Surface glue coating agent and preparation method thereof

A surface sizing agent and initiator technology, which is applied in the addition of water repellents, textiles and papermaking, papermaking, etc., can solve the problem of disturbing the ion balance of the papermaking system. Affect normal production and other problems, achieve good environmental adaptability, improve sizing effect, and cost-effective effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

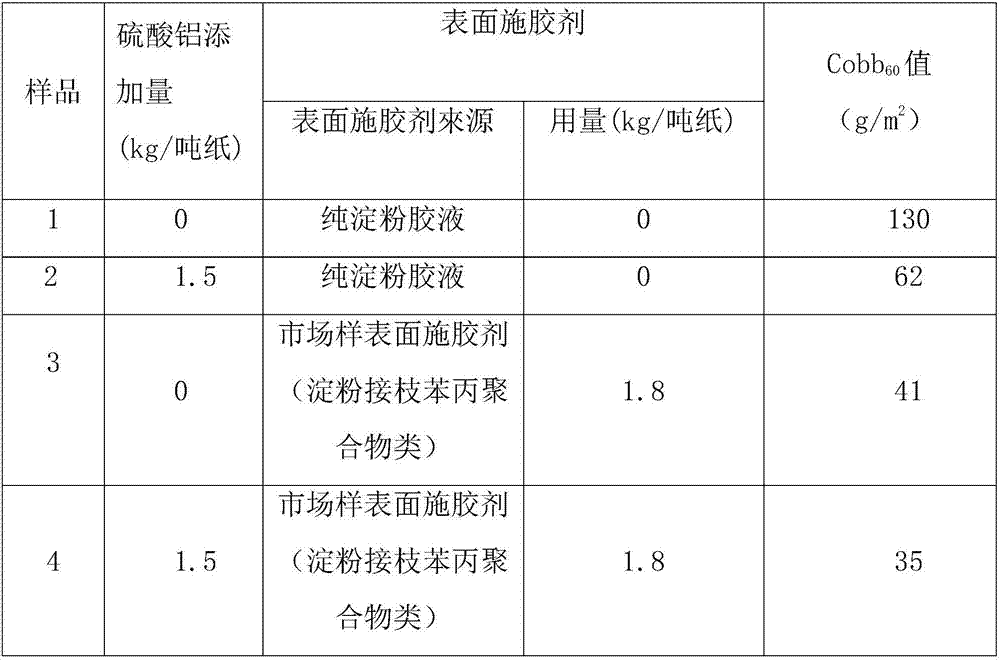

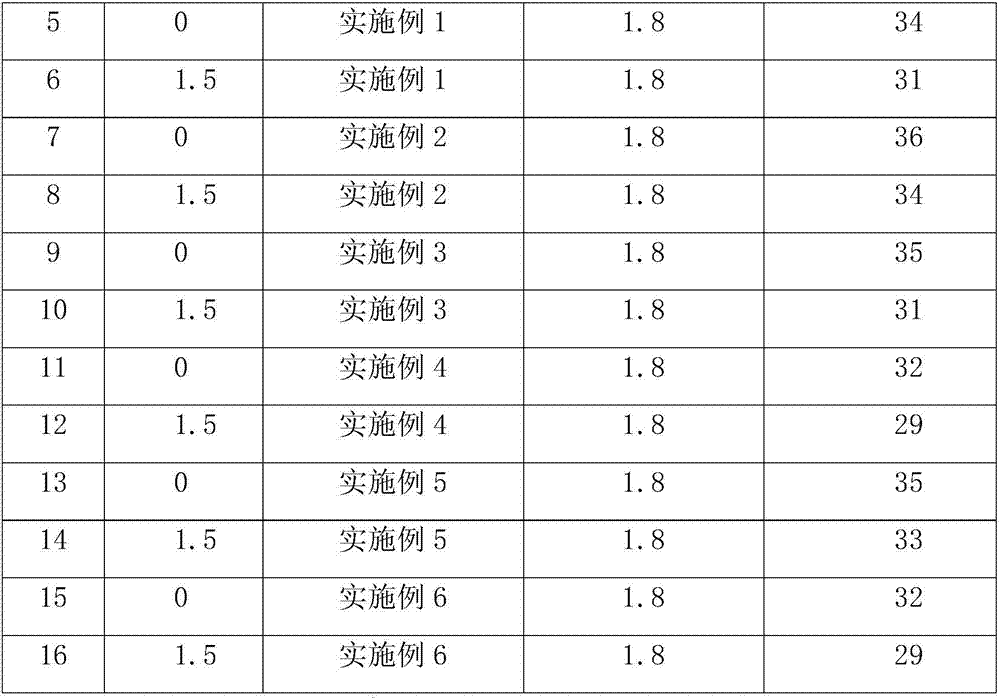

Examples

preparation example Construction

[0049] The preparation method of surface sizing agent, it carries out as follows:

[0050] 1) Cationic modified starch

[0051] Add starch, deionized water, and 10% catalyst solution into the reactor, stir and heat up to 40-60°C, then add cationic etherification agent, react at 40-60°C for 4-8h, and then add 20% acid The solution adjusts the pH value of the reaction system to 4.5-6.5, then adds a cross-linking agent, continues the reaction at 40-60° C. for 1-2 hours, and then separates and dries to obtain cationic modified starch.

[0052] 2) Preparation of surface sizing agent

[0053] (1) Monomer solution preparation: uniformly mix the first unsaturated monomer, the second unsaturated monomer, the cationic monomer and the functional monomer to obtain a monomer solution;

[0054] (2) Initiator I solution preparation: Initiator I and 15% deionized water are mixed uniformly to make free radical initiator I solution;

[0055] (3) Add the above-mentioned self-made cationic mod...

Embodiment 1

[0070] 1) Preparation of cationic modified starch

