsion for papermaking. The stable alkenyl succinic anhydride sizing emulsion for papermaking comprises deionized water, alkenyl succinic anhydride, hectorite and alanine, wherein a mass ratio of the alkenyl succinic anhydride to the water is 1:(1-5); a mass ratio of the hectorite to the alkenyl succinic anhydride is 1:(20-200); and a mass ratio of the alanine to the hectorite is 1:(20-200). A preparation method is characterized by comprising the following steps of: dispersing the hectorite in the deionized water to obtain a hectorite colloid; adding an aqueous solution of alanine into the hectorite colloid; regulating pH, and uniformly mixing with the alkenyl succinic anhydride (ASA) to obtain the stable alkenyl succinic anhydride sizing emulsion for papermaking. The using amount of an emulsifier is small, and the emulsification cost is low; and the prepared emulsion has high concentration, stability and sizing efficiency. An emulsification process is simple, and the sizing efficiency of the obtained emulsion can be greatly improved.

Owner:QILU UNIV OF TECH

A kind of Fengdan seed natural active skin cream and preparation method thereof

InactiveCN103432028BGood sun protectionWith suppressed backupCosmetic preparationsToilet preparationsGlycerolSolvent

Owner:佰氏健康(广州)大健康科技有限公司

Emulsified biomass fuel oil and emulsifying method thereof

InactiveCN101906331BImprove stabilityEmulsification is cheapLiquid carbonaceous fuelsFuel additivesFuel oilImpurity

The invention discloses emulsified biomass fuel oil, which comprises the following components in percentage by weight: 1 to 15 percent of biomass crude oil, 75 to 95 percent of diesel oil, 0.45 to 9 percent of emulsifying agent, 0.05 to 0.2 percent of co-surfactant, 0.01 to 0.06 percent of oxidation and corrosion inhibitor and 0.01 to 1 percent of isooctyl nitrate. A preparation method for the emulsified oil comprises the following steps of: filtering the biomass crude oil to remove coarse impurities, and removing heavy components from the biomass crude oil by using a centrifugal machine; and then, adding ester emulsifying agent and ether emulsifying agent into the diesel oil and the biomass crude oil respectively, adding the two kinds of mixed solution into a high-shear homogenizing emulsifier, stirring the mixed solution for 20 to 60 minutes with shearing at the temperature of between 30 and 50 DEG C under 1,500 and 3,000rpm, finally adding the co-surfactant, the oxidation and corrosion inhibitor and an inflame improver into the mixed solution, and uniformly emulsifying the mixed solution to obtain the emulsified biomass crude oil. The emulsified biomass crude oil has long stabilization time which can reach over 6 months; the emulsified biomass crude oil has the advantages of high utilization rate of biomass oil, good anti-oxidation stability, low corrosion, low ash content and high combustion heat value; and the preparation method is simple and feasible, and has low environmental pollution.

Owner:HEFEI UNIV OF TECH

A kind of fluorescent ASA papermaking sizing agent and preparation method thereof

InactiveCN103790072BGood emulsifying effectImprove stabilityWater-repelling agents additionPolyelectrolyteEmulsion

The invention relates to a fluorescent alkenyl succinic anhydride (ASA) sizing agent for papermaking and a preparation method of the fluorescent ASA sizing agent for papermaking, belonging to the technical field of sizing agent for papermaking. According to the fluorescent ASA sizing agent for papermaking, firstly, a carbon quantum dot is added into the ASA sizing agent, so that ASA sizing emulsion which can be used as the fluorescent sizing agent for papermaking and effectively improves the water resistance of paper is successfully prepared; a new emulsion stabilizer is provided for the ASA sizing agent, and the stable emulsifying agent enables the sizing agent to have fluorescence property and high sizing efficiency; furthermore, the emulsion stabilizer serving as the carbon quantum dot has the advantages of being few in dosage, non-toxic, low in cost, etc. The fluorescent ASA sizing agent for papermaking adopts a simple preparation technology, and a surface active agent, a polymer polyelectrolyte and a dye type fluorescent agent do not need to be added into the fluorescent ASA sizing agent.

