Digital sizing machine

A sizing machine, digital technology, used in heating/cooling fabrics, textiles and papermaking, fabric surface trimming, etc., can solve problems such as unfavorable printing, uneven heating, etc., to achieve uniform and stable heating, easy temperature control, and unmanned Effects of operating functions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

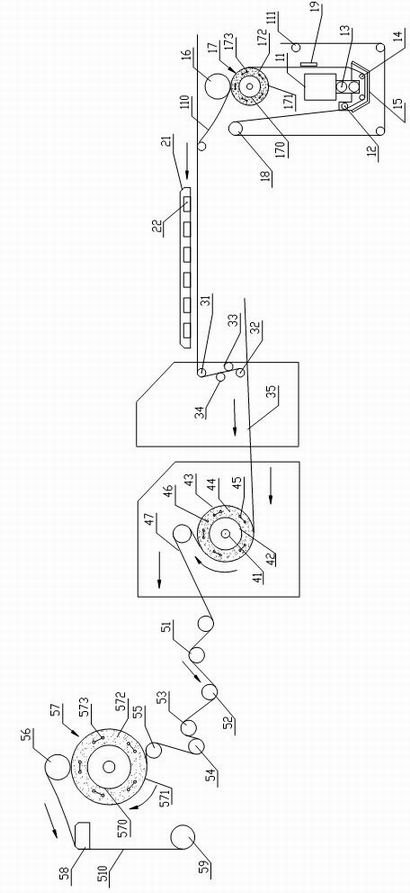

[0035] The present invention will be further described below in conjunction with accompanying drawing:

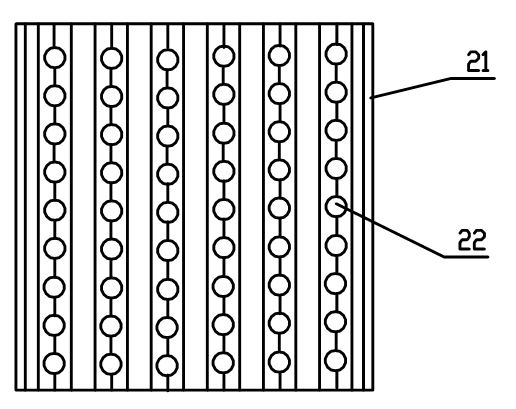

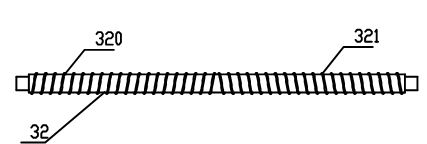

[0036]The digital sizing machine sizing system of the present invention includes a sizing system cloth releasing roller 111, one side of the sizing system cloth releasing roller 111 is provided with a spreader roller 18, and a sizing system is provided with a size tank between the sizing system cloth release roller 111 and the sizing system spreader roller 18 15. There is a lifting motor system 11 sizing and pressing shaft 13 above the size tank 15, a sizing system drum-type heat-conducting oil heating device 17 is installed above the size tank 15, and a pressure roller 16 is arranged above the sizing system drum-type heat-conducting oil heating device 17. The fabric that has finished expanding, sizing, and heating enters the next process after being pressed between the drum-type heat-conducting oil heating device 17 of the sizing system and the pressing roller 16. A plura...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wavelength | aaaaa | aaaaa |

| Helix angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com