Patents

Literature

38results about How to "Emulsification process is simple" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for preparing ASA paper-making sizing agent emulsion

InactiveCN101333789AReduce dosageEmulsification is cheapWater-repelling agents additionPolyelectrolyteHigh concentration

The invention relates to a process for preparing an emulsion of ASA paper sizing agent, comprising the following steps of: (1) mixing and then dispersing inorganic nano-particles with positive charges and inorganic nano-particles with negative charges to form a water phase; (2) mixing oily ASA with the water phase to form an oil-water mixture; and (3) cutting and emulsifying the mixture by a high-speed mixing device to obtain an ASA emulsion. Wherein, the oil-water mixture ratio is 1: 4 to 1:1, particles with negative charges and ASA are in a ratio of 1:30 to 1:5, and particles with positive charges and particles with negative charges are in a ratio of 1:150 to 1:7.5. The preparation process has advantages of simple emulsification process, having no need of surface active agent and complex polyelectrolyte particles for emulsifying the ASA into stable emulsion, low emulsifying agent consumption, low emulsification cost, and high concentration, good stability and high sizing efficiency of the prepared emulsion.

Owner:QILU UNIV OF TECH

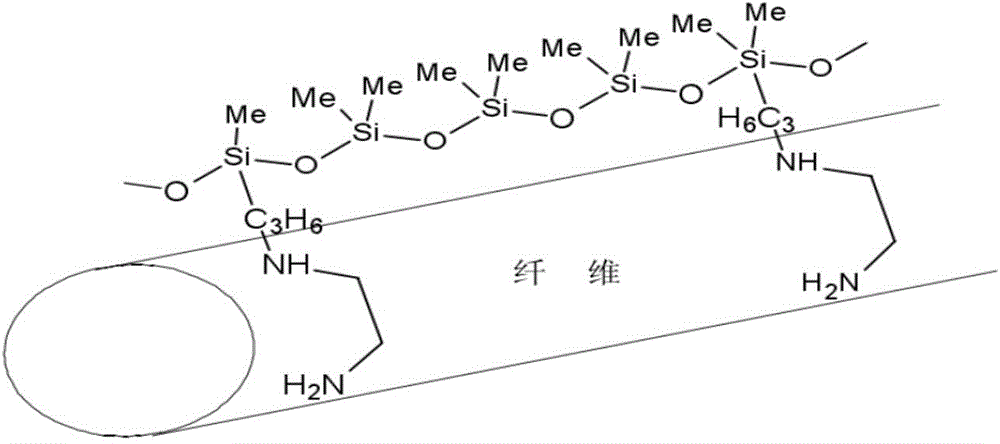

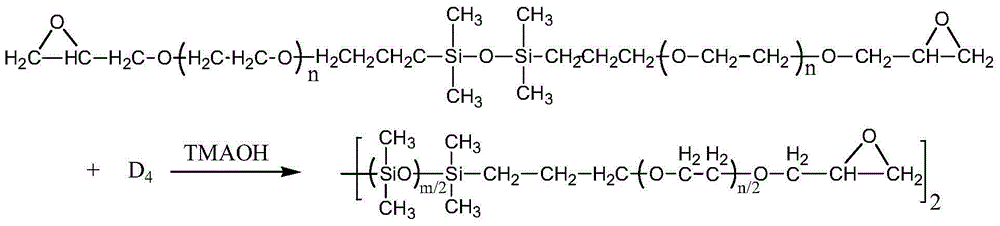

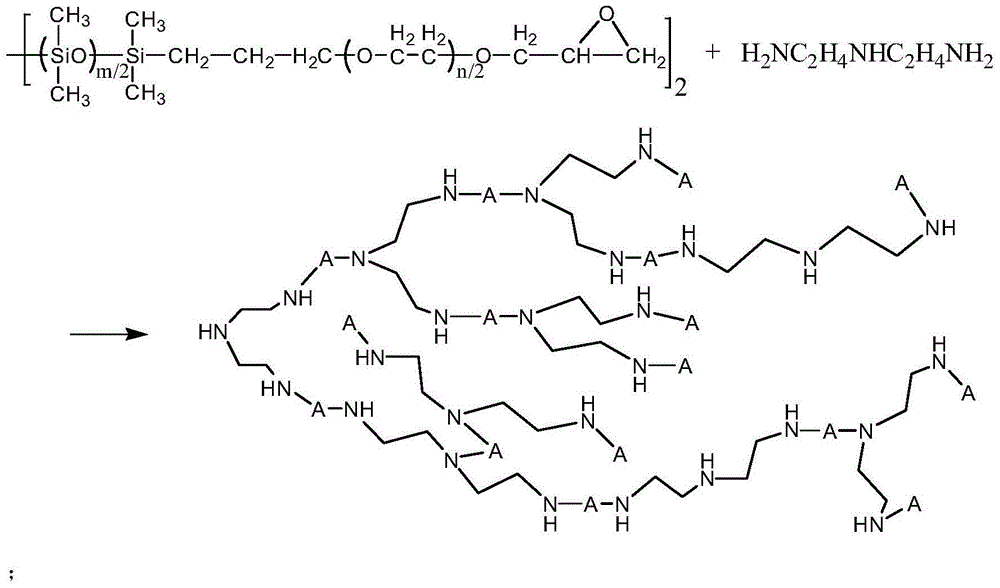

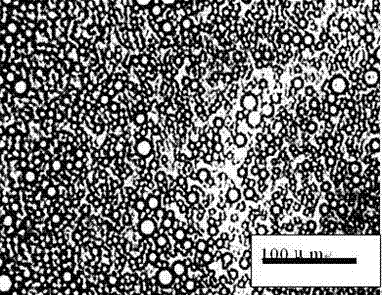

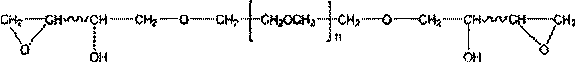

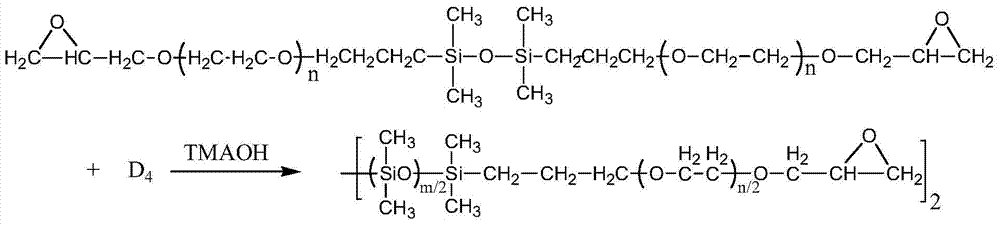

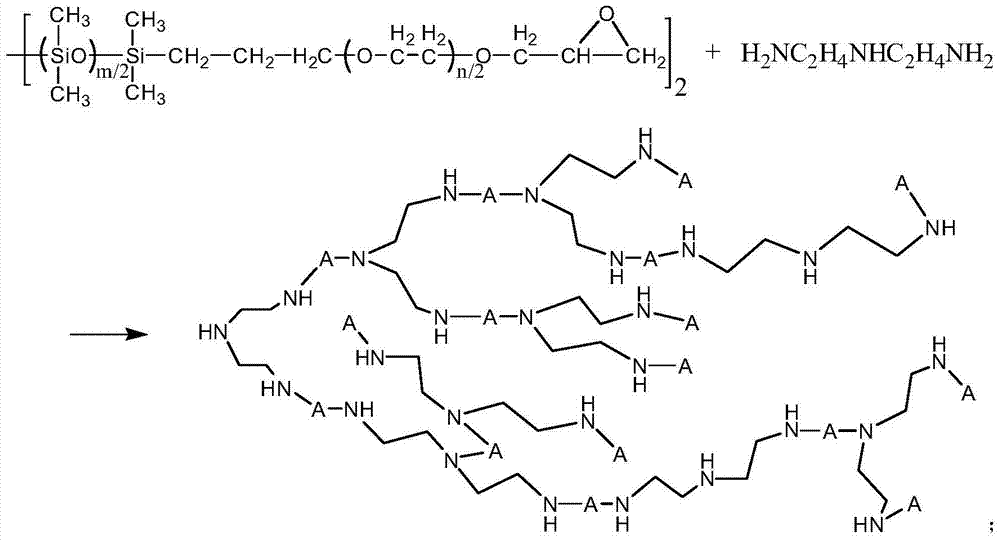

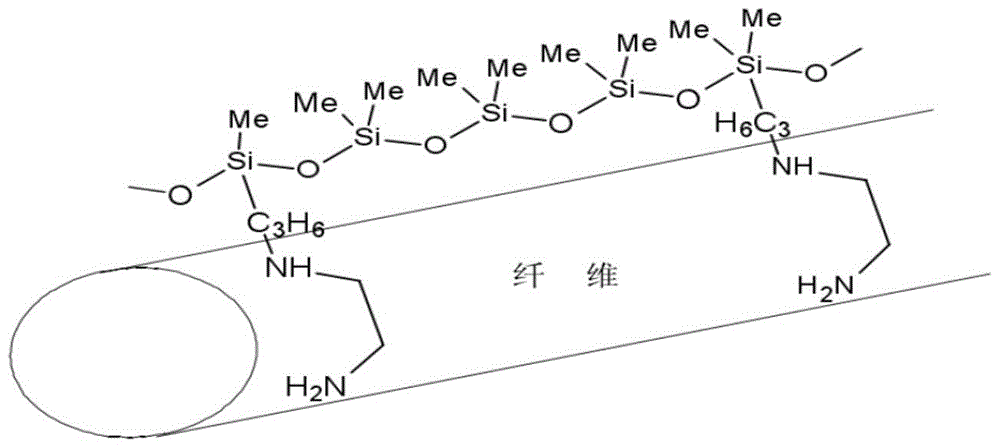

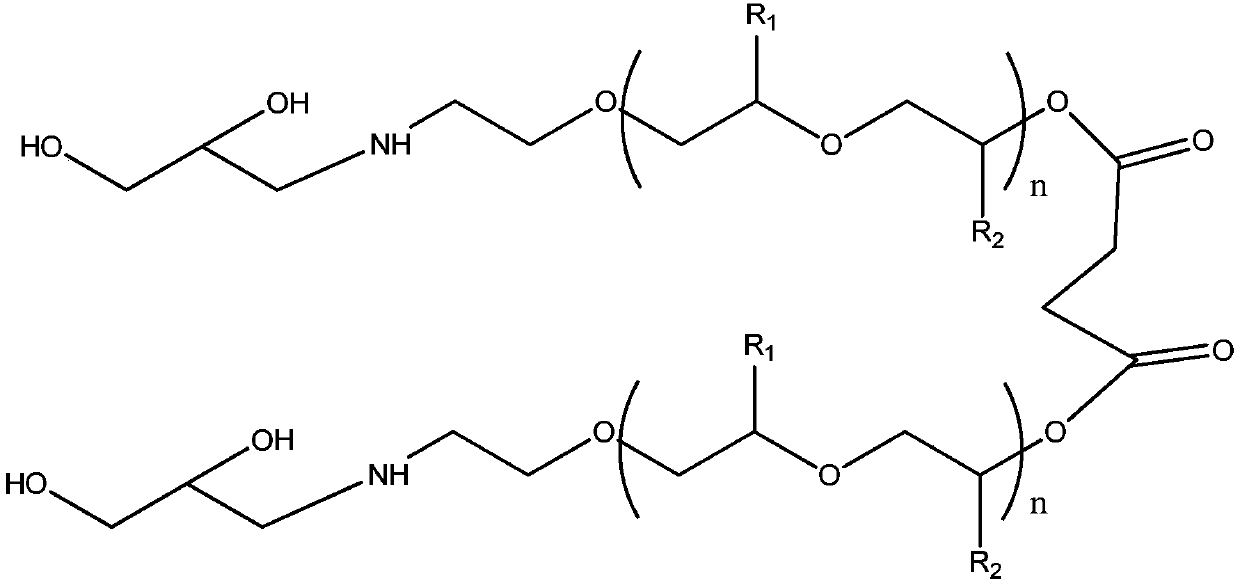

Preparation method of hyper-branched polyether amide block silicone

The invention discloses a preparation method of hyper-branched polyether amide block silicone. The preparation method comprises the following steps: preparing polyether / epoxy block silicone oil and preparing hyper-branched polyether amide block silicone. According to the preparation method, hyper-branched polymers and linear polyether amino block silicone are combined together to develop a new silicone softening agent with a newly modified silicone chemical structure; the synthesized hyper-branched material has a reticular structure which not only strengthens cohesive force between fibers, but also strengthens cohesive force between yarns; the invention is high in molecular weight, low in viscosity, rich in hydrophilic groups and capable of endowing soft, well-rounded and washable touch on fabrics; the problem of easy demulsification of traditional amino-modified silicone oil is solved; the product has self-emulsifying performance in water and is good in emulsion stability; the hyper-branched polyether amide block silicone is reduced in yellowing performance and enhanced in hydrophilicity; fabrics made accordingly has good hydrophilicity and low yellowing performance; and the hyper-branched polyether amide block silicone combines with the fabrics in a form of chemical bonds, so that the wash resistances is enhanced and the soft effect of amino silicone oil is achieved.

Owner:南通曙光染织有限公司

Preparation method of pickering emulsion type asa papermaking sizing agent

InactiveCN102268839AEmulsification process is simpleImprove stabilityWater-repelling agents additionMagnesium saltMicroparticle

The invention provides a method for preparing Pickering emulsion type alkenyl succinic anhydrides (ASA) papermaking sizing agent. The method comprises the following steps of: intercalating quaternary ammonium salt into nano cation-based modified montmorillonite to prepare nano solid fine grain emulsifier; dispersing the nano solid fine grain emulsifier and magnesium salt into deionized water to form a water phase, mixing the water phase and oil phase ASA, and emulsifying the mixture through high speed shearing to obtain the Pickering emulsion type ASA papermaking sizing agent, wherein the volume ratio of the oil phase to the water phase is (1:1)-(1:6). The Pickering emulsion type ASA papermaking sizing agent is coupled with the emulsion and stabilization characteristics of organic surfaceactive substances and inorganic solid fine grains; compared with the emulsion which is emulsified and stabilized by independently using the surface active substances, the Pickering emulsion type ASA papermaking sizing agent is more stable and higher in sizing efficiency; furthermore, the preparation process is simple, and the ASA can be emulsified into stable emulsion without adding any surfactant and high-molecule polyelectrolyte; and the using amount of the emulsifier is small and the emulsifying cost is low.

Owner:SOUTH CHINA UNIV OF TECH

Water-based epoxy emulsion type carbon fiber sizing agent and preparation method thereof

The invention relates to a water-based epoxy emulsion type carbon fiber sizing agent and a preparation method thereof. The water-based epoxy emulsion type carbon fiber sizing agent comprises the following components in percentage by weight: 15%-35% of epoxide resin, 5%-20% of surface active agent, 0.1%-0.5% of lubricating agent, 0.1%-0.5% defoaming agent and 55%-65% of deionized water. According to the water-based epoxy emulsion type carbon fiber sizing agent and the preparation method thereof, no volatile organic compound is added, so that the harm to production equipment and operators in preparation and application processes of the sizing agent is greatly reduced, and the environment protection is facilitated. The water-based epoxy emulsion type carbon fiber sizing agent and the preparation method thereof which are disclosed by the invention have the advantages of simple emulsifying process, safety in operation, low requirement on the production equipment, easiness for raw material obtaining, low price and suitability for large-scale production.

Owner:HENGSHEN

Method for preparing magnetism papermaking sizing agent stabilized by magnetism solid particle emulsification

InactiveCN103225234AEmulsification process is simpleMagnetically responsiveWater-repelling agents additionPaper/cardboardActive agentSolid particle

