A kind of alkenyl succinic anhydride sizing agent and its preparation method and application

An alkenyl succinic anhydride and sizing agent technology, applied in the field of papermaking, can solve the problems of low ASA emulsion concentration, large particle component addition, general emulsion stability, etc., and achieve good paper sizing performance, ultra-high flocculation, etc. Stability, the effect of improving hydrolysis resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0052] The present invention provides the preparation method of the alkenyl succinic anhydride sizing agent described in the above technical scheme, comprising the following steps:

[0053] Dispersing ethyl lauroyl arginate and hectorite in water to obtain an aqueous solution of ethyl lauroyl arginate modified hectorite;

[0054] Dispersing ethyl lauroyl arginate and cellulose nanocrystals in water to obtain an aqueous solution of ethyl lauroyl arginate modified cellulose nanocrystals;

[0055] mixing alkenyl succinic anhydride with the aqueous solution of ethyl lauroyl arginate modified hectorite, and performing first emulsification to obtain ASA-1 emulsion;

[0056] Mixing the aqueous solution of ethyl lauroyl arginate modified cellulose nanocrystals with the ASA-1 emulsion for second emulsification to obtain ASA-2 emulsion;

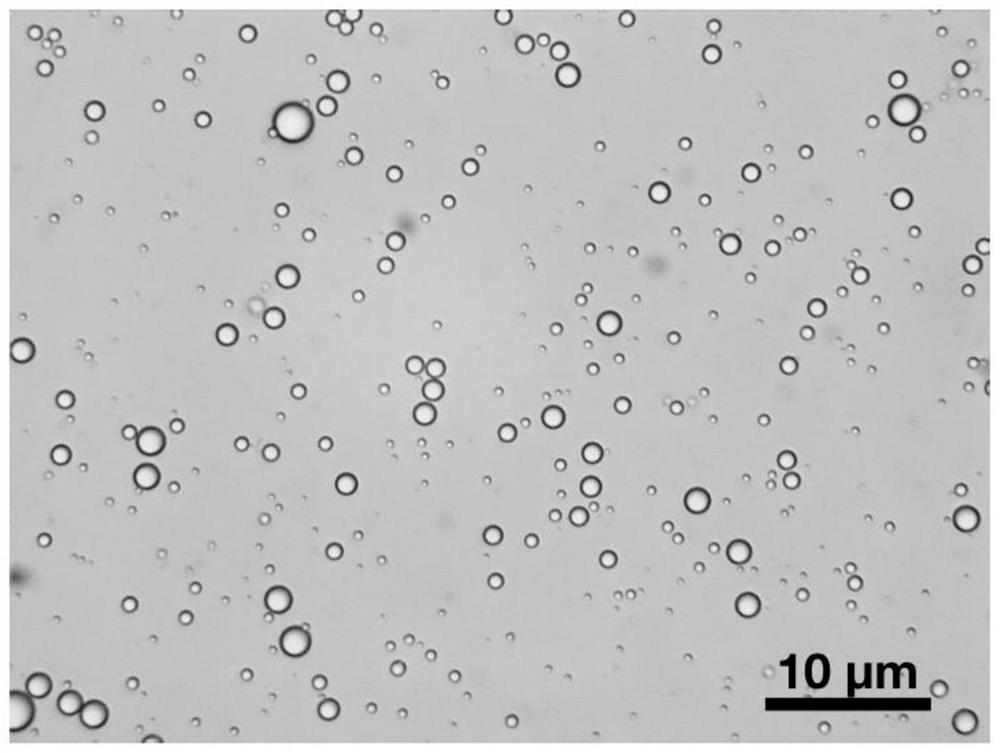

[0057] The nanocellulose fiber aqueous solution is mixed with the ASA-2 emulsion for the third emulsification to obtain the alkenyl succinic anhydrid...

Embodiment 1

[0069] Disperse ELA and LP in deionized water according to the mass ratio of 1:2, and ultrasonically oscillate for 30 minutes at room temperature under 600W power to obtain an ELA-LP aqueous solution with a mass fraction of 0.1%.

[0070] Disperse ELA and CNC in deionized water at a mass ratio of 1:5, and ultrasonically oscillate for 30 minutes at room temperature with a power of 600W to obtain an aqueous solution of ELA-CNC with a mass fraction of 0.05%;

