A kind of surface sizing agent and preparation method thereof

A technology of surface sizing agent and initiator, which is used in the addition of water repellents, textiles, papermaking, and paper coatings, etc., can solve the problem that styrene-acrylic polymers are difficult to achieve sizing effect and disturb the ion balance of papermaking system. , affecting normal production, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

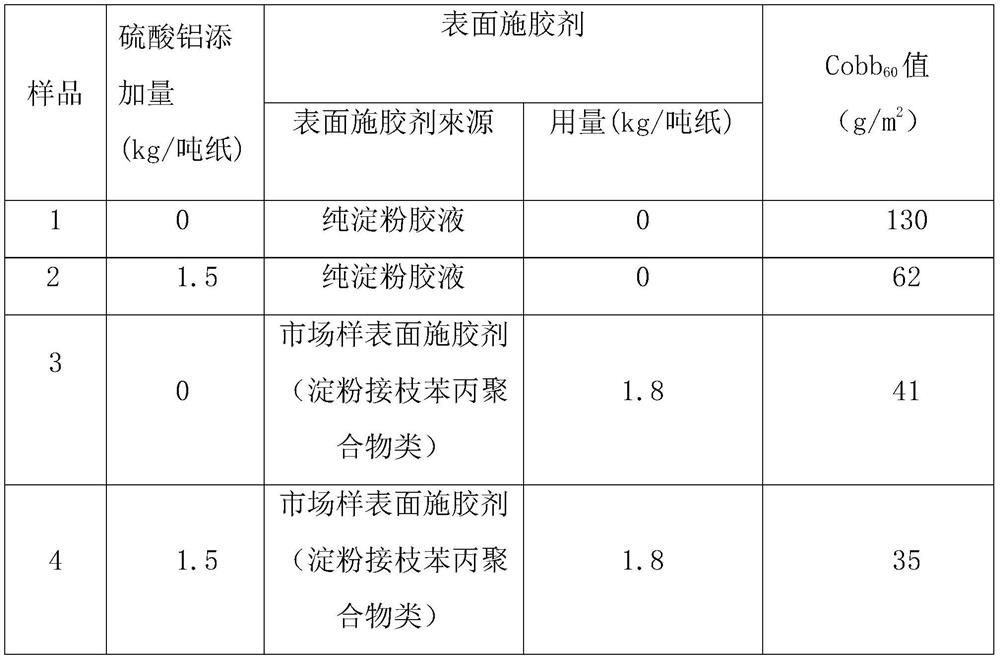

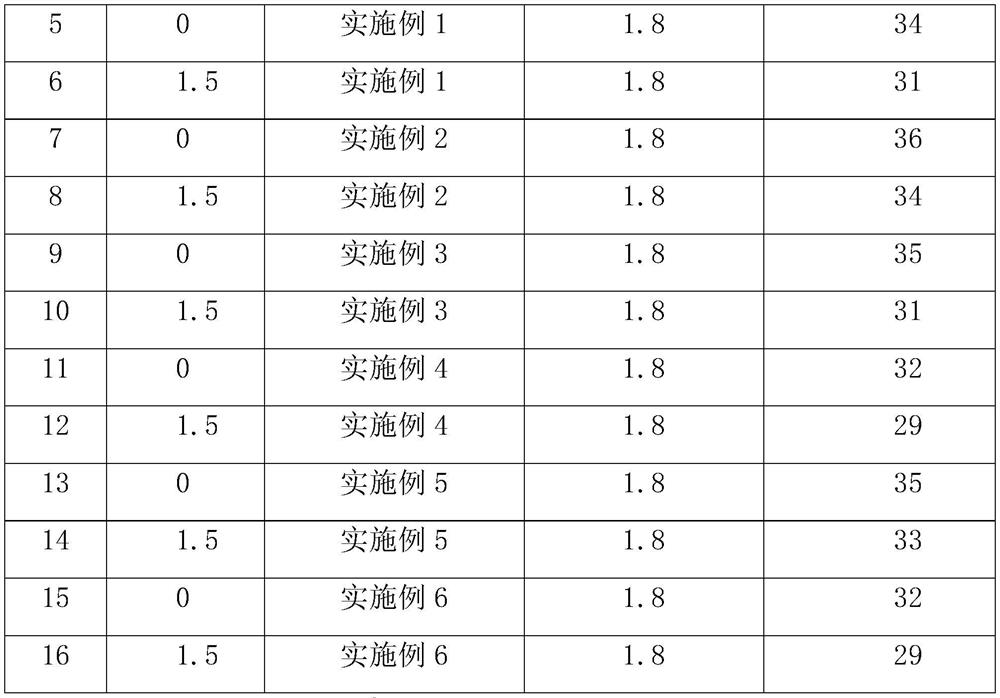

Examples

preparation example Construction

[0049] The preparation method of surface sizing agent, it carries out as follows:

[0050] 1) Cationic modified starch

[0051] Add starch, deionized water, and 10% catalyst solution into the reactor, stir and heat up to 40-60°C, then add cationic etherification agent, react at 40-60°C for 4-8h, and then add 20% acid The solution adjusts the pH value of the reaction system to 4.5-6.5, then adds a cross-linking agent, continues the reaction at 40-60° C. for 1-2 hours, and then separates and dries to obtain cationic modified starch.

[0052] 2) Preparation of surface sizing agent

[0053] (1) Monomer solution preparation: uniformly mix the first unsaturated monomer, the second unsaturated monomer, the cationic monomer and the functional monomer to obtain a monomer solution;

[0054] (2) Initiator I solution preparation: Initiator I and 15% deionized water are mixed uniformly to make free radical initiator I solution;

[0055] (3) Add the above-mentioned self-made cationic mod...

Embodiment 1

[0070] 1) Preparation of cationic modified starch