The invention discloses a method for preparing a magnetism papermaking sizing agent stabilized by magnetism solid particle emulsification. The method comprises the steps of adding magnetism nanometer solid particles in the particle diameter of 18nm to 50nm into deionized water, carrying out ultrasonic dispersion, adding absolute ethyl alcohol, then adding a silane coupling agent, stirring, standing the solution, cooling the solution to room temperature, obtaining magnetism nanometer solid particles modified by the silane coupling agent, then dispersing the magnetism nanometer solid particles into deionized water, mixing the solution with alkenyl succinic anhydride oil liquid, carrying out high-speed shearing emulsification, and obtaining the magnetism papermaking sizing agent stabilized by the magnetism solid particle emulsification. The magnetism papermaking sizing agent with the stable magnetism solid particle emulsification prepared by the method allows a paper sheet to have water resistance, meanwhile has magnetism, and is high in sizing efficiency, simple in preparation, capable of allowing alkenyl succinic anhydride to be emulsified into Pickering type emulsion with quite high stability without addition of any superficial active agent, little in emulsion emulsifier dosage, high in stability and low in foam, toxicity and cost.

Owner:SOUTH CHINA UNIV OF TECH

Preparation method of paper making sizing agent formed by emulsification of flaky solid particles

InactiveCN103194934AImprove stabilityEmulsification process is simpleWater-repelling agents additionParaffin waxIon

The invention discloses a preparation method of a paper making sizing agent formed by emulsification of flaky solid particles. The method comprises the following steps of: firstly, mixing a silane coupling agent with flaky nanometer bentonite solid particles and dispersing the mixture in deionized water; secondly, adding methylbenzene or absolute ethyl alcohol to prepare modified bentonite suspension liquid; thirdly, dispersing the flaky nanometer bentonite solid particles modified by the silane coupling agent into the deionized water, stirring uniformly, and regulating the pH value to 3.5-9.5; fourthly, mixing liquid paraffin with vinyl succinic anhydride and stirring uniformly to obtain mixed sizing oil liquid; and at last mixing the sizing oil liquid with the bentonite suspension liquid, wherein the paper making sizing agent with stably emulsified flaky solid particles is obtained after the mixture is emulsified. The paper making sizing gent has quite high stability, and the preparation method is simple, can be used for emulsifying the vinyl succinic anhydride into a stable emulsion without adding any surface active agent or high-molecular polyelectrolyte, also uses little emulsifying agent, is low in emulsification cost, and causes low pollution to the environment.

Owner:SOUTH CHINA UNIV OF TECH

Method for preparing EPT rubber graft by emulsion method

ActiveCN101348545APolymerization process is stableEmulsification process is simpleEmulsionContinuous production

The invention relates to a method for synthesizing a styrene-ethylene propylene terpolymer-acrylonitrile graft through an emulsion polymerization method. The obtained styrene- ethylene propylene terpolymer-acrylonitrile graft can be used for preparing a styrene- ethylene propylene terpolymer-acrylonitrile graft resin through mixing with SAN. Because of the simple emulsification process and the high grafting efficiency, the method can save production cost and is characterized by continuous production.

Owner:PETROCHINA CO LTD

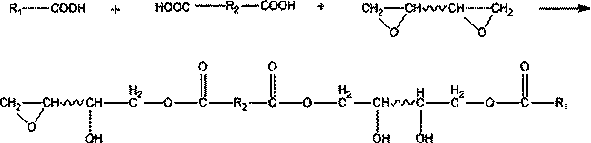

Preparation method of binary acid chain extension modified epoxy resin

The invention relates to the field of high molecular materials, and specifically relates to a preparation method of binary acid chain extension modified epoxy resin. The preparation method comprises the following steps: adding epoxy resin and dihydric alcohol into a reactor, enabling the molar ratio of epoxy resin to poly dihydric alcohol to be (2: 1) to (10: 1), heating and stirring, so that themixture is dispersed uniformly, using a hydrochloric acid-acetone method to measure an initial epoxy number, then adding a catalyst, raising the temperature until 110 to 175 DEG C, reacting for 2 to 3h, using the hydrochloric acid-acetone method to measure an epoxy number remaining after the reaction to reach an expected epoxy number, then adding mixed acid compounded with monobasic acid and binary acid into the product, raising the temperature, stirring and mixing uniformly, enabling the molar ratio of monobasic acid to binary acid is (1: 1) to (1: 5), then adding an accelerant, reacting for3 to 5 h at the temperature of 110 to 150 DEG C, and finally obtaining the product being binary acid chain extension modified epoxy resin. The preparation method solves the problem that an existing carbon fiber sizing agent is complex in emulsification technology, unstable in emulsion storage, low in strand bundling after sizing, hardened in strands, low in adhesiveness with matrix resin and thelike.

Owner:WEIHAI TUOZHAN FIBER

Method for preparing ethylene-propylene rubber-styrene-acrylonitrile terpolymer

InactiveCN101735399AEmulsification process is simpleImprove grafting efficiencyAcrylonitrilePotassium

The invention provides a method for preparing an ethylene-propylene rubber-styrene-acrylonitrile terpolymer and belongs to the field of macromolecular chemistry. The method comprises the following steps of: adding an emulsifier consisting of disproportionated rosin and potassium hydroxide into normal hexane solution of ethylene propylene terpolymer, wherein the dosage of the emulsifier is 3.5 to 4.5 percent based on the mass of the normal hexane solution of ethylene propylene terpolymer, and the dosage of the potassium hydroxide is half the mass of the disproportionated rosin; stirring the mixed solution by a stirrer, wherein the stirring speed is 6,000 and 16,000rpm; and at the temperature of 60 and 70 DEG C, and under an action of an initiator and the protection of nitrogen gas, and adding styrene-acrylonitrile monomers for polymerization for 10 to 12 hours, wherein the mass ratio of the styrene monomers to the acrylonitrile monomers is 3:1, the initiator is potassium persulphate, the dosage of the potassium persulphate is 0.6 to 1.5 percent based on the mass of the monomers, and in the polymerization process, the dosage of the distilled water is 100 to 200 percent of the mass of the normal hexane solution of ethylene propylene terpolymer. The method has the advantages of simple emulsifying process, high grafting efficiency, low production cost and the realization of continuous production.

