Hydrolysis-resistant alkenyl succinic anhydride sizing agent as well as preparation method and application thereof

A technology of alkenyl succinic anhydride and alkenyl succinic acid, applied in the field of papermaking, can solve problems such as unfavorable emulsion storage, inability to completely avoid adverse effects of surfactants, serious hydrolysis of ASA, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

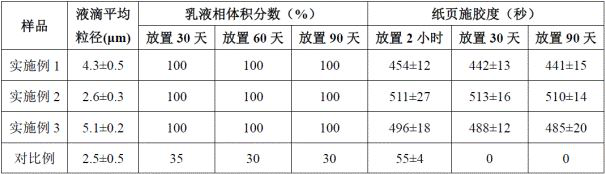

[0029] Example 1 Preparation of hydrolysis-resistant dodecenyl succinic anhydride sizing agent

[0030] (1) 1 part by weight of CNC (diameter 3nm, length 100nm) is dispersed in water to form a dispersion with a mass fraction of 0.05%, add 2 parts by weight of acetone, 10 parts by weight of ammonia monohydrate, and 0.02 parts by weight of cetyltrimethyl 25°C, 500W ultrasonic dispersion for 1 hour to obtain a mixed solution I; add 0.05 parts by weight of perfluorooctyltriethoxysilane to the mixed solution I, and continue ultrasonic dispersion for 1 hour to obtain a mixed solution II; Dry the mixed solution II under vacuum at 65°C to obtain CNC-R powder;

[0031] (2) Mix 1 part by weight of CNC-R powder with 20 parts by weight of perfluorohexane, ultrasonically disperse at 500W at 25°C for 1 hour, add 200 parts by weight of dodecenyl succinic anhydride and mix, and continue ultrasonic emulsification for 15 minutes to obtain ASA -A lotion;

[0032] (3) Mix 2 parts by weight of A...

Embodiment 2

[0033] Example 2 Preparation of hydrolysis-resistant hexadecenyl succinic anhydride sizing agent

[0034] (1) 1 part by weight of CNC (diameter 5nm, length 220nm) is dispersed in water to form a dispersion with a mass fraction of 1%, add 10 parts by weight of acetone, 20 parts by weight of ammonia monohydrate, and 0.2 parts by weight of cetyltrimethyl 1,000W ultrasonic dispersion at 25°C for 1 hour to obtain a mixed solution I; add 0.1 parts by weight of perfluorooctyltriethoxysilane to the mixed solution I, and continue to ultrasonically disperse for 1 hour to obtain a mixed solution II; Dry the mixed solution II under vacuum at 65°C to obtain CNC-R powder;