Owner:QILU UNIV OF TECH

A preparation method of papermaking sizing agent emulsified by flake solid particles

InactiveCN103194934BImprove stabilityEmulsification process is simpleWater-repelling agents additionParaffin waxBentonite suspension

The invention discloses a preparation method of a paper making sizing agent formed by emulsification of flaky solid particles. The method comprises the following steps of: firstly, mixing a silane coupling agent with flaky nanometer bentonite solid particles and dispersing the mixture in deionized water; secondly, adding methylbenzene or absolute ethyl alcohol to prepare modified bentonite suspension liquid; thirdly, dispersing the flaky nanometer bentonite solid particles modified by the silane coupling agent into the deionized water, stirring uniformly, and regulating the pH value to 3.5-9.5; fourthly, mixing liquid paraffin with vinyl succinic anhydride and stirring uniformly to obtain mixed sizing oil liquid; and at last mixing the sizing oil liquid with the bentonite suspension liquid, wherein the paper making sizing agent with stably emulsified flaky solid particles is obtained after the mixture is emulsified. The paper making sizing gent has quite high stability, and the preparation method is simple, can be used for emulsifying the vinyl succinic anhydride into a stable emulsion without adding any surface active agent or high-molecular polyelectrolyte, also uses little emulsifying agent, is low in emulsification cost, and causes low pollution to the environment.

Owner:SOUTH CHINA UNIV OF TECH

A kind of foot-and-mouth disease vaccine diluent and its preparation method and application

ActiveCN106109414BAccurately obtain actual efficacy dataPrecision inoculationInorganic non-active ingredientsEmulsion deliveryMedicineDiluent

The invention discloses foot-and-mouth disease vaccine diluent as well as a preparation method and application thereof. When the foot-and-mouth disease vaccine diluent is used for diluting a foot-and-mouth disease vaccine, precise inoculation can be realized, and the defect that the actual potency data can not be accurately obtained in an existing testing process can be overcome, so that potency testing precision and accuracy are improved. Besides, by virtue of the foot-and-mouth disease vaccine diluent disclosed by the invention, the vaccine can be concentrated for more times, storage and transportation cost is reduced, large-scale inoculation in a farm, an immune station and the like is facilitated, volume of an emulsification tank can also be reduced in a subsequent emulsifying process, and stirring and temperature are more uniform during emulsifying, so that emulsifying effect can be improved, and meanwhile emulsification cost is saved.

Owner:JINYUBAOLING BIO PHARMA CO LTD

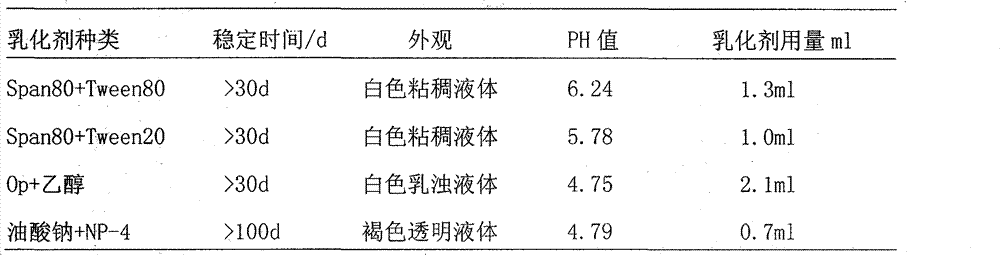

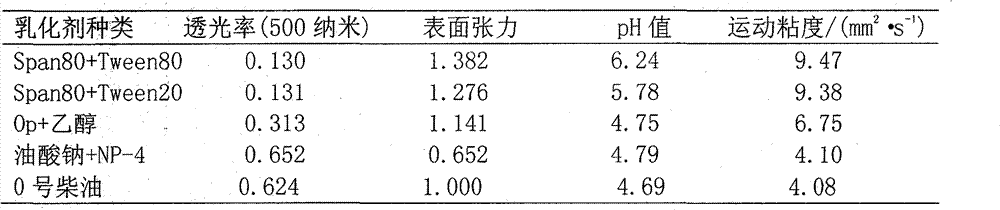

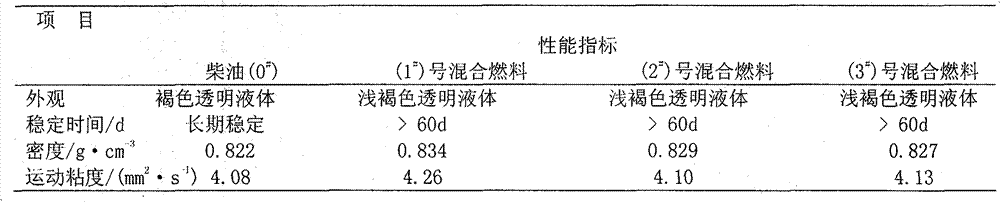

Engine diesel oil emulsifying agent and engine emulsified diesel oil

ActiveCN101906333BMeet job requirementsEmission reductionLiquid carbonaceous fuelsPhenyl EthersPolyethylene glycol

The invention provides an engine diesel oil emulsifying agent and engine emulsified diesel oil. The engine diesel oil emulsifying agent is prepared by mixing sodium oleate saturated solution, OP-ethanol and nonyl phenol polyethylene glycol (4) ether NP-4 in a volume ratio of 2:5:(8-12), wherein the OP-ethanol is prepared by mixing polyglycol octyl phenyl ether and ethanol in the same volume ratio. The engine diesel oil emulsifying agent is mixed with water-containing diesel oil in a volume ratio of 1:500, wherein the water content of the diesel oil is 9 to 10 percent of the volume of the diesel oil, and the mixture is emulsified at the temperature of between 40 DEG C and 55 DEG C to prepare the engine emulsified diesel oil. The engine diesel oil emulsifying agent and the engine emulsified diesel oil of the technical scheme have the technical advantages of viscosity and density close to those of purified diesel oil, high transparence, stability and no demixing; besides, the emulsification amount is low, and the emulsification cost is low.