Owner:BEIJING UNIV OF TECH

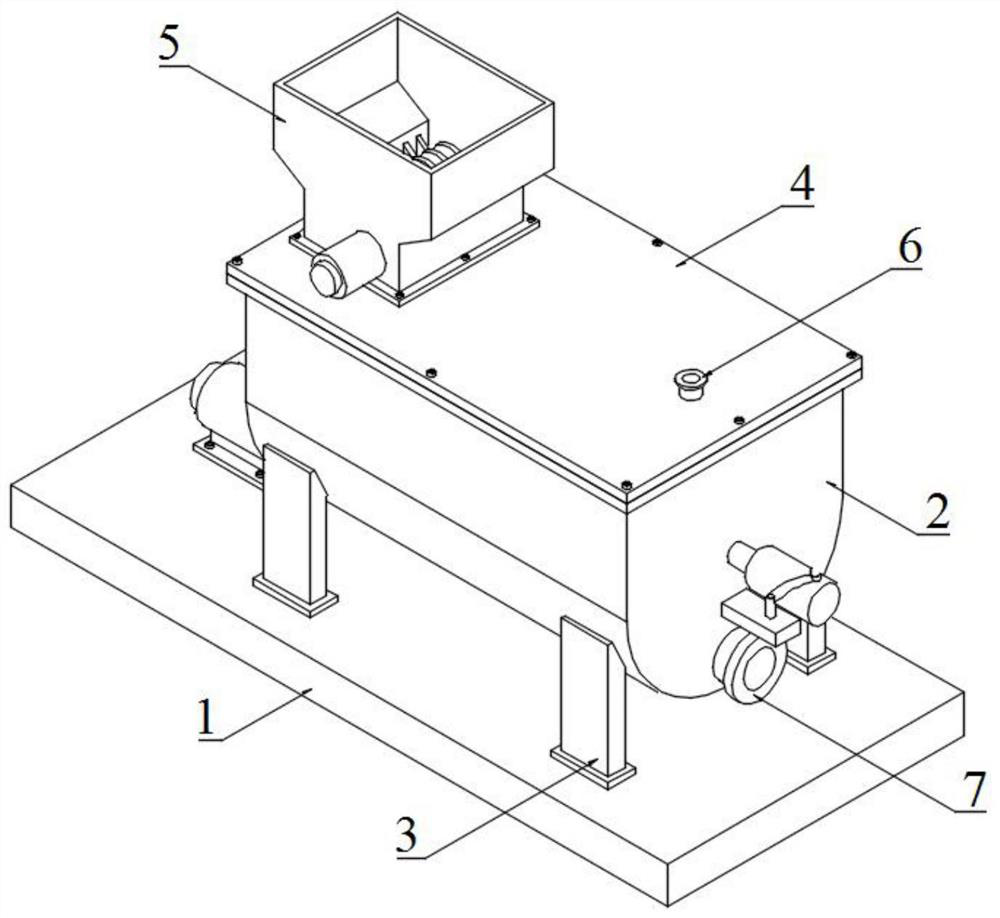

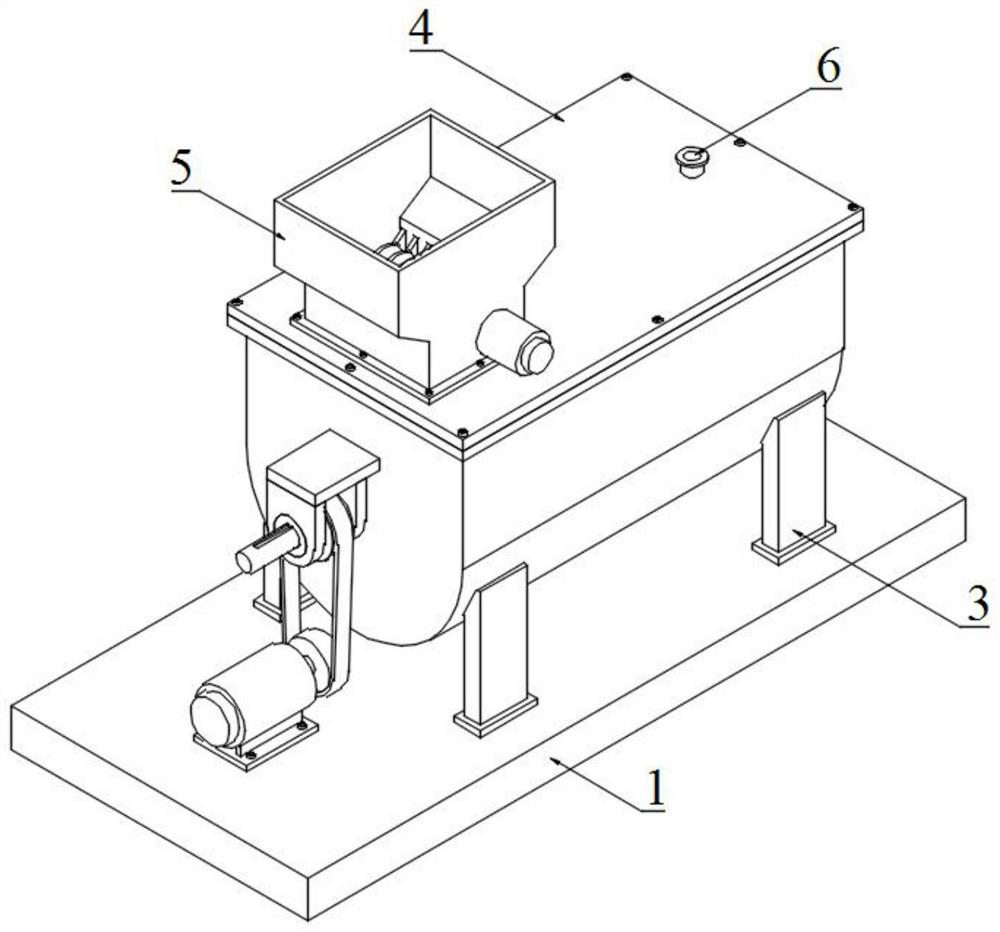

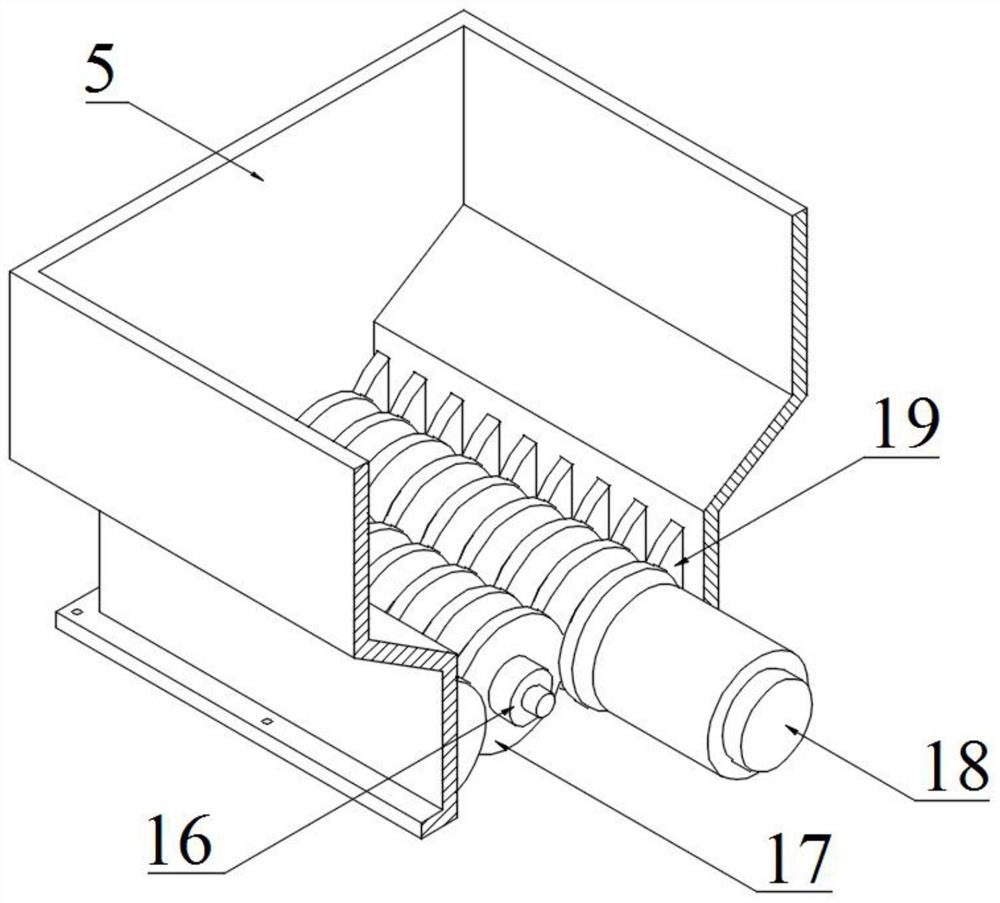

Moisture-proof and corrosion-proof corrugated paper production process and device

InactiveCN112813728AHigh strengthImprove water resistanceWater-repelling agents additionNon-macromolecular organic additionCardboardFiber

The invention discloses a moisture-proof and corrosion-proof corrugated paper production process and device, the moisture-proof and corrosion-proof corrugated paper is formed by bonding at least one layer of core paper and cardboard paper, the core paper is made of corrugated base paper through machining, the corrugated base paper is divided into a surface layer and a bottom layer, the surface layer is made of long fiber pulp, short fiber pulp and broken pulp of waste paper pulp, the bottom layer is made of short fiber pulp and waste paper pulp of waste paper pulp, and the preparation method of the corrugated base paper comprises the following steps: S1, pulping waste paper; s2, performing internal sizing treatment on the raw material slurry; s3, performing net feeding, squeezing and drying treatment on the raw material paper pulp, and then obtaining a base paper blank; and S4, sizing the surface of the base paper blank, and drying to obtain the corrugated base paper. According to the moisture-proof and corrosion-proof corrugated paper, the corrugated base paper of the moisture-proof and corrosion-proof corrugated paper is prepared from the waste paper pulp through a dual sizing process, and then the core paper machined from the corrugated base paper is bonded with the cardboard paper so that the prepared moisture-proof and corrosion-proof corrugated paper is high in machine strength and has good water resistance and corrosion resistance.