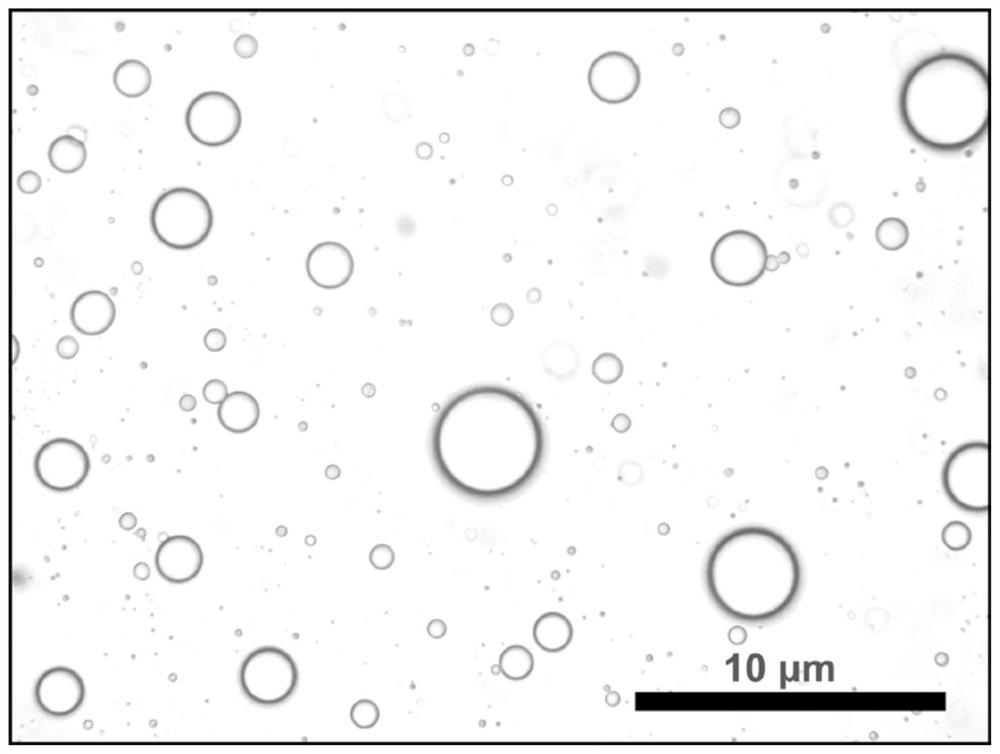

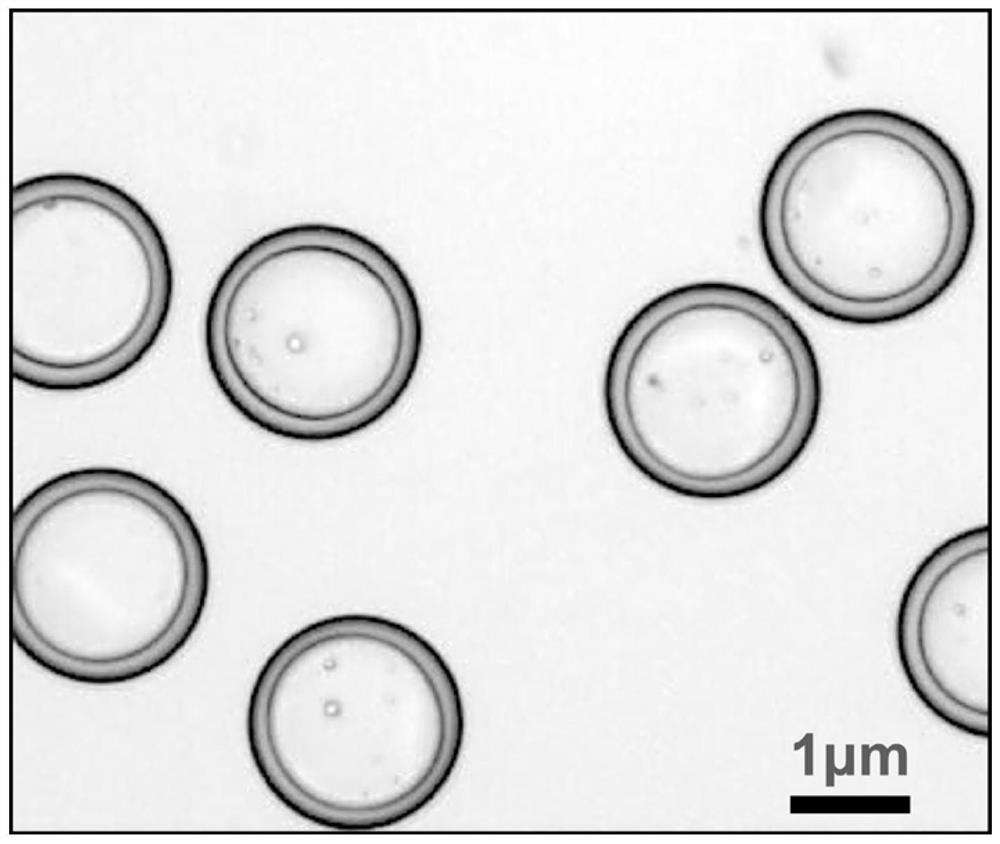

[0035](2) Mix 1 part by weight of CNC-R powder with 60 parts by weight of perfluorohexane, ultrasonically disperse at 1000W at 25°C for 1 hour, add 60 parts by weight of hexadecenyl succinic anhydride and mix, and continue ultrasonic emulsification for 15 minutes to obtain ASA -A emulsion; its micrograph is as figure 1...

Embodiment 3

[0038] Example 3 Preparation of hydrolysis-resistant alkenyl succinic anhydride sizing agent

[0039] (1) 2 parts by weight of CNC (diameter 10nm, length 500nm) are dispersed in water to form a dispersion with a mass fraction of 2%, add 1 part by weight of acetone, 2 parts by weight of ammonia monohydrate, and 0.6 parts by weight of cetyl trimethyl 25°C, 3000W ultrasonic dispersion for 1 hour to obtain mixed solution I; add 0.4 parts by weight of perfluorooctyltriethoxysilane to mixed solution I, and continue ultrasonic dispersion for 1 hour to obtain mixed solution II; Dry the mixture II in vacuum at 65°C to obtain CNC-R powder;

[0040] (2) Mix 1 part by weight of CNC-R powder with 100 parts by weight of perfluorohexane, ultrasonically disperse at 3000W at 25°C for 1 hour, add 10 parts by weight of octadecenyl succinic anhydride and mix, and continue ultrasonic emulsification for 15 minutes to obtain ASA -A lotion;

[0041] (3) Mix 1 part by weight of ASA-A emulsion with 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com