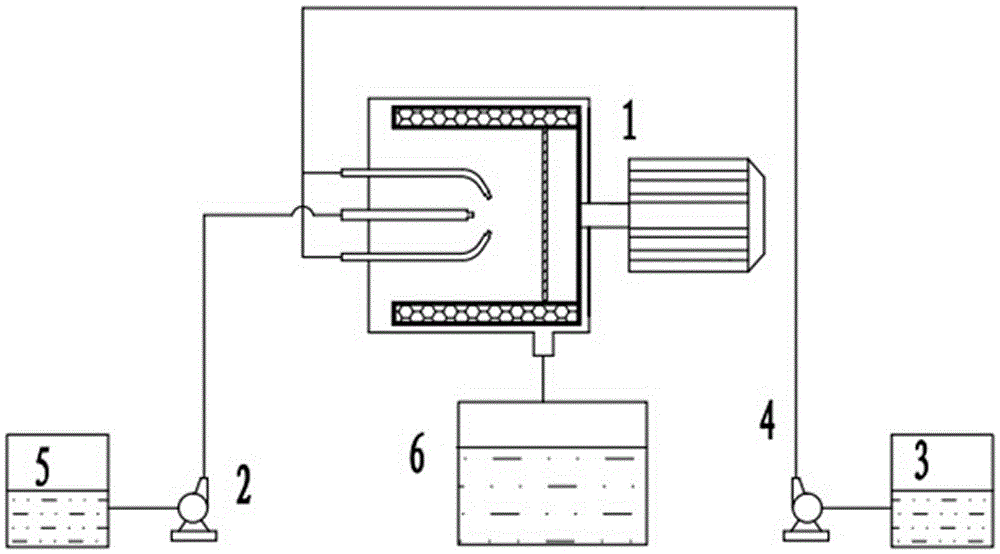

A Sichuan-shaped supergravity device and process for continuously preparing methanol emulsified diesel oil

A technology for emulsified diesel oil and supergravity, which is used in the petroleum industry, chemical instruments and methods, and liquid carbon-containing fuels, etc. It can solve the problems of unsatisfactory mixing effect, large difference in volume flow ratio, and unevenness, and achieve long stability. , The effect of uniform particle size distribution and less emulsifier dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

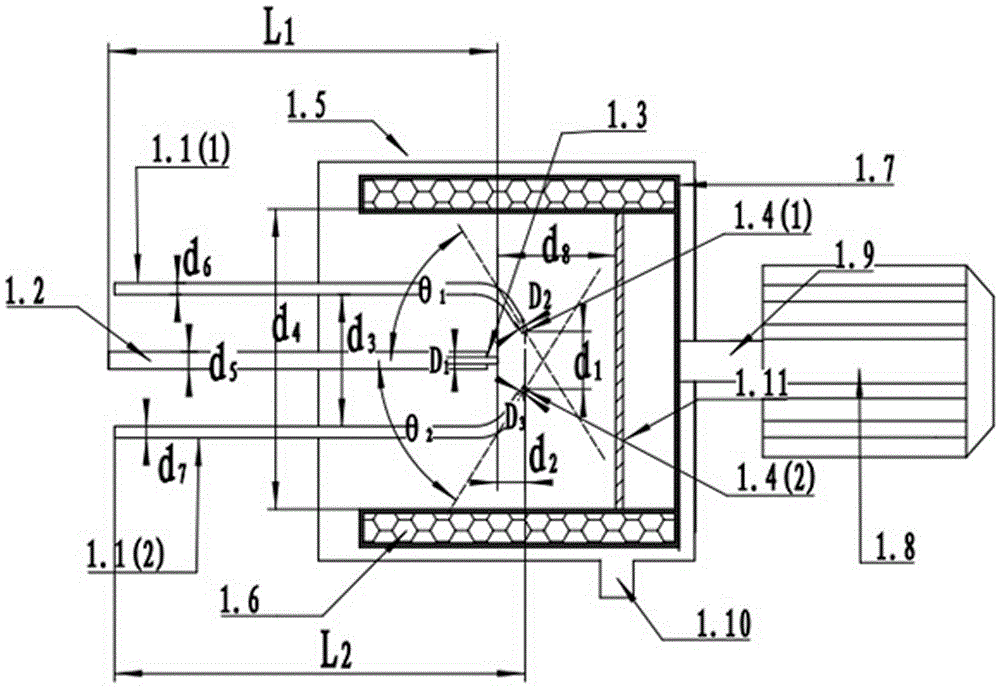

Embodiment 1

[0027] Prepare the water phase containing the hydrophilic emulsifier in the methanol storage tank and the oil phase containing the lipophilic emulsifier in the diesel storage tank. Prepare 45 tons / h of methanol diesel emulsion, and enter the new impinging flow-rotating packed bed emulsification device according to the ratio of water phase: oil phase = 10:90. The structural dimensions and characteristics of the new impinging flow-rotating packed bed device are: main Feed pipe diameter d 5 with main feed nozzle diameter D 1 The ratio range is 1; the main feed pipe length L 1 and main feed pipe diameter d 5 The ratio is 10, the length of the auxiliary feed pipe L 2 and auxiliary feed pipe diameter d 6 、d 7 The ratio is 10; the diameter of the two feed pipes d 6 , d 7 Equal, and the ratio range of the diameter of the auxiliary feed pipe to the main feed pipe is 2; the nozzle diameter of the auxiliary feed pipe D 2 ,D 3 Equal, and the ratio range to its pipe diameter is 50...

Embodiment 2

[0029] Prepare the water phase containing the hydrophilic emulsifier in the methanol storage tank and the oil phase containing the lipophilic emulsifier in the diesel storage tank. Prepare 8 tons / h of methanol diesel emulsion, according to the ratio of water phase: oil phase = 30:70, enter the new impinging flow-rotating packed bed emulsification device, the characteristic size and characteristics of the new impinging flow-rotating packed bed device are: Main feed pipe diameter d 5 with main feed nozzle diameter D 1 The ratio range is 20; the main feed pipe length L 1 and main feed pipe diameter d 5 The ratio is 50, the length of the auxiliary feed pipe L 2 and auxiliary feed pipe diameter d 6 、d 7 The ratio of the ratio is 50; the diameter of the two feed pipes d 6 , d 7 Equal, and the ratio range of the diameter of the auxiliary feed pipe to the main feed pipe is 5; the diameter of the nozzle of the auxiliary feed pipe D 2 ,D 3 Equal, and the ratio range to its pipe...

Embodiment 3

[0031] Prepare the water phase containing the hydrophilic emulsifier in the methanol storage tank and the oil phase containing the lipophilic emulsifier in the diesel storage tank. Prepare 10 tons / h of methanol diesel emulsion, and enter the new impinging flow-rotating packed bed emulsification device at the ratio of water phase: oil phase = 20:80. The characteristic dimensions and characteristics of the new impinging flow-rotating packed bed device are: Main feed pipe diameter d 5 with main feed nozzle diameter D 1 The ratio range is 50; the main feed pipe length L 1 and main feed pipe diameter d 5 The ratio is 25, the length of the auxiliary feed pipe L 2 and auxiliary feed pipe diameter d 6 、d 7 The ratio is 25; the diameter of the two feed pipes is d 6 , d 7 Equal, and the ratio range of the diameter of the auxiliary feed pipe to the main feed pipe is 0.5; the diameter of the nozzle of the auxiliary feed pipe D 2 ,D 3 Equal, and the ratio range to its pipe diamete...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com