Owner:ANHUI UNIV OF SCI & TECH

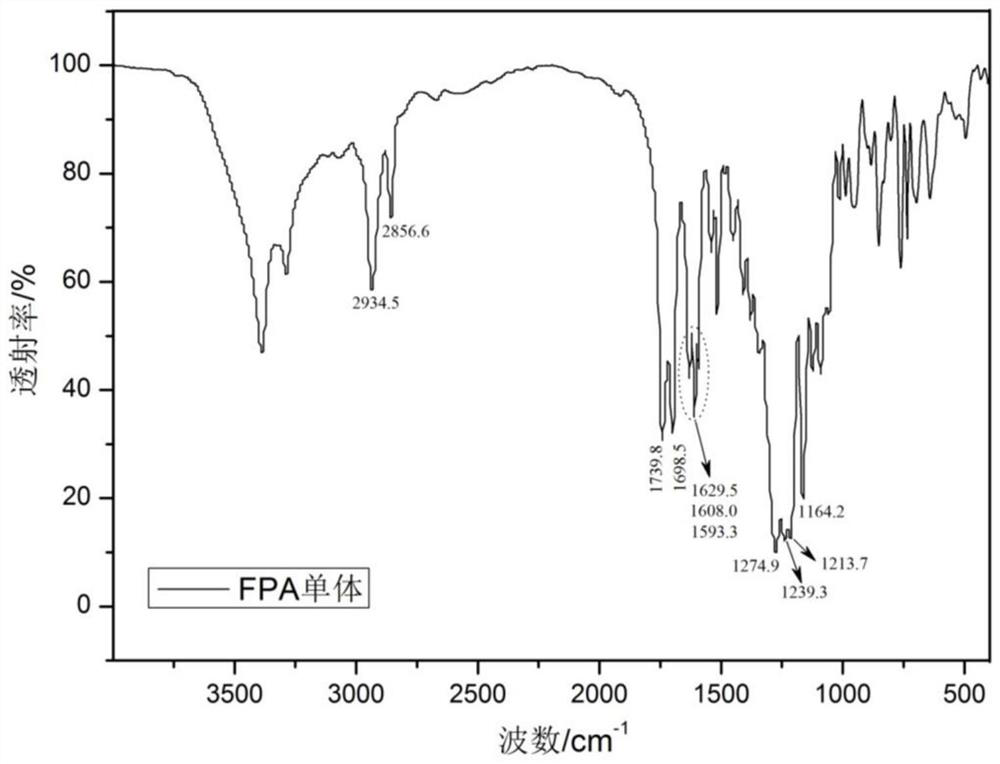

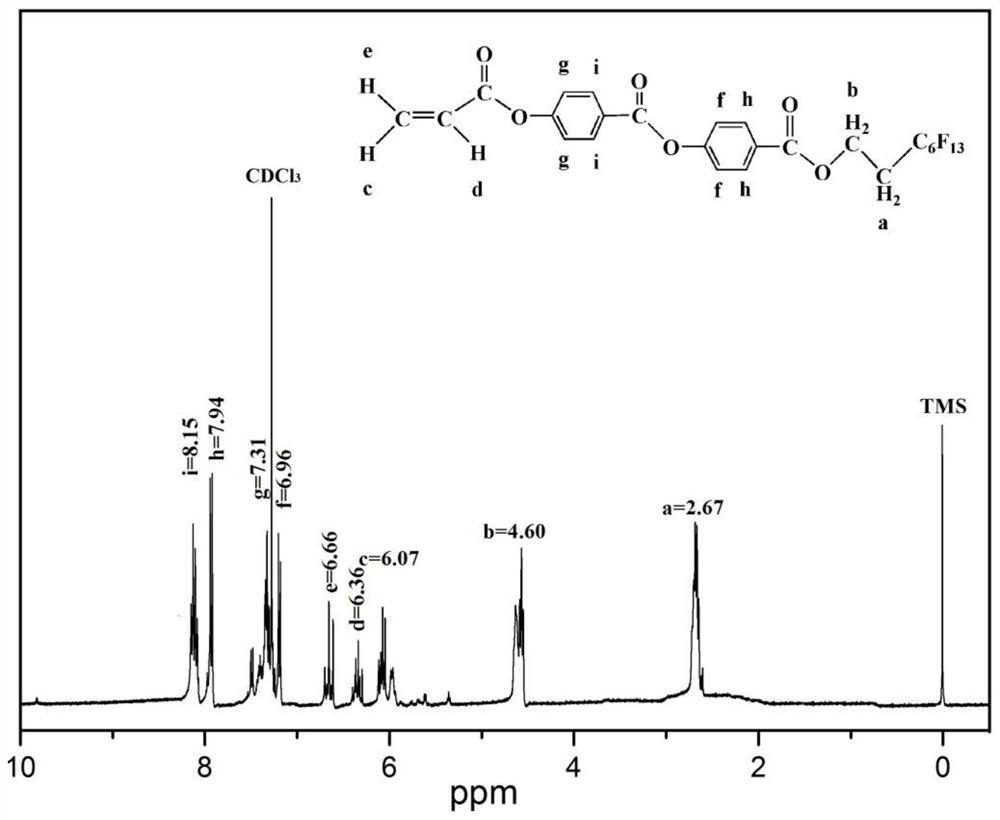

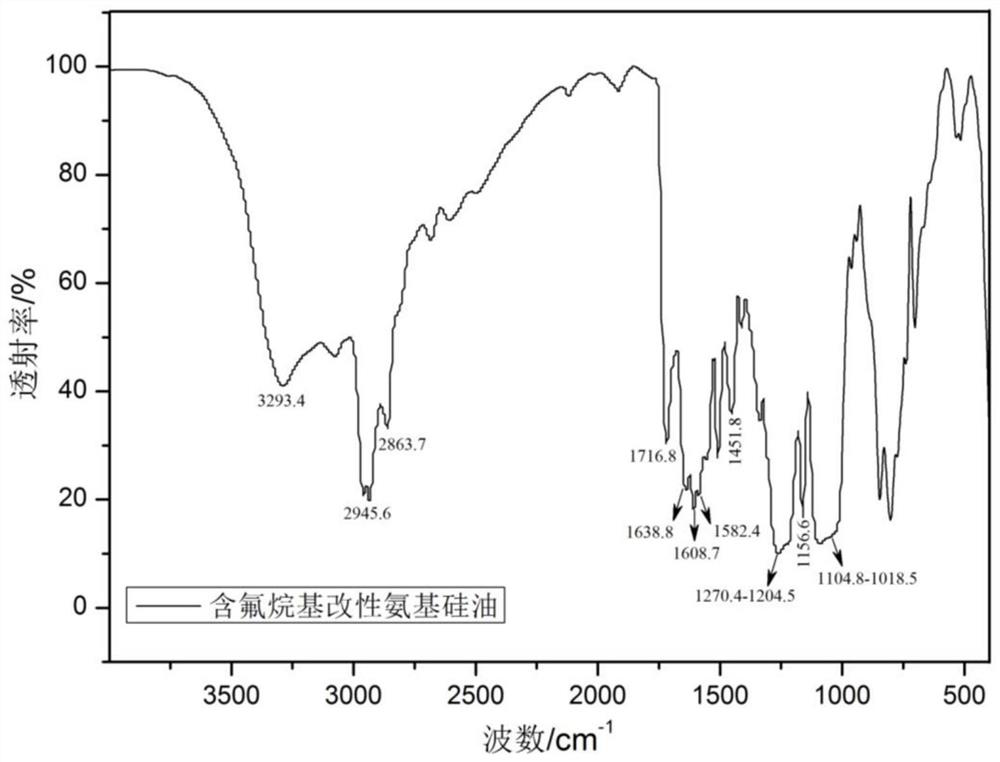

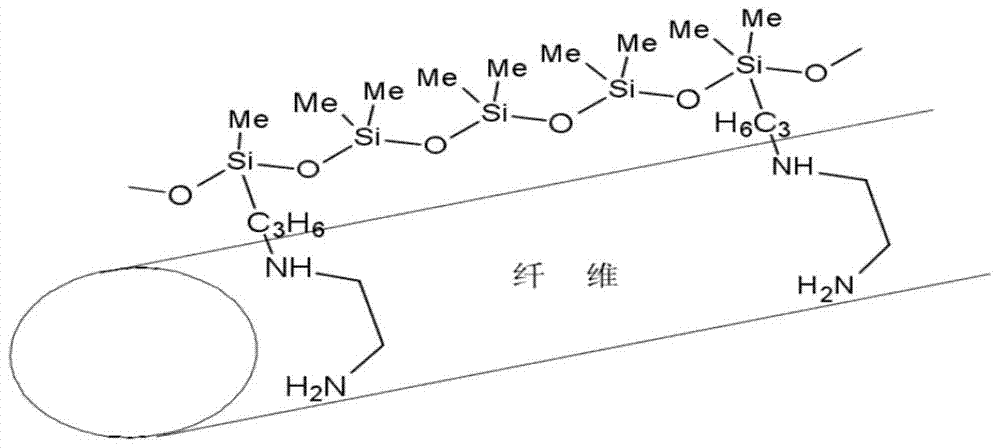

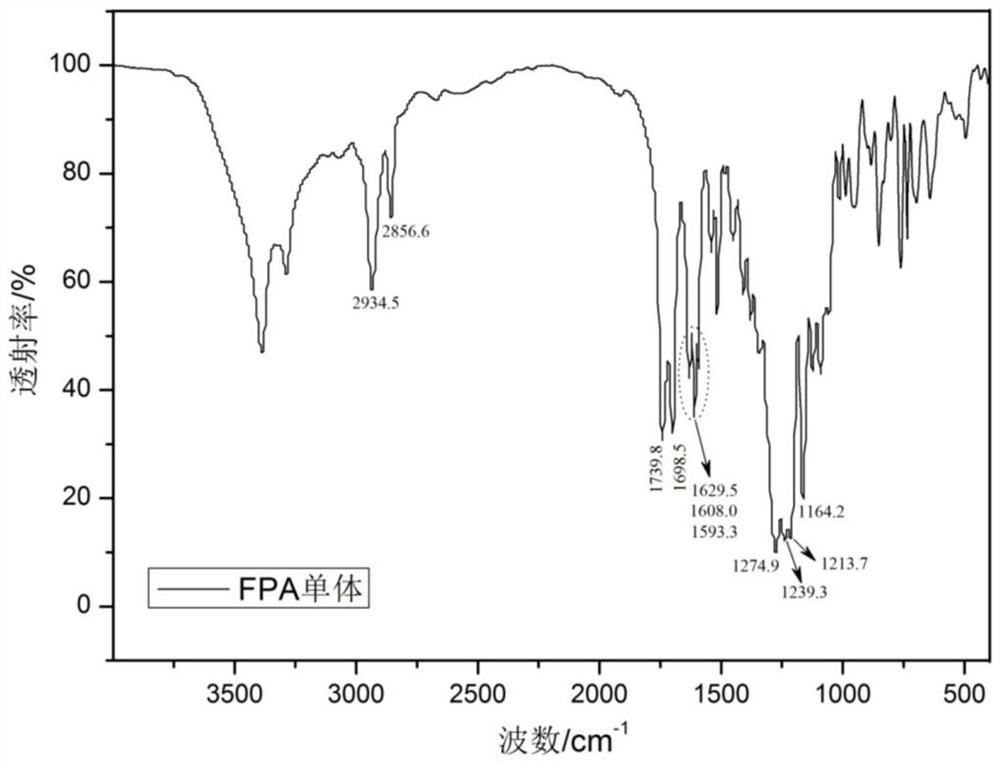

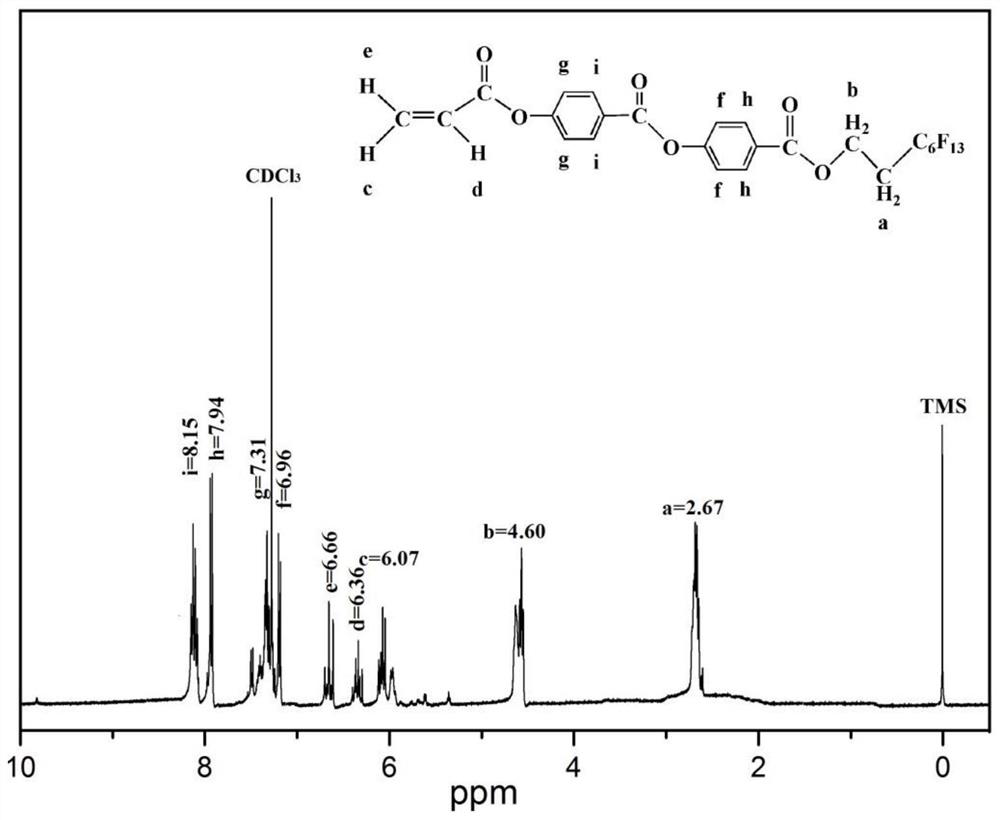

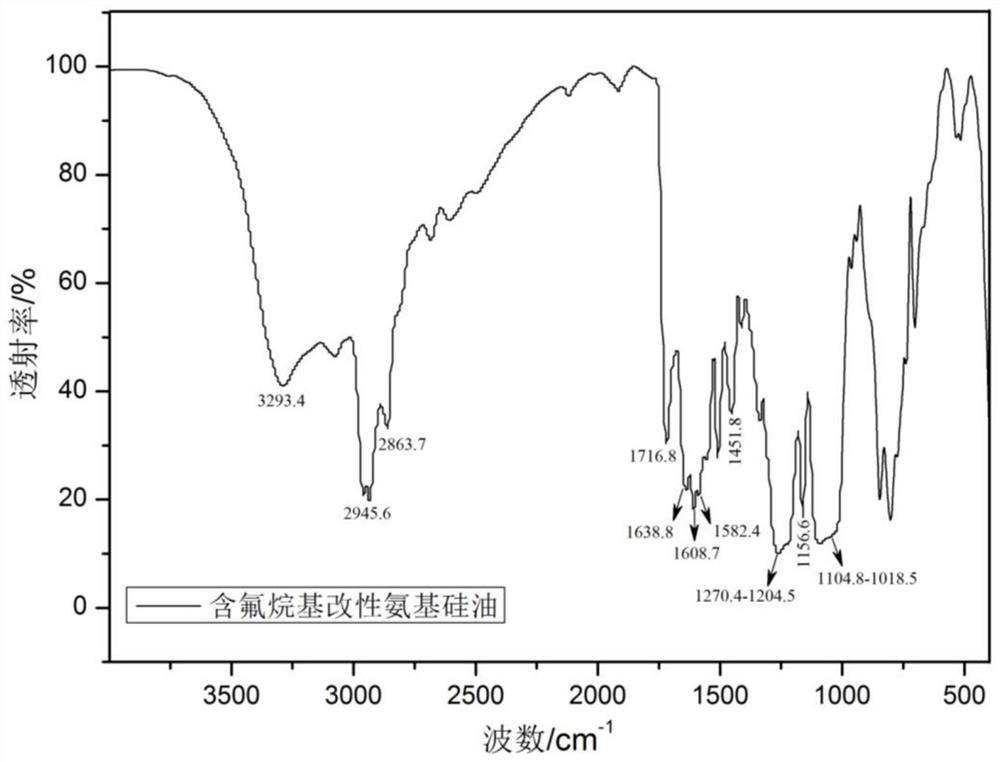

Preparation method of fabric waterproof deepening finishing agent and product prepared by preparation method

ActiveCN111877021ASignificantly effective shielding effectExcellent waterproof effectLiquid repellent fibresVegetal fibresBenzoic acidPolymer science

The invention discloses a preparation method of a fabric waterproof deepening finishing agent and a product prepared by the preparation method. The preparation method comprises the following steps ofpreparing p-acryloyloxybenzoic acid; preparing tridecafluorooctyl p-hydroxybenzoate; preparing 2-(perfluorohexyl)ethyl-4-[4-(acryloyloxy)-benzoyloxy]benzoate; preparing fluorine-containing alkyl modified amino silicon oil; and preparing the fluorine-containing alkyl modified amino silicone oil emulsion. In the molecular structure of the fabric waterproof deepening finishing agent, 2-(perfluorohexyl)ethyl-4-[4-(acryloyloxy)-benzoyloxy]benzoate is used as a fluorine-containing functional monomer, two rigid benzene rings are connected through an ester group, and an environment-friendly short fluorocarbon chain is bonded to an amino silicon oil molecule by using the 2-(perfluorohexyl)ethyl-4-[4-(acryloyloxy)-benzoyloxy]benzoate as a linking group. The liquid crystal effect of the biphenyl group is utilized to promote the short fluorocarbon chain to be outwards perpendicular to the surface of a matrix for regular arrangement, and a more remarkable and effective fluoroalkyl shielding effectis provided, so that an excellent waterproof deepening effect is brought.

Owner:YANCHENG INST OF TECH

Papermaking surface sizing agent emulsified by magnetic composite particles and preparation method thereof

InactiveCN104153244AEmulsification process is simpleSlow hydrolysisWater-repelling agents additionPapermakingSolid particle

The invention belongs to the technical field of papermaking, and discloses a papermaking surface sizing agent emulsified by magnetic composite particles and a preparation method thereof. The preparation method disclosed by the invention comprises the following steps: (1), dispersing ferroferric oxide nano solid particles wrapped by silicon dioxide in water, uniformly stirring to obtain suspension, and adjusting the pH value of the suspension, thereby obtaining the suspension of the magnetic composite particles; (2), adding alkyl ketene dimer into a reaction kettle, adding polyvinyl alcohol again, heating till the additives become liquid, and stirring with heat preservation, thereby obtaining sizing oil and liquid of the modified alkyl ketene dimer; and (3), heating the suspension of the magnetic composite particles by water bathing, adding the sizing oil and liquid of the modified alkyl ketene dimer, mixing, and emulsifying with heat preservation, thereby obtaining the papermaking surface sizing agent emulsified by the magnetic composite particles. The papermaking surface sizing agent disclosed by the invention is steady in emulsion and high in sizing efficiency and can endow paper with the water-resisting property and the magnetism; a surface active agent is unnecessary to add in the method; the use amount of an emulsifier is low; the method disclosed by the invention is low in cost and pollution and short in maturing time.

