Processing method for improving toughness of bar material

A processing method and rod technology, which is applied in the field of processing to improve the toughness of rods, can solve the problems that springs cannot be directly selected, and achieve the effects of easy acquisition, uniform and stable stiffness coefficient, and convenient processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will now be described in further detail with reference to the drawings. These drawings are all simplified schematic diagrams, which merely illustrate the basic structure of the present invention in a schematic manner, so they only show the structures related to the present invention.

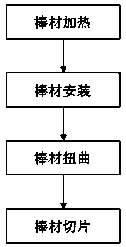

[0024] A processing method for improving the toughness of bars, including the following steps:

[0025] (1) Bar heating: Place the bar in a rotating roller in an electromagnetic induction heating furnace, and keep the rotating roller rotating at a predetermined speed. After the bar is heated to a preset temperature, the bar is heated by an infrared temperature control device The subsequent temperature is stable within the preset temperature floating range; so that the bar is heated uniformly and stably, and the bar can be kept within the preset temperature floating range before twisting, ensuring the stability and uniformity of the bar during twisting, thereby ensuring T...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Axial length | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com