Owner:EASTERN LIAONING UNIV

A biodegradable solid particle emulsifier and paper-making sizing agent

ActiveCN105056830BImprove stabilityImprove sizing effectWater-repelling agents additionTransportation and packagingPickering emulsionSolid particle

The invention relates to a biodegradable solid particle emulsifier and a papermaking sizing agent, belonging to the technical field of papermaking sizing agents and related industrial emulsification. The biodegradable solid particle emulsifier (hereinafter referred to as "CPs") of the present invention is prepared from cellulose nanocrystals and poly(lactic-co-glycolic acid) copolymer. The ASA emulsion prepared by using the "CPs" of the present invention is a Pickering emulsion, the droplet size is about 3.4 μm; it has high stability, and the emulsion will not produce particle aggregation, precipitation or precipitation of the water phase after being placed for 24 hours; the emulsion Good internal sizing performance of papermaking pulp can still be maintained after being placed for 3 hours; the preparation process is simple, the amount of emulsifier used is small, the cost of emulsification is low, the method is biodegradable, and has low environmental pollution.

Owner:山东熙来淀粉有限公司

A kind of alkenyl succinic anhydride sizing agent and its preparation method and application

ActiveCN111749045BImprove sizing effectHigh flocculation stabilityWater-repelling agents additionFiberPolymer science

The invention belongs to the technical field of papermaking, and in particular relates to an alkenyl succinic anhydride sizing agent. The invention uses ethyl lauroyl arginate, cellulose nanocrystals and nanocellulose fibers as raw materials to obtain the alkenyl succinic anhydride sizing agent The agent emulsion is a Pickering type emulsion, which has super high flocculation stability, hydrolysis resistance stability and paper pulp internal sizing performance. The surface and internal sizing properties of the alkenyl succinic anhydride sizing agent emulsion provided by the present invention are significantly improved, and at the same time, the hydrolysis resistance of the alkenyl succinic anhydride sizing agent can be greatly improved. Good paper sizing performance can still be maintained for 48-72 hours; and the alkenyl succinic anhydride sizing agent emulsion will not produce particle aggregation, precipitation or phase precipitation within 180 days, and has good stability.