Owner:SOUTH CHINA UNIV OF TECH

Method for preparing ASA paper-making sizing agent emulsion

InactiveCN101333789BReduce dosageEmulsification is cheapWater-repelling agents additionPolyelectrolyteHigh concentration

The present invention relates to a process for preparing an emulsion of ASA paper sizing agent, comprising the following steps of: (1) mixing and then dispersing inorganic nano-particles with positive charges and inorganic nano-particles with negative charges to form a water phase; (2) mixing oily ASA with the water phase to form an oil-water mixture; and (3) cutting and emulsifying the mixture by a high-speed mixing device to obtain an ASA emulsion. Wherein, the oil-water mixture ratio is 1: 4 to 1:1, particles with negative charges and ASA are in a ratio of 1:30 to 1:5, and particles with positive charges and particles with negative charges are in a ratio of 1:150 to 1:7.5. The preparation process has advantages of simple emulsification process, having no need of surface active agent and complex polyelectrolyte particles for emulsifying the ASA into stable emulsion, low emulsifying agent consumption, low emulsification cost, and high concentration, good stability and high sizing efficiency of the prepared emulsion.

Owner:QILU UNIV OF TECH

Alkenyl succinic anhydride sizing agent emulsion and preparation method thereof

InactiveCN102493277AAchieve recyclingSolve pollutionWater-repelling agents additionPaper/cardboardPolymer scienceEmulsion

Owner:QILU UNIV OF TECH

A kind of preparation method of hyperbranched polyether amino block silicone

The invention discloses a preparation method of hyper-branched polyether amide block silicone. The preparation method comprises the following steps: preparing polyether / epoxy block silicone oil and preparing hyper-branched polyether amide block silicone. According to the preparation method, hyper-branched polymers and linear polyether amino block silicone are combined together to develop a new silicone softening agent with a newly modified silicone chemical structure; the synthesized hyper-branched material has a reticular structure which not only strengthens cohesive force between fibers, but also strengthens cohesive force between yarns; the invention is high in molecular weight, low in viscosity, rich in hydrophilic groups and capable of endowing soft, well-rounded and washable touch on fabrics; the problem of easy demulsification of traditional amino-modified silicone oil is solved; the product has self-emulsifying performance in water and is good in emulsion stability; the hyper-branched polyether amide block silicone is reduced in yellowing performance and enhanced in hydrophilicity; fabrics made accordingly has good hydrophilicity and low yellowing performance; and the hyper-branched polyether amide block silicone combines with the fabrics in a form of chemical bonds, so that the wash resistances is enhanced and the soft effect of amino silicone oil is achieved.