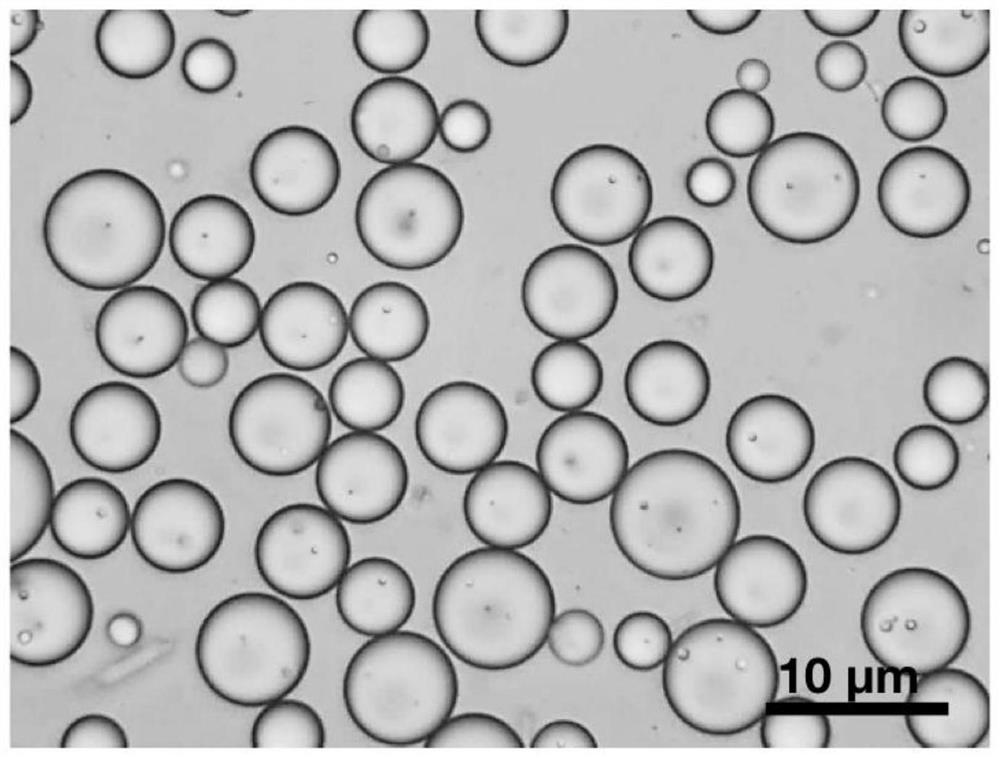

[0071] ASA was added to the ELA-LP aqueous solution (the oil-water mass ratio of ASA and ELA-LP aqueous solution was 1:50), and a high-speed shear emulsifier was used to carry out the first emulsification at 1000rpm and 5-50°C for 2 minutes to obtain ASA-1 emulsion, the average particle size of emulsion droplets is 6.8μm, such as figure 1 shown;

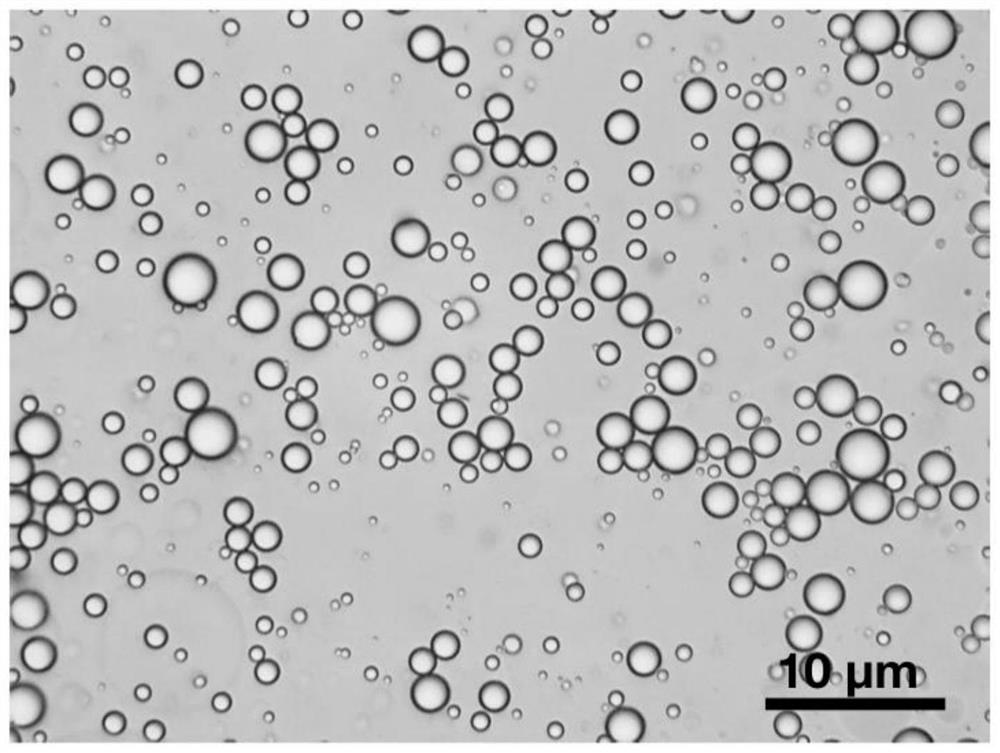

[0072] Mix the ELA-CNC aqueous solution and the ASA-1 emulsion according to the mass ratio of 1:20, continue to carry out the second emulsification at 65°C with a high-speed shea...

Embodiment 2

[0096] Disperse ELA and LP in deionized water at a mass ratio of 1:10, and ultrasonically shake at room temperature for 30 minutes at a power of 1200W to obtain an aqueous solution of ELA-LP with a mass fraction of 0.5%.

[0097] Disperse ELA and CNC in deionized water at a mass ratio of 1:10, and oscillate ultrasonically for 30 minutes at room temperature to obtain a 0.45% ELA-CNC aqueous solution;

[0098] Add ASA to the ELA-LP aqueous solution (the oil-water mass ratio of ASA and ELA-LP aqueous solution is 1:20), and use a high-speed shear emulsifier at 6000rpm to perform the first emulsification at 30°C for 5 minutes to obtain ASA-1 Emulsion, the average particle size of emulsion droplets is 7.6 μm;

[0099] Mix the ELA-CNC aqueous solution and the ASA-1 emulsion at a mass ratio of 1:10, continue to perform the second emulsification with a high-speed shear emulsifier at 10,000 rpm for 5 minutes at 65°C, and cool to room temperature to obtain ASA-2 emulsion, emulsion The a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com