Owner:山东济清科技服务有限公司

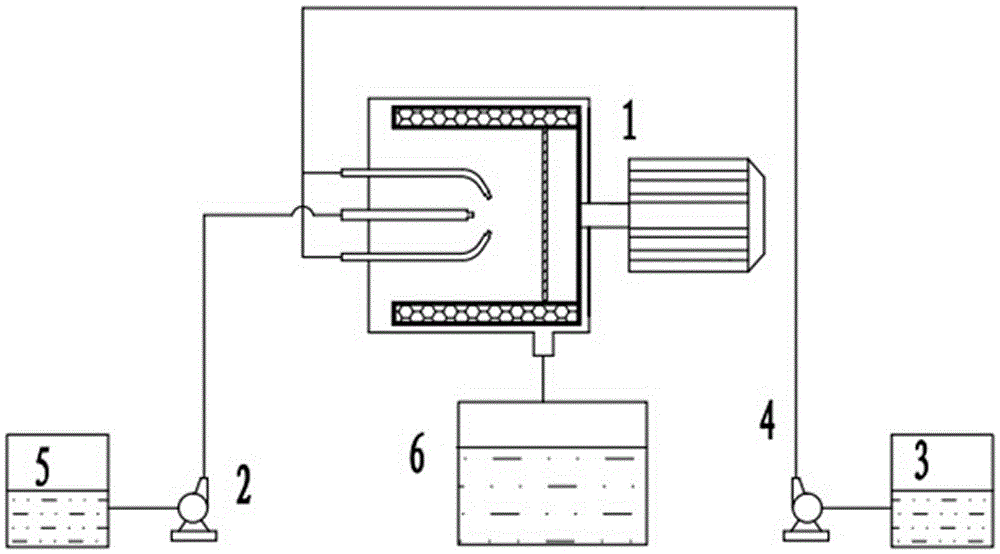

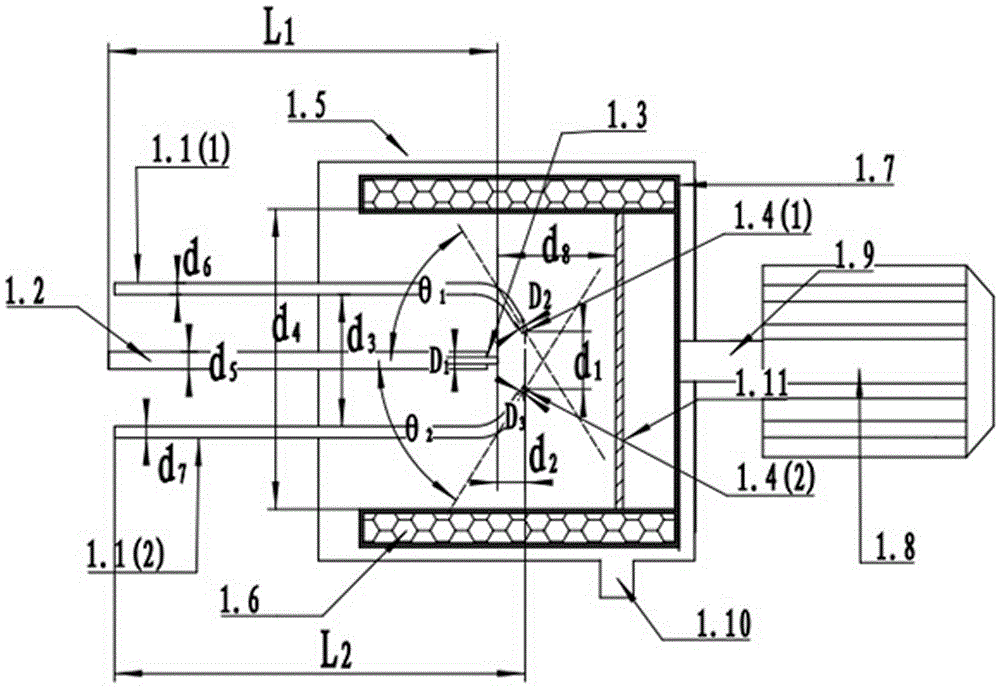

A Sichuan-shaped supergravity device and process for continuously preparing methanol emulsified diesel oil

The invention belongs to the technical field of methanol-emulsified diesel production, and specifically relates to a continuous preparation of methanol-emulsified diesel with a river-shaped supergravity device and process, which solves the problem of large differences in material volume flow ratio in the existing methanol-diesel emulsion production process , The mixing effect is not ideal and the problem is uneven. The supergravity device includes an impingement flow structure and a supergravity structure. The impingement flow structure is a non-limiting impingement flow structure, including an auxiliary feed pipe I, an auxiliary feed pipe II and a main feed pipe; the main feed pipe nozzle and two The liquids ejected from the nozzles of the auxiliary feeding pipes meet at one point; the non-limiting impingement flow structure is arranged in the cavity of the rotor. process, the water phase and the oil phase are collided by an impinging flow mixer to quickly complete the initial mixing, and then enter the rotating packing to form a water-in-oil methanol diesel emulsion. The invention changes the impact form of the two-phase flow, improves the effect of the impact of the two-phase flow, and can simultaneously realize large-flow emulsion preparation and continuous operation.

Owner:ZHONGBEI UNIV

Alkenyl succinic anhydride sizing agent emulsion and preparation method thereof

InactiveCN102493277BAchieve recyclingSolve pollutionWater-repelling agents additionPaper/cardboardPapermakingSuccinic anhydride

The invention relates to the field of sizing agents in the papermaking industry, in particular to an alkenyl succinic anhydride sizing agent emulsion, which contains white mud waste residue, alkenyl succinic anhydride and water, and the mass ratio of alkenyl succinic anhydride to water is 1:1~4 ; The mass ratio of white mud waste residue to alkenyl succinic anhydride is 1:20~1000. The preparation method is to disperse the white mud waste residue into alkenyl succinic anhydride, and then add water to mix evenly; or disperse white mud waste residue into water, and then mix evenly with alkenyl succinic anhydride to prepare a stable O / W type ASA emulsion . Realize the recycling of industrial waste residues, and realize a virtuous economic cycle; the amount of emulsifier used when white mud is used as an emulsifier is lower than that of inorganic nanomaterials, and it can achieve good results at a lower amount of emulsifier. sizing effect, so the cost of emulsification is lower, and it also has the advantages of simple emulsification process and high concentration of the prepared emulsion. After diluting and emulsifying with water, it is added to the paper material for in-pulp sizing, and the sizing efficiency is high.

Owner:QILU UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com