[0071] 1.5 parts by mass of potassium hydroxide, 2 parts by mass of hydrochloric acid were mixed with deionized water respectively into 10%, 20% solutions; in the reactor, 80 parts by mass of tapioca starch, 189.5 parts by mass of deionized water, 15 parts by mass of 10 % mass concentration of potassium hydroxide solution, stirred and heated to 40°C, then added 4 parts by mass of 2,3-epoxypropyltrimethylammonium chloride, reacted at 40°C for 4h, and then added 10 parts by mass of 20% The hydrochloric acid solution of mass concentration adjusted the pH value of the reaction system to 6, then added 3 parts by mass of epichlorohydrin, and continued the reaction at 40° C. for 1 h. During the entire reaction process, the mass fraction of cationic modified starch was 30%. Separating and drying to obtain cationic modified starch.

[0072] 2) Preparation of surface sizing agent

[0073] (1) Monomer solution preparation: 5 parts by ...

Embodiment 2

[0077] 1) Preparation of cationic modified starch

[0078] First, 3 parts by mass of sodium hydroxide and 4 parts by mass of hydrochloric acid were prepared into 10% and 20% solutions with deionized water respectively; 82 parts by mass of cornstarch, 144 parts by mass of deionized water, 30 parts by mass of 10% sodium hydroxide solution, stirred and heated to 45°C, then added 8 parts by mass of 3-chloro-2-hydroxypropyltrimethylammonium chloride, reacted at 45°C for 5h, then added 20 parts by mass of 20% hydrochloric acid solution to adjust the pH value of the reaction system to 6.5, then add 4 parts by mass of epichlorohydrin, and continue the reaction at 45°C for 1.5h. During the entire reaction process, the mass fraction of cationic modified starch is 35%, and then separated and drying to obtain cationic modified starch.

[0079] 2) Preparation of surface sizing agent

[0080] (1) Monomer solution preparation: 10 parts by mass of α-methylstyrene, 10 parts by mass of methyl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com