[0071] 1.5 parts by mass of potassium hydroxide, 2 parts by mass of hydrochloric acid were mixed with deionized water respectively into 10%, 20% solutions; in the reactor, 80 parts by mass of tapioca starch, 189.5 parts by mass of deionized water, 15 parts by mass of 10 % mass concentration of potassium hydroxide solution, stirred and heated to 40°C, then added 4 parts by mass of 2,3-epoxypropyltrimethylammonium chloride, reacted at 40°C for 4h, and then added 10 parts by mass of 20% The hydrochloric acid solution of mass concentration adjusted the pH value of the reaction system to 6, then added 3 parts by mass of epichlorohydrin, and continued the reaction at 40° C. for 1 h. During the entire reaction process, the mass fraction of cationic modified starch was 30%. Separating and drying to obtain cationic modified starch.

[0072] 2) Preparation of surface sizing agent

[0073] (1) Monomer solution preparation: 5 parts by ...

Embodiment 2

[0077] 1) Preparation of cationic modified starch

[0078] First, 3 parts by mass of sodium hydroxide and 4 parts by mass of hydrochloric acid were prepared into 10% and 20% solutions with deionized water respectively; 82 parts by mass of cornstarch, 144 parts by mass of deionized water, 30 parts by mass of 10% sodium hydroxide solution, stirred and heated to 45°C, then added 8 parts by mass of 3-chloro-2-hydroxypropyltrimethylammonium chloride, reacted at 45°C for 5h, then added 20 parts by mass of 20% hydrochloric acid solution to adjust the pH value of the reaction system to 6.5, then add 4 parts by mass of epichlorohydrin, and continue the reaction at 45°C for 1.5h. During the entire reaction process, the mass fraction of cationic modified starch is 35%, and then separated and drying to obtain cationic modified starch.

[0079] 2) Preparation of surface sizing agent

[0080] (1) Monomer solution preparation: 10 parts by mass of α-methylstyrene, 10 parts by mass of methyl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com