Alkyl ketene dimer sizing agent as well as preparation method and application thereof

A technology of alkyl ketene dimer and sizing agent, which is applied in the direction of water-repellent addition, textile and papermaking, pigmented coating, etc. It can solve problems such as the need to improve the stability of emulsion droplet coalescence and fast curing speed , to achieve the effects of low emulsification cost, simple preparation process, and less emulsifier dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0026] The invention provides a kind of preparation method of alkyl ketene dimer sizing agent, comprises the following steps:

[0027] mixing the cellulose nanocrystal dispersion, magnesium aluminum hydroxide and alkyl ketene dimer, and performing first emulsification to obtain an emulsion;

[0028] The nanocellulose fiber is added into the emulsion for second emulsification to obtain the alkylketene dimer sizing agent.

[0029] In the present invention, unless otherwise specified, the required preparation materials are commercially available products well known to those skilled in the art.

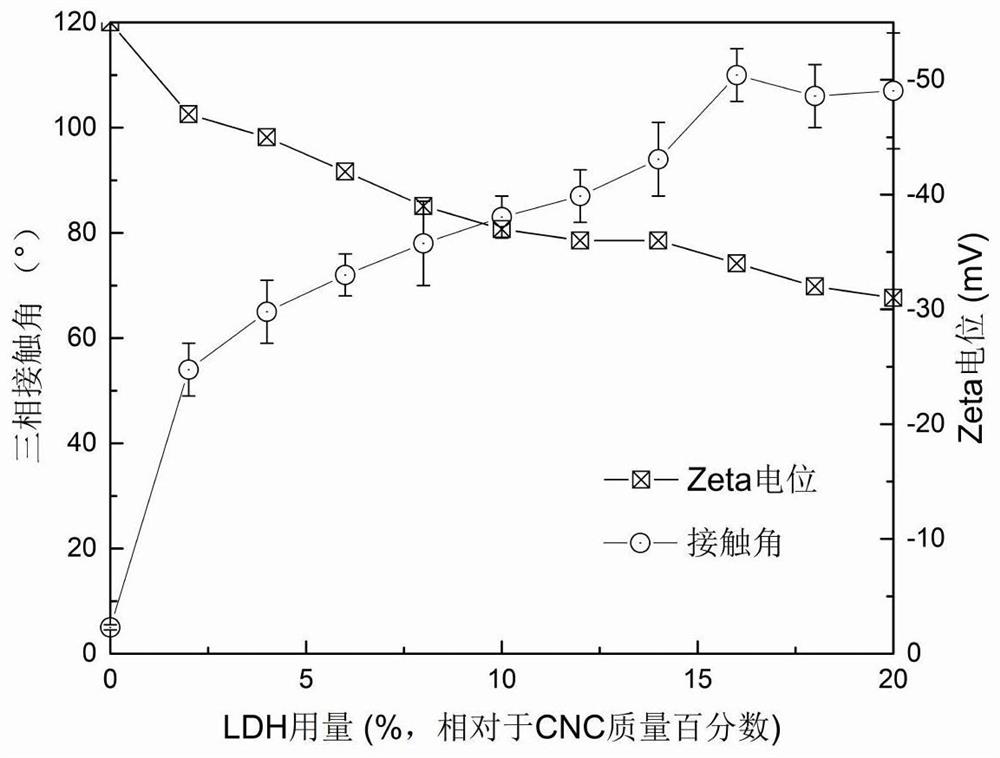

[0030] The invention mixes cellulose nano crystal dispersion liquid, magnesium aluminum hydroxide and alkyl ketene dimer, performs first emulsification, and obtains emulsion. In the present invention, the preparation method of the cellulose nanocrystal dispersion is preferably to disperse the cellulose nanocrystal (CNC) in deionized water to obtain the cellulose nanocrystal dispersion. ...