Owner:南通曙光染织有限公司

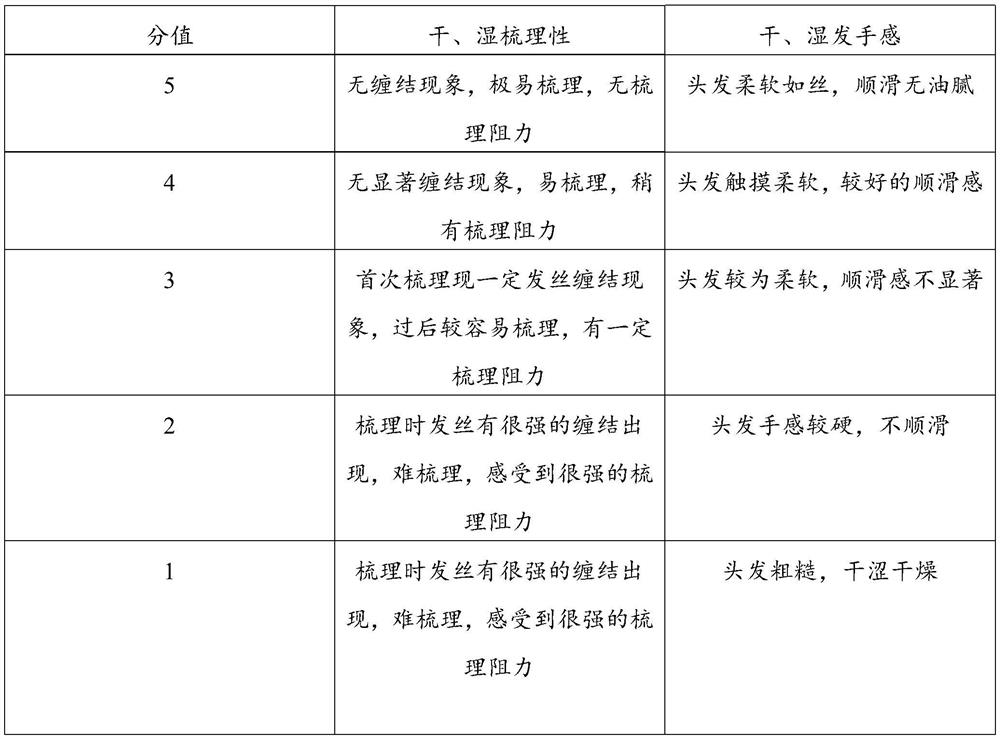

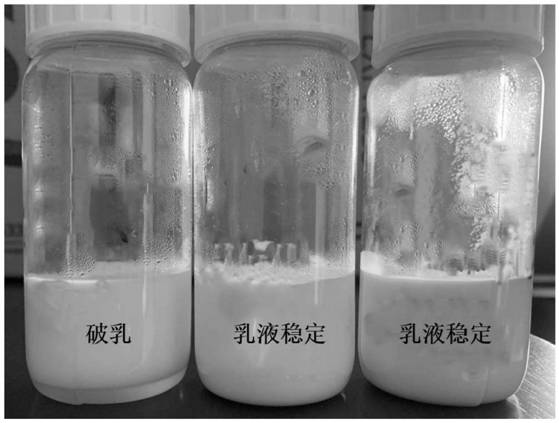

Amino silicone oil emulsion and preparation method thereof

ActiveCN113185710AEmulsification process is simpleEvenly dispersedCosmetic preparationsHair cosmeticsPolymer scienceOil emulsion

The invention discloses an amino silicone oil emulsion and a preparation method thereof. The emulsion with a bicontinuous phase structure between O / W and W / O is obtained by firstly mixing an emulsifier and a stabilizer amino silicon oil and then adding a co-emulsifier and water, the emulsification process is simple, and popularization and production are facilitated. The amino silicone oil emulsion obtained by the emulsification process has high stability, can be uniformly dispersed in a system when being applied to shampoo and hair conditioner products, and effectively maintains the smoothness and moist degree of hair.

Owner:广东赛安特新材料有限公司

Release agent for isocyanate adhesive and preparing method of release agent

ActiveCN105602467AAvoid bondingImprove stabilityNon-macromolecular adhesive additivesMacromolecular adhesive additivesEmulsionAdhesive

The invention discloses a release agent for an isocyanate adhesive. The release agent is prepared from, by weight, 8-10 parts of peregal O, 5-7 parts of sodium tripolyphosphate, 1-2 parts of sodium dodecyl benzene sulfonate, 800-1000 parts of water and 100-120 parts of higher aliphatic acid. According to the release agent, the emulsification process is simple, the stability of emulsion is good, the die release performance is superior, and adhesion of a board and a steel plate or a steel band is effectively prevented when the isocyanate adhesive is used for producing a shaving board or a medium-density fiberboard.

Owner:JIANGXI LYVFENG NEW MATERIAL CO LTD

Soft nanoparticle-stabilized silicone oil emulsion and preparation method thereof

The invention belongs to the technical field of textile assistants, and particularly relates to a silicone oil emulsion with stable soft nanoparticles. The product comprises the following components in parts by mass: 20-30 parts of amino silicon oil, 2-8 parts of an emulsifier, 3-32 parts of a soft nanoparticle emulsion, 0.8-1.5 parts of a pH regulator and 50-60 parts of deionized water. The invention further provides a specific preparation method. The problems that a traditional silicone oil emulsion is poor in stability and the textile finishing effect is poor are solved, the emulsion stability is excellent, the adhesiveness on fibers is good, the air permeability and softness of textiles can be effectively improved, and therefore the practicability and comfort of the textiles are improved; meanwhile, the product has the characteristics of low cost and simple process.

Owner:ZHEJIANG SCI TECH UNIV SHAOXING KEQIAO RES INST CO LTD +1

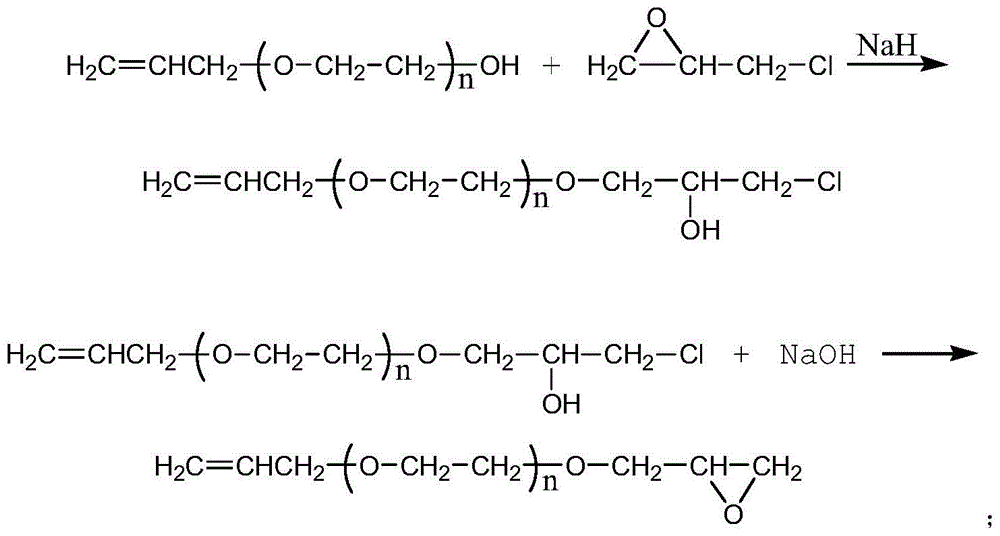

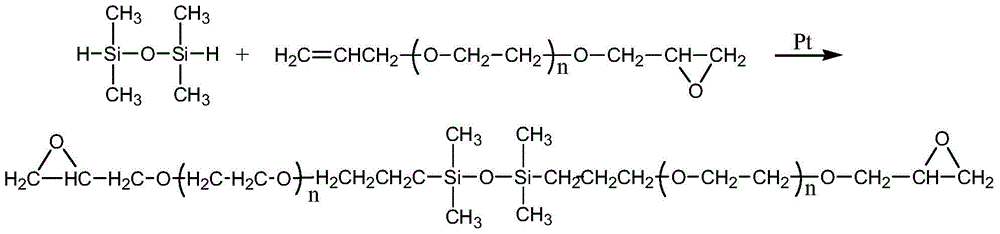

A kind of preparation method of hyperbranched ternary copolymerization organosilicon

The invention discloses a preparation method of hyperbranched ternary polymerization organic silicon. The preparation method comprises the following steps: preparing allyl polyoxyethylene glycidyl ether; preparing epoxy-terminated polyether block siloxane; preparing polyether / epoxy block silicone oil; preparing hyperbranched ternary polymerization organic silicon. According to the preparation method, a hyperbranched polymer and linear polyether amino block organic silicon are bonded together to research a novel organic silicon softener with a novel modified organic silicon chemical structure, and a synthesized hyperbranched matter is capable of enhancing the cohesive force among fibers and endowing a fabric with soft, plump and washable hand feel, high in molecular mass and low in viscosity and has much hydrophilic groups; the problem that emulsion of traditional amino modified silicon oil is easily broken is solved, the product has self-emulsifying property in water and is good in emulsion stability; the yellowing property is reduced, and the hydrophily is enhanced; a processed fabric is good in hydrophily and low in yellowing property and is bonded with fabric by virtue of chemical bonds, so that the washability is improved, and the fabric has a flexible effect of amino silicon oil.

