Silkworm cocoon evacuation direct steaming device and silkworm cocoon evacuation direct steaming method using silkworm cocoon evacuation direct steaming device

A silkworm cocoon and touch steaming technology, which is applied in silk fiber production, textile and papermaking, mechanical treatment, etc. It can solve the problems that affect the spinning effect and the quality of finished products, and the uneven thickness of silkworm cocoons, so as to achieve stable and reliable spinning and high purity , heating evenly and stably

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

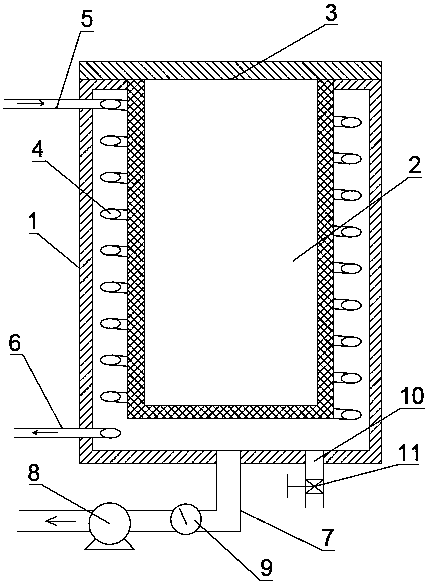

[0014] Such as figure 1 As shown, a cocoon evacuation steaming device described in this embodiment includes an outer barrel body 1 and an inner barrel body 2. The upper end of the outer barrel body 1 is an opening structure, and a sealing end cover 3 is arranged at the opening structure. The sealing end cover 3 and the outer barrel 1 are in a sealed state after they are closed, an inner barrel 2 is arranged inside the outer barrel 1, and there is a gap between the inner barrel 2 and the outer barrel 1, and the barrel wall of the inner barrel 2 There are a number of air holes in a uniform array, and a steam pipe 4 is arranged on the inner plate in the gap between the inner barrel body 2 and the outer barrel body 1, and the inlet pipe 5 and the air outlet pipe 6 of the steam pipe 4 pass through the outer barrel body 1. The bottom of 1 is provided with vacuum tube 7, is provided with vacuum pump 8 on vacuum tube 7, is provided with pressure gauge 9 on the vacuum tube 7 between va...

Embodiment 2

[0017] This example describes a method of using the equipment in Example 1 to evacuate cocoons and touch steam them. Put the cocoons into the mesh bag and place them inside the inner barrel, then close the sealing end cover to make the seal between the sealing end cover and the outer barrel body, and then Use a vacuum pump to evacuate the inside of the barrel, the evacuation pressure is 0.7MPa, then use the steam pipe to heat the inside of the barrel to 105°C, keep heating at 105°C for 7 minutes, then stop heating and let it cool down naturally for 7 minutes Finally, the material is discharged, and the cocoons taken out are left to stand for 24 hours under natural conditions in the room before entering the subsequent silkworm making process.

[0018] The silkworm making process is as follows: add the steamed cocoons into water, raise the temperature to 45°C, keep it warm for 1 minute, then raise the temperature to 100°C, keep it warm for 2 minutes, then lower the temperature to...

Embodiment 3

[0020] The difference between this example and Example 2 is that the silkworm production process is as follows: add the steamed cocoons into water, heat up to 45°C, keep warm for 2 minutes, then heat up to 99°C, keep warm for 3 minutes, then cool down to 70°C, keep warm 1min, and then put the cocoons into cold water, so that the temperature of the cocoons is lowered to below 20°C, and the silkworm making process is completed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com