Surface sizing agent for papermaking, surface sizing coating liquid and paper

A surface sizing agent and water-based emulsion technology, which is applied in papermaking, paper coating, textiles and papermaking, etc., can solve the problems of manufacturing adverse effects, friction coefficient reduction, time-consuming, etc., and achieve the suppression of friction coefficient reduction and sizing effect good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

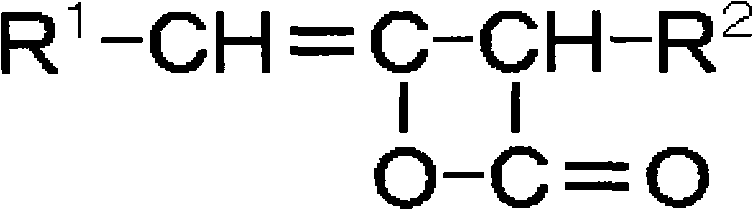

Method used

Image

Examples

Embodiment

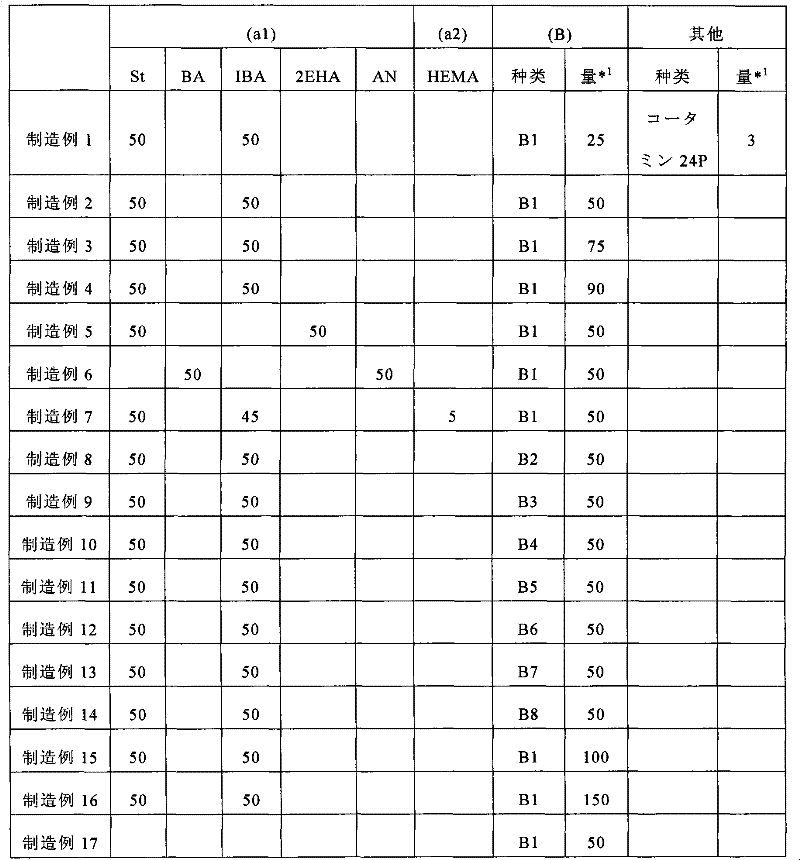

[0048] The following examples and comparative examples are given to specifically describe the present invention, but the present invention is not limited to these examples. In addition, in each example, parts and % are all based on weight unless otherwise indicated.

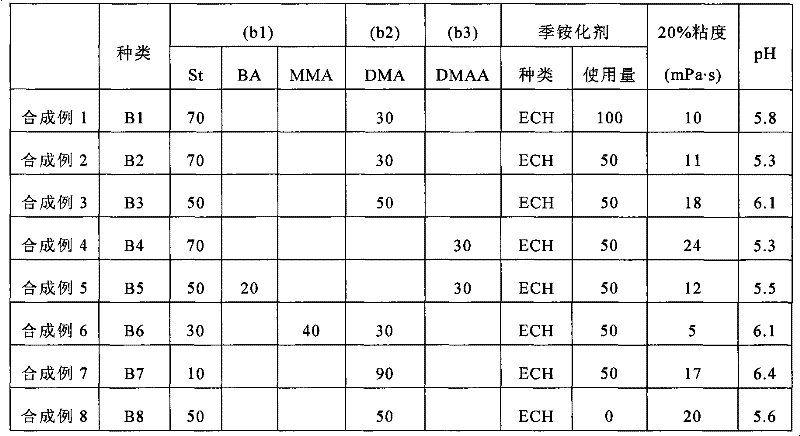

Synthetic example 1

[0050] Into a flask equipped with a stirrer, a condenser, a dropping funnel, a nitrogen inlet tube, and a thermometer, put 70 parts of styrene, 30 parts of dimethylaminoethyl methacrylate, 42.9 parts of isopropanol, and 2,2'- 2.5 parts of azodiisobutyronitrile were polymerized at 80 to 85° C. for 5 hours while stirring under a nitrogen stream. Next, 11.5 parts of acetic acid and 300 parts of water were added. Then, 17.7 parts of epichlorohydrin were added to the obtained copolymer, and kept at 80° C. for 2 hours to quaternize the copolymer to form a cationic copolymer compound, and then further add a predetermined amount of water to obtain a solid The component concentrations were adjusted to 20% to obtain a cationic water-soluble polymer (B1). Table 1 shows the viscosity and pH of the obtained cationic water-soluble polymer (B1). In addition, viscosity was measured by putting a sample into a 225 ml mayonnaise bottle, and using a BM type viscometer (manufactured by TOKIMEC) ...

Synthetic example 2~8

[0052] In the same manner as in Synthesis Example 1, except that the type and amount of monomers used for synthesis and the amount of epichlorohydrin used for quaternization were changed as shown in Table 1 in Synthesis Example 1 The reaction was carried out to obtain various cationic water-soluble polymers (B2 to B8) having a solid content concentration of 20%. Table 1 shows the viscosity and pH at 25° C. of the obtained cationic water-soluble polymers (B2 to B8).

[0053] Table 1

[0054]

[0055]The notation in the table is as follows. St: Styrene, BA: Butyl Acrylate, MMA: Methyl Methacrylate, DMA: N,N-Dimethylaminoethyl Methacrylate, DMAA: N,N-Dimethylaminopropyl Acrylamide, ECH: Epichlorohydrin

[0056] In addition, the usage-amount of a component (b1) - a component (b3) shows a weight part, and the usage-amount of a quaternization agent shows the molar ratio with respect to a component (b2) or a component (b3).

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com