Owner:南通曙光染织有限公司

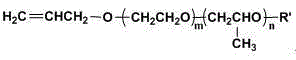

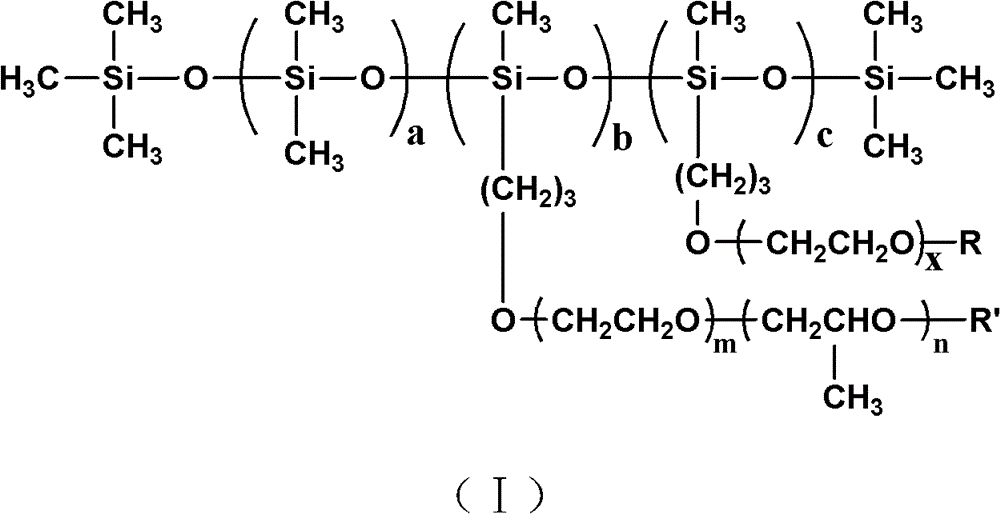

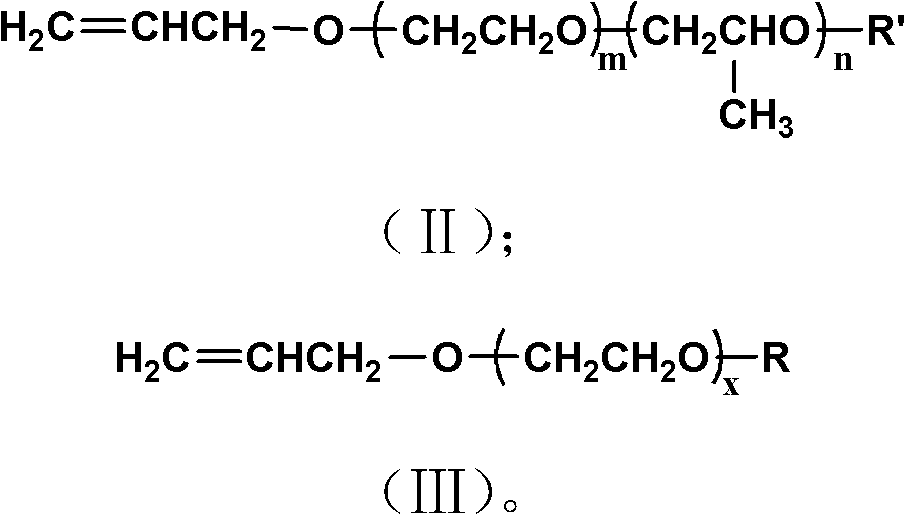

A kind of organosilicon surfactant and its preparation method and application

ActiveCN103182271BStrong emulsificationGood emulsificationSilicon organic compoundsTransportation and packagingEmulsionSilicone oil

Disclosed are a silicone surfactant, and a preparation method and the use thereof. The silicone surfactant has a structure as shown in formula (I), wherein c is not 0; a, b, c are all integers and 10< a + b + c < 200; m = 0-40; n = 0-30; x = 3-30; x,m,and n are all integers, and m and n are not both 0; R is a C6 - 20 linear or branched long-chain alkyl, or an alkyl phenyl; and R' is H, CH3, C2H5, C3H7, or C4H9. The silicone surfactant has a novel structure, and an excellent emulsifying ability. The silicone surfactant has a good emulsifying ability for polydimethyl siloxanes and a variety of modified polydimethyl siloxanes in a very wide viscosity range. A good emulsifying effect can be achieved using the surfactant alone without formulating with other emulsifiers, and the emulsifying process thereof is simple and convenient to use without needing any homogenizer or any other special emulsifying process, in order to obtain a stable O / W type silicone oil emulsion.

Owner:广州标美药用辅料有限公司

A papermaking surface sizing agent emulsified by magnetic composite particles and its preparation method

InactiveCN104153244BEmulsification process is simpleSlow hydrolysisWater-repelling agents additionWater bathsPolyvinyl alcohol

The invention belongs to the technical field of papermaking, and discloses a papermaking surface sizing agent emulsified by magnetic composite particles and a preparation method thereof. The preparation method is as follows: (1) dispersing ferric ferric oxide nanometer solid particles coated with silicon dioxide in In water, stir evenly to obtain a suspension, adjust the pH value of the suspension to obtain a suspension of magnetic complex particles; (2) Add the alkyl ketene dimer to the reaction kettle, then add polyvinyl alcohol, and heat up to make the additive into a liquid state, insulated and stirred to obtain the modified alkyl ketene dimer sizing oil; (3) heating the magnetic composite particle suspension in a water bath, then adding the modified alkyl ketene dimer sizing oil, After mixing, heat-preserve and emulsify to obtain the papermaking surface sizing agent emulsified by the magnetic composite particles. The paper-making surface sizing agent emulsion is stable, has high sizing efficiency, and can endow paper with water resistance and magnetism; the method does not need to add surfactants, uses less emulsifiers, is low in cost, low in pollution and short in curing time.

Owner:SOUTH CHINA UNIV OF TECH

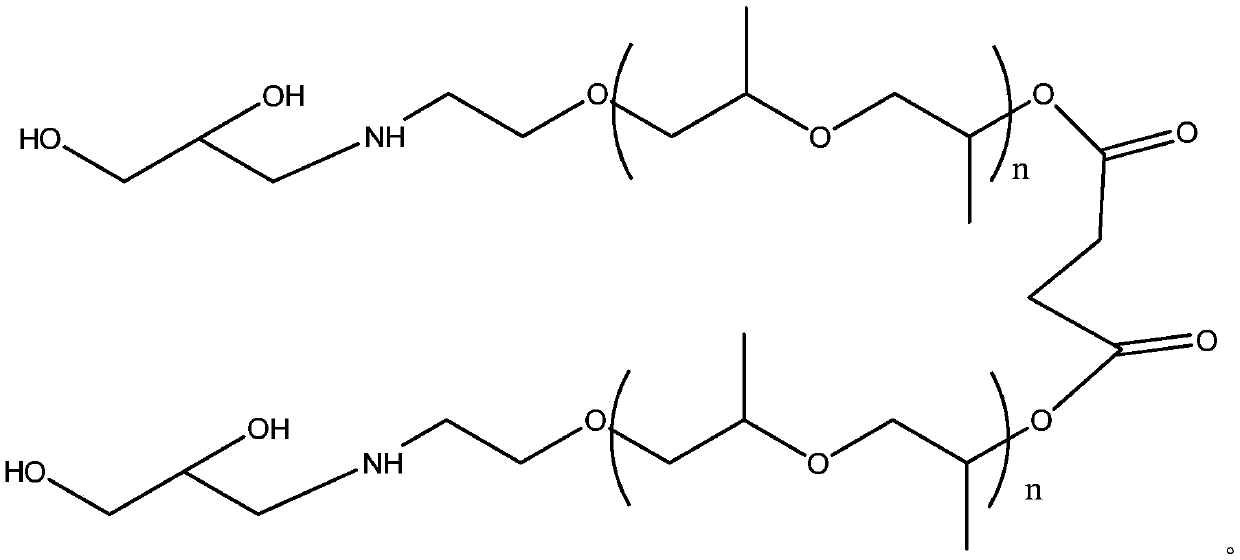

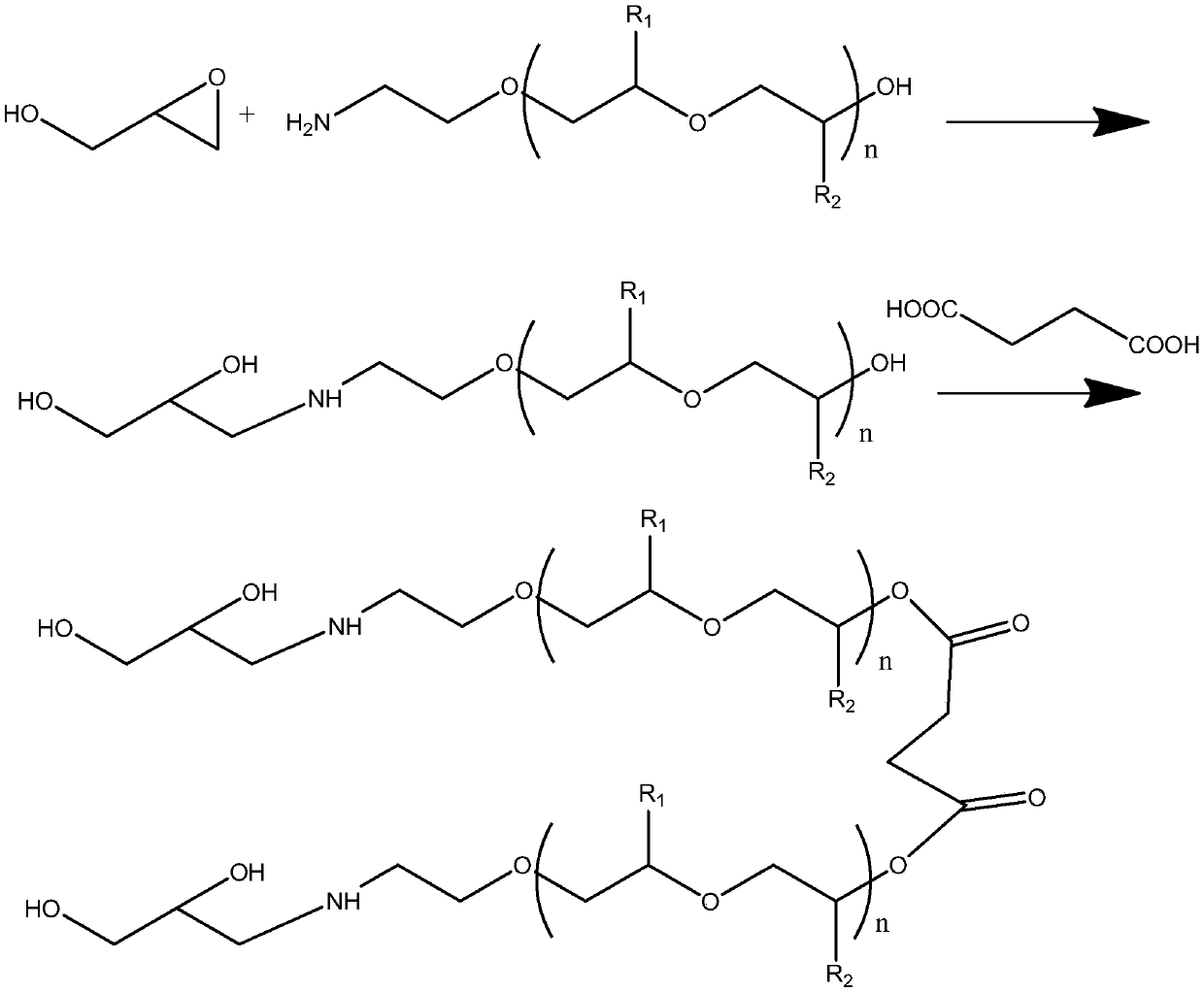

Emulsifier for low-solid-content waterborne epoxy resin coating and preparation method thereof

InactiveCN110917989APrevent demulsificationAvoid demulsificationTransportation and packagingMixingEpoxyPolymer science

An emulsifier for waterborne epoxy resin provided by the invention is at least prepared from the following components in parts by weight: 2 parts of polyether amine, 2-4 parts of epoxypropanol and 1-2parts of succinic acid. The invention further provides a preparation method of the emulsifier for waterborne epoxy resin. The emulsifier provided by the invention can prevent demulsification during direct pulping of epoxy emulsion, the emulsification process is simple, the emulsification time is short, and waterborne epoxy resin prepared by using the emulsifier is high in quality.