Embodiment 1

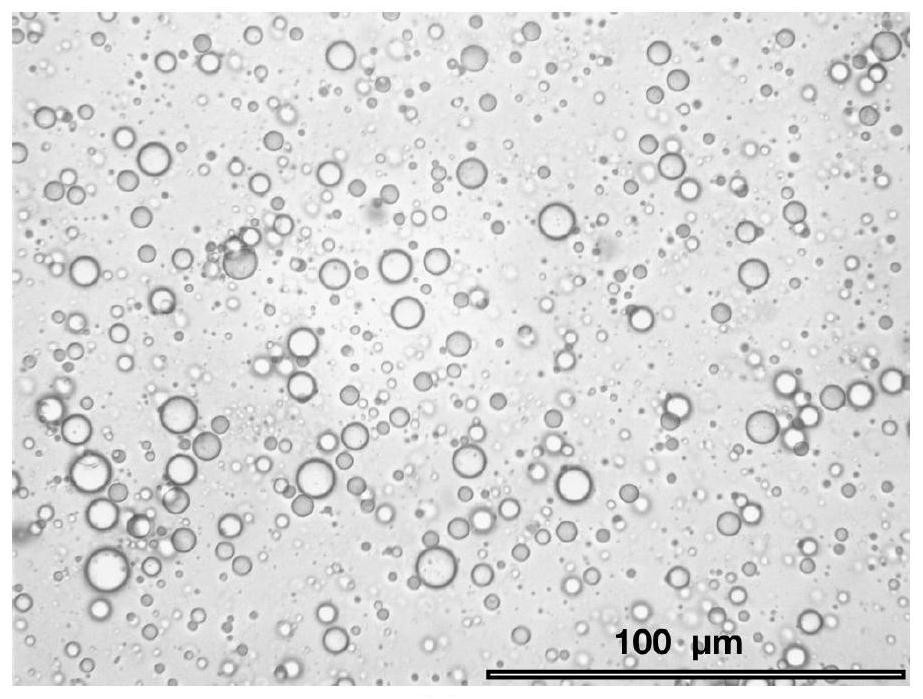

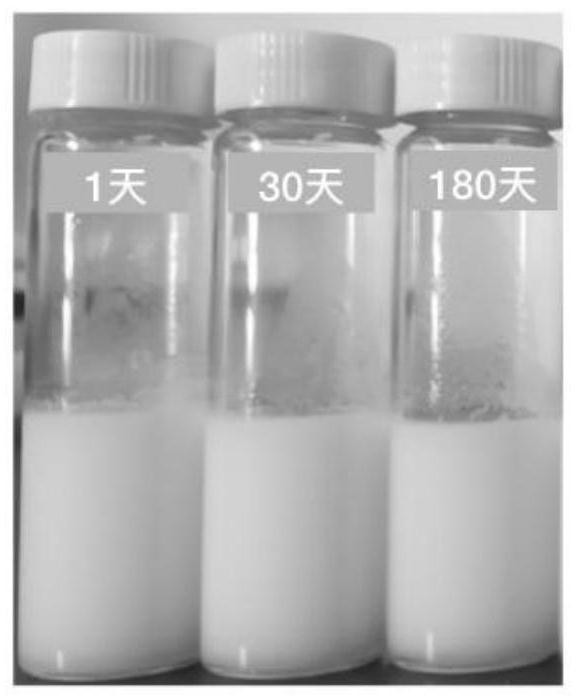

[0045] CNC (the CNC prepared by the hydrochloric acid method) is dispersed in deionized water with a high-speed shear disperser under the condition of 5000rpm, and it is prepared into a CNC aqueous solution with a mass fraction of 0.05%, and LDH is added to the CNC aqueous solution, and the mass ratio of LDH to CNC is 1:5, stirred at 1000rpm at room temperature for 10min to obtain CNC / LDH dispersion; then AKD (alkyl ketene dimer) was heated and melted at 80°C, and added to CNC according to the volume ratio of 1:100 In / LDH dispersion liquid, continue to carry out the first emulsification 3min under 5000r / min rotating speed with high-speed shear disperser, obtain emulsion (CNC / LDH emulsified stable emulsion), cool to room temperature, then add 0.1% ( Relative to the mass percentage of the CNC dispersion) of CNF, a high-speed shear disperser was used to carry out the second emulsification at 5000r / min and 75°C for 2min to obtain the AKD sizing agent (CNC / LDH / CNF emulsification-st...

Embodiment 2

[0053] Disperse CNC (CNC-S) in deionized water with a high-speed shear disperser at 10,000 rpm to prepare a CNC aqueous solution with a mass fraction of 0.2%. Add LDH to the CNC aqueous solution, and the mass ratio of LDH to CNC is 1 :10, stirred at 5000rpm at room temperature for 10min to obtain a CNC / LDH dispersion; then heated and melted AKD at 80°C, added it to the CNC / LDH dispersion at a volume ratio of 1:35, and continued to use high-speed shear The disperser carried out the first emulsification for 3min at a rotating speed of 10000r / min to obtain an emulsion (CNC / LDH emulsified stable emulsion), cooled to room temperature, and then added 0.5% CNF (relative to the mass percentage of the CNC dispersion liquid) in the resulting emulsion, Use a high-speed shear disperser to carry out the second emulsification for 2 minutes under the conditions of 10000r / min and 80°C to obtain an AKD sizing agent (CNC / LDH / CNF emulsification-stabilized Pickering type emulsion).

[0054] Perfo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com