Owner:上海瀚岱化学有限公司

Method for preparing Pickering emulsion type alkenyl succinic anhydrides (ASA) papermaking sizing agent

InactiveCN102268839BEmulsification process is simpleImprove stabilityWater-repelling agents additionPolyelectrolyteQuaternary ammonium cation

The invention provides a method for preparing Pickering emulsion type alkenyl succinic anhydrides (ASA) papermaking sizing agent. The method comprises the following steps of: intercalating quaternary ammonium salt into nano cation-based modified montmorillonite to prepare nano solid fine grain emulsifier; dispersing the nano solid fine grain emulsifier and magnesium salt into deionized water to form a water phase, mixing the water phase and oil phase ASA, and emulsifying the mixture through high speed shearing to obtain the Pickering emulsion type ASA papermaking sizing agent, wherein the volume ratio of the oil phase to the water phase is (1:1)-(1:6). The Pickering emulsion type ASA papermaking sizing agent is coupled with the emulsion and stabilization characteristics of organic surfaceactive substances and inorganic solid fine grains; compared with the emulsion which is emulsified and stabilized by independently using the surface active substances, the Pickering emulsion type ASA papermaking sizing agent is more stable and higher in sizing efficiency; furthermore, the preparation process is simple, and the ASA can be emulsified into stable emulsion without adding any surfactant and high-molecule polyelectrolyte; and the using amount of the emulsifier is small and the emulsifying cost is low.

Owner:SOUTH CHINA UNIV OF TECH

Preparation method of solid particle emulsified and stabilized papermaking sizing agent

InactiveCN103233392BEmulsification process is simpleImprove emulsion stabilityWater-repelling agents additionWax additionParaffin waxOil phase

The invention discloses a preparation method of a solid particle emulsified and stabilized papermaking sizing agent. The method includes: dispersing nano-bentonite solid particles with a single particle diameter of 25nm-800nm in deionized water, and stirring them evenly to obtain a suspension solution; heating solid paraffin to a liquid oil phase, then mixing it with alkenyl succinic anhydride, and stirring them evenly at 65DEG C-90DEG C, thus obtaining a mixed sizing oil fluid; mixing the sizing oil fluid with the suspension solution according to a volume ratio of 1:7-3:1, and emulsifying the mixture so as to obtain a solid particle emulsified and stabilized papermaking sizing agent emulsion. The papermaking sizing agent emulsion has higher sizing efficiency. Also, the preparation process involved in the invention is simple, and the alkenyl succinic anhydride can be emulsified into a stable emulsion without adding any surfactant and high polymer polyelectrolyte. The emulsifying agent dosage is small, the emulsification cost is low, and environmental pollution is little.

Owner:SOUTH CHINA UNIV OF TECH

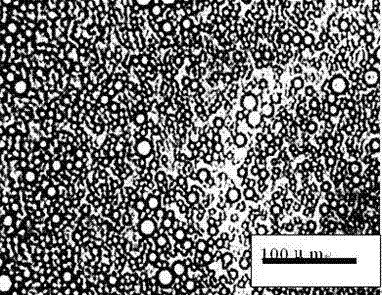

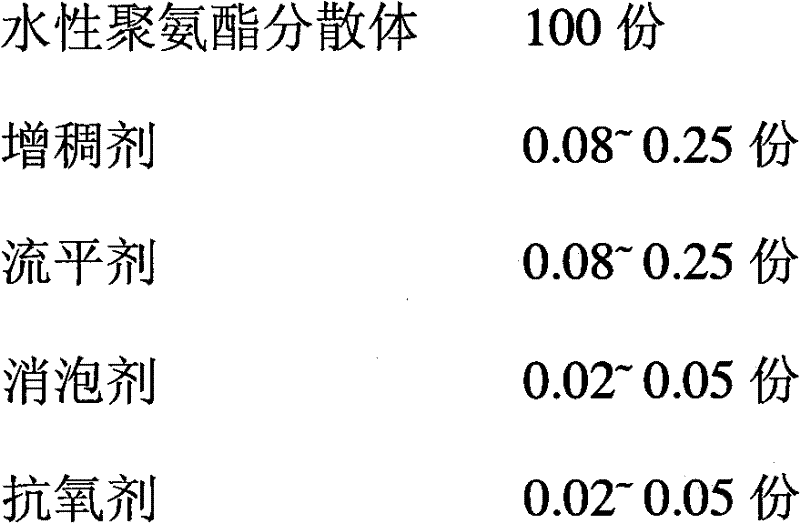

Aqueous polyurethane adhesive and preparation thereof

InactiveCN101348703BSmall molecular weightSolve process problemsFilm/foil adhesivesPolyureas/polyurethane adhesivesPolyurethane dispersionPolyurethane adhesive

The invention discloses a waterborne polyurethane adhesive which comprises the following compositions in mass portion: 100 portions of waterborne polyurethane dispersoid, 0.08 to 0.25 portion of thickener, 0.08 to 0.25 portion of flatting agent, 0.02 to 0.05 portion of antifoaming agent and 0.02 to 0.05 portion of antioxidant. The invention also discloses a method for preparing the adhesive. The preparation method is to drip multi-amine compound into the waterborne polyurethane dispersoid, to react for 15 to 30 minutes at a temperature of between 10 and 25 DEG C, to remove organic solvent in the waterborne polyurethane dispersoid, to add the thickener, the flatting agent, the antifoaming agent and the antioxidant again, to uniformly mix the materials, and then to obtain the waterborne polyurethane adhesive. The preparation method disclosed by the invention has a simple technology, and the waterborne polyurethane adhesive prepared has the characteristics of high solid content, quick drying speed, large bonding strength, large tensile strength, good elasticity, and superior water resistance, solvent resistance and high and low temperature resistance.

Owner:SUN YAT SEN UNIV

Preparation and application of new energy multifunctional emulsifier

PendingCN114231325AImprove stabilityExtended shelf lifeLiquid carbonaceous fuelsFuel additivesNitrogen oxidesCombustion

The invention discloses preparation and application of a new energy multifunctional emulsifier, and is characterized in that the multifunctional emulsifier is a compound type, and comprises a component A and a component B according to a weight ratio of 4: 6, the preparation method of the multifunctional emulsifier comprises the following steps: S1, respectively weighing the component A and the component B according to the weight part ratio; the new energy multifunctional emulsifier has the advantages that the emulsifying process is simple, the emulsifier is easy to prepare by professional equipment, emulsified oil produced by using the new energy multifunctional emulsifier is high in stability, resistant to high temperature, long in shelf life, green and environment-friendly, small in addition amount and sufficient in combustion, emission of smoke dust and harmful gas is greatly reduced, the smoke dust amount is reduced by 55%-90% or above, carbon emission is reduced by 20%-50% or above, and the new energy multifunctional emulsifier is suitable for industrial production. The nitrogen oxide is reduced by more than 25%, the sulfur oxide is reduced by more than 30%-55%, the oil saving rate reaches more than 5%-18%, the price is reduced by 400-800 yuan / ton, and a large amount of production cost is saved for oil supply units.

Owner:易信三农(沈阳)石化有限公司

Stable alkenyl succinic anhydride sizing emulsion for papermaking and preparation method thereof

InactiveCN102493276BHigh sizing efficiencyEmulsification process is simpleWater-repelling agents additionInorganic compound additionPolymer sciencePapermaking

The invention relates to a sizing agent in the technical field of papermaking, in particular to stable alkenyl succinic anhydride sizing emulsion for papermaking. The stable alkenyl succinic anhydride sizing emulsion for papermaking comprises deionized water, alkenyl succinic anhydride, hectorite and alanine, wherein a mass ratio of the alkenyl succinic anhydride to the water is 1:(1-5); a mass ratio of the hectorite to the alkenyl succinic anhydride is 1:(20-200); and a mass ratio of the alanine to the hectorite is 1:(20-200). A preparation method is characterized by comprising the following steps of: dispersing the hectorite in the deionized water to obtain a hectorite colloid; adding an aqueous solution of alanine into the hectorite colloid; regulating pH, and uniformly mixing with the alkenyl succinic anhydride (ASA) to obtain the stable alkenyl succinic anhydride sizing emulsion for papermaking. The using amount of an emulsifier is small, and the emulsification cost is low; and the prepared emulsion has high concentration, stability and sizing efficiency. An emulsification process is simple, and the sizing efficiency of the obtained emulsion can be greatly improved.

Owner:QILU UNIV OF TECH

Release agent for isocyanate adhesive and preparation method thereof

ActiveCN105602467BAvoid bondingImprove stabilityNon-macromolecular adhesive additivesMacromolecular adhesive additivesEmulsionAdhesive

The invention discloses a release agent for an isocyanate adhesive. The release agent is prepared from, by weight, 8-10 parts of peregal O, 5-7 parts of sodium tripolyphosphate, 1-2 parts of sodium dodecyl benzene sulfonate, 800-1000 parts of water and 100-120 parts of higher aliphatic acid. According to the release agent, the emulsification process is simple, the stability of emulsion is good, the die release performance is superior, and adhesion of a board and a steel plate or a steel band is effectively prevented when the isocyanate adhesive is used for producing a shaving board or a medium-density fiberboard.

Owner:JIANGXI LYVFENG NEW MATERIAL CO LTD

Preparation method and product thereof for fabric waterproof and darkening finishing agent

ActiveCN111877021BSignificantly effective shielding effectImprove waterproof performanceLiquid repellent fibresVegetal fibresBenzoic acidPolymer science

The invention discloses a preparation method and a product of a fabric waterproof and darkening finishing agent, including the preparation of p-acryloyloxybenzoic acid; the preparation of tridefluorooctyl p-hydroxybenzoate; 2-(perfluorohexyl) Preparation of ethyl-4-[4-(acryloyloxy)-benzoyloxy]benzoate; preparation of fluorine-containing alkyl modified amino silicone oil; preparation of fluorine-containing alkyl modified amino silicone oil emulsion . In the molecular structure of the fabric waterproof and darkening finishing agent of the present invention, 2-(perfluorohexyl) ethyl-4-[4-(acryloyloxy)-benzoyloxy] benzoate is used as the fluorine-containing functional unit The body, which connects two rigid benzene rings through an ester group, and uses it as a linking group to bond an environmentally friendly short fluorocarbon chain to the amino silicone oil molecule, and uses the liquid crystal effect of the biphenyl group to promote short fluorocarbon chains. Regularly arranged outward and perpendicular to the surface of the substrate, it provides a more significant and effective fluoroalkyl shielding effect, resulting in an excellent waterproof and deepening effect.

Owner:YANCHENG INST OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com